Industrial Plastic Strip Curtains and Doors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442553 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Industrial Plastic Strip Curtains and Doors Market Size

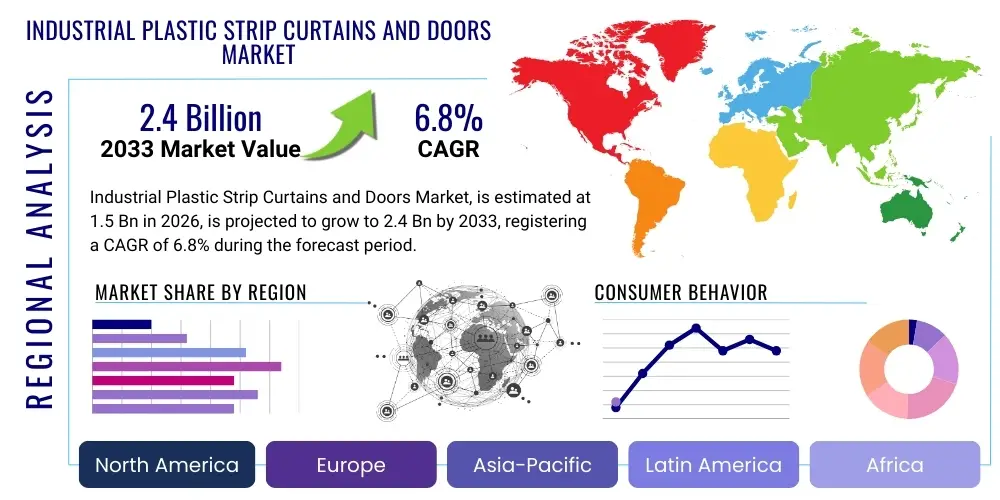

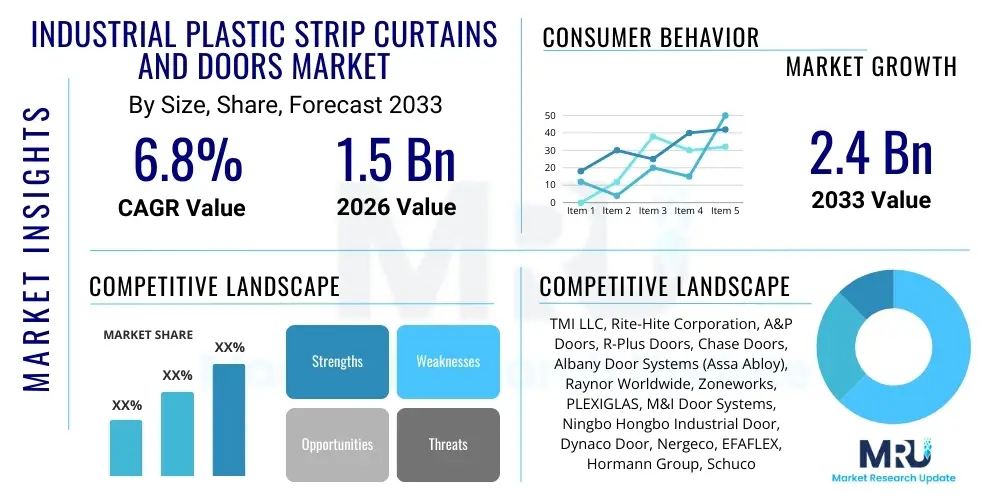

The Industrial Plastic Strip Curtains and Doors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Industrial Plastic Strip Curtains and Doors Market introduction

The Industrial Plastic Strip Curtains and Doors Market encompasses protective and insulating barriers used across various industrial and commercial settings, primarily to control environmental conditions, manage traffic flow, and ensure energy efficiency. These products, ranging from standard PVC strip curtains to specialized rapid-roll doors, function as passive or active separators between distinct temperature or contamination zones, offering a cost-effective alternative to traditional rigid wall systems. The core mechanism involves utilizing overlapping polymer strips or flexible sheet materials to create a thermal seal while permitting personnel, forklift, and vehicular passage with minimal disruption. They are engineered to mitigate the transfer of heat, cold, dust, debris, noise, and airborne contaminants, making them indispensable components in sectors demanding stringent environmental control.

The primary applications of industrial plastic barriers span warehousing and distribution centers, food processing plants, cold storage facilities, manufacturing sites, and pharmaceutical cleanrooms. Key benefits include substantial energy savings by minimizing conditioned air loss, improved workplace safety through high visibility and protection against environmental hazards, and enhanced operational efficiency due to easy and quick access. Furthermore, these barriers play a crucial role in maintaining regulatory compliance, especially within the food and beverage industry where hygiene standards necessitate effective separation of processing areas from loading docks or raw material storage zones.

Driving factors for sustained market growth include the global expansion of the cold chain logistics sector, increasing emphasis on energy consumption reduction in manufacturing operations, and strict government regulations pertaining to workplace health and safety. The technological evolution toward specialized materials, such as anti-microbial and low-temperature PVC, further solidifies their adoption across niche markets. The continuous demand from emerging economies undergoing rapid industrialization and modernization of existing infrastructure ensures a stable trajectory for market expansion throughout the forecast period.

Industrial Plastic Strip Curtains and Doors Market Executive Summary

The Industrial Plastic Strip Curtains and Doors Market is experiencing robust expansion, fundamentally driven by pervasive business trends focusing on operational optimization, environmental sustainability, and supply chain resilience. Manufacturers are increasingly prioritizing investment in high-performance polymer materials that offer enhanced durability, superior insulation properties, and compliance with stringent fire safety and hygiene standards. A significant trend involves the transition from purely passive strip curtains to high-speed automated doors utilizing advanced flexible materials, reflecting industry demand for solutions that maximize throughput while minimizing thermal leakage. The competitive landscape is characterized by moderate consolidation, with leading players focusing on product customization, integrating IoT capabilities for monitoring system performance, and developing modular systems that simplify installation and maintenance.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market segment, primarily fueled by massive infrastructure development in cold storage and food processing sectors across countries like China and India, coupled with widespread expansion of automotive and electronics manufacturing. North America and Europe, while mature, maintain strong market positions due to high regulatory standards regarding energy efficiency and worker safety, necessitating regular replacement and upgrade cycles for existing installations. These developed regions show a higher penetration of specialized products, including temperature-controlled flexible doors and specialized anti-static curtains required in highly sensitive production environments.

Segment trends indicate that PVC remains the dominant material choice due to its versatility and cost-effectiveness, although advanced materials like reinforced vinyl and specialized polymer blends are gaining traction in high-end applications demanding extreme durability or chemical resistance. By application, warehousing and logistics represent the largest segment, directly correlating with the proliferation of e-commerce and subsequent expansion of global distribution networks. The cold storage segment, encompassing refrigerated warehouses and freezers, demonstrates the highest growth potential, as stringent requirements for temperature integrity mandate the utilization of heavy-duty, insulated plastic barriers to prevent spoilage and reduce energy costs associated with refrigeration equipment operation.

AI Impact Analysis on Industrial Plastic Strip Curtains and Doors Market

User inquiries regarding AI's influence on the Industrial Plastic Strip Curtains and Doors Market frequently revolve around how intelligence can transition these traditionally passive safety components into active, data-generating systems. Common questions address the potential for AI algorithms to optimize door operation speed based on observed traffic patterns, whether predictive maintenance powered by AI could extend the lifespan of high-speed motorized doors, and the feasibility of integrating sensor data (captured by proximity sensors or thermal cameras near the barriers) into wider facility management systems. Key themes highlight expectations for increased energy efficiency through automated adjustments, enhanced security protocols via smart access control based on real-time authorization, and streamlining warehouse logistics by predicting bottlenecks at loading dock entrances. Users are keen to understand how AI-driven insights can quantify and justify the return on investment for premium, automated curtain and door solutions over basic, manual configurations.

- Optimization of automatic door cycles based on real-time traffic flow data.

- Predictive maintenance alerts for motorized door components, reducing unexpected downtime.

- Integration of thermal imaging and AI to monitor air leakage and suggest energy saving adjustments.

- Smart access control systems verifying authorization before initiating door opening sequences.

- Anomaly detection in material flow or security breaches near barrier zones.

- Automated compliance reporting based on monitoring operational parameters (e.g., door closure times).

DRO & Impact Forces Of Industrial Plastic Strip Curtains and Doors Market

The Industrial Plastic Strip Curtains and Doors Market is shaped by a strong interplay of influential market dynamics, primarily driven by regulatory frameworks and operational efficiency mandates. Key drivers include the global expansion of temperature-sensitive supply chains, particularly the pharmaceutical and perishables sectors, which require highly reliable thermal separation barriers to maintain product integrity and comply with international food safety standards (such as HACCP). Furthermore, the intensifying focus on reducing carbon footprints and operational costs is accelerating the adoption of high-performance insulated doors and curtains capable of minimizing energy loss in heated or cooled industrial environments. These drivers collectively create a compelling business case for ongoing investment in modern barrier technologies.

However, the market faces significant restraints that temper overall growth rates. The high initial capital expenditure associated with sophisticated, high-speed automated doors, compared to the relatively low cost of traditional vinyl strip curtains, poses an adoption barrier, especially for small and medium-sized enterprises (SMEs) in emerging markets. Another major restraint is the inherent material degradation of PVC and flexible polymers over time due to exposure to UV radiation, harsh cleaning chemicals, and mechanical impact from vehicle traffic, necessitating frequent replacement and contributing to operational expenditure. These material limitations push manufacturers towards developing highly durable and sustainable alternative solutions.

Opportunities for future expansion lie in the development and proliferation of smart strip curtains and doors integrated with IoT sensors for real-time monitoring of temperature, humidity, and air pressure differentials, providing critical data for facility management systems. The growing demand for specialized products, such as anti-static, cleanroom-grade, and weld-screen curtains, opens high-margin niche markets. The primary impact force driving continuous innovation remains stringent government regulation regarding workplace safety (e.g., OSHA standards) and energy efficiency mandates (e.g., European energy directives), compelling industries to adopt superior separation technologies to ensure compliance and reduce operating expenses.

Segmentation Analysis

The Industrial Plastic Strip Curtains and Doors Market is broadly segmented based on Material Type, Product Type, Operating Mechanism, and End-Use Application. This granular segmentation allows market stakeholders to identify specific pockets of demand and tailor product offerings accordingly. The material type segmentation distinguishes between standard PVC, low-temperature PVC (for freezer applications), reinforced vinyl, and specialized polymers like anti-microbial variants. Product type categorization differentiates simple passive strip curtains from flexible roll-up doors, specialized speed doors, and hinged barrier systems. Analyzing these segments provides crucial insights into product preference based on operational requirements, regulatory environment, and ambient temperature specifications of the facility.

The segmentation by operating mechanism is vital, separating manual or push-through systems from motorized, automated, and high-speed opening systems, reflecting investment capacity and traffic volume. Automated systems are increasingly preferred in high-throughput environments like logistics hubs where rapid cycle times are critical. Finally, the end-use application segment—covering Food & Beverage, Cold Storage, Manufacturing, Pharmaceutical, and Automotive—provides the most substantial delineation of demand, with cold storage and food processing demanding the highest standards of hygiene and thermal performance, thus commanding premium product pricing and technology specifications. Understanding the intricate relationships between these segments is essential for strategic market positioning.

- By Material Type:

- Standard PVC

- Low-Temperature PVC (Freezer Grade)

- Anti-Static PVC

- Weld Screen PVC

- Reinforced Vinyl

- Specialized Polymers

- By Product Type:

- Strip Curtains

- Flexible Roll-Up Doors (High-Speed Doors)

- Swing Doors / Impact Doors

- Sliding Doors

- By Operating Mechanism:

- Manual/Passive

- Motorized/Automated

- By End-Use Application:

- Food & Beverage Processing

- Cold Storage & Refrigeration

- Manufacturing & Assembly

- Warehousing & Logistics

- Pharmaceutical & Healthcare (Cleanrooms)

- Automotive

- Chemical Processing

Value Chain Analysis For Industrial Plastic Strip Curtains and Doors Market

The value chain for Industrial Plastic Strip Curtains and Doors begins with the upstream suppliers of raw materials, primarily petrochemical companies that produce the core resins and plasticizers necessary for manufacturing PVC and other flexible polymers. Specialized material compounding firms then process these raw materials, incorporating additives for fire resistance, UV stability, low-temperature flexibility, and anti-static properties, ensuring the final material meets specific industrial requirements. Efficiency and cost optimization at this stage are crucial, as fluctuations in crude oil and petrochemical prices directly impact the production cost of the final barrier products. Manufacturers often seek long-term supply agreements to mitigate price volatility and ensure a consistent supply of specialized polymer compounds necessary for high-specification products.

Midstream activities involve the primary manufacturing and assembly processes, where polymer compounds are extruded into strip form or sheet panels, followed by cutting, fabrication of mounting hardware (e.g., tracks and rails, motorized mechanisms), and final system assembly. Direct sales channels, where manufacturers sell directly to large end-users (e.g., major cold storage chains or large automotive plants), allow for greater control over installation and servicing. However, indirect channels, relying heavily on distributors, industrial suppliers, and specialized installation contractors, are more prevalent, particularly for standardized strip curtain products and smaller-scale installations across fragmented geographical regions. These intermediaries play a vital role in local stocking, site assessment, and providing immediate after-sales support and installation services to the final customers.

Downstream analysis focuses on the end-user deployment and the aftermarket services, which include maintenance, repair, and essential replacement of damaged or degraded strips and components. The selection of the distribution channel often depends on the complexity of the product; high-speed automated doors typically require highly specialized installers trained by the manufacturer, constituting a quasi-direct distribution model due to the technical integration required. In contrast, standard strip curtains are frequently sold through broad industrial distribution networks or e-commerce platforms. Service and maintenance contracts represent a significant, recurring revenue stream in the downstream segment, highlighting the importance of durable and easily repairable product designs to satisfy the needs of industrial facilities seeking long operational lifecycles.

Industrial Plastic Strip Curtains and Doors Market Potential Customers

The potential customer base for Industrial Plastic Strip Curtains and Doors is extremely diverse, spanning all major sectors of the modern economy that rely on controlled environments, efficient material handling, or strict regulatory compliance. The primary end-users, or buyers, are typically facility managers, operational directors, procurement specialists, and engineering teams within organizations that operate large industrial spaces. These buyers are primarily driven by the need for operational continuity, compliance with occupational safety and health standards, and a strong imperative to reduce energy overheads associated with heating, ventilation, and air conditioning (HVAC) systems in expansive facilities. Their purchasing decisions are often weighted by initial cost versus the long-term energy savings and durability of the barrier system.

The largest and most rapidly expanding segment of potential customers includes operators of cold storage facilities, refrigerated warehouses, and quick-service restaurant (QSR) chains. In these environments, maintaining precise temperature gradients is non-negotiable, positioning high-insulation PVC curtains and motorized freezer doors as critical infrastructure investments rather than mere auxiliary equipment. Furthermore, the massive global expansion of e-commerce has led to the proliferation of large-scale, automated logistics and distribution centers, which require numerous high-speed barrier solutions at loading docks and internal separation points to manage the high volume of traffic while preventing environmental contamination and reducing external air ingress.

Beyond logistics and temperature control, the manufacturing sector, encompassing automotive assembly, electronics production, and chemical processing, represents another significant segment. These customers utilize strip curtains to contain dust, noise, welding light, and airborne particles, protecting sensitive equipment and ensuring worker comfort and safety. Pharmaceutical and biomedical facilities constitute a high-value niche, where specialized cleanroom-grade, anti-microbial PVC curtains are mandatory for maintaining aseptic conditions and preventing cross-contamination in research, development, and packaging areas, adhering to rigorous Good Manufacturing Practices (GMP) standards enforced globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TMI LLC, Rite-Hite Corporation, A&P Doors, R-Plus Doors, Chase Doors, Albany Door Systems (Assa Abloy), Raynor Worldwide, Zoneworks, PLEXIGLAS, M&I Door Systems, Ningbo Hongbo Industrial Door, Dynaco Door, Nergeco, EFAFLEX, Hormann Group, Schuco International KG, Premier Industrial Curtains, Curtron Products, Vidir Solutions, Flexon. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Plastic Strip Curtains and Doors Market Key Technology Landscape

The technological landscape of the Industrial Plastic Strip Curtains and Doors Market is characterized by material science advancements and increasing integration of automation and sensor technology, moving beyond basic PVC strips. Material innovation is paramount, focusing on developing highly durable, non-phthalate PVC compounds that meet increasing environmental safety regulations while offering enhanced resistance to temperature extremes, chemical exposure, and abrasion. Specialized materials such as reinforced polyester mesh and composite fabrics are increasingly used in high-speed roll-up doors to provide superior wind load resistance and thermal insulation without compromising opening velocity. This material development aims to extend product lifecycles, reduce maintenance frequency, and improve overall energy performance in demanding industrial settings.

A major area of technological focus is the development of advanced operating mechanisms and control systems for high-speed flexible doors. Modern industrial doors utilize sophisticated variable frequency drive (VFD) motors and highly reliable encoder technology to achieve rapid opening and closing cycles (up to 100 inches per second). This speed minimizes the time the barrier is open, thus drastically limiting air exchange and heat loss, which is critical in freezer and cleanroom applications. Furthermore, the incorporation of advanced sensing technologies, including infrared motion detectors, ground-level loop detectors, and radar sensors, ensures optimal timing and prevents accidental impact, thereby enhancing worker safety and prolonging door integrity.

The most transformative technology trend involves the integration of connectivity and smart features, aligning industrial doors and high-performance curtains with the tenets of Industry 4.0. IoT-enabled doors can transmit real-time diagnostic data regarding cycle counts, motor health, and performance deviations to a central facility management dashboard. This capability supports sophisticated predictive maintenance schedules, reducing unplanned downtime and optimizing overall logistical flow within a facility. Moreover, these smart systems can communicate with other industrial equipment, such as automated guided vehicles (AGVs) or conveyor systems, to coordinate movement and further automate material handling processes seamlessly across different separated zones within the factory or warehouse environment.

Regional Highlights

- North America: This region holds a significant market share, characterized by high adoption rates of advanced, automated door systems, particularly in the e-commerce fulfillment and cold chain logistics sectors. Strict occupational safety and health regulations (OSHA) mandate the use of high-visibility, durable industrial barriers, driving demand for premium products. The market here is mature, focusing heavily on technology upgrades, energy efficiency compliance, and replacing older installations with high-speed, high-insulation flexible doors to reduce substantial energy costs.

- Europe: Europe is a key market propelled by stringent energy performance directives (EPDs) and a strong commitment to sustainable operations. This regulatory environment mandates the use of highly insulated and thermally efficient plastic curtains and doors, especially in the cold storage and pharmaceutical industries. Western European countries exhibit high demand for customizable and certified fire-resistant barrier solutions, while Eastern European nations are experiencing increasing demand driven by the modernization of their manufacturing bases and logistics infrastructure.

- Asia Pacific (APAC): The APAC region is poised for the highest growth rate globally, primarily due to unprecedented industrial expansion, robust manufacturing activity, and massive investment in building modern cold chain infrastructure, particularly in India, China, and Southeast Asia. The focus is currently on cost-effective yet compliant solutions, leading to massive consumption of standard PVC strip curtains. However, rapid foreign investment is simultaneously increasing the demand for high-end, automated doors in specialized sectors like electronics and high-tech automotive manufacturing.

- Latin America (LATAM): This region displays moderate growth, primarily concentrated in key markets like Brazil and Mexico, driven by foreign direct investment in food processing and automotive assembly. The market is highly price-sensitive, with a strong preference for durable, low-maintenance strip curtain solutions. Increasing urbanization and modernization efforts are slowly transitioning demand toward automated, mid-range flexible door options to improve energy efficiency in large-scale facilities.

- Middle East and Africa (MEA): The MEA market shows promising potential, spurred by infrastructural development, especially related to food security initiatives and growing pharmaceutical manufacturing in the Gulf Cooperation Council (GCC) countries. Extreme climatic conditions necessitate the use of heavy-duty, UV-stabilized, and high-insulation barriers. Investment in large-scale refrigerated storage and distribution centers across Saudi Arabia and the UAE is a primary driver of high-specification industrial door purchases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Plastic Strip Curtains and Doors Market.- TMI LLC

- Rite-Hite Corporation

- A&P Doors

- R-Plus Doors

- Chase Doors

- Albany Door Systems (Assa Abloy)

- Raynor Worldwide

- Zoneworks

- PLEXIGLAS (Evonik)

- M&I Door Systems

- Ningbo Hongbo Industrial Door

- Dynaco Door

- Nergeco

- EFAFLEX

- Hormann Group

- Schuco International KG

- Premier Industrial Curtains

- Curtron Products

- Vidir Solutions

- Flexon

- Rytec Corporation

- Perma-Tech Inc.

Frequently Asked Questions

Analyze common user questions about the Industrial Plastic Strip Curtains and Doors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for high-speed flexible doors over standard strip curtains?

The increasing need for enhanced energy efficiency and high operational throughput is the primary driver. High-speed flexible doors minimize the exposure time between two environments, drastically reducing air exchange, contamination risk, and energy loss, which provides a fast return on investment, particularly in freezer and logistics applications with high traffic volumes.

Which end-use application segment currently offers the highest growth potential for industrial plastic barriers?

The Cold Storage and Refrigeration segment presents the highest growth potential. The expansion of global cold chain logistics, stringent requirements for product integrity in food and pharmaceuticals, and the high cost of energy to maintain low temperatures mandate continuous investment in specialized, insulated low-temperature PVC curtains and high-speed thermal doors.

How do regulatory standards in North America and Europe influence product specifications?

Regulatory standards strongly influence material and performance specifications. North American regulations emphasize safety features (e.g., impact resistance, visibility) while European standards heavily mandate thermal performance, requiring superior insulation properties and documented energy savings credentials, pushing manufacturers toward advanced, certified materials and automated systems.

What are the key technological advancements being incorporated into modern industrial curtains and doors?

Key technological advancements include the use of Variable Frequency Drive (VFD) motors for ultra-high speed operation, integrated IoT sensors for real-time monitoring and predictive maintenance reporting, and specialized polymer formulations (e.g., non-phthalate and anti-microbial PVC) to meet high hygiene and safety compliance standards.

What are the main drawbacks associated with using standard PVC strip curtains?

The primary drawbacks include material degradation over time due to UV exposure or chemical cleaning, resulting in clouding and brittleness. Furthermore, standard strip curtains require manual cleaning and maintenance, and while cost-effective, they are less energy efficient than high-speed doors due to the constant minor air seepage between overlapping strips.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager