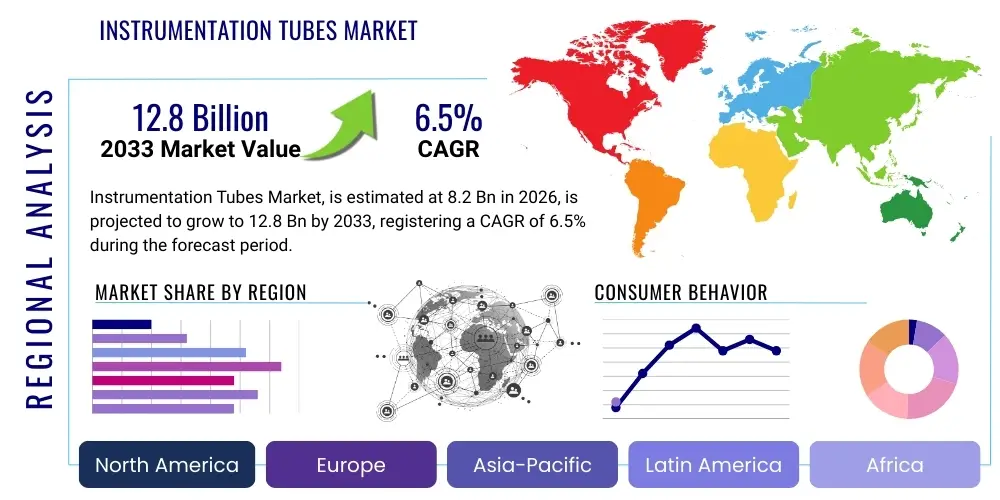

Instrumentation Tubes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440839 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Instrumentation Tubes Market Size

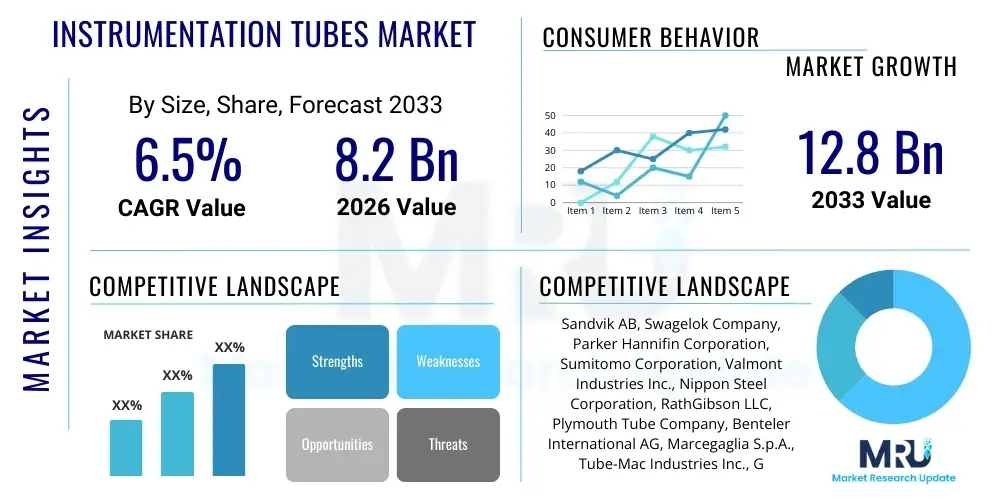

The Instrumentation Tubes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 8.2 Billion in 2026 and is projected to reach USD 12.8 Billion by the end of the forecast period in 2033.

Instrumentation Tubes Market introduction

The Instrumentation Tubes Market encompasses a critical segment within industrial infrastructure, providing specialized tubing solutions essential for precise measurement, control, and analytical processes across diverse sectors. These tubes are meticulously engineered to transmit fluids or gases under varying conditions of pressure, temperature, and corrosive environments, ensuring the integrity and accuracy of sophisticated instrumentation systems. The market is defined by the demand for high-performance tubing that can withstand the rigorous requirements of industrial applications, supporting complex operational parameters and contributing significantly to process efficiency and safety.

Instrumentation tubes are typically manufactured from high-grade materials such as stainless steel (304, 316, 316L), nickel alloys (Inconel, Monel, Hastelloy), and duplex alloys, chosen for their superior corrosion resistance, mechanical strength, and thermal stability. They are available in various forms, including seamless and welded configurations, and are selected based on the specific application's pressure ratings, chemical compatibility, and environmental factors. Key benefits include enhanced system reliability, reduced maintenance requirements, and precise signal transmission, which are paramount for critical industrial operations.

Major applications span process control systems, hydraulic and pneumatic systems, analytical instrumentation, and specialized industrial equipment where accurate sensing and transfer of media are non-negotiable. The market's growth is predominantly driven by increasing industrial automation, stringent regulatory standards for safety and environmental protection, and the expansion of key end-use industries such as oil and gas, chemical and petrochemical, power generation, and pharmaceuticals. The inherent need for dependable and precise fluid handling solutions underpins the sustained demand for these specialized tubes, making them indispensable components in modern industrial landscapes.

Instrumentation Tubes Market Executive Summary

The global Instrumentation Tubes Market is characterized by robust growth, propelled by the relentless pursuit of operational efficiency, safety, and precision across industrial sectors. Current business trends indicate a significant shift towards smart manufacturing and Industry 4.0 paradigms, integrating advanced instrumentation with digital control systems, thereby escalating the demand for high-integrity, reliable tubing solutions. The market is witnessing increasing investment in research and development to produce tubes capable of operating under extreme conditions, including ultra-high pressures and temperatures, and in highly corrosive environments. Customization and material innovation, particularly in superalloys and specialized stainless steels, are key drivers for market differentiation, addressing unique industry-specific challenges and compliance requirements.

Regionally, the market exhibits varied growth dynamics. Asia Pacific stands out as a primary growth engine, fueled by rapid industrialization, massive infrastructure projects, and expanding manufacturing bases in countries like China, India, and Southeast Asian nations. North America and Europe, while mature, maintain a strong demand for advanced instrumentation tubes, driven by technological upgrades, strict environmental regulations, and significant investments in high-tech industries such such as pharmaceuticals, biotechnology, and semiconductor manufacturing. The Middle East and Africa continue to present lucrative opportunities, largely due to ongoing expansion and modernization projects within the oil and gas and petrochemical industries, necessitating robust and durable instrumentation infrastructure.

Segmentation trends highlight a pronounced increase in demand for nickel-based alloys and duplex steels, preferred for their superior performance in harsh operating conditions compared to traditional stainless steel. Furthermore, the market for small-diameter, precision-engineered tubes is experiencing accelerated growth, primarily driven by the miniaturization of analytical instruments and the increasing complexity of process control systems. The energy sector, including both conventional and renewable energy projects, remains a dominant end-user, with significant uptake also observed in the pharmaceutical and food and beverage industries, where hygienic and non-contaminating tubing solutions are paramount. These trends collectively underscore a dynamic market landscape focused on performance, durability, and technological advancement.

AI Impact Analysis on Instrumentation Tubes Market

The integration of Artificial Intelligence (AI) is poised to significantly transform various facets of the Instrumentation Tubes Market, addressing key user concerns and expectations related to operational efficiency, product quality, and predictive maintenance. Common user questions revolve around how AI can optimize manufacturing processes for tubes, enhance the accuracy and reliability of instrumentation systems, and improve the lifecycle management of tubing infrastructure. Users are keen to understand AI's role in predictive analytics for equipment failure, real-time quality control during production, and intelligent design for specific application environments. The overarching theme is leveraging AI to achieve higher precision, reduce downtime, and foster more sustainable and cost-effective operations within critical industrial settings where instrumentation tubes are deployed.

AI's influence extends from the initial design phase to the end-of-life management of instrumentation tubes. In manufacturing, AI-powered systems can analyze vast datasets from production lines, identifying anomalies, optimizing machine parameters for reduced waste, and ensuring consistent product quality. This leads to tubes with fewer defects and improved performance characteristics, directly addressing concerns about product reliability. For operational deployment, AI algorithms can process sensor data from installed instrumentation, predicting potential failures in tubing systems due to corrosion, fatigue, or stress, thereby enabling proactive maintenance rather than reactive repairs, significantly reducing costly downtime and enhancing safety protocols.

Furthermore, AI is instrumental in advancing material science and accelerating the development of next-generation instrumentation tubes. Machine learning models can simulate the performance of various alloys and coatings under extreme conditions, drastically shortening the R&D cycle for materials with superior corrosion resistance or high-temperature capabilities. Supply chain optimization, driven by AI, can also ensure the timely availability of raw materials and finished products, mitigating supply disruptions. These capabilities collectively address the core expectations of users for more reliable, efficient, and intelligently managed instrumentation tube solutions that support the evolving demands of modern industrial processes.

- Enhanced predictive maintenance of tubing systems, minimizing unexpected failures and downtime.

- Optimized manufacturing processes leading to improved tube quality, reduced material waste, and increased production efficiency.

- Real-time quality control and defect detection during tube production through machine vision and AI analytics.

- Accelerated material development and selection for specialized alloys based on performance predictions and simulated stress tests.

- Improved supply chain management for raw materials and finished tubes, ensuring availability and reducing lead times.

- Advanced data analysis for better design and customization of instrumentation tubes for specific industrial applications.

- Integration with smart monitoring systems for continuous performance assessment and anomaly detection in operational environments.

DRO & Impact Forces Of Instrumentation Tubes Market

The Instrumentation Tubes Market is significantly influenced by a confluence of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating pace of industrialization and infrastructure development globally, particularly in emerging economies. As industries expand and modernize, the demand for precise and reliable measurement and control systems escalates, directly translating into increased consumption of instrumentation tubes. Furthermore, the relentless push towards automation across manufacturing, process industries, and energy sectors necessitates advanced instrumentation, which in turn fuels the market. Stringent regulatory standards for safety, environmental protection, and operational integrity, especially in critical sectors like oil and gas, chemical processing, and power generation, compel industries to adopt high-quality, certified instrumentation tubes, acting as a crucial market driver.

However, the market also faces notable restraints. Volatility in raw material prices, particularly for metals like nickel, chromium, and molybdenum, which are key components of high-performance alloys, poses a significant challenge. These fluctuations can impact manufacturing costs and, consequently, the final product prices, affecting market stability and profitability. Additionally, the high initial investment required for specialized manufacturing equipment and the need for skilled labor to produce and install complex instrumentation tubing systems can deter new entrants and limit expansion. The availability of alternative technologies, such as fiber optics for signal transmission in some applications, while currently limited, represents a potential long-term restraint, although instrumentation tubes remain indispensable for fluid and gas transport.

Despite these restraints, the market is rich with opportunities. The burgeoning demand from emerging economies, driven by massive investments in new industrial capacities and infrastructure, presents significant growth avenues. The increasing trend towards customization and specialized solutions, where tubes are designed to meet unique operational demands for specific pressures, temperatures, and corrosive media, offers premium market segments. Moreover, the integration of instrumentation tubes with smart sensors and IoT platforms for enhanced real-time monitoring and predictive maintenance opens new technological frontiers. The expansion of the renewable energy sector, including solar, wind, and hydrogen technologies, which require specialized tubing for various processes, also represents a burgeoning opportunity for market players to diversify their offerings and capitalize on sustainable industrial growth initiatives. These impact forces necessitate strategic planning and innovation from market participants to navigate challenges and leverage growth prospects effectively.

Segmentation Analysis

The Instrumentation Tubes Market is extensively segmented based on various critical parameters, providing a granular view of market dynamics and catering to diverse industrial requirements. These segmentations allow market participants to understand specific demand patterns, identify niche opportunities, and tailor their product offerings and strategic initiatives accordingly. The primary segmentation criteria typically include material type, outer diameter, application, and end-use industry, each reflecting distinct performance requirements and market influences. This detailed categorization helps in analyzing market trends, competitive landscapes, and future growth prospects across different product categories and consumer groups.

By material type, the market differentiates between standard and advanced alloys, reflecting the varying degrees of corrosion resistance, strength, and temperature tolerance required in different operating environments. Outer diameter segmentation addresses the precision and flow rate needs of specific instrumentation setups, from miniature analytical systems to large-scale process control lines. Application-based segmentation highlights the functional use of these tubes, whether for transmitting signals, controlling hydraulic pressures, or sampling analytical data. Finally, the end-use industry segment illustrates the diverse sectors that rely on instrumentation tubes, each with its unique operational challenges and regulatory frameworks.

Understanding these segments is crucial for manufacturers to innovate and develop products that precisely meet the demands of their target markets. For instance, the oil and gas sector demands highly robust and corrosion-resistant tubes, while the pharmaceutical industry requires ultra-pure and hygienic solutions. Analyzing these segments provides strategic insights into market penetration, product development, and geographic expansion, ensuring that investments are aligned with areas of highest growth and demand. The intricate interdependencies between these segments define the overall market structure and future trajectory.

- Material Type:

- Stainless Steel (e.g., 304, 316, 316L)

- Nickel Alloys (e.g., Inconel, Monel, Hastelloy)

- Duplex Alloys (e.g., Super Duplex, Lean Duplex)

- Copper Alloys

- Others (e.g., Titanium, Specialty Alloys)

- Outer Diameter:

- Up to 1/2 Inch

- 1/2 Inch to 1 Inch

- Above 1 Inch

- Application:

- Process Control Systems

- Hydraulic & Pneumatic Systems

- Analytical Instrumentation

- Medical Devices

- General Industrial Applications

- End-Use Industry:

- Oil & Gas

- Chemical & Petrochemical

- Power Generation (Thermal, Nuclear, Renewables)

- Pharmaceutical & Biotechnology

- Food & Beverage

- Semiconductor & Electronics

- Marine

- Aerospace & Defense

- Others (e.g., Automotive, Water Treatment)

Value Chain Analysis For Instrumentation Tubes Market

The value chain for the Instrumentation Tubes Market is a complex network involving several stages, starting from raw material extraction and culminating in the end-user application, with each stage adding value and expertise. The upstream segment primarily involves the extraction and processing of raw materials, such as nickel, chromium, iron ore, and molybdenum, which are crucial for producing high-grade stainless steels, nickel alloys, and duplex steels. Major steel mills and specialty alloy manufacturers form the backbone of this initial phase, supplying billets and coils to tube manufacturers. The quality and purity of these raw materials directly impact the final properties and performance of the instrumentation tubes, making strong relationships with reliable suppliers critical for tube manufacturers. Effective upstream management ensures consistent supply, controlled costs, and adherence to material specifications, which are vital for maintaining product quality and competitive pricing.

Midstream activities involve the actual manufacturing of the instrumentation tubes. This includes processes such as cold drawing, welding, annealing, and various finishing treatments to achieve precise dimensions, surface finishes, and mechanical properties. Tube manufacturers invest heavily in advanced machinery, quality control systems, and skilled labor to produce seamless or welded tubes that meet stringent industry standards and customer specifications. After manufacturing, the tubes move to the downstream segment, which includes distributors, fabricators, and system integrators. Distributors play a crucial role in inventory management, logistical support, and providing local access to a wide range of products for various end-users. Fabricators further process the tubes into specific components, assemblies, or custom lengths, often involving bending, flaring, and fitting installations, tailored to the unique requirements of a project or system.

Distribution channels for instrumentation tubes can be categorized as direct and indirect. Direct channels involve manufacturers selling directly to large original equipment manufacturers (OEMs) or major industrial projects, often for customized or high-volume orders. This approach allows for closer collaboration, technical support, and direct feedback from the end-user. Indirect channels, on the other hand, rely on a network of authorized distributors, wholesalers, and specialized suppliers who stock a comprehensive range of standard tubes and fittings. These indirect channels are particularly important for serving smaller clients, regional markets, and providing just-in-time delivery services. The choice of distribution channel often depends on the scale of the order, the complexity of the product, and the geographic reach required, with a mix of both direct and indirect strategies being common to maximize market penetration and customer service. The efficiency and effectiveness of these distribution networks are paramount in ensuring that products reach end-users reliably and cost-effectively, maintaining the integrity of the overall value chain.

Instrumentation Tubes Market Potential Customers

The potential customers for instrumentation tubes span a wide array of industrial sectors, each requiring precise, reliable, and durable tubing solutions for their critical operations. These end-users are primarily organizations that rely on sophisticated process control, measurement, and analytical systems where the accurate and safe conveyance of fluids and gases is paramount. The fundamental need for robust infrastructure to support automation, regulatory compliance, and operational efficiency drives the demand from these diverse industries, making instrumentation tubes an indispensable component in their operational framework.

Among the most significant end-users are companies within the oil and gas industry, including upstream exploration and production, midstream transportation and storage, and downstream refining and petrochemical processing. These sectors utilize instrumentation tubes extensively in offshore platforms, refineries, pipelines, and processing plants for pressure monitoring, chemical injection, and sampling systems, demanding high resistance to corrosion and extreme pressures. Similarly, the chemical and petrochemical industries are major consumers, employing these tubes for conveying corrosive chemicals, monitoring reaction processes, and ensuring precise material handling in their complex manufacturing environments, where material compatibility and inertness are critical factors.

Beyond these heavy industries, the power generation sector, encompassing thermal, nuclear, and renewable energy plants, also represents a substantial customer base, using instrumentation tubes for boiler controls, steam lines, cooling systems, and critical sensor connections. The pharmaceutical and biotechnology industries require ultra-high purity and hygienic instrumentation tubes for sterile processing, fluid transfer, and cleanroom applications, adhering to stringent health and safety regulations. Furthermore, the food and beverage industry, semiconductor manufacturing, and marine applications also demonstrate significant demand, each with unique requirements for material properties, surface finish, and operational performance, thereby illustrating the broad and diversified customer landscape for instrumentation tubes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.2 Billion |

| Market Forecast in 2033 | USD 12.8 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sandvik AB, Swagelok Company, Parker Hannifin Corporation, Sumitomo Corporation, Valmont Industries Inc., Nippon Steel Corporation, RathGibson LLC, Plymouth Tube Company, Benteler International AG, Marcegaglia S.p.A., Tube-Mac Industries Inc., Gemini Group, Fine Tubes Ltd (part of AMETEK), Marmon/Keystone LLC, Bristol Metals LLC, Tenaris S.A., TPCO Enterprise Inc., Columbus Stainless (part of Acerinox), AK Steel Corporation (part of Cleveland-Cliffs), ArcelorMittal |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Instrumentation Tubes Market Key Technology Landscape

The Instrumentation Tubes Market is heavily influenced by a dynamic and evolving technological landscape, driven by the continuous demand for higher performance, greater reliability, and enhanced durability in challenging industrial environments. Advanced manufacturing processes are at the forefront, enabling the production of tubes with tighter tolerances, superior surface finishes, and consistent mechanical properties. Technologies such as precision cold drawing and cold rolling are critical for producing seamless tubes with exact dimensional accuracy and enhanced strength, minimizing internal stresses and improving fatigue resistance, which are crucial for high-pressure applications. Similarly, sophisticated welding techniques, including orbital welding and laser welding, are employed for welded tubes, ensuring the integrity and corrosion resistance of the weld seam, which is paramount for critical fluid transport.

Material science innovation also plays a pivotal role, with ongoing research and development in new alloys and composite materials. The development of superalloys and specialized stainless steels, designed to withstand extreme temperatures, pressures, and highly corrosive media, continues to push the boundaries of performance. These advanced materials, often incorporating elements like nickel, chromium, molybdenum, and titanium, offer superior chemical compatibility and mechanical strength compared to conventional steels, enabling instrumentation tubes to perform reliably in increasingly harsh operating conditions. Furthermore, surface treatment technologies, such as passivation, electro-polishing, and specialized coatings, are deployed to enhance corrosion resistance, prevent contamination, and improve flow characteristics, particularly in applications requiring ultra-high purity like semiconductor and pharmaceutical manufacturing.

Beyond material and manufacturing advancements, the integration of advanced inspection and testing methodologies is fundamental to ensuring the quality and integrity of instrumentation tubes. Non-destructive testing (NDT) techniques, including eddy current testing, ultrasonic testing, and radiographic inspection, are routinely used to detect internal and external defects without compromising the tube structure. These technologies are crucial for meeting stringent industry standards and regulatory requirements, guaranteeing the safety and reliability of the tubes once installed. Furthermore, automation and digital control systems in the manufacturing process are becoming increasingly common, allowing for real-time monitoring, data analytics, and process optimization, ultimately leading to higher production efficiency, reduced waste, and consistently superior product quality. The synergy of these technological advancements ensures that instrumentation tubes continue to meet the evolving demands of modern industrial instrumentation.

Regional Highlights

The global Instrumentation Tubes Market exhibits distinct regional dynamics, influenced by varying industrialization rates, regulatory environments, and technological adoption across major geographical areas. Each region contributes uniquely to the market's overall growth and demand patterns, reflecting their specific economic development stages and industrial priorities. Understanding these regional nuances is crucial for market players to formulate effective strategies for market penetration, product distribution, and investment allocation.

North America is a mature yet significant market, characterized by strong demand from the oil and gas, petrochemical, and high-tech industries, including pharmaceuticals and semiconductor manufacturing. The region benefits from stringent safety and environmental regulations, which drive the adoption of high-quality, high-performance instrumentation tubes. Innovation in advanced materials and smart manufacturing practices also propels market growth, with a focus on upgrading existing infrastructure and incorporating advanced automation technologies. The presence of major market players and research institutions further strengthens its market position.

Europe represents another well-established market, driven by robust manufacturing sectors in Germany, France, and the UK, coupled with strict industry standards for quality and safety. The chemical, pharmaceutical, and power generation industries are key consumers, consistently demanding sophisticated and durable instrumentation tubes. The region is also a hub for technological innovation, with a growing emphasis on sustainable practices and advanced material development, which translates into a demand for environmentally compliant and energy-efficient tubing solutions.

Asia Pacific (APAC) stands out as the fastest-growing region, fueled by rapid industrialization, burgeoning infrastructure projects, and expanding manufacturing bases, particularly in China, India, Japan, and South Korea. Investments in chemical processing, power generation, and automotive industries significantly contribute to market expansion. The increasing adoption of automation and modern industrial practices, coupled with a growing focus on improving safety standards, is driving the demand for high-quality instrumentation tubes across diverse applications within the region.

Latin America shows steady growth, primarily driven by investments in the oil and gas sector, particularly in countries like Brazil and Mexico, as well as the mining industry. The region's market is influenced by efforts to modernize industrial infrastructure and enhance operational efficiency. While often reliant on imports, there's a growing trend towards local manufacturing and fabrication capabilities to meet regional demand and reduce lead times.

The Middle East and Africa (MEA) region is projected to experience substantial growth, largely attributed to extensive investments in oil and gas exploration, production, and refining projects, alongside significant infrastructure development initiatives. Countries like Saudi Arabia, UAE, and Qatar are major consumers, demanding robust and corrosion-resistant instrumentation tubes for their vast petrochemical and energy complexes. Economic diversification efforts in the region are also fostering growth in other industrial sectors, further boosting the demand for specialized tubing solutions.

- North America: Strong demand from oil & gas, petrochemical, pharmaceutical, and semiconductor industries; driven by stringent regulations and technological advancements.

- Europe: High demand from chemical, pharmaceutical, and power generation sectors; focus on high-quality, sustainable solutions and technological innovation.

- Asia Pacific (APAC): Rapid growth due to industrialization, infrastructure development, and expanding manufacturing in countries like China, India, and Southeast Asia.

- Latin America: Growth driven by oil & gas investments and mining sector modernization; increasing focus on improving industrial efficiency.

- Middle East and Africa (MEA): Significant growth from extensive oil & gas projects and infrastructure development; demand for robust, corrosion-resistant tubes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Instrumentation Tubes Market.- Sandvik AB

- Swagelok Company

- Parker Hannifin Corporation

- Sumitomo Corporation

- Valmont Industries Inc.

- Nippon Steel Corporation

- RathGibson LLC

- Plymouth Tube Company

- Benteler International AG

- Marcegaglia S.p.A.

- Tube-Mac Industries Inc.

- Gemini Group

- Fine Tubes Ltd (part of AMETEK)

- Marmon/Keystone LLC

- Bristol Metals LLC

- Tenaris S.A.

- TPCO Enterprise Inc.

- Columbus Stainless (part of Acerinox)

- AK Steel Corporation (part of Cleveland-Cliffs)

- ArcelorMittal

Frequently Asked Questions

What materials are most commonly used for instrumentation tubes and why?

Stainless steel, particularly grades 316 and 316L, along with various nickel alloys (e.g., Inconel, Monel, Hastelloy) and duplex alloys, are most commonly used due to their excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures inherent in industrial process environments.

What are the primary applications of instrumentation tubes?

Instrumentation tubes are primarily used in process control systems, hydraulic and pneumatic systems, analytical instrumentation, and general industrial applications across sectors like oil and gas, chemical and petrochemical, power generation, and pharmaceuticals for precise fluid and gas transmission.

How do instrumentation tubes differ from standard piping?

Instrumentation tubes are typically manufactured to much tighter dimensional tolerances, with superior surface finishes and material purity, to ensure precise flow rates, accurate pressure transmission, and minimal contamination, which are critical for sensitive measurement and control systems, unlike standard piping used for bulk fluid transport.

What key factors drive the growth of the Instrumentation Tubes Market?

The market growth is primarily driven by increasing industrial automation, stringent safety and environmental regulations, the expansion of core end-use industries (e.g., oil and gas, chemical), and rising demand for high-performance materials capable of operating in harsh and complex industrial environments.

What role does Artificial Intelligence (AI) play in the Instrumentation Tubes Market?

AI is increasingly impacting the market by optimizing manufacturing processes for improved quality and efficiency, enabling predictive maintenance for installed tubing systems, aiding in accelerated material development, and enhancing overall supply chain management for instrumentation tube products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager