Hydraulic Expanding Mandrels Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440854 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Hydraulic Expanding Mandrels Market Size

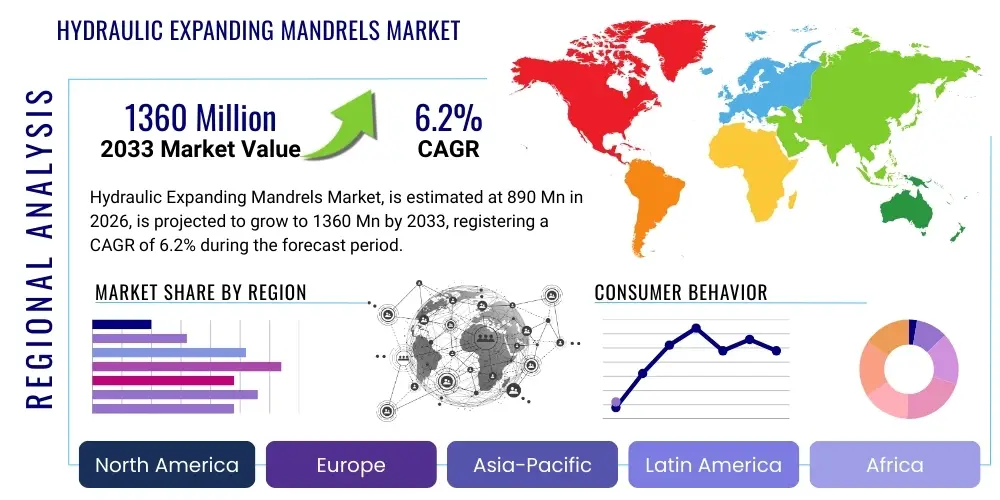

The Hydraulic Expanding Mandrels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 890 million in 2026 and is projected to reach USD 1360 million by the end of the forecast period in 2033.

Hydraulic Expanding Mandrels Market introduction

The Hydraulic Expanding Mandrels market encompasses a specialized segment within industrial workholding solutions, characterized by the use of hydraulic pressure to achieve precise and concentric clamping of workpieces. These devices are engineered to offer exceptional repeatability and accuracy, making them indispensable in applications demanding high precision, such as turning, grinding, milling, gear hobbing, and inspection processes. The fundamental principle involves hydraulic fluid uniformly expanding a thin-walled sleeve or body, which then securely grips the inside diameter of the workpiece. This mechanism ensures minimal runout and vibration dampening, crucial for achieving superior surface finishes and tight dimensional tolerances in manufacturing operations.

The product’s primary benefits include its unparalleled clamping accuracy, high repeatability, quick setup times, and the ability to minimize workpiece distortion due to even pressure distribution. Major applications span across critical sectors including automotive, aerospace and defense, machine tools, medical device manufacturing, and energy production, where stringent quality standards are paramount. Driving factors for market growth include the escalating demand for automation in manufacturing, the continuous pursuit of higher precision and efficiency in production processes, and the increasing adoption of advanced machining technologies that necessitate superior workholding solutions. Furthermore, the global expansion of industries requiring high-precision components, coupled with advancements in material science and engineering, continues to bolster the market's trajectory.

Hydraulic Expanding Mandrels Market Executive Summary

The Hydraulic Expanding Mandrels market is experiencing robust growth driven by an unwavering global focus on precision manufacturing and enhanced automation. Key business trends indicate a significant shift towards integrated workholding solutions that seamlessly interface with automated production lines and advanced CNC machinery, reducing human intervention and boosting productivity. Manufacturers are increasingly investing in research and development to offer customized mandrel designs tailored to specific application requirements, addressing complex geometries and demanding material properties. The adoption of smart mandrels featuring integrated sensors for real-time monitoring of clamping force, temperature, and runout is also emerging as a pivotal trend, aligning with Industry 4.0 initiatives to create more intelligent and adaptive manufacturing ecosystems.

Regionally, the market exhibits dynamic growth patterns, with Asia Pacific leading in terms of manufacturing output and investment in new industrial capacities, particularly in countries like China, India, and South Korea. North America and Europe continue to be strongholds for high-value-added manufacturing sectors, such as aerospace, automotive, and medical devices, driving demand for premium hydraulic expanding mandrels. These regions are also at the forefront of adopting advanced automation and digital manufacturing technologies. Segment-wise, the market is primarily propelled by the automotive industry's consistent demand for high-precision components for engines, transmissions, and chassis, alongside the aerospace sector's critical need for flawless parts for turbines, landing gear, and airframe structures. The expanding scope of applications in the energy sector, particularly for components in renewable energy systems, also presents significant growth opportunities, indicating a diversified yet specialized demand landscape.

AI Impact Analysis on Hydraulic Expanding Mandrels Market

The advent of Artificial Intelligence (AI) is poised to significantly transform the Hydraulic Expanding Mandrels market by addressing critical user concerns related to operational efficiency, predictive maintenance, and quality assurance. Common user questions often revolve around how AI can minimize downtime, optimize machining parameters for superior part quality, and extend the lifespan of costly workholding equipment. Users also frequently inquire about AI's potential to facilitate rapid customization and adapt mandrels to varying production demands without extensive manual recalibration. The consensus among market stakeholders is that AI integration will lead to more intelligent, self-optimizing workholding solutions, moving beyond mere mechanical precision to incorporate adaptive control and data-driven insights, thereby enhancing overall manufacturing performance and reducing operational complexities.

Specifically, AI algorithms can process vast amounts of operational data from various sensors embedded within or around mandrels, including clamping force, temperature, vibration, and workpiece dimensional feedback. This data enables predictive analytics, forecasting potential failures or performance degradation before they occur, thus shifting from reactive to proactive maintenance strategies. Furthermore, AI-driven process optimization can dynamically adjust clamping parameters based on workpiece material, cutting tool conditions, and desired surface finish, leading to higher throughput, reduced scrap rates, and consistent product quality. The integration of AI also promises to streamline design processes by simulating performance under various conditions, accelerating the development of highly customized and application-specific hydraulic expanding mandrels. This evolution is expected to elevate the entire workholding industry towards a new era of smart manufacturing, where precision and efficiency are augmented by intelligent systems.

- Enhanced Predictive Maintenance: AI analyzes operational data to predict mandrel wear and potential failures, enabling proactive maintenance and reducing unscheduled downtime.

- Optimized Machining Parameters: AI algorithms recommend ideal clamping forces and speeds based on workpiece material, tool wear, and desired output, leading to improved quality and efficiency.

- Real-time Quality Control: Integrated AI systems monitor clamping accuracy and workpiece concentricity in real-time, identifying and correcting deviations instantly to minimize defects.

- Adaptive Workholding: AI facilitates the dynamic adjustment of mandrel settings to accommodate variations in workpiece dimensions or machining conditions, ensuring consistent precision.

- Design and Customization Acceleration: AI-driven simulations and generative design tools can rapidly prototype and optimize mandrel designs for specific applications, significantly reducing development cycles.

- Autonomous Operation Integration: AI enables mandrels to communicate with other smart factory components, contributing to fully automated and self-regulating production lines.

DRO & Impact Forces Of Hydraulic Expanding Mandrels Market

The Hydraulic Expanding Mandrels market is profoundly influenced by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that shape its trajectory. The primary drivers include the escalating global demand for high-precision components across various industries, the pervasive trend of automation and Industry 4.0 adoption in manufacturing, and the critical need for enhanced productivity and reduced cycle times. Industries such as automotive, aerospace, and medical devices are continuously seeking advanced workholding solutions to meet stringent quality standards and accelerate production. However, market growth is tempered by certain restraints, notably the relatively high initial investment cost associated with these precision instruments compared to conventional workholding devices. Furthermore, the requirement for specialized technical expertise for installation, operation, and maintenance, along with the competitive threat from alternative workholding technologies, presents ongoing challenges. Opportunities for market expansion largely reside in the burgeoning manufacturing sectors of developing economies, the growing customization demand for unique applications, and the integration of smart technologies like IoT and AI to create more intelligent and adaptive mandrels, expanding their utility and value proposition.

Beyond these internal dynamics, external impact forces significantly mold the market landscape. The bargaining power of buyers is moderate; while end-users seek high performance and competitive pricing, the specialized nature of hydraulic mandrels limits their options. The bargaining power of suppliers, particularly for specialized hydraulic components and high-grade materials, is also moderate to high, influencing production costs. The threat of new entrants is relatively low due to the substantial capital investment, technical expertise, and established distribution networks required, creating significant barriers. Conversely, the threat of substitute products, such as mechanical mandrels, collet chucks, or pneumatic systems, is moderate. While these alternatives may offer lower initial costs, they often fall short on precision, repeatability, and uniform clamping force, especially for demanding applications. Intense rivalry among existing players, characterized by continuous product innovation, performance improvements, and strategic partnerships, is a constant force driving market advancements and competitive pricing strategies, ultimately benefiting end-users by fostering technological evolution and broader product availability.

Segmentation Analysis

The Hydraulic Expanding Mandrels market is comprehensively segmented to reflect the diverse applications, technological variations, and end-user requirements prevalent across the global manufacturing landscape. This granular segmentation provides critical insights into specific market dynamics, growth potential, and competitive landscapes within each sub-category. Understanding these segments is crucial for manufacturers to tailor their product offerings, develop targeted marketing strategies, and allocate resources effectively to capitalize on emerging trends and unmet customer needs. The segmentation typically considers the design and operational mechanism of the mandrels, the specific manufacturing processes they facilitate, and the primary industrial sectors that are their predominant end-users.

- By Type:

- Hydraulic Mandrels (Self-Contained, External Power Unit)

- Pneumatic Expanding Mandrels

- Hydro-mechanical Mandrels

- Manual Expanding Mandrels

- Custom Engineered Mandrels

- By Application:

- Turning

- Grinding (Internal, External)

- Milling

- Gear Hobbing and Shaping

- Drilling and Reaming

- Balancing

- Inspection and Measurement

- Assembly

- By End-User Industry:

- Automotive

- Aerospace and Defense

- Machine Tools and Industrial Equipment

- Medical Devices

- Energy (Oil & Gas, Wind Power)

- Heavy Machinery

- Precision Electronics

- Tool & Die

- By Clamping Diameter Range:

- Small Diameter (e.g., up to 20mm)

- Medium Diameter (e.g., 20mm - 100mm)

- Large Diameter (e.g., above 100mm)

- By Sales Channel:

- Direct Sales

- Distributors and Resellers

- Online Channels

Value Chain Analysis For Hydraulic Expanding Mandrels Market

The value chain for the Hydraulic Expanding Mandrels market is intricate, involving multiple stages from raw material procurement to end-user application, each adding significant value. The upstream segment primarily involves the sourcing and processing of high-grade materials crucial for manufacturing precision components. This includes specialized steels for the mandrel body and expanding sleeves, high-performance seals, and hydraulic fluids. Key suppliers in this stage are metallurgical companies, precision casting and forging providers, and specialized component manufacturers for hydraulic pumps and valves. The quality and availability of these raw materials directly impact the performance, durability, and cost-effectiveness of the final product. Collaboration with reliable upstream partners is critical to ensure material consistency and supply chain stability, as any compromise in material quality can severely affect the mandrel's precision and lifespan.

Further along the value chain, the manufacturing stage involves precision machining, assembly, and rigorous testing of the mandrels. This is where core intellectual property and manufacturing expertise are concentrated, transforming raw materials into highly accurate workholding devices. Following manufacturing, the distribution channel plays a pivotal role in connecting producers with end-users. This typically involves a mix of direct sales by the manufacturers, particularly for large industrial clients or highly customized solutions, and indirect distribution through a network of specialized industrial distributors, agents, and resellers. These indirect channels often provide value-added services such as technical support, localized inventory, and after-sales service, which are essential for reaching a broader customer base and ensuring effective product integration. The downstream analysis focuses on the end-user industries, including automotive, aerospace, medical, and general manufacturing, where these mandrels are integrated into various machining, grinding, and inspection processes. The effectiveness of the mandrels directly impacts the quality and efficiency of the end-user's production, making strong after-sales support and technical consultation vital components of the overall value proposition. Continuous feedback from downstream customers also drives innovation and product development in the upstream and manufacturing stages.

Hydraulic Expanding Mandrels Market Potential Customers

The primary potential customers for Hydraulic Expanding Mandrels are manufacturers operating in industries that demand exceptionally high precision, concentricity, and repeatability in their machining and inspection processes. These end-users typically produce components with tight tolerances and complex geometries, where conventional clamping methods might induce distortion, compromise accuracy, or lead to excessive runout. Major buying segments include companies engaged in the production of automotive powertrain components (e.g., gears, shafts, transmission parts), aerospace structural elements and engine parts (e.g., turbine blades, landing gear components), and critical medical device components (e.g., surgical instruments, implants).

Beyond these high-value sectors, the market also targets general machine shops and contract manufacturers specializing in precision engineering for various industries, often requiring versatile and highly accurate workholding solutions for diverse production runs. Furthermore, manufacturers of machine tools and industrial equipment represent a significant customer base, integrating these mandrels into their own offerings or using them internally for the production of their proprietary machinery. Companies involved in the energy sector, particularly those manufacturing components for oil and gas exploration, wind turbines, and other renewable energy systems, also constitute a growing segment of potential customers due to the critical nature and demanding specifications of their products. The overarching characteristic of these potential customers is their continuous pursuit of manufacturing excellence, process optimization, and a reduced total cost of ownership through reliable and high-performance workholding technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 890 million |

| Market Forecast in 2033 | USD 1360 million |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SCHUNK GmbH & Co. KG, Hainbuch GmbH, ROEMHELD GmbH, Forkardt, OTT-JAKOB Spanntechnik GmbH, Berg & Co. GmbH Spanntechnik, Fixturkraft Inc., HWR Spanntechnik GmbH, Hommel + Keller Präzisionswerkzeuge GmbH, Kintek SpA, LMC Workholding, Northfield Precision Instrument Corp., Richter Spanntechnik GmbH, Tecnara Tooling Systems Inc., TE-CO, Inc., ZIPPEL Industrial Workholding. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Expanding Mandrels Market Key Technology Landscape

The technology landscape for Hydraulic Expanding Mandrels is continuously evolving, driven by the relentless pursuit of higher precision, increased efficiency, and greater adaptability in modern manufacturing. At its core, the technology relies on the principle of hydraulic pressure applied to an internal chamber, causing a thin-walled sleeve or body to expand uniformly and grip the workpiece with extreme concentricity and repeatability. This fundamental hydraulic expansion mechanism is often enhanced by advancements in material science, utilizing specialized high-strength steels and surface treatments to improve durability, wear resistance, and long-term accuracy, especially in high-speed and heavy-duty machining environments. The integration of advanced sealing technologies ensures leak-proof operation and extended service life, even under extreme operating conditions.

Beyond the core mechanics, the market is witnessing a significant shift towards "smart" or "intelligent" mandrels. This involves embedding various sensors directly into the workholding device to monitor critical operational parameters such as clamping force, temperature, vibration, and even micro-deformations in real-time. These sensors provide valuable data that can be analyzed using advanced analytics and AI algorithms to enable predictive maintenance, optimize machining parameters, and ensure consistent quality control. Furthermore, connectivity solutions, often based on IoT (Internet of Things) protocols, allow these smart mandrels to communicate with CNC machines, automated production systems, and central monitoring platforms, facilitating seamless integration into Industry 4.0 environments. Innovations also include modular designs that allow for quick interchangeability of expanding sleeves for different workpiece diameters, reducing setup times and enhancing versatility, as well as compact hydraulic power units that offer greater flexibility in machine integration and space utilization.

Regional Highlights

- North America: A mature market with high demand from the aerospace and defense, automotive, and medical device industries. Significant investment in advanced manufacturing technologies and automation drives the adoption of high-precision workholding solutions.

- Europe: A leading region for innovation and high-value manufacturing, particularly Germany, Switzerland, and Italy. Strong presence of automotive, machine tool, and precision engineering sectors fosters steady demand for hydraulic expanding mandrels, with a focus on quality and advanced features.

- Asia Pacific (APAC): The fastest-growing market, driven by robust industrialization, expanding manufacturing capabilities, and increasing foreign direct investment in countries like China, India, Japan, and South Korea. Rapid adoption of automation and a growing emphasis on precision in sectors like automotive, electronics, and general manufacturing are key contributors.

- Latin America: An emerging market with growing industrial sectors, particularly in Brazil and Mexico. The automotive industry and increasing investment in infrastructure projects are creating new opportunities for hydraulic expanding mandrels, albeit at a slower pace compared to APAC.

- Middle East and Africa (MEA): A developing market with potential growth stemming from investments in diversifying economies, particularly in industrial and manufacturing capabilities beyond oil and gas. Growth is concentrated in countries like UAE, Saudi Arabia, and South Africa, with increasing demand for quality and precision in developing industrial bases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Expanding Mandrels Market.- SCHUNK GmbH & Co. KG

- Hainbuch GmbH

- ROEMHELD GmbH

- Forkardt

- OTT-JAKOB Spanntechnik GmbH

- Berg & Co. GmbH Spanntechnik

- Fixturkraft Inc.

- HWR Spanntechnik GmbH

- Hommel + Keller Präzisionswerkzeuge GmbH

- Kintek SpA

- LMC Workholding

- Northfield Precision Instrument Corp.

- Richter Spanntechnik GmbH

- Tecnara Tooling Systems Inc.

- TE-CO, Inc.

- ZIPPEL Industrial Workholding

- SMW-Autoblok GmbH

- Kurt Manufacturing Company

- Gressel AG

- Dillon Manufacturing, Inc.

Frequently Asked Questions

Analyze common user questions about the Hydraulic Expanding Mandrels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a hydraulic expanding mandrel and how does it work?

A hydraulic expanding mandrel is a precision workholding device that uses hydraulic pressure to uniformly expand a sleeve or body, clamping a workpiece on its inside diameter with high concentricity and rigidity. It works by injecting hydraulic fluid into an internal chamber, which then exerts even pressure on the expanding element, ensuring distortion-free and highly accurate gripping.

What are the primary benefits of using hydraulic expanding mandrels over other workholding methods?

Hydraulic expanding mandrels offer superior benefits including exceptional clamping accuracy, minimal runout, high repeatability, uniform pressure distribution preventing workpiece distortion, reduced vibration, and quick setup times. These advantages lead to higher part quality, increased productivity, and extended tool life in precision machining operations.

In which industries are hydraulic expanding mandrels most commonly used?

These mandrels are predominantly used in industries requiring high-precision manufacturing, such as automotive (for engine and transmission components), aerospace and defense (for turbine parts, landing gear), medical devices (for implants and surgical tools), machine tools, and general precision engineering sectors where tight tolerances and superior surface finishes are critical.

How does AI impact the future of hydraulic expanding mandrels?

AI is set to revolutionize hydraulic expanding mandrels by enabling predictive maintenance through data analysis, optimizing clamping parameters for enhanced quality and efficiency, and facilitating real-time monitoring and adaptive control. AI integration leads to smarter, self-optimizing workholding solutions, aligning with Industry 4.0 principles for greater automation and manufacturing intelligence.

What are the key factors driving the growth of the Hydraulic Expanding Mandrels market?

The market's growth is primarily driven by the increasing global demand for high-precision components, the widespread adoption of automation and Industry 4.0 technologies in manufacturing, the continuous push for improved productivity and reduced cycle times, and the expansion of key end-user industries such as automotive and aerospace that necessitate advanced workholding solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager