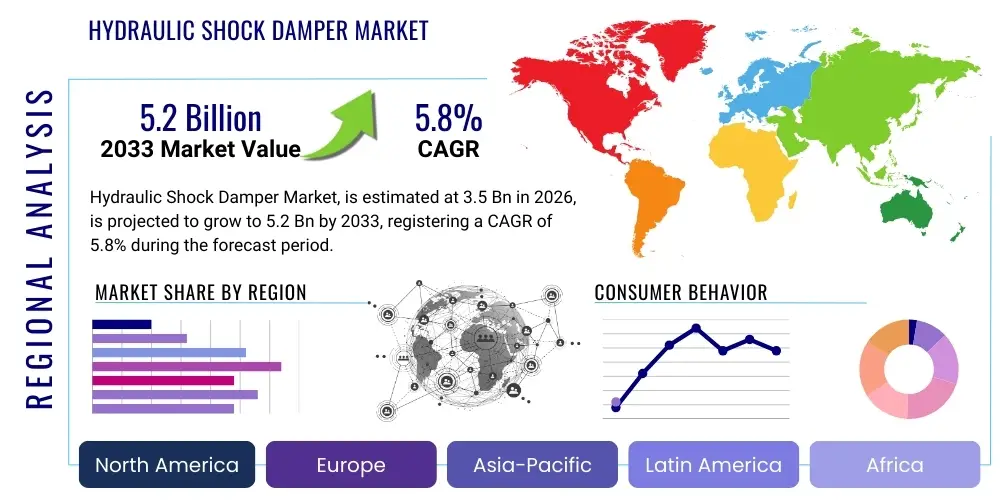

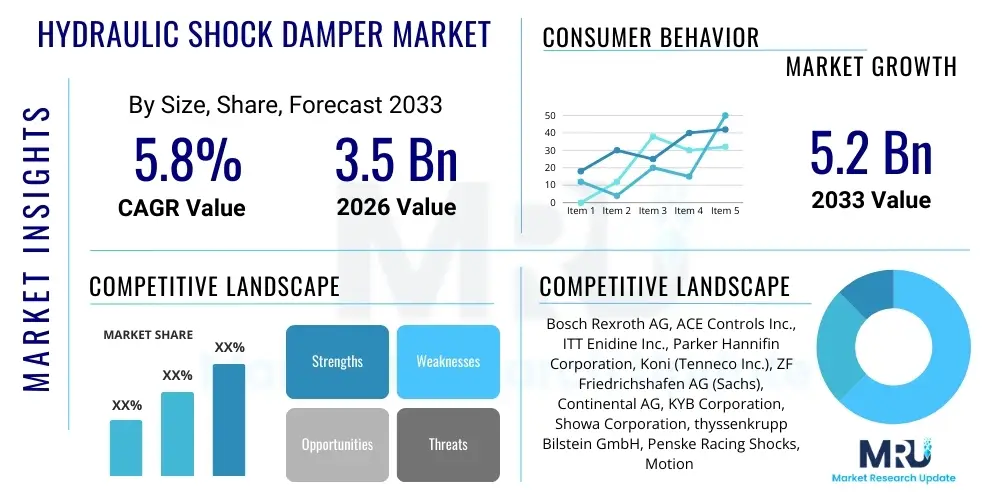

Hydraulic Shock Damper Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440873 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Hydraulic Shock Damper Market Size

The Hydraulic Shock Damper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Hydraulic Shock Damper Market introduction

The Hydraulic Shock Damper Market encompasses a critical sector providing solutions for motion control, vibration isolation, and impact absorption across a vast array of industries. Hydraulic shock dampers are precision-engineered devices that convert kinetic energy into thermal energy through the viscous flow of a fluid, typically oil, making them indispensable for managing transient forces and ensuring smooth, controlled movement in various mechanical systems. These components are designed to absorb and dissipate energy from shocks and vibrations, thereby protecting equipment, improving operational efficiency, and enhancing user comfort and safety. Their core function lies in mitigating the detrimental effects of uncontrolled motion, ranging from sudden impacts to continuous oscillations.

The product range within this market is diverse, including industrial shock absorbers, automotive dampers, aerospace actuators, and heavy-duty buffers, each tailored to specific operational requirements and environmental conditions. Major applications span critical sectors such as automotive, industrial automation, aerospace and defense, construction, and railway systems, where they are integral to vehicle suspension systems, robotic arms, manufacturing machinery, structural elements, and high-speed rail bogies. The benefits derived from their implementation are substantial, including extended equipment lifespan, reduced maintenance costs, improved operational accuracy, enhanced safety for personnel and cargo, and superior ride comfort in transport applications. These advantages collectively underscore the vital role hydraulic shock dampers play in modern engineering and industrial design.

Driving factors for market growth are multifaceted and robust. The global push towards industrial automation and robotics necessitates precise motion control and impact protection for sophisticated machinery. Growth in the automotive sector, particularly with the advent of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), demands more sophisticated damping solutions for improved ride dynamics and safety. Furthermore, ongoing infrastructure development projects globally, coupled with a rising emphasis on worker safety and equipment longevity in industrial settings, continuously fuel the demand for high-performance hydraulic shock dampers. The increasing complexity and speed of modern machinery inherently generate higher dynamic forces, making effective damping solutions more crucial than ever before, thereby cementing the market's trajectory for sustained expansion.

Hydraulic Shock Damper Market Executive Summary

The Hydraulic Shock Damper Market is experiencing robust growth, driven by an expanding industrial automation landscape, the proliferation of advanced automotive technologies, and significant infrastructure development across emerging economies. Business trends indicate a strong emphasis on product customization, integration of smart technologies, and the adoption of lightweight, durable materials to meet evolving industry demands. Manufacturers are increasingly investing in research and development to introduce innovative damping solutions that offer higher efficiency, longer service life, and adaptability to diverse operating environments. Mergers, acquisitions, and strategic partnerships are also becoming prevalent as companies seek to expand their technological capabilities, broaden their product portfolios, and gain a competitive edge in a highly specialized market. The push for energy-efficient and sustainable solutions is further shaping business strategies, prompting development of regenerative damping systems and more environmentally friendly hydraulic fluids.

Regionally, Asia Pacific continues to dominate the market, propelled by rapid industrialization, robust automotive manufacturing sectors, and extensive construction activities, particularly in China, India, and Southeast Asian nations. North America and Europe demonstrate a strong demand for advanced and high-performance damping systems, driven by strict regulatory standards for safety and precision in industrial and automotive applications, alongside ongoing modernization of existing infrastructure. These regions also lead in the adoption of smart damping technologies and premium solutions. Latin America, the Middle East, and Africa are emerging as significant growth markets, fueled by increasing investment in manufacturing, mining, and transportation infrastructure, although growth trajectories may be more varied due to differing levels of industrial maturity and economic stability. Local manufacturing capabilities and distribution networks are also expanding in these regions to cater to rising demand.

Segment-wise, the market sees significant traction in both industrial and automotive applications. Within the industrial segment, machinery and robotics are leading the demand, requiring dampers for precision control, vibration reduction, and impact absorption in high-speed, automated processes. The automotive segment is being driven by the continuous evolution of vehicle suspension systems, with a particular focus on enhancing passenger comfort and vehicle stability in traditional internal combustion engine vehicles, hybrid, and electric vehicles. Demand for adjustable and smart dampers is growing across various end-use industries, reflecting a shift towards more adaptable and predictive maintenance solutions. Furthermore, specialized applications in aerospace and defense, as well as railway systems, continue to represent niche but high-value segments, emphasizing durability, reliability, and extreme performance capabilities. This segmentation highlights the broad utility and diverse requirements that hydraulic shock dampers fulfill, underpinning a dynamic and expanding market landscape.

AI Impact Analysis on Hydraulic Shock Damper Market

User inquiries about AI's impact on the Hydraulic Shock Damper Market frequently revolve around how artificial intelligence can enhance damper performance, facilitate predictive maintenance, and optimize design and manufacturing processes. Users are keen to understand if AI will lead to "smart" dampers that adapt to real-time conditions, how it might extend product lifespan, and whether it could reduce operational costs through improved efficiency. Concerns also touch upon the complexity of integrating AI, potential data security issues, and the need for specialized skills to manage AI-driven systems. The overarching expectation is for AI to usher in a new era of intelligent, proactive, and highly efficient damping solutions, moving beyond traditional passive or manually adjustable systems to truly adaptive and self-optimizing mechanisms. This points to a desire for greater autonomy and precision in motion control, with AI serving as the core enabler for next-generation shock damper capabilities.

- AI-driven predictive maintenance for optimal damper performance and extended lifespan, reducing unplanned downtime.

- Development of adaptive damping systems that utilize AI algorithms to adjust damping characteristics in real-time based on road conditions, load, or operational parameters.

- AI optimization of damper design and material selection, leading to lighter, more durable, and more efficient components through advanced simulations.

- Enhanced manufacturing processes via AI-powered robotics and quality control systems, ensuring higher precision and consistency in damper production.

- Integration of IoT sensors with AI analytics to monitor damper health, provide operational insights, and enable remote diagnostics.

- Facilitation of new business models, such as "damper-as-a-service," where performance and maintenance are managed and optimized by AI.

- Improved energy efficiency in regenerative dampers through AI-controlled energy harvesting optimization.

DRO & Impact Forces Of Hydraulic Shock Damper Market

The Hydraulic Shock Damper Market is significantly influenced by a confluence of drivers, restraints, opportunities, and inherent impact forces. Key drivers propelling market expansion include the sustained growth in global industrial automation and robotics, which demands precise motion control and robust vibration dampening for sophisticated machinery to ensure operational efficiency and extend equipment lifespan. The automotive industry's continuous evolution, particularly with the advent of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), necessitates more advanced and responsive damping solutions for enhanced ride comfort, stability, and safety. Furthermore, extensive infrastructure development projects worldwide, particularly in transportation (railways, bridges) and construction sectors, consistently create demand for heavy-duty and reliable hydraulic dampers. Stringent safety regulations and the growing emphasis on worker protection across various industries also drive the adoption of high-performance damping solutions to mitigate impact risks and improve operational environments. These factors collectively create a strong foundation for market growth.

However, the market also faces notable restraints. The relatively high initial cost associated with advanced hydraulic shock dampers, especially customized or smart variants, can be a barrier to adoption for small and medium-sized enterprises (SMEs) or in cost-sensitive applications. The complexity and maintenance requirements of hydraulic systems, including the need for regular fluid checks and seal replacements, contribute to the total cost of ownership, which can deter some potential buyers. Moreover, the emergence of alternative damping technologies, such as air springs, magnetic rheological (MR) dampers, and eddy current dampers, poses a competitive threat, offering different performance characteristics and potentially lower maintenance in certain niche applications. Economic downturns, supply chain disruptions, and fluctuations in raw material prices (e.g., steel, specialized fluids, seals) can also negatively impact manufacturing costs and market stability, leading to price volatility and reduced profit margins for market players.

Despite these challenges, significant opportunities abound within the Hydraulic Shock Damper Market. The increasing demand for customized damping solutions tailored to specific application requirements presents a lucrative avenue for manufacturers to differentiate their offerings and capture niche markets. The integration of smart technologies, such as IoT sensors and AI-driven adaptive control systems, offers a path to developing intelligent dampers that can dynamically adjust their performance, provide predictive maintenance insights, and enhance overall system efficiency. Moreover, the growth in emerging economies, fueled by rapid industrialization and urbanization, represents untapped market potential for both standard and advanced damping solutions. The retrofitting of existing machinery and infrastructure with modern damping systems to improve performance and safety also provides a substantial market opportunity. From a Porter's Five Forces perspective, the bargaining power of buyers is moderate due to standardized product offerings but increases with customization demands. The bargaining power of suppliers is also moderate, influenced by the availability of raw materials and specialized components. The threat of new entrants is moderate, given the capital intensity and technical expertise required. The threat of substitutes is also moderate, as alternative technologies continuously evolve. Lastly, the intensity of rivalry among existing players is high, driven by technological innovation, competitive pricing, and global market presence strategies.

Segmentation Analysis

The Hydraulic Shock Damper Market is intricately segmented based on various critical parameters, reflecting the diverse applications and technological requirements across industries. This segmentation provides a granular view of the market, allowing for targeted strategies and a comprehensive understanding of demand drivers within each category. The primary segmentation often includes type, application, end-use industry, and geographical regions, each revealing unique market dynamics and growth patterns. Understanding these segments is crucial for stakeholders to identify key growth areas, assess competitive landscapes, and formulate effective market penetration and product development strategies. The market is driven by the specific needs of these segments, ranging from precision industrial operations to robust automotive suspension systems and heavy-duty construction equipment.

- By Type:

- Single-Acting Shock Dampers

- Double-Acting Shock Dampers

- Adjustable Shock Dampers

- Non-Adjustable Shock Dampers

- Regenerative Shock Dampers

- Heavy Duty Shock Dampers

- Standard Duty Shock Dampers

- By Application:

- Industrial Automation & Robotics

- Material Handling Equipment

- Conveyor Systems

- Medical & Healthcare Equipment

- Packaging Machinery

- Machine Tools

- Test & Measurement Equipment

- Off-Highway Vehicles (Construction, Mining, Agriculture)

- On-Highway Vehicles (Passenger Cars, Commercial Vehicles)

- Aerospace & Defense

- Railways

- Marine

- Structures & Bridges

- Energy & Utilities

- By End-Use Industry:

- Automotive

- Manufacturing

- Aerospace & Defense

- Construction

- Transportation (Rail, Marine, Commercial Road)

- Robotics & Automation

- Medical

- Energy & Power

- Metals & Mining

- By Damping Medium:

- Oil Dampers

- Gas Dampers (Hydro-Pneumatic)

- Viscous Dampers

- By Mounting Type:

- Flange Mounted

- Threaded Body Mounted

- Clevis Mounted

- Foot Mounted

- By Sales Channel:

- Original Equipment Manufacturers (OEMs)

- Aftermarket

Value Chain Analysis For Hydraulic Shock Damper Market

The value chain for the Hydraulic Shock Damper Market is a complex ecosystem involving multiple stages, from raw material procurement to end-user application and aftermarket services. Upstream analysis reveals a critical reliance on suppliers of specialized raw materials, including high-grade steel alloys for damper bodies and piston rods, precision seals (elastomers, fluoropolymers), and high-performance hydraulic fluids (oils with specific viscosity and thermal properties). Other essential components such as springs, valves, and bushings are also sourced from specialized manufacturers. The quality and availability of these materials and components directly impact the performance, durability, and cost-effectiveness of the final hydraulic damper. Strong relationships with reliable and quality-focused suppliers are paramount for damper manufacturers to maintain production consistency and product integrity, ensuring the robustness required for their applications.

Midstream activities primarily involve the design, engineering, manufacturing, assembly, and testing of hydraulic shock dampers. Manufacturers leverage advanced CAD/CAM software, fluid dynamics simulations, and precision machining techniques to produce components with tight tolerances. Assembly lines incorporate quality control measures at various stages, often including automated systems and human inspection to ensure each damper meets stringent performance specifications. R&D plays a crucial role here, driving innovation in damping technology, material science, and intelligent system integration. This stage also includes compliance with various international standards and certifications, which are essential for market acceptance and ensuring product safety and reliability. The manufacturing process often involves complex hydraulic circuits, requiring specialized expertise in fluid power systems.

Downstream analysis focuses on the distribution channels, sales, and aftermarket services. Distribution channels for hydraulic shock dampers are diverse, encompassing both direct and indirect models. Direct sales typically involve large original equipment manufacturers (OEMs) in sectors like automotive, aerospace, and heavy machinery, where dampers are integrated directly into their products. This often involves long-term contracts and close collaboration between the damper manufacturer and the OEM for custom solutions. Indirect channels involve a network of distributors, wholesalers, and specialized industrial suppliers who cater to the aftermarket segment, smaller OEMs, and various industrial MRO (Maintenance, Repair, and Operations) needs. These channels provide local support, technical expertise, and quicker access to products for a broader customer base. Aftermarket services, including repair, replacement parts, and technical support, represent a significant portion of the value chain, ensuring the long-term functionality and customer satisfaction of installed dampers, thereby extending their operational life and cementing brand loyalty. The effectiveness of this downstream network is vital for market reach and customer retention.

Hydraulic Shock Damper Market Potential Customers

Potential customers for hydraulic shock dampers represent a broad spectrum of industries, primarily comprising end-users and original equipment manufacturers (OEMs) who integrate these components into their final products or use them to enhance operational processes. In the automotive sector, this includes manufacturers of passenger cars, commercial vehicles, motorcycles, and specialized off-highway vehicles (such as construction machinery, mining trucks, and agricultural equipment), all of whom require dampers for suspension systems to ensure vehicle stability, ride comfort, and safety. The industrial automation and robotics industry constitutes a major customer base, where dampers are essential for precise motion control, impact absorption in robotic arms, conveyor systems, and various automated production lines, protecting equipment from wear and tear and enabling high-speed operations. These customers seek dampers that can withstand repetitive cycles, offer precise adjustability, and integrate seamlessly into complex mechanical systems.

Beyond traditional manufacturing and automotive, the construction industry relies heavily on hydraulic dampers for heavy machinery like excavators, cranes, and bulldozers, as well as for structural damping in buildings and bridges to mitigate seismic activity or wind-induced vibrations. The aerospace and defense sector also represents a high-value customer segment, demanding highly specialized and ultra-reliable dampers for aircraft landing gear, missile launch systems, and other critical defense applications where performance and safety are paramount. Furthermore, the railway industry utilizes dampers extensively in train bogies for passenger comfort and structural integrity, while material handling equipment, packaging machinery, and even medical devices incorporate smaller, precision dampers for smooth and controlled movements. These diverse applications highlight the fundamental need for hydraulic shock dampers to manage kinetic energy, protect valuable assets, and ensure optimal operational performance across a wide array of technological landscapes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth AG, ACE Controls Inc., ITT Enidine Inc., Parker Hannifin Corporation, Koni (Tenneco Inc.), ZF Friedrichshafen AG (Sachs), Continental AG, KYB Corporation, Showa Corporation, thyssenkrupp Bilstein GmbH, Penske Racing Shocks, Motion Control Corp., Indu-Flex, Weforma Dämpfungstechnik GmbH, Fichtel & Sachs, Trelleborg AB, Vibracorp, Norgren (IMI Plc), Actuant Corporation (Enerpac), Eibach Springs Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Shock Damper Market Key Technology Landscape

The Hydraulic Shock Damper Market is characterized by a dynamic technology landscape, constantly evolving to meet the demands for higher performance, greater efficiency, and enhanced adaptability across diverse applications. A cornerstone of this landscape is advanced fluid dynamics simulation, including Computational Fluid Dynamics (CFD), which allows engineers to precisely model and predict the behavior of hydraulic fluids within damper mechanisms. This technology is critical for optimizing internal flow paths, valve designs, and piston architectures to achieve desired damping characteristics, minimize cavitation, and maximize energy dissipation efficiency. Alongside this, material science advancements play a pivotal role, with ongoing research into lightweight, high-strength alloys for damper bodies and rods, as well as the development of low-friction, durable seals and specialized hydraulic fluids that can withstand extreme temperatures and pressures, thereby extending product lifespan and performance in harsh environments.

Another significant technological trend is the integration of sensor technology and smart control systems. This involves embedding various sensors (e.g., position, pressure, temperature, acceleration) directly into dampers to gather real-time operational data. This data, when coupled with advanced control algorithms and often artificial intelligence (AI), enables the development of adaptive or semi-active damping systems. These intelligent dampers can dynamically adjust their damping force and characteristics in response to changing load conditions, terrain, or operational requirements, optimizing performance for comfort, stability, or protection. Such systems represent a significant leap from traditional passive dampers, offering unparalleled control and predictive capabilities. The adoption of IoT (Internet of Things) principles further enhances these capabilities, allowing for remote monitoring, diagnostic capabilities, and predictive maintenance schedules, thereby reducing downtime and operational costs for end-users. This blend of mechanical precision with digital intelligence is reshaping the expectations for shock damper performance.

Furthermore, manufacturing technologies are also undergoing substantial transformation within the market. Precision manufacturing techniques, including advanced CNC machining and robotic assembly, ensure the tight tolerances and consistent quality essential for hydraulic components. Additive manufacturing (3D printing) is beginning to gain traction for prototyping complex internal geometries and for producing specialized, custom components with intricate designs that would be difficult or impossible to achieve with conventional methods. This not only accelerates product development but also opens new avenues for customization and performance enhancement. The pursuit of regenerative damping, which aims to convert dissipated kinetic energy back into usable electrical energy rather than just heat, represents another innovative frontier, particularly relevant in applications like automotive suspension and large industrial machinery where energy efficiency is a growing concern. These technological advancements collectively drive the market towards more intelligent, efficient, and sustainable damping solutions.

Regional Highlights

- North America: A mature market characterized by high adoption of advanced damping solutions in automotive, aerospace, and industrial sectors. Driven by stringent safety regulations, a strong focus on automation, and demand for high-performance products. The United States and Canada are key contributors.

- Europe: A significant market with a strong emphasis on precision engineering, sustainability, and technological innovation. Germany, France, and the UK lead in automotive and industrial machinery applications, with a growing trend towards smart and energy-efficient damping systems.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, robust growth in the automotive manufacturing sector (especially in China, India, Japan, and South Korea), and extensive infrastructure development. Increasing foreign investments and a growing middle class also fuel demand.

- Latin America: An emerging market exhibiting steady growth, particularly in automotive production, mining, and construction sectors in countries like Brazil and Mexico. Economic development and increasing industrialization are driving the demand for reliable hydraulic damping solutions.

- Middle East and Africa (MEA): A developing market with increasing investments in infrastructure, oil & gas, and manufacturing sectors. Countries in the GCC region and South Africa are key growth areas, driven by diversification efforts and industrial expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Shock Damper Market.- Bosch Rexroth AG

- ACE Controls Inc.

- ITT Enidine Inc.

- Parker Hannifin Corporation

- Koni (Tenneco Inc.)

- ZF Friedrichshafen AG (Sachs)

- Continental AG

- KYB Corporation

- Showa Corporation

- thyssenkrupp Bilstein GmbH

- Penske Racing Shocks

- Motion Control Corp.

- Indu-Flex

- Weforma Dämpfungstechnik GmbH

- Fichtel & Sachs

- Trelleborg AB

- Vibracorp

- Norgren (IMI Plc)

- Actuant Corporation (Enerpac)

- Eibach Springs Inc.

Frequently Asked Questions

Analyze common user questions about the Hydraulic Shock Damper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a hydraulic shock damper and how does it function?

A hydraulic shock damper is a mechanical device designed to absorb and dissipate kinetic energy, converting it into heat through the viscous resistance of a fluid (typically oil). When an external force causes movement, a piston inside the damper pushes the fluid through orifices, generating resistance that dampens the motion and prevents uncontrolled oscillations or impacts. This controlled energy dissipation protects machinery, enhances stability, and improves comfort.

What are the primary applications of hydraulic shock dampers?

Hydraulic shock dampers are widely used across diverse industries. Key applications include automotive suspension systems (for vehicles ranging from passenger cars to heavy trucks), industrial automation and robotics (for precise motion control and impact absorption in machinery), construction equipment (such as excavators and cranes), aerospace (for landing gear and control surfaces), and railway systems (for bogie suspension). They are critical for managing kinetic energy in any system experiencing sudden impacts or sustained vibrations.

How does AI impact the future of hydraulic shock dampers?

AI is transforming hydraulic shock dampers by enabling "smart" and adaptive systems. AI algorithms can analyze real-time sensor data to dynamically adjust damping characteristics, optimizing performance for varying conditions. This leads to features like predictive maintenance, where AI identifies potential failures before they occur, extends product lifespan, and enhances overall efficiency. AI also aids in design optimization and advanced manufacturing processes, leading to more robust and precise damper solutions.

What are the key factors driving growth in the Hydraulic Shock Damper Market?

Market growth is primarily driven by the expansion of industrial automation and robotics, which demands highly precise motion control and vibration dampening. The continuous evolution of the automotive industry, particularly electric vehicles and ADAS, also fuels demand for advanced damping solutions. Additionally, global infrastructure development projects, stringent safety regulations, and the need for enhanced equipment longevity across various sectors contribute significantly to market expansion.

What are the main types of hydraulic shock dampers available?

Hydraulic shock dampers are categorized by their operational characteristics and adjustability. Common types include single-acting (dampens in one direction), double-acting (dampens in both directions), adjustable (damping force can be manually or electronically altered), non-adjustable (fixed damping force), and regenerative dampers (which convert kinetic energy into electricity). They are also classified by application as heavy-duty or standard-duty, and by their fluid medium like oil or hydro-pneumatic (gas-oil mixture).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager