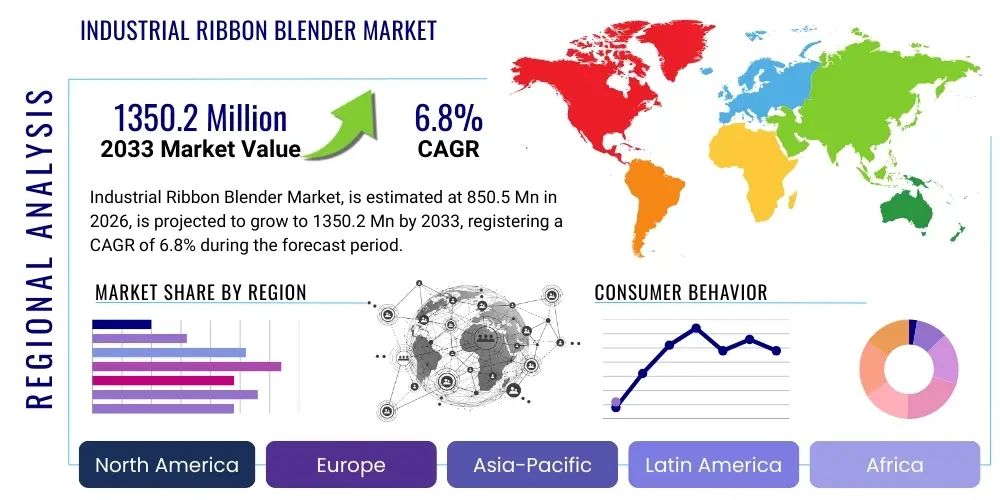

Industrial Ribbon Blender Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440722 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Industrial Ribbon Blender Market Size

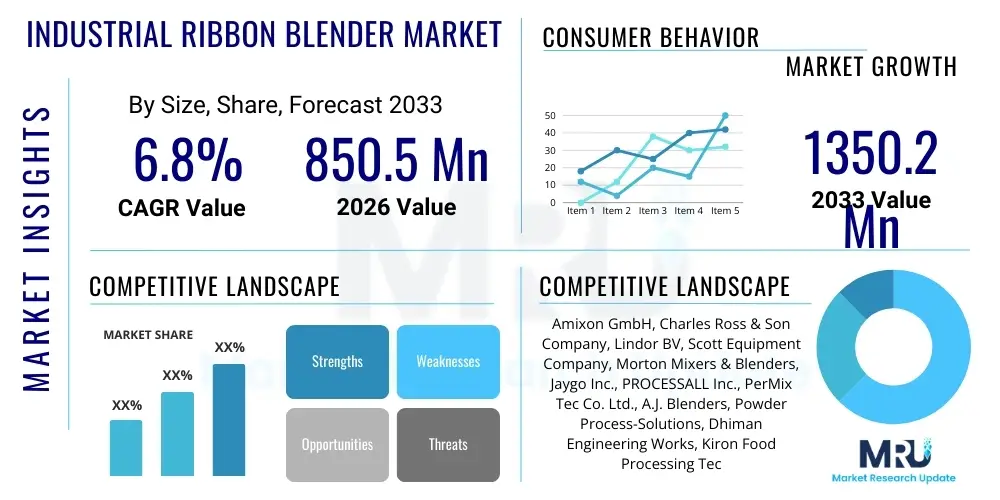

The Industrial Ribbon Blender Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 850.5 Million in 2026 and is projected to reach USD 1350.2 Million by the end of the forecast period in 2033.

Industrial Ribbon Blender Market introduction

The industrial ribbon blender market is characterized by robust demand for efficient, high-capacity mixing solutions across various processing industries. Ribbon blenders, distinguished by their U-shaped trough and a rotating agitator comprised of inner and outer helical ribbons, are engineered to achieve homogeneous blending of dry powders, granules, pastes, and slurries. This mechanical mixing ensures that materials are moved in opposing directions, creating a highly effective convective and shear mixing action, making them indispensable in applications requiring precise blend uniformity and consistent product quality across diverse industrial applications.

Major applications for industrial ribbon blenders span a broad spectrum of sectors, including food and beverage processing, pharmaceuticals, chemicals, plastics, minerals, and cosmetics. In the food industry, they are crucial for mixing spices, flours, nutritional supplements, and dry beverage mixes, where hygienic design and thorough blending are paramount. Pharmaceutical manufacturers rely on them for blending active pharmaceutical ingredients (APIs) with excipients, ensuring consistent drug dosage and adherence to strict regulatory standards. Chemical plants utilize them for mixing fertilizers, pigments, and detergents, while plastics processors use them for compounding resins and additives, often requiring robust construction for abrasive materials. Their inherent versatility allows for customization to handle a wide array of material properties, including those that are abrasive, corrosive, or heat-sensitive, ensuring optimal performance for specific processing needs.

The primary benefits driving their adoption include high blending efficiency, relatively low energy consumption compared to other mixing technologies, ease of cleaning and maintenance, and adaptability to a wide range of materials and batch sizes, from laboratory scale to high-volume industrial production. These blenders are pivotal in enhancing productivity, ensuring superior product quality, and reducing operational costs for manufacturers by minimizing blend times and rework. Key driving factors for market growth include the expanding global food processing industry fueled by changing dietary patterns, increasing demand for pharmaceutical products due to an aging population and advancements in healthcare, rapid industrialization and infrastructural development in emerging economies, and the continuous need for advanced material processing equipment that offers improved reliability, throughput, and automation capabilities. The growing focus on process optimization and the integration of smart manufacturing technologies further underpins the market's positive trajectory and future growth prospects.

Industrial Ribbon Blender Market Executive Summary

The industrial ribbon blender market is experiencing dynamic business trends, marked by a strong emphasis on automation, customization, and energy efficiency to meet evolving industry demands. Manufacturers are increasingly integrating advanced control systems, IoT sensors, and Artificial Intelligence (AI) capabilities into ribbon blenders. These integrations facilitate real-time process monitoring, predictive maintenance, and optimized blending cycles, which collectively lead to reduced downtime, enhanced operational performance, and greater precision in product formulation. Furthermore, there is a growing demand for highly customized solutions tailored to specific industrial requirements, such as specialized materials of construction (e.g., specific stainless steel grades, exotic alloys for highly corrosive environments), unique mixing agitator designs for particular product viscosities, and advanced dust containment or vacuum systems. This reflects a significant shift towards more application-specific engineering and integrated processing solutions that can handle diverse and complex material characteristics while maintaining regulatory compliance.

Regional trends indicate robust growth in the Asia Pacific market, which is propelled by rapid industrialization, expanding manufacturing sectors, and increasing investments in food processing, pharmaceutical production, and chemical industries, particularly in economically booming countries like China, India, and various Southeast Asian nations. This region benefits from a large consumer base and significant government support for manufacturing initiatives. North America and Europe continue to be significant and mature markets, driven by stringent quality control regulations, the widespread adoption of advanced manufacturing technologies, and a strong emphasis on process optimization, energy efficiency, and automation to maintain competitive advantages. Latin America and the Middle East & Africa regions are also showing promising growth, fueled by developing industrial infrastructure, increasing foreign direct investment, and rising demand for processed goods. These emerging regions are increasingly becoming attractive investment destinations for global manufacturers seeking to expand their market reach and capitalize on nascent industrialization trends and infrastructure development projects.

Segment trends within the industrial ribbon blender market highlight significant developments and shifts in demand patterns. By material of construction, stainless steel variants, particularly SS304 and SS316L, continue to dominate due to their superior corrosion resistance, hygienic properties, and suitability for industries like food and pharmaceuticals. However, there is a niche but growing demand for blenders made from specialized alloys designed for highly corrosive, abrasive, or high-temperature applications. In terms of operating principle, batch blenders currently hold a larger market share, serving a wide range of industries with discrete production runs, but continuous ribbon blenders are rapidly gaining traction in high-volume production environments that require uninterrupted processing and maximized throughput. Application-wise, the food and beverage sector remains the largest consumer, driven by ever-increasing demand for processed and convenience foods, with pharmaceuticals and chemicals showing consistent and significant demand due to regulatory requirements and complex formulations. The market is also witnessing an increase in demand for ribbon blenders equipped with advanced safety features, ergonomic designs, and those designed for easy integration into existing production lines, reflecting a broader industry trend towards safer, more efficient, and highly integrated manufacturing systems.

AI Impact Analysis on Industrial Ribbon Blender Market

Common user questions regarding AI's impact on industrial ribbon blenders primarily revolve around how AI can enhance blending accuracy, optimize energy consumption, predict maintenance needs, and improve overall operational efficiency. Users are intensely interested in understanding the practical, tangible applications of AI in real-time process control, precise ingredient dosing, and comprehensive quality assurance. There's also significant curiosity about how AI can facilitate better material flow analysis, mitigate human error through intelligent automation, and integrate seamlessly with existing production line automation systems for holistic process management. Concerns often include the initial capital cost of AI implementation, the perceived complexity of data analysis and model training, and the crucial need for skilled personnel to manage and troubleshoot these advanced systems. Overall, the sentiment within the industry is one of cautious optimism, with a strong desire for demonstrable benefits in terms of significant cost savings, increased throughput, and consistently superior product quality. The overarching expectation is that AI will fundamentally transform ribbon blenders into intelligent, self-optimizing machines capable of adapting dynamically to varying material properties, environmental conditions, and production demands with minimal human intervention, leading to a new era of smart blending technology.

- Enhanced blending uniformity and consistency through real-time sensor data analysis and adaptive control algorithms, leading to superior product quality.

- Predictive maintenance schedules generated by AI models analyzing operational data, significantly reducing unplanned downtime and optimizing maintenance costs.

- Optimized energy consumption via AI-driven motor control and dynamic blending cycle adjustments based on material properties and desired outcomes.

- Automated fault detection and diagnostics, improving troubleshooting efficiency, minimizing production interruptions, and enhancing overall system reliability.

- Intelligent recipe management and automatic adjustment of blending parameters, ensuring consistent product quality across multiple batches and reducing human error.

- Seamless integration with broader Industrial Internet of Things (IIoT) ecosystems for comprehensive data exchange, process synchronization, and factory-wide optimization.

- Improved material traceability, inventory management, and supply chain visibility through AI-powered data analytics and advanced tracking systems.

- Enhanced operator safety through AI-monitored operational parameters, anomaly detection, and automated shutdown protocols in critical situations.

- Optimized material flow analysis and identification of potential bottlenecks within the blending process, leading to improved throughput and efficiency.

DRO & Impact Forces Of Industrial Ribbon Blender Market

The industrial ribbon blender market is propelled by several robust drivers, primarily the escalating global demand for processed food and beverage products, which necessitates highly efficient, hygienic, and scalable blending solutions. The rapid expansion of the pharmaceutical industry, driven by an aging global population, increasing prevalence of chronic diseases, and rising healthcare expenditure, also fuels consistent demand for precise blending equipment essential for drug manufacturing and formulation, adhering to stringent quality and safety standards. Furthermore, accelerated industrialization and infrastructural development in emerging economies are creating new and substantial opportunities for manufacturers of chemicals, plastics, and construction materials, all of which rely heavily on efficient and homogeneous mixing processes for their diverse product portfolios. Continuous advancements in material science and processing technologies, leading to the development of new product formulations and complex material blends, continually drive the need for adaptable and high-performance blenders capable of handling diverse and challenging material characteristics.

Despite these significant drivers, several restraints challenge the sustained growth of the industrial ribbon blender market. The substantial capital investment required for purchasing, installing, and commissioning advanced industrial ribbon blenders can deter small and medium-sized enterprises (SMEs) with limited budgets, forcing them to consider less efficient or smaller-scale alternatives. The inherent complexity of maintaining and operating sophisticated blending systems, coupled with a persistent shortage of skilled labor proficient in automation and advanced machinery, poses significant operational hurdles for many manufacturers. Intense competition from alternative mixing technologies, such as paddle blenders, conical blenders, fluid bed mixers, and high-shear mixers, which may offer distinct advantages for specific applications or material types, can also limit market expansion and adoption rates for traditional ribbon blenders. Furthermore, increasingly stringent regulatory compliance, particularly in highly scrutinized industries like pharmaceuticals and food processing, concerning hygiene, safety, material contact, and validation, necessitates costly design modifications, specialized materials, and rigorous certification processes, adding substantially to the overall cost and complexity for manufacturers.

Opportunities for significant market growth primarily lie in technological innovations aimed at improving blending efficiency, reducing energy consumption, and incorporating smart manufacturing features like the Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) for enhanced automation, real-time monitoring, and predictive analytics. The increasing demand for highly customized blending solutions, specifically tailored to unique material properties, specific production scales, and distinct industry requirements, presents a lucrative avenue for manufacturers to differentiate their offerings and capture niche markets. Expanding into untapped or rapidly developing markets in emerging regions, where industrialization is accelerating and demand for processed goods is surging, offers substantial long-term growth potential. Furthermore, a growing focus on sustainability and eco-friendly designs, including blenders with reduced environmental impact, improved energy efficiency, and enhanced waste management capabilities, could attract environmentally conscious consumers and enterprises, thereby creating a crucial competitive advantage. Strategic partnerships and deep collaborations with end-user industries to co-develop application-specific blenders and integrated processing lines will also be crucial for unlocking new market segments and ensuring long-term market relevance and growth.

Segmentation Analysis

The Industrial Ribbon Blender Market is comprehensively segmented across various critical parameters to provide a granular understanding of its structure, dynamics, and growth potential. These segmentations typically include the material of construction, design type, operating principle, capacity range, and end-use industry. Analyzing these distinct segments helps market stakeholders identify key growth areas, understand competitive landscapes, and tailor their product development, marketing, and sales strategies to specific market niches. Each segment reflects unique operational requirements, material handling challenges, and often stringent regulatory considerations, thereby directly influencing product specifications, distribution channels, and pricing strategies within the market. A detailed understanding of the interplay between these segments is absolutely vital for accurate market forecasting, strategic planning, and identifying unmet customer needs for targeted innovation.

- By Material of Construction: This segment is critical for determining the blender's suitability for various materials and environments.

- Stainless Steel (SS304, SS316L, SS321): Dominant due to corrosion resistance, hygiene, and durability, widely used in food, pharma, and chemical sectors.

- Carbon Steel: Economical for non-corrosive and non-sanitary applications, typically in heavy industries like building materials or general chemicals.

- Specialty Alloys (e.g., Hastelloy, Inconel): Used for highly corrosive, abrasive, or high-temperature applications where standard stainless steel is insufficient.

- By Design Type: Variations in design cater to specific mixing requirements and operational needs.

- Standard Ribbon Blenders: Most common configuration, versatile for a wide range of dry and semi-dry materials.

- Paddle Blenders: Often grouped with ribbon blenders, ideal for fragile materials or when higher shear is desired, reducing product degradation.

- Vacuum Ribbon Blenders: Designed for deaeration, drying, or solvent recovery processes, operating under negative pressure.

- Jacketed Ribbon Blenders: Feature a jacket for heating or cooling the product during mixing, crucial for temperature-sensitive processes.

- Sanitary Ribbon Blenders: Engineered for easy cleaning, minimal bacterial traps, and high hygiene standards, essential for food and pharmaceutical industries.

- Heavy-Duty Ribbon Blenders: Robustly constructed for abrasive or high-density materials, common in minerals and heavy chemical applications.

- By Operating Principle: Distinguishes between discrete or continuous production methods.

- Batch Ribbon Blenders: Process materials in discrete batches, offering flexibility for varied recipes and smaller production runs.

- Continuous Ribbon Blenders: Designed for uninterrupted, high-volume production, ideal for consistent output and large-scale operations.

- By Capacity Range: Categorizes blenders based on their volume handling capabilities.

- Small (Under 500 Liters): Laboratory scale, pilot plants, or small-batch production for specialty chemicals or research.

- Medium (500-2000 Liters): Versatile for a wide range of industrial applications, balancing efficiency and production volume.

- Large (Over 2000 Liters): High-volume industrial production, typically in large-scale food, chemical, or building materials facilities.

- By End-Use Industry: Identifies the primary sectors utilizing ribbon blenders, highlighting specific industry needs.

- Food & Beverage: Mixing spices, flours, bakery mixes, nutritional supplements, dairy powders, and confectioneries.

- Pharmaceuticals: Blending active pharmaceutical ingredients (APIs), excipients, and granulating powders for tablets and capsules.

- Chemicals & Fertilizers: Producing pigments, detergents, polymers, pesticides, and various chemical compounds.

- Plastics & Rubber: Compounding plastics, masterbatches, rubber additives, and other polymer components.

- Minerals & Mining: Mixing ores, catalysts, aggregates, and various mineral powders for processing.

- Cosmetics & Personal Care: Blending powders, creams, lotions, and other cosmetic formulations.

- Building Materials: Producing dry mortar mixes, cement additives, specialty plasters, and construction chemicals.

- Others (e.g., Agriculture, Waste Treatment): Includes applications in animal feed production, bio-solids processing, and other niche industrial uses.

Value Chain Analysis For Industrial Ribbon Blender Market

The value chain for the industrial ribbon blender market begins with a thorough upstream analysis, encompassing the critical sourcing of raw materials and essential components. This initial stage involves securing various grades of stainless steel (such as SS304, SS316L for hygienic applications, or SS321 for high-temperature resistance), carbon steel for general industrial uses, and specialized alloys (e.g., Hastelloy, Inconel) for highly corrosive or abrasive environments. Beyond the primary metals, key components like high-performance motors, robust gearboxes, precision bearings, advanced sealing mechanisms, and sophisticated control systems (PLCs, HMIs) are procured from specialized suppliers. The quality, availability, and cost-effectiveness of these raw materials and components directly and significantly impact the overall manufacturing cost, the durability, the operational performance, and the final market price of the industrial ribbon blender. Establishing strategic, long-term relationships with reliable, high-quality suppliers is paramount for ensuring consistent material quality, managing supply chain risks effectively, and maintaining competitive pricing, especially for specialized alloys or custom-engineered parts.

Moving downstream along the value chain, the subsequent stage meticulously encompasses the core manufacturing process itself. This phase involves intricate design and engineering utilizing advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to ensure optimal blending performance, structural integrity, and adherence to specific industry standards. It proceeds through precision metal fabrication, expert welding, meticulous assembly of components, specialized surface finishing (such as mirror polishing for sanitary applications in food and pharma), rigorous quality control checks at every stage, and comprehensive factory acceptance testing. After the manufacturing and quality assurance phases are complete, the finished industrial ribbon blenders are strategically transported to their designated distribution channels, which can be broadly categorized into direct and indirect methods. Direct channels typically involve manufacturers selling and delivering blenders directly to end-users. This approach is often preferred for large-scale, highly customized projects or for clients with whom manufacturers have established long-standing strategic relationships, allowing for direct communication, tailored support, and specialized service contracts, ensuring a precise fit for complex industrial needs.

Indirect distribution channels, on the other hand, involve leveraging a broad network of specialized distributors, local agents, and experienced system integrators who market and sell industrial ribbon blenders to a wider, more diverse customer base across various geographical regions. These intermediaries often play a crucial role in market penetration, particularly in developing or niche markets, by providing localized sales support, essential technical assistance, professional installation services, and critical after-sales maintenance and spare parts supply. They also act as important conduits for market feedback, informing manufacturers about evolving customer requirements and regional preferences. Both direct and indirect channels are significantly complemented by extensive after-sales services, which include detailed installation guidance, seamless commissioning, comprehensive operator training, preventative maintenance contracts, readily available spare parts supply, and responsive technical support. This robust service component is absolutely critical for ensuring high levels of customer satisfaction, fostering long-term client relationships, and guaranteeing the optimal performance and longevity of industrial ribbon blenders throughout their entire operational lifespan, thereby contributing significantly to the overall value proposition and market reputation of the product.

Industrial Ribbon Blender Market Potential Customers

Potential customers for industrial ribbon blenders are diverse and span across a multitude of manufacturing sectors, primarily driven by the universal and fundamental need for efficient, consistent, and homogeneous mixing of various powdered, granular, or semi-solid materials. In the critical food and beverage industry, key buyers include a wide range of manufacturers involved in producing bakery mixes, essential spices, gourmet coffee blends, specialized nutritional powders, dairy products (like powdered milk or whey), processed meats, and confectionery items, where consistent texture, uniform ingredient distribution, and strict hygiene are paramount for ensuring superior product quality and consumer satisfaction. These companies actively seek blenders that not only meet stringent hygienic design standards but also offer exceptional ease of cleaning, are built with food-grade materials, and can efficiently handle a wide spectrum of dry and semi-dry ingredients, thus ensuring the utmost safety and integrity of their food products.

The pharmaceutical sector represents another extremely critical and demanding customer base, with companies extensively involved in the precision production of tablets, capsules, ointments, creams, and veterinary medicines. These customers require highly precise, often sanitary, and validated ribbon blenders capable of achieving uniform blending of active pharmaceutical ingredients (APIs) with various excipients, all while rigorously adhering to Good Manufacturing Practices (GMP) and other stringent international regulatory requirements. Similarly, the robust chemical industry constitutes a substantial segment of potential buyers, including manufacturers of high-performance pigments, industrial detergents, agricultural fertilizers, specialized adhesives, advanced polymers, and a wide array of specialty chemicals, where thorough and efficient mixing is absolutely essential for consistent product formulation, reliable reaction consistency, and achieving desired material properties. The inherent versatility of ribbon blenders allows them to effectively handle both delicate dry powders and highly viscous pastes, which are common challenges in these diverse and demanding applications.

Furthermore, the rapidly growing plastics and rubber industries extensively utilize industrial ribbon blenders for compounding various polymers, creating custom masterbatches, and incorporating a wide range of additives to achieve desired material characteristics, mechanical properties, and aesthetic finishes. Companies operating in the minerals and mining sector also employ them for blending diverse ores, specialized catalysts, aggregates, and various mineral powders for subsequent processing. The dynamic cosmetics and personal care industry relies heavily on ribbon blenders for mixing powders, creams, lotions, and other intricate cosmetic formulations, where homogeneity and gentle mixing are key. Lastly, building materials manufacturers, involved in producing diverse products such as dry mortar mixes, essential cement additives, specialized plasters, and various construction chemicals, also represent substantial end-users. Each of these diverse industry segments requires blenders that are specifically optimized for their unique material properties, preferred batch sizes, and demanding processing environments, emphatically underscoring the ongoing need for highly adaptable, durable, and high-performance blending solutions that can be customized to meet precise operational demands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850.5 Million |

| Market Forecast in 2033 | USD 1350.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amixon GmbH, Charles Ross & Son Company, Lindor BV, Scott Equipment Company, Morton Mixers & Blenders, Jaygo Inc., PROCESSALL Inc., PerMix Tec Co. Ltd., A.J. Blenders, Powder Process-Solutions, Dhiman Engineering Works, Kiron Food Processing Technologies, Continental Products Corporation, Mixing Solutions Ltd., Excel Pharma Technologies, Shree Bhagwati Engineering, Rathi Engineering Works, Satake USA Inc., PME Group, GEA Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Ribbon Blender Market Key Technology Landscape

The industrial ribbon blender market is continuously evolving with significant advancements in its technology landscape, primarily aimed at enhancing mixing efficiency, ensuring stringent hygiene, and providing unparalleled operational control. A primary technological focus is on precision engineering of the agitator and trough designs, optimizing the ribbon geometry, pitch, and precise clearances to achieve superior blend uniformity, minimize dead zones, and accelerate cycle times. This is particularly crucial for challenging materials with widely varying bulk densities, particle sizes, or flow characteristics. Furthermore, the integration of advanced sealing technologies, such as robust mechanical seals, specialized air purges, and sophisticated packing glands, is absolutely crucial to prevent cross-contamination, minimize product leakage, and significantly extend equipment lifespan, especially in highly sanitary and abrasive applications, ensuring rigorous compliance with stringent industry standards like FDA and GMP.

Automation and advanced control systems represent another pivotal and rapidly developing area within the technological landscape of industrial ribbon blenders. Modern ribbon blenders are increasingly equipped with sophisticated Programmable Logic Controllers (PLCs) and intuitive Human Machine Interfaces (HMIs) that allow for precise, real-time control over critical blending parameters such as agitator speed, mixing duration, and internal trough temperature. These advanced systems enable comprehensive recipe management, detailed data logging for traceability, and seamless integration with Supervisory Control and Data Acquisition (SCADA) systems, thereby facilitating fully automated batch processing and efficient remote operation and monitoring. The widespread incorporation of Variable Frequency Drives (VFDs) for motor control not only offers significant energy efficiency improvements by dynamically adjusting agitator speed according to material load and desired process outcomes but also provides essential soft start/stop capabilities, which effectively reduce mechanical stress on components and significantly extend the overall equipment lifespan.

Furthermore, the accelerating adoption of Industry 4.0 principles, including the Industrial Internet of Things (IIoT) and Artificial Intelligence (AI), is profoundly transforming the technological landscape of industrial ribbon blenders. IIoT sensors are strategically deployed throughout the blending system to monitor critical operational parameters such as temperature, pressure, motor current draw, vibration levels, and material moisture content in real-time, providing invaluable data for comprehensive performance analysis and predictive maintenance strategies. AI algorithms are designed to meticulously analyze this vast stream of data to anticipate potential mechanical failures, recommend optimal blending settings for diverse materials, and even dynamically self-adjust process parameters to maintain consistent product quality under varying conditions, thereby minimizing unplanned downtime and maximizing throughput. Additionally, continuous advancements in material science are leading to the development and use of specialized coatings, advanced surface treatments, and innovative construction materials that significantly enhance corrosion resistance, reduce material adhesion to internal surfaces, and dramatically simplify cleaning processes, further improving the overall performance, longevity, and operational efficiency of industrial ribbon blenders across all applications.

Regional Highlights

- North America: A highly mature and technologically advanced market characterized by stringent quality standards, high adoption rates of automation and smart manufacturing technologies, and significant, consistent demand from the robust food & beverage and pharmaceutical industries. Continuous innovation in smart blending solutions, custom engineering, and efficiency improvements remains a key strategic focus for manufacturers in this region.

- Europe: Driven by advanced manufacturing capabilities, a strong and growing emphasis on sustainability and energy efficiency, and highly developed pharmaceutical, chemical, and specialty food sectors. Countries such as Germany, the UK, France, and Italy are key contributors, focusing heavily on precision-engineered, energy-efficient designs, and strict adherence to evolving regulatory compliance standards like CE and ATEX.

- Asia Pacific (APAC): The fastest-growing regional market, fueled by rapid industrialization, the exponential expansion of the manufacturing base particularly in economic powerhouses like China and India, and increasing, substantial investments in food processing, pharmaceutical production, and infrastructure development across the region. Price competitiveness, rising demand for mid-range capacity blenders, and the need for adaptable, robust equipment are notable trends here.

- Latin America: An emerging market experiencing increasing industrial investments and expanding production capabilities, particularly within the food processing, agricultural chemicals, and basic materials sectors. Growth is primarily driven by expanding local manufacturing and production capacities, increasing consumer demand for processed goods, and a rising need for cost-effective yet reliable blending solutions to support industrial expansion.

- Middle East & Africa (MEA): A developing market witnessing significant growth in construction, chemicals, and nascent food processing industries, propelled by diversification efforts away from oil economies and substantial investment in new industrial facilities and infrastructure projects. Opportunities are largely driven by the need for robust, durable, and adaptable equipment capable of performing reliably in challenging environmental conditions, often with a focus on ease of maintenance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Ribbon Blender Market.- Amixon GmbH

- Charles Ross & Son Company

- Lindor BV

- Scott Equipment Company

- Morton Mixers & Blenders

- Jaygo Inc.

- PROCESSALL Inc.

- PerMix Tec Co. Ltd.

- A.J. Blenders

- Powder Process-Solutions

- Dhiman Engineering Works

- Kiron Food Processing Technologies

- Continental Products Corporation

- Mixing Solutions Ltd.

- Excel Pharma Technologies

- Shree Bhagwati Engineering

- Rathi Engineering Works

- Satake USA Inc.

- PME Group

- GEA Group

Frequently Asked Questions

What is an industrial ribbon blender and how does it work?

An industrial ribbon blender is a versatile mixing machine consisting of a U-shaped trough and a central agitator with inner and outer helical ribbons. The ribbons rotate to move materials in opposing directions, creating a highly efficient convective and shear mixing action that homogenizes dry powders, granules, pastes, and slurries across various industries like food, pharma, and chemicals, ensuring uniform blends for consistent product quality.

Which industries primarily use industrial ribbon blenders?

Industrial ribbon blenders are widely utilized across a broad spectrum of industries, including food and beverage (for spices, flour, mixes, supplements), pharmaceuticals (for API and excipient blending), chemicals (for pigments, fertilizers, polymers), plastics (for compounding resins), minerals, cosmetics, and building materials due to their ability to achieve uniform blends of diverse materials efficiently and hygienically.

What are the key benefits of using a ribbon blender for industrial mixing?

Key benefits include high blending efficiency for achieving homogeneous mixtures rapidly, versatility in handling various material types and consistencies, relatively low energy consumption compared to other mixers, ease of cleaning and maintenance, and suitability for both batch and continuous processing. These attributes collectively lead to improved product quality, increased throughput, and significant operational cost savings for manufacturers.

How is AI impacting the industrial ribbon blender market and its operations?

AI is transforming the market by enabling enhanced blending uniformity through real-time sensor data analysis and adaptive control, predictive maintenance for reduced downtime, optimized energy consumption, automated fault detection, and intelligent recipe management. This integration leads to more efficient, reliable, and self-optimizing blending operations, addressing key user concerns about performance, cost, and overall process consistency, pushing towards Industry 4.0 standards.

What factors are primarily driving the growth of the industrial ribbon blender market?

Market growth is primarily driven by the increasing global demand for processed food and pharmaceutical products due to population growth and changing lifestyles, rapid industrialization and infrastructural development in emerging economies, the continuous need for advanced material processing equipment offering improved efficiency, and a growing emphasis on automation and process optimization across diverse manufacturing sectors seeking to enhance productivity and reduce operational costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager