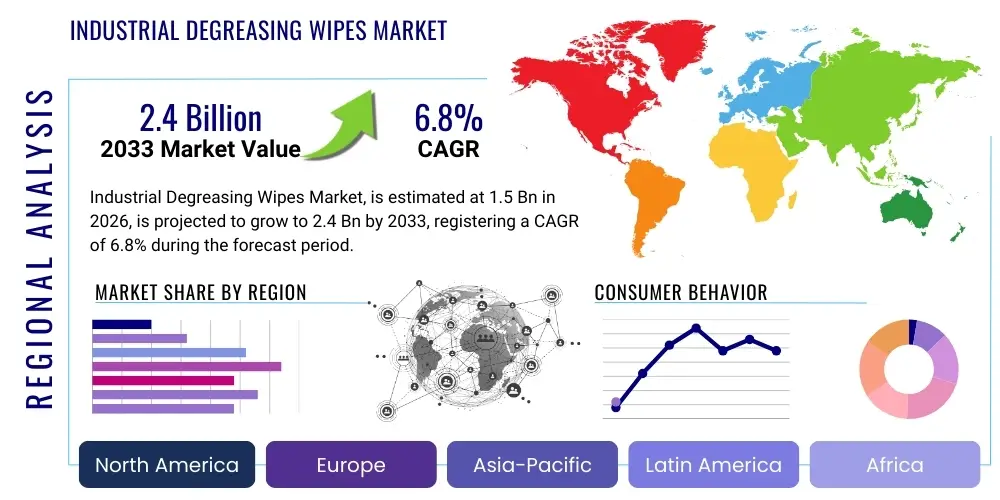

Industrial Degreasing Wipes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441935 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Industrial Degreasing Wipes Market Size

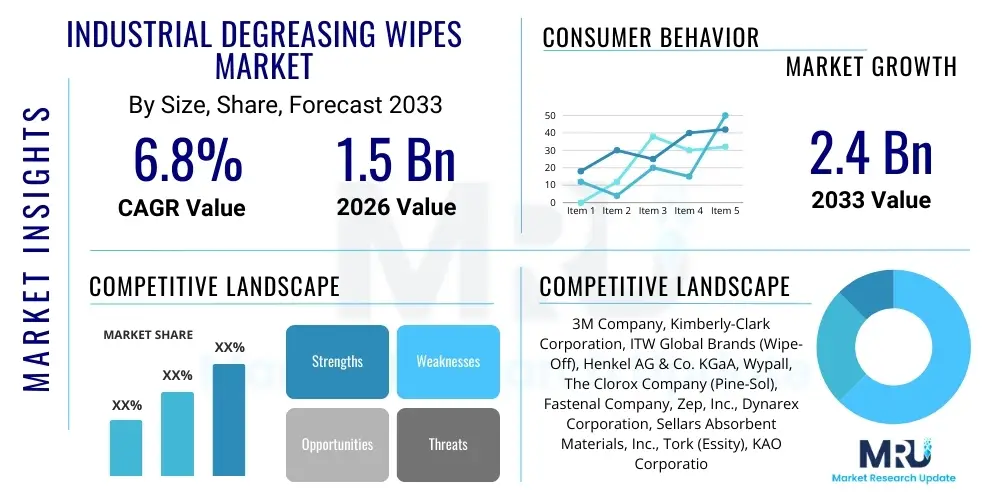

The Industrial Degreasing Wipes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Industrial Degreasing Wipes Market introduction

The Industrial Degreasing Wipes Market encompasses specialized cleaning solutions designed for heavy-duty grease, oil, grime, and industrial residue removal across various demanding environments. These pre-saturated or dry wipes, often utilizing powerful solvents and high-absorption substrates, offer a convenient, efficient, and safer alternative to traditional solvent-and-rag methods, significantly reducing Volatile Organic Compound (VOC) emissions and improving workplace hygiene. The primary function of these products is to maintain machinery, components, tools, and surfaces in operational condition, ensuring safety and longevity in production settings.

Product descriptions vary widely based on material composition—ranging from durable non-woven fabrics like polypropylene and polyester blends to cellulose-based papers—and the chemical formulation, which includes bio-based solvents, citrus extracts, or specialized industrial degreasers. Major applications span critical sectors such as automotive repair and manufacturing, aerospace maintenance (MRO), heavy equipment fabrication, and general machinery upkeep. The convenience factor, coupled with regulated standards emphasizing cleanliness and operator safety in industrial settings, solidifies the indispensable role of these wipes.

Key benefits derived from the adoption of industrial degreasing wipes include superior efficacy in contaminant removal, streamlined cleaning processes leading to reduced downtime, and enhanced worker safety due to minimizing direct contact with harsh liquids. Driving factors for market expansion are primarily anchored in the increasing automation and precision required in manufacturing, stringent regulatory pressures concerning environmental waste and VOCs, and the continuous push towards portable, single-use solutions that minimize cross-contamination risks and improve operational workflow efficiency across global industrial complexes.

Industrial Degreasing Wipes Market Executive Summary

The Industrial Degreasing Wipes Market is experiencing robust growth driven by accelerating industrial maintenance requirements and a paradigm shift towards disposable, high-performance cleaning materials. Business trends highlight a strong focus on sustainability, compelling manufacturers to innovate with bio-degradable substrates and eco-friendly, less-toxic degreasing agents, moving away from harsh petroleum-based solvents. Strategic collaborations between wipe manufacturers and chemical suppliers are becoming common to develop tailored solutions for niche industrial applications, such as aviation MRO or electronics manufacturing, requiring specific material compatibility and residue-free cleaning.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, propelled by rapid industrialization, particularly in the manufacturing and automotive sectors of China and India, where large-scale infrastructure development necessitates continuous equipment maintenance. North America and Europe, while mature, demonstrate stable demand fueled by stringent occupational safety regulations and a high adoption rate of premium, performance-oriented wipes designed for critical cleaning tasks. The competitive landscape is characterized by established global players leveraging vast distribution networks and smaller, specialized companies focusing on innovative, sustainable formulations to capture emerging market niches.

Segment trends reveal that the non-woven segment dominates the market due to its superior durability and absorption capacity, essential for heavy industrial use. Furthermore, the automotive and general manufacturing applications hold the largest market share, consistently driving demand for high-strength degreasing solutions used in engine part cleaning and pre-painting preparation. The shift towards solvent-free or citrus-based degreasers within the chemical composition segment reflects the industry’s response to environmental governance and user health concerns, positioning sustainable products as a primary growth driver over the forecast period.

AI Impact Analysis on Industrial Degreasing Wipes Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Industrial Degreasing Wipes Market center primarily on optimizing logistics, forecasting demand volatility, and enhancing product formulation efficiency. Common questions revolve around how predictive maintenance systems—often enabled by AI—might influence the consumption patterns of cleaning supplies, asking if smarter machinery might require less cleaning, or if it will simply demand more precise, specialized cleaning at specific intervals. There is also significant interest in how AI and machine learning (ML) algorithms can be utilized in R&D to quickly screen and optimize novel, environmentally friendly solvent compositions that meet stringent regulatory and performance requirements, thereby accelerating the time-to-market for sustainable degreasing wipe solutions.

The key themes emerging from this analysis include the optimization of supply chain management through AI-driven demand sensing, ensuring wipes are delivered Just-In-Time (JIT) to maintenance facilities, reducing inventory costs and spoilage. Furthermore, users express expectations that AI-integrated monitoring systems, which detect contamination levels or machinery degradation using computer vision, could trigger automated orders for specific types of wipes, moving the market from bulk purchasing to usage-based procurement. While AI will not directly replace the physical product, it is expected to fundamentally transform the distribution efficiency and customization potential of industrial cleaning consumables, linking cleaning supply consumption directly to real-time operational needs and maintenance schedules.

- AI-driven Predictive Maintenance: Reduces reactive cleaning cycles, leading to consumption linked directly to real-time equipment status rather than scheduled routines.

- Supply Chain Optimization: ML algorithms forecast precise demand levels based on industrial output and maintenance schedules, minimizing inventory waste and logistical bottlenecks.

- Formulation R&D: AI simulates molecular interactions to accelerate the development of high-performance, low-VOC or bio-based degreasing chemicals.

- Automated Inspection Integration: Computer vision systems identify contamination, triggering automated procurement or dispensing of the appropriate type of degreasing wipe.

- Quality Control Enhancement: AI monitors production lines for substrate consistency and chemical saturation accuracy, ensuring high product quality and reducing manufacturing defects.

DRO & Impact Forces Of Industrial Degreasing Wipes Market

The dynamics of the Industrial Degreasing Wipes Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming the Impact Forces influencing long-term market trajectory. A primary driver is the accelerating focus on operational efficiency and worker safety across global industrial sectors, which favors the adoption of pre-saturated wipes over traditional cleaning methods due to ease of use, consistent dosage control, and reduced exposure to hazardous solvents. The increasing deployment of advanced machinery and robotic systems in manufacturing also necessitates specialized, non-abrasive cleaning solutions to maintain the integrity of sensitive components, further bolstering demand. Opportunities are heavily concentrated in the development of "green" degreasing chemistries and biodegradable substrates, appealing to corporate sustainability mandates and opening doors to highly regulated environments like electronics and medical device manufacturing.

Conversely, the market faces significant restraints, notably the relatively higher cost of specialized industrial wipes compared to bulk solvent and rag alternatives, presenting a barrier to entry, particularly in cost-sensitive emerging markets. Furthermore, the regulatory complexity surrounding the disposal of wipes saturated with hazardous industrial waste poses a logistical and compliance challenge for end-users. The Impact Forces analysis suggests that while environmental regulations (Restraints regarding disposal) necessitate higher R&D investment, they simultaneously act as a powerful driver toward innovation (Opportunities in bio-based solutions). The immediate impact of improved workplace safety standards heavily favors market growth, outweighing the current cost constraints, particularly in developed economies.

Impact forces indicate a trend towards consolidation among manufacturers seeking economies of scale to mitigate input material cost volatility, which affects pricing pressure. The market is moderately fragmented but moving towards higher differentiation based on specialized performance characteristics (e.g., aerospace-grade, electro-static discharge-safe). Technological advancements in substrate materials, enhancing absorption and tear resistance, coupled with strategic geographic expansion into industrializing nations, are anticipated to solidify the market's positive growth trajectory, despite ongoing challenges related to raw material sustainability and stringent waste management protocols.

Segmentation Analysis

The Industrial Degreasing Wipes Market is strategically segmented based on factors including the type of material used for the wipe substrate, the specific chemical formulation of the degreaser, the primary end-use application, and the distribution channel employed. This segmentation allows manufacturers to tailor products precisely to industrial requirements, whether it involves the high absorbency and durability needed for heavy machinery cleaning (Non-woven) or the specific chemical compatibility required in aviation maintenance (Solvent-free). Understanding these segments is crucial for market stakeholders to capitalize on distinct growth pockets, such as the increasing demand for specialized wipes in the sensitive electronics and aerospace sectors, which prioritize low-lint and precise chemical delivery systems.

- By Material Type:

- Non-woven Wipes (e.g., Polypropylene, Polyester Blends)

- Paper/Cellulose-based Wipes

- By Chemical Formulation:

- Solvent-based (e.g., Hydrocarbon, Alcohol)

- Solvent-free (e.g., Water-based, Citrus/Bio-based)

- By Application:

- Automotive and Transportation

- General Manufacturing and Machinery

- Aerospace and Defense (MRO)

- Oil & Gas and Energy

- Marine and Ship Building

- Electronics and Precision Engineering

- By Distribution Channel:

- Offline (Industrial Distributors, Retailers)

- Online (E-commerce Platforms, Direct-to-Business Portals)

Value Chain Analysis For Industrial Degreasing Wipes Market

The value chain for the Industrial Degreasing Wipes Market begins with the Upstream Analysis, which encompasses the procurement and processing of key raw materials. This includes fibrous raw materials like polypropylene, polyester, wood pulp, and specialized cellulose required for the wipe substrate, alongside the sourcing of complex chemical ingredients such as solvents (including eco-friendly variants like citrus extracts or specialized surfactants), emulsifiers, and preservatives. Supplier relationships in this segment are critical, particularly given the volatility in petrochemical prices and the increasing mandate for sustainable sourcing, which heavily influences the final product cost and environmental profile. Efficient inventory management and bulk purchasing are essential upstream strategies to maintain competitive pricing.

The core manufacturing stage involves converting these raw materials through processes such as spunlacing or thermal bonding to create the non-woven fabric, followed by slitting, folding, saturation, and packaging. Quality control is paramount during saturation to ensure consistent chemical load and shelf life. Downstream analysis focuses on effective market penetration through established distribution channels. The market heavily relies on industrial distributors and B2B specialty suppliers (Offline Channel) who offer logistical support and application expertise to end-users. However, the indirect channel through e-commerce platforms is gaining traction, especially for smaller businesses and repeatable standardized purchases, driven by the need for quick turnaround and transparent pricing.

Direct sales are usually reserved for large, enterprise-level clients, such as major automotive OEMs or aerospace MRO facilities, where customized formulations or extremely high volumes necessitate direct negotiation and dedicated supply lines. The complexity of regulatory compliance, particularly regarding transport and storage of pre-saturated wipes (potentially classified as hazardous materials), significantly impacts distribution channel selection and logistical planning. Optimized packaging solutions that ensure long-term moisture retention and ease of dispensing are key differentiators in the final stage before reaching the end-user.

Industrial Degreasing Wipes Market Potential Customers

Potential customers, or end-users, for industrial degreasing wipes are broadly categorized as any entity involved in maintenance, repair, and overhaul (MRO) activities across heavy and light industries where machinery, parts, or operational surfaces accumulate oil, grease, or sticky residues. The Automotive and Transportation sector represents a foundational customer base, encompassing vehicle assembly plants, component manufacturers, engine repair garages, and public transit maintenance depots, all requiring reliable degreasing solutions for preparing surfaces for painting or cleaning essential engine components. These users prioritize high solvent power and durability to handle thick, viscous contaminants quickly and effectively in high-volume settings.

Another high-value customer group includes the Aerospace and Defense industry, specifically MRO centers for aircraft and defense machinery. These applications demand specialized, low-lint wipes with non-corrosive, often water-based or solvent-free degreasers to prevent damage to sensitive alloys, composite materials, and electronic components, adhering to exceptionally strict quality and residue standards. Furthermore, the burgeoning Oil & Gas and Heavy Equipment sectors, encompassing drilling operations, pipeline maintenance, and construction machinery repair, represent key buyers who utilize durable wipes for routine field maintenance, where portability and immediate cleaning capacity are critical success factors.

The Electronics and Precision Engineering industries are increasingly relevant buyers, requiring specialized, antistatic degreasing wipes for cleaning circuit boards, sensors, and precision tools without leaving behind particulate contamination or interfering with electrical conductivity. General Manufacturing, spanning everything from metal fabrication to food processing (where NSF-certified products are required), provides the broadest consumer base, valuing versatility and cost-effectiveness. The purchasing decision across all these customer segments is increasingly influenced not only by cleaning performance but also by regulatory compliance, sustainability certifications, and the vendor's ability to provide safety data sheets and training.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Kimberly-Clark Corporation, ITW Global Brands (Wipe-Off), Henkel AG & Co. KGaA, Wypall, The Clorox Company (Pine-Sol), Fastenal Company, Zep, Inc., Dynarex Corporation, Sellars Absorbent Materials, Inc., Tork (Essity), KAO Corporation, ABRO Industries, Inc., CRC Industries, Inc., Kutol Products Company, S.C. Johnson & Son, Inc., Saint-Gobain, Unicorn Products, Inc., Chemours Company, PDI, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Degreasing Wipes Market Key Technology Landscape

The technological evolution of the Industrial Degreasing Wipes Market centers predominantly on advancements in substrate engineering and chemical formulation methodologies, aiming for a balance between high performance, environmental compliance, and cost-efficiency. Substrate technology is focused on creating non-woven fabrics with superior structural integrity, tear resistance, and optimal absorption capacity to handle aggressive industrial environments without shredding or leaving lint behind. Techniques like hydroentanglement (spunlace technology) are widely adopted to bond fibers, typically blends of polypropylene and wood pulp, achieving the necessary strength and texture. The current technological imperative involves incorporating sustainable, bio-degradable fibers while maintaining or enhancing the mechanical properties required for heavy-duty degreasing tasks.

In terms of chemical technology, a significant trend is the shift towards advanced surfactant systems and bio-based solvents, moving away from high-VOC petroleum distillates. Manufacturers are leveraging green chemistry principles to formulate powerful degreasers using ingredients derived from natural sources, such as limonene (citrus extracts) or specialized fermentation products, which offer efficacy comparable to traditional solvents but with a reduced environmental footprint and improved user safety profile. Furthermore, encapsulation technology is being explored to stabilize volatile components, prolong shelf life, and ensure consistent chemical delivery upon wipe activation, contributing to the perceived value and reliability of the premium product offerings in highly technical applications like aerospace MRO.

Dispensing technology also represents a key area of innovation. Advanced canister and bucket designs now incorporate hermetic seals and one-at-a-time dispensing mechanisms to prevent premature drying out of pre-saturated wipes, a common issue impacting usability and perceived quality. Smart packaging solutions, incorporating indicators for usage or depletion, are also beginning to emerge, particularly in high-throughput environments where inventory tracking needs to be seamlessly integrated into enterprise resource planning (ERP) systems. These technological integrations ultimately contribute to enhanced product lifecycle and optimized usage control at the industrial consumer level.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to massive investments in manufacturing, automotive production, and infrastructure development, particularly in China, India, and Southeast Asia. The region’s lower labor costs and burgeoning MRO activities drive high volume consumption, although pricing sensitivity remains a factor, leading to robust demand for both economy and premium industrial wipes.

- North America: This region holds a significant market share, characterized by high adoption rates of premium, specialized degreasing wipes, driven by stringent workplace safety and environmental regulations (EPA/OSHA). The mature automotive, aerospace, and oil & gas sectors consistently demand high-performance, often certified, low-VOC products, favoring innovation and market stability.

- Europe: Europe is a key market defined by early adoption of sustainability mandates and advanced regulatory frameworks (REACH). Demand is focused on solvent-free, bio-degradable, and eco-labeled industrial wipes. Germany, the UK, and France, with their strong manufacturing bases, prioritize solutions that enhance efficiency while strictly adhering to occupational health standards.

- Latin America (LATAM): Growth in LATAM is moderate but steady, fueled by the expansion of mining, heavy machinery, and automotive assembly operations, particularly in Brazil and Mexico. Price competitiveness is essential, often favoring less specialized, volume-based degreasing solutions, although regulatory alignment with global standards is slowly pushing demand toward safer alternatives.

- Middle East and Africa (MEA): The MEA market is heavily influenced by the massive Oil & Gas and petrochemical industries, creating specialized demand for heavy-duty, robust wipes suitable for harsh environments and extreme degreasing tasks. Infrastructure investments in the GCC countries also contribute significantly to the MRO demand in the construction and transportation segments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Degreasing Wipes Market.- 3M Company

- Kimberly-Clark Corporation

- ITW Global Brands (Wipe-Off, Permatex)

- Henkel AG & Co. KGaA

- Wypall (a brand of Kimberly-Clark)

- The Clorox Company (Pine-Sol Professional)

- Fastenal Company

- Zep, Inc.

- Dynarex Corporation

- Sellars Absorbent Materials, Inc.

- Tork (Essity AB)

- KAO Corporation

- ABRO Industries, Inc.

- CRC Industries, Inc.

- Kutol Products Company

- S.C. Johnson & Son, Inc.

- Saint-Gobain

- Unicorn Products, Inc.

- Chemours Company

- PDI, Inc.

Frequently Asked Questions

Analyze common user questions about the Industrial Degreasing Wipes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected CAGR for the Industrial Degreasing Wipes Market between 2026 and 2033?

The Industrial Degreasing Wipes Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period from 2026 to 2033, driven by increasing industrial MRO activities and demand for safety-compliant cleaning solutions.

Which application segment drives the highest demand for industrial degreasing wipes?

The Automotive and General Manufacturing sectors collectively drive the highest demand, utilizing degreasing wipes extensively for machinery maintenance, component cleaning, and surface preparation before critical processes like welding or painting.

What are the primary factors restraining growth in the industrial wipes market?

Key restraints include the relatively high unit cost of specialized pre-saturated wipes compared to bulk cleaning chemicals and rags, coupled with the logistical and regulatory complexities associated with the compliant disposal of chemically contaminated industrial waste materials.

How is sustainability impacting the formulation of degreasing wipes?

Sustainability is driving innovation toward solvent-free and bio-based chemical formulations, such as those utilizing citrus extracts (limonene), and the incorporation of biodegradable substrates like specialized cellulose blends to meet stringent environmental regulations and corporate green mandates.

Which region shows the most significant growth potential for industrial degreasing wipes?

Asia Pacific (APAC) represents the region with the highest growth potential, fueled by massive, ongoing industrialization and the rapid expansion of manufacturing, infrastructure, and automotive sectors in economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager