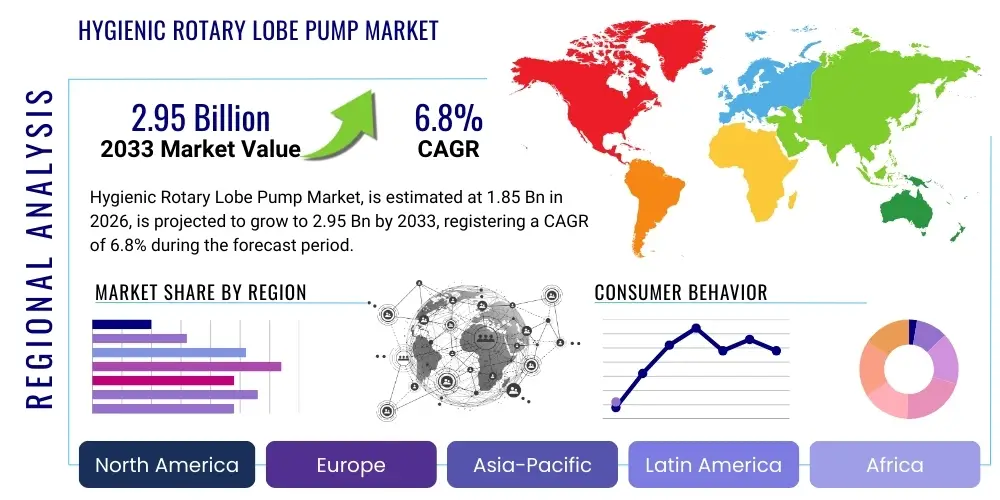

Hygienic Rotary Lobe Pump Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443254 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Hygienic Rotary Lobe Pump Market Size

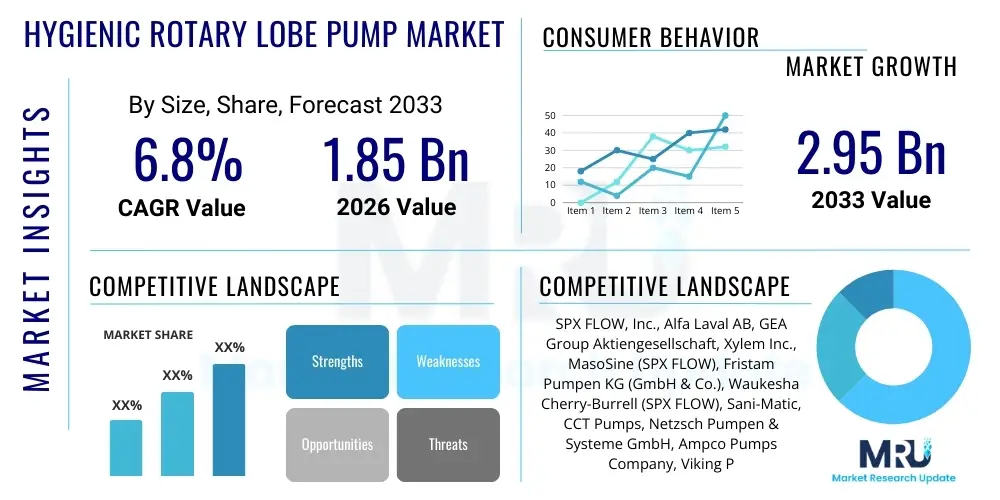

The Hygienic Rotary Lobe Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 2.95 billion by the end of the forecast period in 2033.

Hygienic Rotary Lobe Pump Market introduction

The Hygienic Rotary Lobe Pump Market encompasses specialized positive displacement pumps designed exclusively for handling sensitive, often high-viscosity fluids in processing environments where absolute sterility and non-contamination are indispensable requirements. These sophisticated devices are engineered with meticulous attention to surface finish, employing materials such as highly polished 316L stainless steel for all wetted components to prevent product adhesion and bacterial entrapment. The design ethos centers around minimizing crevices, dead spaces, and stagnant zones, which aligns with international sanitary standards set by organizations like the European Hygienic Engineering & Design Group (EHEDG) and the 3-A Sanitary Standards Inc. The inherent capability of these pumps to handle product gently, minimizing shear stress, makes them critical for transferring delicate media such as live cell cultures, dairy products, and high-value pharmaceutical ingredients without damaging their structural integrity or biological activity.

These pumps function based on the principle of volumetric fluid transfer, utilizing counter-rotating rotors (lobes) within a pump head to draw in and displace a precise volume of fluid with each rotation. Key applications span critical processes within the food and beverage industry, including the transfer of viscous sauces, chocolate, fermentation starters, and beverage concentrates. Within the pharmaceutical and biotechnology sectors, hygienic rotary lobe pumps are indispensable for metering expensive Active Pharmaceutical Ingredients (APIs), handling complex biological media, and accurately dosing components in sterile filling lines. Their reliability and volumetric accuracy across a wide range of fluid viscosities—from thin liquids to heavy pastes—provide significant operational advantages over centrifugal pumps in these high-stakes applications.

The principal benefits driving the pervasive market penetration of these pumps include superior hygienic design facilitating efficient and validated Clean-in-Place (CIP) and Sterilize-in-Place (SIP) cycles, which dramatically reduce turnaround time and validation costs. Furthermore, the robust construction, typically featuring heavy-duty bearings separated from the pump chamber, ensures prolonged operational life and isolates the pumped product from potential lubricant contamination. The escalating global focus on enforcing stringent regulatory compliance in food safety and drug manufacturing quality necessitates the continuous upgrade to certified hygienic equipment, acting as the primary macro-economic driver for sustained market growth across developed and rapidly developing economies. The adoption of magnetic coupled options further elevates the hygiene factor by eliminating shaft penetrations and associated seal leak risks.

Hygienic Rotary Lobe Pump Market Executive Summary

The global Hygienic Rotary Lobe Pump Market is characterized by steady expansion, underpinned by the convergence of intensified global regulatory pressure and robust investment in biopharmaceutical manufacturing capacity. Current business trends heavily favor manufacturers who offer modular designs and flexible solutions that can be easily integrated into automated production lines, adhering to the principles of Industry 4.0. There is a discernible strategic shift toward value-added services, including advanced predictive maintenance packages, extended warranties, and comprehensive documentation support necessary for pharmaceutical validation protocols (IQ/OQ/PQ). Leading companies are focusing their research and development efforts on optimizing rotor geometry to handle ultra-high viscosity fluids more efficiently and developing novel, chemical-resistant elastomers for seals that withstand aggressive cleaning agents and higher operating temperatures.

Geographically, market demand remains concentrated in regions with highly mature regulatory landscapes, specifically North America and Western Europe. These regions command the largest market share due to the established presence of global pharmaceutical giants and high-throughput food processing facilities that mandate immediate adoption of the latest hygienic standards. However, the future growth narrative is dominated by the Asia Pacific (APAC) region, which is witnessing explosive expansion in domestic pharmaceutical production, especially in biosimilars and generics, alongside rapid modernization of local food supply chains. This modernization requires substantial investment in certified processing equipment, positioning APAC as the highest growth CAGR market, driving localized manufacturing and distribution partnerships.

Segmentation analysis reveals that the pharmaceutical and biotechnology sector remains the most lucrative segment in terms of revenue per unit, demanding premium, highly customized pumps with full material traceability and mandatory certification packages. Conversely, the Food & Beverage segment provides the largest volume opportunity, driven primarily by the dairy, brewery, and confectionery sub-sectors requiring durable, high-flow pumps optimized for CIP cycles. Across all segments, the trend is toward digitalization; customers are increasingly demanding pumps equipped with integrated sensors and connectivity features for remote diagnostics, operational parameter tracking, and real-time process verification, essential for maintaining continuous operational compliance and efficiency in complex manufacturing environments. The sustained requirement for gentle handling across virtually all high-value product streams reinforces the fundamental market positioning of rotary lobe technology.

AI Impact Analysis on Hygienic Rotary Lobe Pump Market

The most pressing user inquiries regarding the application of Artificial Intelligence (AI) in the Hygienic Rotary Lobe Pump Market center on leveraging machine learning to transition from costly, scheduled preventative maintenance to highly accurate, condition-based predictive maintenance. Users are concerned with how AI platforms can process multi-sensor data—including vibration spectrums, motor current draw, and subtle temperature variations in the bearing housing or seal area—to accurately forecast the Remaining Useful Life (RUL) of critical components, particularly mechanical seals, which are often the weakest link in high-pressure hygienic applications. The core expectation is that AI will virtually eliminate unexpected operational failures, which can result in catastrophic batch loss in sterile manufacturing, simultaneously optimizing inventory management for specialized, long lead-time spare parts.

Furthermore, AI algorithms are being deployed to revolutionize the validation and optimization of Clean-in-Place (CIP) and Sterilize-in-Place (SIP) sequences. Traditional CIP relies on conservative, predetermined parameters (time, temperature, flow rate, chemical concentration) to ensure cleanliness, often resulting in excessive utility consumption. AI models analyze real-time data on the product residue being pumped and historical cleaning efficacy data to dynamically adjust these parameters for each batch, ensuring the necessary level of cleanliness validation is achieved with the absolute minimum use of water, energy, and expensive cleaning chemicals. This not only yields substantial operational savings but also directly supports corporate sustainability goals (ESG reporting) without compromising regulatory adherence, addressing a key market expectation for efficiency.

Beyond maintenance and cleaning, AI integration is vital for optimizing the pump's operational performance in real-time, especially when handling shear-sensitive media or highly non-Newtonian fluids. Machine learning models continuously analyze viscosity changes due to temperature fluctuation or changing formulation characteristics during a batch run. Based on this analysis, the AI system can automatically adjust the pump's Variable Frequency Drive (VFD) speed to maintain a precise, consistent flow rate while ensuring the applied shear force remains below the product damage threshold. This capability is paramount in biotechnology for handling delicate cell suspensions or in food processing for maintaining emulsion stability, thereby guaranteeing end-product quality uniformity across multi-stage processes and reducing dependence on manual operator adjustments.

- AI-driven predictive analytics minimize unplanned downtime by forecasting mechanical seal and bearing failures based on vibration signatures.

- Machine Learning algorithms optimize CIP/SIP efficiency, reducing utility consumption (water, energy, chemicals) while ensuring validated sterility.

- Real-time flow control optimization using AI guarantees gentle product handling, crucial for shear-sensitive biological and food products.

- Enhanced process validation and traceability through AI correlation of operational data with batch quality parameters.

- AI assists in dynamic inventory management for highly specialized pump spares, reducing stockholding costs and logistical delays.

DRO & Impact Forces Of Hygienic Rotary Lobe Pump Market

The market trajectory for Hygienic Rotary Lobe Pumps is heavily defined by regulatory adherence, process efficiency needs, and financial constraints. Primary drivers include the global harmonization and strict enforcement of sanitary standards (EHEDG, 3-A) across critical industries, making non-compliant equipment obsolete. The rapid expansion of the biopharmaceutical sector, demanding highly precise, low-shear pumping solutions for sensitive media, provides a significant tailwind. Furthermore, the persistent push towards complete process automation and the implementation of Industry 4.0 principles necessitates pumps that are sensor-ready, VFD-compatible, and capable of integrating seamlessly into digital control architectures for enhanced transparency and remote monitoring.

Market restraints primarily revolve around the high acquisition and installation costs associated with certified hygienic equipment. The specialized materials (polished 316L SS) and advanced sealing mechanisms required for regulatory compliance make these pumps significantly more expensive than standard industrial counterparts, presenting a barrier to entry, particularly for Small and Medium Enterprises (SMEs) in emerging markets. Additionally, the complexity of maintaining and validating these systems requires specialized technical expertise. The ongoing threat of alternative hygienic positive displacement technologies, such as circumferential piston pumps and twin-screw pumps, which offer competitive advantages in certain high-pressure or CIP requirements, also acts as a subtle restraint, forcing continuous innovation in the lobe pump segment.

Opportunities for growth are concentrated in the rapid modernization of infrastructure across Asia Pacific and Latin America, where demand for safe, packaged food and locally produced pharmaceuticals is soaring. Technological opportunities include developing magnetic drive hygienic lobe pumps to eliminate mechanical seals entirely, improving pump longevity and sterility assurance. The market also benefits significantly from the opportunity to provide retrofit solutions—upgrading legacy facilities with current-generation, high-efficiency, and compliant pumps. The impact forces are thus dominated by regulatory mandates (forcing adoption) and efficiency demands (pushing technological limits), creating an environment where superior hygienic design and low total cost of ownership (TCO) are the critical differentiators for market success and competitive advantage.

Segmentation Analysis

The Hygienic Rotary Lobe Pump Market is meticulously segmented to reflect the diverse operational requirements across its primary end-user base. Segmentation by industry reveals that while Pharmaceuticals and Biotechnology demand the highest technical specifications and certification levels, yielding premium pricing, the Food and Beverage sector, particularly dairy and non-alcoholic beverages, represents the highest volume application due to mass production scales. This variance dictates different priorities for manufacturers; pharmaceutical pumps require absolute material traceability and precision, whereas F&B pumps prioritize robust construction for continuous, high-throughput operation and rapid CIP cycles. The material segment is nearly universally dominated by 316L stainless steel, differentiated mainly by the surface roughness (Ra value) required for specific applications (e.g., lower Ra for biotech versus slightly higher for standard food products).

Segmentation based on the mechanical configuration, specifically the type of seal and drive mechanism, is crucial. Double mechanical seals flushed with sterile barrier fluid are heavily preferred in pharmaceutical applications to mitigate the risk of product contact with the environment, ensuring zero leakage. Conversely, single seals may suffice in many standard food applications. The differentiation between bare shaft pumps, offering configuration flexibility with specialized motors, and close-coupled designs, favored for their compact footprint and simplified installation, caters to diverse space and integration constraints across end-user facilities. Capacity segmentation, from small pilot-scale pumps to large industrial transfer systems, directly correlates with the scale of the customer's manufacturing process, influencing factors such as port size and motor power requirements.

- By End-User Industry:

- Food & Beverage: Includes Dairy (Milk, Cream, Yogurt), Beverages (Juices, Syrups), Confectionery (Chocolate, Glucose), and Processed Foods (Sauces, Soups).

- Pharmaceuticals & Biotechnology: Encompasses API processing, Vaccine manufacturing, Media and buffer preparation, Sterile filling, and Cell culture transfer.

- Cosmetics & Personal Care: Used for handling High-viscosity creams, Lotions, Gels, and Specialty chemical ingredients.

- Chemical Processing: Focused on handling specialty chemicals, High-purity solvents, and delicate chemical precursors requiring strict non-contamination.

- By Material of Construction (Wetted Parts):

- 316L Stainless Steel: Standard material offering excellent corrosion resistance and cleanability.

- Specialty Alloys (e.g., Hastelloy): Used for highly aggressive chemical media or extreme operating conditions.

- Elastomers/Seals: PTFE (Teflon), EPDM, FKM, and high-performance perfluoroelastomers (FFKM) tailored for chemical and temperature resistance.

- By Mechanism/Design:

- Bare Shaft Pumps: Offer maximum flexibility for motor and transmission choice, often for high power applications.

- Close-Coupled Pumps: Compact design, cost-effective, ideal for applications where space is limited.

- Single Lobe and Multi-Lobe Rotors: Differentiation based on shear requirement and solid handling capacity.

- By Capacity/Flow Rate:

- Low Capacity (<5 m³/hr): Primarily R&D, pilot plants, and precision dosing applications.

- Medium Capacity (5-30 m³/hr): Standard batch production lines in F&B and smaller pharma operations.

- High Capacity (>30 m³/hr): Large-scale transfer, main processing lines, and utility applications.

Value Chain Analysis For Hygienic Rotary Lobe Pump Market

The Value Chain for the Hygienic Rotary Lobe Pump Market initiates with specialized upstream material procurement. Unlike general industrial pumps, the upstream sourcing is highly selective, requiring certified stainless steel billets (316L or higher grade) with mandatory Material Test Reports (MTRs) to ensure full traceability and chemical composition compliance, critical for validation in FDA-regulated processes. Suppliers of high-performance elastomers (e.g., FDA-approved PTFE or EPDM compounds) are also essential partners, as the quality and resilience of these sealing components directly impact the pump's hygiene, lifespan, and resistance to aggressive CIP chemicals. This upstream phase requires deep integration and auditing to ensure material quality adheres to sanitary regulations before manufacturing even begins.

The core manufacturing stage involves highly specialized processes, including advanced CNC machining to achieve exceptionally tight dimensional tolerances and surface finishes with roughness averages (Ra) often below 0.8 µm, and sometimes down to 0.4 µm for aseptic applications. The assembly process must often occur in dedicated clean environments to prevent contamination. Downstream activities involve rigorous quality assurance testing, hydrostatic pressure tests, and functional performance testing across the required flow and pressure envelopes. A critical component of the downstream value proposition is obtaining and maintaining required third-party certifications (3-A, EHEDG) and compiling comprehensive documentation packages necessary for customer validation (Installation Qualification/Operational Qualification/Performance Qualification).

Distribution channels are multifaceted, utilizing both direct sales engineers for strategic, large-scale pharmaceutical projects requiring extensive customization, and a robust network of indirect distributors and system integrators. Indirect channels are vital for penetrating smaller regional markets and providing essential localized support, including spare parts stocking and rapid field servicing. The success of the final stage is heavily dependent on the distributor's technical competency to install, commission, and troubleshoot these precise systems, ensuring optimal operational performance. The post-sales phase, including technical support, preventative maintenance contracts, and the supply of certified spare parts, contributes significantly to the long-term customer value proposition and manufacturer profitability, solidifying customer loyalty in this highly specialized sector.

Hygienic Rotary Lobe Pump Market Potential Customers

The primary consumers of Hygienic Rotary Lobe Pumps are entities involved in the production of consumer goods and sensitive ingredients that necessitate fluid transfer under rigorously controlled sanitary conditions. Key potential customers include global pharmaceutical manufacturers and Contract Manufacturing Organizations (CMOs) specializing in complex injectables, biologics, and over-the-counter liquid medications. These customers demand pumps capable of validated sterility, precise dosing, and extremely gentle handling of high-value raw materials, where the cost of batch failure far outweighs the pump's initial investment. They typically focus on minimizing Total Cost of Ownership (TCO) through reduced maintenance and enhanced uptime.

The Food and Beverage sector represents the broadest customer base, encompassing major international food conglomerates and regional dairy co-operatives. Within this segment, customers in dairy processing, brewery operations (yeast and mash transfer), and confectionery production (molten chocolate, sugar syrups) are key buyers. Their purchasing criteria often prioritize high flow rates, robustness against temperature fluctuations, and ease of automated Clean-in-Place cycles, ensuring maximum productivity in high-volume production environments. These customers seek reliable pumps that can withstand abrasive media and operate continuously with minimal manual intervention while adhering to national and international food safety codes.

Additional significant potential customer segments include cosmetics manufacturers, particularly those producing premium personal care items such as high-viscosity lotions, specialized toothpaste, and hair care products, where maintaining product texture and stability is paramount. The specialty chemical industry also relies on these pumps for handling high-purity or expensive chemical precursors where contamination must be avoided at all costs. These diverse end-users share a fundamental requirement: the need for reliable, certifiable positive displacement equipment that guarantees product integrity and process safety throughout the critical fluid transfer stages.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SPX FLOW, Inc., Alfa Laval AB, GEA Group Aktiengesellschaft, Xylem Inc., MasoSine (SPX FLOW), Fristam Pumpen KG (GmbH & Co.), Waukesha Cherry-Burrell (SPX FLOW), Sani-Matic, CCT Pumps, Netzsch Pumpen & Systeme GmbH, Ampco Pumps Company, Viking Pump (IDEX Corporation), Wright Flow Technologies, Murzan, Inc., Inoxpa S.A., Watson-Marlow Fluid Technology Solutions, Topline Stainless Steel Products, Q-Pumps, Axiflow Technologies, PDI Pumps. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hygienic Rotary Lobe Pump Market Key Technology Landscape

The contemporary technology landscape of the Hygienic Rotary Lobe Pump Market is defined by innovations aimed at achieving absolute containment, minimizing operational complexity, and maximizing energy efficiency while strictly adhering to zero-contamination mandates. One significant advancement is the prevalence of specialized rotor profiles, such as anti-cavitation and helical designs, which are engineered not only to reduce fluid pulsation but also to provide enhanced suction capabilities, particularly critical for handling highly viscous fluids that tend to vaporize or cavitate under typical pumping conditions. These geometric advancements allow for smoother product transfer at higher speeds without inducing excessive shear, a performance metric highly valued in the production of delicate biological materials and smooth food textures.

A crucial area of technical innovation lies in the mechanical seal technology, which is paramount for maintaining the hygienic barrier. Modern pumps frequently incorporate Balanced Double Mechanical Seals, often coupled with a sterile flush system utilizing high-purity barrier fluid, providing an added layer of security against both product leakage and external contamination ingress. Furthermore, the design of seal assemblies has been simplified, allowing for rapid front-loading or cartridge replacement. This ease of maintenance significantly reduces the risk of technician error during reassembly and minimizes the time the production line is down for preventative or corrective maintenance, addressing the high-cost implications of downtime in pharmaceutical environments.

Integration of smart technology, synonymous with the industrial Internet of Things (IIoT), represents a third pillar of technological evolution. Contemporary hygienic rotary lobe pumps are frequently outfitted with advanced sensor packages for monitoring critical operational variables, including casing temperature, bearing vibration, and differential pressure across the pump head. This real-time data acquisition feeds into proprietary pump monitoring software or integrated Process Control Systems (PCS). This capability allows for continuous condition monitoring, facilitating the shift toward proactive, predictive maintenance scheduling. Manufacturers are also increasingly focusing on optimizing material surface treatments, utilizing advanced electropolishing techniques to achieve passive, low-Ra surfaces that resist corrosion and microbiological adhesion even after hundreds of aggressive CIP/SIP cycles, extending the certified life of the pump components.

Regional Highlights

Regional variations in the Hygienic Rotary Lobe Pump Market are dictated by the maturity of the regulatory bodies, the concentration of global pharmaceutical manufacturing, and the pace of modernization in the food supply chain. North America, especially the United States, holds a premium market position, driven by the world's leading biopharmaceutical cluster and rigorous FDA enforcement. The region demands the highest level of validation and traceability for equipment used in sterile processes, leading to higher average unit prices and robust demand for digitally integrated, high-specification pumps. Investment in capacity expansion for vaccines and advanced cell and gene therapies ensures sustained growth in this sector.

Europe represents a technologically advanced and highly standardized market. The ubiquity of EHEDG (European Hygienic Engineering & Design Group) compliance acts as a non-negotiable benchmark, focusing market competition on energy efficiency, compactness, and superior CIP compatibility. Countries like Germany and the Nordic region maintain strong manufacturing bases for complex processed foods and high-quality dairy products, requiring continuous investment in equipment that supports sustainable operation and minimized product waste, further stimulating the replacement market for older non-compliant installations.

The Asia Pacific (APAC) region is projected to be the engine of future market growth, exhibiting the highest CAGR through 2033. This growth is bifurcated: established markets like Japan and Australia mimic North American and European demands for high quality, while rapidly industrializing nations such as China and India are undergoing massive overhauls of their production facilities. Driven by increasing domestic wealth, stricter government oversight on domestic food quality, and a surge in generic and biosimilar pharmaceutical production, APAC presents immense opportunities, often favoring localized manufacturing partnerships to meet volume demand while navigating regional pricing pressures.

- North America (USA & Canada): Market leadership in value terms; driven by stringent FDA regulation, high expenditure on biotech and precision medicine R&D, and rapid adoption of predictive maintenance technologies.

- Europe (Germany, France, UK): High maturity market focused on EHEDG compliance, sustainability mandates, and energy efficiency; strong replacement cycle driven by strict environmental and food safety laws.

- Asia Pacific (China, India, Southeast Asia): Fastest growing region due to accelerated pharmaceutical expansion, modernization of the food processing industry, and improving alignment of local standards with international hygienic benchmarks.

- Latin America (Brazil, Mexico): Emerging market where growth is concentrated in the upgrade of dairy, sugar, and beverage facilities; growth is reliant on foreign investment and localized regulatory enforcement strength.

- Middle East & Africa (MEA): Niche market focused on water treatment and developing self-sufficient food production capabilities; slow but steady growth propelled by government infrastructure projects and efforts to achieve export quality standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hygienic Rotary Lobe Pump Market.- SPX FLOW, Inc.

- Alfa Laval AB

- GEA Group Aktiengesellschaft

- Xylem Inc.

- MasoSine (SPX FLOW)

- Fristam Pumpen KG (GmbH & Co.)

- Waukesha Cherry-Burrell (SPX FLOW)

- Sani-Matic

- CCT Pumps

- Netzsch Pumpen & Systeme GmbH

- Ampco Pumps Company

- Viking Pump (IDEX Corporation)

- Wright Flow Technologies

- Murzan, Inc.

- Inoxpa S.A.

- Watson-Marlow Fluid Technology Solutions

- Topline Stainless Steel Products

- Q-Pumps

- Axiflow Technologies

- PDI Pumps

Frequently Asked Questions

Analyze common user questions about the Hygienic Rotary Lobe Pump market and generate a concise list of summarized FAQs reflecting key topics and concerns.What key design features define a pump as truly hygienic?

A truly hygienic pump must feature highly polished wetted surfaces (low Ra), be constructed from certified materials (e.g., 316L SS), possess crevice-free interiors, ensure complete drainability, and utilize seals and elastomers compliant with FDA and 3-A or EHEDG standards. Ease of disassembly for inspection and cleaning is also a critical design feature.

In which applications are rotary lobe pumps preferred over twin-screw or centrifugal pumps?

Rotary lobe pumps are preferred for applications involving high-viscosity fluids (like syrups, creams, or batters), shear-sensitive media (like delicate biological cultures or emulsions), and situations requiring precise metering and volumetric accuracy, where low pulsation and gentle product handling are paramount.

What role does the surface finish (Ra value) play in pharmaceutical compliance?

The Surface Roughness Average (Ra value) dictates the cleanability and resistance to bacterial adhesion. Lower Ra values (typically 0.8 µm down to 0.4 µm) are mandatory in pharmaceutical and aseptic applications to ensure effective sterilization and prevent the formation of biofilm, which is critical for process validation.

How do manufacturers address the high maintenance cost of mechanical seals?

Manufacturers are addressing this by implementing advanced technologies such as predictive maintenance sensors (IoT), utilizing durable, chemically resistant perfluoroelastomers, and designing quick-change, front-loading mechanical seal cartridges that minimize maintenance complexity and the duration of production downtime.

What is the primary factor driving the high growth rate in the Asia Pacific market?

The high growth rate in the Asia Pacific is primarily driven by massive government and private sector investment in modernizing the regional food safety infrastructure and the accelerated expansion of localized pharmaceutical and vaccine manufacturing capabilities to serve large domestic and export markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager