Insulated Electrical Gloves Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442665 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Insulated Electrical Gloves Market Size

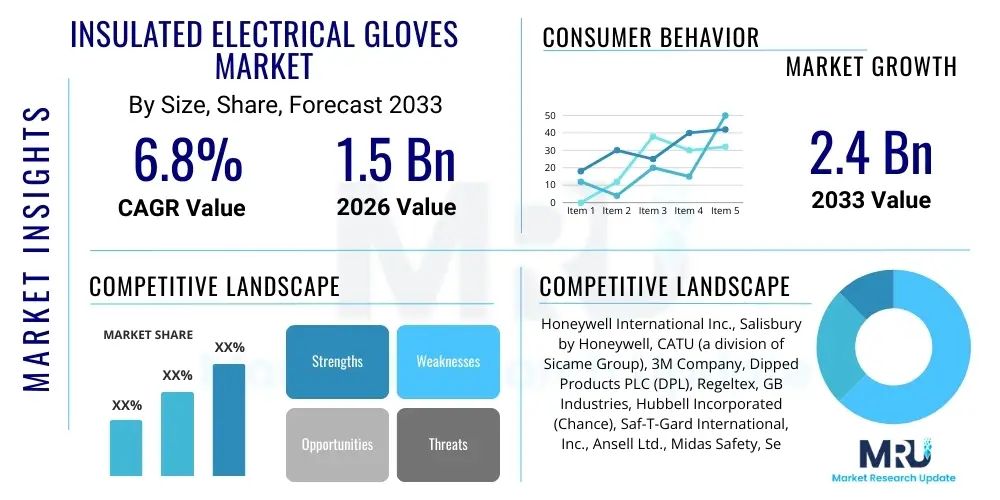

The Insulated Electrical Gloves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033. This consistent growth trajectory is fundamentally underpinned by increasing global emphasis on occupational safety, particularly within high-voltage environments across industrial, utility, and infrastructure sectors. Mandatory regulatory compliance, coupled with significant investments in electrical infrastructure modernization in emerging economies, are key contributors to this expansion, ensuring a stable and escalating demand for reliable electrical personal protective equipment (PPE).

Insulated Electrical Gloves Market introduction

Insulated electrical gloves are critical pieces of personal protective equipment (PPE) designed specifically to safeguard workers from electrical shocks and burns when working near or on energized equipment. These specialized gloves are typically constructed from high-quality dielectric materials, such as natural rubber or specialized synthetic composites, possessing inherent electrical resistance properties. Their functionality is classified based on the maximum voltage they can safely withstand, ranging from Class 00 (up to 500 Volts AC) to Class 4 (up to 36,000 Volts AC), adhering strictly to international safety standards like ASTM D120 and EN 60903. The rigorous testing and certification processes these gloves undergo ensure maximum protection and reliability in hazardous environments.

The primary application sectors for these gloves span across the entire electrical ecosystem, including power generation, transmission, and distribution utilities; commercial and residential electrical installations; and industrial maintenance operations. They are indispensable for linemen, electricians, utility technicians, and factory maintenance personnel performing tasks such as switchgear operation, cable splicing, and preventative maintenance on high-tension lines. The inherent benefits of utilizing these gloves include life preservation, compliance with stringent governmental occupational safety regulations (such as OSHA and equivalent regional bodies), and minimizing costly downtime resulting from electrical accidents. Furthermore, advanced designs now focus on ergonomic improvements, enhancing worker dexterity and reducing hand fatigue, which promotes consistent usage compliance.

Key factors driving the sustained expansion of the Insulated Electrical Gloves Market include rapid global urbanization and the subsequent expansion of smart grids, which necessitates extensive electrical network maintenance and upgrade cycles. Additionally, the proliferation of renewable energy infrastructure, particularly large-scale solar farms and wind power installations, introduces new operational environments that require highly specific, certified electrical protection equipment. Government-mandated safety campaigns and rising insurance liabilities for workplace accidents further compel organizations across all scales to invest proactively in superior-quality insulated gloves, reinforcing market growth across major industrial regions.

Insulated Electrical Gloves Market Executive Summary

The Insulated Electrical Gloves Market exhibits strong growth driven primarily by rigorous safety standards and the acceleration of global electrification projects. Business trends emphasize product innovation focusing on composite materials offering enhanced mechanical protection alongside dielectric strength, and the integration of smart features like RFID tracking for compliance monitoring and inventory management. Manufacturers are also prioritizing sustainable sourcing and manufacturing processes to align with growing corporate social responsibility mandates. Strategic partnerships between PPE suppliers and utility companies are becoming crucial for tailored product development and large-scale procurement agreements, setting the pace for competitive market dynamics and sustained revenue generation in the forecast period.

Regionally, Asia Pacific is anticipated to demonstrate the most aggressive growth rate, fueled by massive government investments in power infrastructure development, particularly in China and India, alongside mandatory adoption of global safety standards in rapidly industrializing sectors. North America and Europe, characterized by established regulatory frameworks and high labor safety costs, represent mature but steady markets focused on replacement cycles and premium-quality, high-specification products. These regions are also leading the adoption of sophisticated testing equipment and training protocols, which drives demand for gloves with enhanced durability and certification integrity, mitigating risks associated with high-voltage work and compliance failures.

Segment trends reveal that the Class 2 and Class 3 gloves, designed for medium voltage applications commonly found in industrial facilities and power distribution grids, command the largest market share due to their broad utility. By material, rubber gloves continue to dominate due to their proven dielectric properties and cost-effectiveness, although synthetic and composite gloves are gaining traction for applications requiring superior mechanical strength against cuts, tears, and punctures. End-user analysis highlights the Electric Utilities segment as the primary consumer, although the burgeoning Automotive and Manufacturing sectors, especially those involved in electric vehicle (EV) production and battery manufacturing, are rapidly emerging as significant growth opportunities, demanding specialized, lower-voltage gloves and sleeves.

AI Impact Analysis on Insulated Electrical Gloves Market

User queries regarding the impact of Artificial Intelligence (AI) on the Insulated Electrical Gloves Market typically revolve around quality assurance, predictive maintenance, and training methodologies. Users are keenly interested in how AI-powered visual inspection systems can detect manufacturing flaws or wear patterns invisible to the human eye, thereby ensuring the highest level of dielectric integrity before use. Furthermore, there is significant curiosity about leveraging AI to predict the service life of gloves based on usage data, environmental exposure (temperature, humidity), and historical testing results, moving beyond simple time-based replacement schedules. Concerns often focus on the complexity and cost of integrating such smart monitoring systems into traditional PPE, and how AI can improve worker compliance and training efficacy in high-risk electrical environments, making safety protocols more dynamic and personalized.

- AI-Powered Quality Control: Utilizing computer vision and machine learning algorithms to perform real-time, high-precision visual inspection during the manufacturing process, identifying minor defects, air pockets, or material inconsistencies that could compromise electrical integrity.

- Predictive Maintenance and Service Life Modeling: AI systems analyze environmental conditions and historical usage data (e.g., integrated sensors for temperature exposure or puncture events) to predict optimal replacement timing, minimizing unnecessary waste while maximizing worker safety and compliance.

- Enhanced Training Simulations: Employing AI-driven virtual reality (VR) and augmented reality (AR) training modules that simulate complex electrical scenarios, providing safe, repetitive practice for donning, doffing, and proper use of insulated gloves, thereby increasing proficiency and adherence to safety protocols.

- Smart Inventory and Compliance Management: Integrating AI with RFID or embedded sensor technology to automate inventory tracking, monitor glove expiration dates, and ensure that only certified, tested equipment is issued for specific job requirements, drastically reducing administrative oversight burden.

- Optimizing Manufacturing Processes: AI analyzes production data to fine-tune material mixing, curing times, and dipping consistency, reducing variability and waste in the fabrication of highly specialized dielectric rubber and composite compounds, leading to cost savings and higher product consistency.

DRO & Impact Forces Of Insulated Electrical Gloves Market

The market dynamics are significantly shaped by a confluence of stringent regulatory mandates (Driver), supply chain vulnerabilities for specialized raw materials (Restraint), and the expansive growth of renewable energy infrastructure (Opportunity). The impact forces, characterized by high barriers to entry due to demanding certification requirements, coupled with the critical nature of product failure in this safety-critical sector, ensure that innovation is heavily skewed towards reliability and durability. Global economic shifts, particularly infrastructure spending patterns, exert a medium-term impact on procurement volumes, while regulatory harmonization efforts across different geographical regions pose both opportunities for standardization and challenges for niche market compliance, creating a complex operating landscape for manufacturers seeking global scale.

Drivers: Growing global regulatory pressure mandating zero-tolerance policies for electrical accidents is the primary catalyst. National bodies are continuously updating safety codes (e.g., NFPA 70E, ASTM D120 updates), necessitating the regular replacement of aging equipment and the adoption of higher-class protection levels. Furthermore, the massive global capital expenditure directed towards electricity grid resilience, smart grid deployment, and the extension of high-voltage transmission networks, particularly across developing Asia and Africa, directly translates into increased demand for reliable and certified electrical safety gear, including gloves and accompanying protector gloves, creating a robust baseline demand that is resistant to minor economic downturns.

Restraints: The market faces significant headwinds from the volatility in raw material prices, notably natural rubber latex, which is vulnerable to agricultural yield variations, climate change impacts, and global commodity price fluctuations. This price instability complicates cost management and forecasting for manufacturers. Additionally, the lack of widespread awareness and enforcement of safety standards in some developing regions leads to the proliferation of non-certified or substandard, low-cost alternatives, undermining the market for high-quality, certified PPE. Furthermore, the mandatory periodic testing and replacement cycles, while beneficial for safety, represent a significant operational expense for end-users, sometimes leading to non-compliance in smaller, less regulated organizations.

Opportunities: The transition towards green energy sources, including large-scale wind turbine maintenance and utility-scale solar installations, represents a high-growth opportunity, as these operations require specialized maintenance teams utilizing certified insulated gloves frequently. Moreover, the rapid proliferation of Electric Vehicles (EVs) and the construction of associated charging infrastructure and battery manufacturing gigafactories are generating substantial demand for medium to low-voltage insulated gloves tailored for handling battery packs (often 400V to 800V DC). Technological advancements, such as gloves incorporating sensors for self-monitoring (detecting punctures or excessive wear), offer lucrative differentiation opportunities for companies capable of integrating smart technology into traditional PPE. Finally, the vast, untapped market potential in Central and South America and specific African nations, where industrialization is accelerating but safety standards are still nascent, provides long-term expansion pathways.

Segmentation Analysis

The Insulated Electrical Gloves Market is meticulously segmented across various critical parameters including the glove's voltage class, the foundational material used in its construction, and the specific end-user industry where it is deployed. This multilayered segmentation allows market participants to tailor product offerings precisely to regulatory requirements and operational hazards. Segmentation by voltage class (Class 00 to Class 4) directly reflects the risk exposure level, with higher classes demanding more rigorous manufacturing specifications and quality control. Material segmentation, primarily between natural rubber (latex) and various synthetic composites, reflects trade-offs between dielectric performance, mechanical strength, and chemical resistance, while end-user segmentation reveals consumption patterns heavily dominated by utility companies, but with increasing diversification into specialized sectors like telecommunications and mass transit infrastructure, ensuring the market remains dynamically responsive to industry-specific demands and large infrastructure project cycles.

- By Voltage Class:

- Class 00 (Max Use Voltage AC 500V / DC 750V)

- Class 0 (Max Use Voltage AC 1,000V / DC 1,500V)

- Class 1 (Max Use Voltage AC 7,500V / DC 11,250V)

- Class 2 (Max Use Voltage AC 17,000V / DC 25,500V)

- Class 3 (Max Use Voltage AC 26,500V / DC 39,750V)

- Class 4 (Max Use Voltage AC 36,000V / DC 54,000V)

- By Material Type:

- Natural Rubber (Latex)

- Synthetic Rubber (Neoprene, EPDM)

- Composite Materials (Blends offering enhanced mechanical properties)

- By End-User Industry:

- Electric Utilities (Power Generation, Transmission, and Distribution)

- Telecommunications

- Construction

- Manufacturing (Industrial Maintenance and Assembly)

- Automotive (EV Manufacturing and Maintenance)

- Oil & Gas

- Railways and Mass Transit

- By Product Type:

- Standard Insulated Gloves (Dielectric Layer Only)

- Composite Gloves (Integrated Mechanical and Dielectric Protection)

- Leather Protector Gloves (Worn over insulated gloves for physical abrasion resistance)

- Insulating Sleeves (Arm protection)

- By Distribution Channel:

- Direct Sales (Large utility contracts)

- Indirect Sales (Distributors, Safety Equipment Retailers)

- E-commerce Platforms

Value Chain Analysis For Insulated Electrical Gloves Market

The value chain for insulated electrical gloves is highly structured, beginning with the sourcing of specialized raw materials, primarily high-grade natural or synthetic rubber compounds that offer superior dielectric strength and elasticity. The upstream analysis focuses intensely on maintaining supply chain integrity, as the quality and consistency of these primary materials directly dictate the glove's safety performance and certification validity. Key challenges upstream include mitigating price volatility for rubber latex and managing the complex quality control necessary to ensure compound purity, which is critical for meeting stringent international safety standards such as IEC and ASTM. Relationships with specialized chemical suppliers and rubber plantations are essential for manufacturers to maintain competitive advantages and ensure material suitability for high-voltage applications, demanding strict traceability protocols.

Midstream activities involve specialized manufacturing processes, predominantly precision dipping techniques, followed by curing, vulcanization, and mandatory dielectric testing. This stage is capital-intensive, requiring specialized machinery and highly controlled cleanroom environments to prevent contaminants that could compromise insulation. Testing and certification—often performed both in-house and by accredited third-party laboratories—form the most critical checkpoint, as regulatory compliance is non-negotiable for product marketability. Innovation midstream focuses on developing lighter, more flexible materials that improve worker dexterity without sacrificing voltage protection, and integrating advanced manufacturing techniques like robotic dipping to achieve unmatched uniformity and consistency across product batches.

Downstream analysis highlights the complexity of distribution, which typically involves both direct sales to major national utility companies (who often require custom specifications and large volumes) and indirect sales through specialized industrial safety distributors and retailers. Direct channels facilitate large contract fulfillment and stronger manufacturer-end user feedback loops, while indirect channels are vital for reaching smaller contractors and maintenance firms, where product availability and rapid delivery are paramount. The emergence of professional e-commerce platforms specializing in industrial PPE is streamlining the purchasing process for medium-sized enterprises, but product education and technical support remain vital components of the downstream value proposition, requiring sales teams to possess deep knowledge of voltage classes and specific application requirements.

Insulated Electrical Gloves Market Potential Customers

Potential customers for insulated electrical gloves represent a broad spectrum of industries where high-voltage or low-voltage electrical hazards are inherent to daily operations, mandating strict adherence to global PPE standards. The largest consumer base historically resides within the Electric Power Utility sector, including companies involved in generation, long-distance transmission, and local distribution (T&D), where routine maintenance on energized lines and substations necessitates Class 2 through Class 4 protection. These entities operate under intense regulatory scrutiny and possess the largest procurement budgets for high-end, certified safety equipment, forming the bedrock of sustained market demand, often procuring products through multi-year strategic contracts.

Beyond traditional utilities, a rapidly expanding segment includes infrastructure development and heavy industrial sectors. This encompasses large construction projects involving electrical wiring and control systems, specialized maintenance teams in manufacturing facilities for machinery upkeep, and the expansive telecommunications industry for maintaining complex communication infrastructure power sources. Furthermore, the specialized transportation segment, particularly railway operations (tramways, subways, electrified rail lines) and the swiftly growing electric vehicle manufacturing and service industry, are becoming essential high-growth customer clusters. These segments often require lower-class gloves (Class 00 and Class 0) used in high-frequency, precision tasks involving control panels and battery systems, demanding gloves optimized for tactile sensitivity and comfort during prolonged use.

The core buyer criteria across all these diverse end-users emphasize adherence to relevant safety standards (e.g., IEC 60903, ASTM D120), documented proof of recent dielectric testing, and considerations of ergonomic factors such as fit, flexibility, and compatibility with leather protector gloves. Procurement decisions are increasingly influenced by factors beyond mere price, prioritizing manufacturer reputation, product longevity, and comprehensive support services, including training on proper inspection and care. Smaller contractors and independent electricians rely heavily on local distributors for immediate availability, whereas major multinational corporations implement centralized purchasing strategies to standardize safety equipment globally, driving demand for internationally compliant products from manufacturers with widespread distribution capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Honeywell International Inc., Salisbury by Honeywell, CATU (a division of Sicame Group), 3M Company, Dipped Products PLC (DPL), Regeltex, GB Industries, Hubbell Incorporated (Chance), Saf-T-Gard International, Inc., Ansell Ltd., Midas Safety, Secura B.V., Protective Industrial Products (PIP), Elsec, Boddingtons Electrical Ltd., Sorbent International, Novax, Binaca, Jiangsu Haian Rubber Co. Ltd., Cementex Products Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Insulated Electrical Gloves Market Key Technology Landscape

The technological landscape of the Insulated Electrical Gloves Market is fundamentally centered on material science innovation aimed at enhancing dielectric integrity, mechanical durability, and ergonomic performance. The core technology remains the precision-dipping of high-grade natural and synthetic rubber compounds, a process that requires meticulous control over temperature, curing time, and mold design to ensure uniform wall thickness and defect-free insulation across the entire glove surface. Recent advancements are focused on developing specialized composite materials that integrate multiple layers—combining dielectric rubber with puncture-resistant synthetics—offering protection against electrical hazards simultaneously with enhanced resistance to cuts, abrasions, and tears, thereby reducing the reliance on external leather protector gloves in certain low-risk applications, streamlining worker safety procedures and improving tactile feedback.

A significant technological push involves the integration of advanced testing methodologies and digitization. While traditional air inflation and water bath dielectric testing remain mandatory, manufacturers are increasingly using sophisticated non-destructive testing (NDT) techniques, such as micro-imaging and ultrasonic scanning, to detect sub-surface flaws or micro-cracks before the final certification process, significantly improving product reliability and reducing failure rates. Furthermore, the adoption of digital twin technology in the manufacturing process allows companies to simulate material behavior under various stress conditions, optimizing the formulation of rubber compounds for specific regional climate challenges, such as extreme heat or cold, ensuring performance stability irrespective of the operating environment.

The emerging frontier in the gloves market is the incorporation of "smart" technology. Although still nascent, this includes embedding passive RFID tags or micro-sensors within the glove cuff. RFID allows for automated tracking of usage, mandatory testing schedules, and inventory management, ensuring strict compliance with regulatory requirements regarding product expiration and re-testing intervals. Future iterations are expected to involve integrated sensors capable of detecting physical damage or thermal stress in real-time, providing immediate feedback to the wearer or safety supervisor. This shift towards intelligent PPE represents a pivotal technological evolution, moving insulated gloves from a static safety barrier to an active, connected component of a comprehensive occupational safety monitoring system, improving overall job site risk management and operational efficiency.

Regional Highlights

Regional analysis reveals stark differences in market maturity, regulatory rigor, and growth drivers across the globe. North America, encompassing the United States and Canada, represents a mature market characterized by extremely high levels of regulatory compliance, notably driven by OSHA and electrical code mandates. Demand here is stable, fueled by compulsory replacement cycles, aging infrastructure requiring extensive maintenance, and a strong preference for high-quality, high-end certified products. The US market is highly competitive, focused heavily on Classes 2 and 3, and is a significant adopter of integrated safety solutions, demanding detailed product traceability and manufacturer support for testing facilities. Investment in smart grid technology and the burgeoning oil and gas sector also contribute substantially to regional market stability and premium product demand.

Europe, driven by the stringent IEC 60903 standard and comprehensive EU directives on worker safety, also holds a substantial share of the global market. Key growth aspects in this region include the massive investment in offshore wind energy and cross-border electricity transmission projects, which necessitate specialized, high-class protection (Class 4). Scandinavian countries and Germany are leaders in adopting specialized, cold-weather compatible gloves and advanced composite materials for enhanced durability in harsh climates. The European market exhibits high fragmentation, with a strong presence of local manufacturers specializing in niche protective gear, alongside large multinational corporations. The emphasis on sustainability and ethical sourcing of materials is also increasingly influencing procurement decisions within the EU.

Asia Pacific (APAC) is projected to be the fastest-growing region, dominated by the rapidly expanding industrial bases and infrastructure development in countries like China, India, and Southeast Asia. The explosive growth in power generation capacity, rapid urbanization, and extensive rural electrification programs are creating unprecedented demand for all classes of insulated gloves, especially Class 0 and Class 1 for distribution work. While historically challenging due to the presence of non-certified vendors, regulatory enforcement is improving across key APAC economies, propelling the demand for internationally compliant products. Government initiatives promoting occupational health and safety (OHS) standards, coupled with substantial foreign direct investment into manufacturing and high-tech sectors, are accelerating the shift toward certified PPE, making APAC a critical future revenue driver for global manufacturers.

Latin America (LATAM) and the Middle East & Africa (MEA) represent substantial emerging markets. In LATAM, investments in mining, utility privatization, and grid modernization projects are fueling demand, although economic instability and varying regulatory enforcement levels pose challenges. MEA's market expansion is inextricably linked to large-scale oil and gas exploration, utility development in Gulf Cooperation Council (GCC) nations, and significant infrastructure build-out, particularly in South Africa and Nigeria. Demand in these regions is characterized by a high need for durable, robust gloves that can withstand demanding environmental conditions, often requiring manufacturers to adapt material formulations to resist UV degradation and extreme temperatures, providing a unique set of market requirements focused on material resilience and extended service life.

- North America (US, Canada): Mature market; High compliance with OSHA and ASTM; Focus on Class 2/3 replacement cycles; Significant use in utility maintenance and oil/gas sectors; Premium product demand.

- Europe (Germany, UK, France, Scandinavia): Strong regulatory environment (IEC 60903); Driven by renewable energy (offshore wind); High demand for cold-weather and composite gloves; Focus on sustainability and material traceability.

- Asia Pacific (China, India, Japan, South Korea): Highest growth rate; Driven by massive infrastructure and industrial expansion; Rapid regulatory tightening; Increasing adoption of global safety standards; High volume demand for Class 0/1/2.

- Latin America (Brazil, Mexico): Emerging market; Demand linked to grid modernization and mining; Challenges include economic volatility and fragmented regulatory landscape; Growing need for training and certification support.

- Middle East & Africa (GCC, South Africa): Growth tied to oil & gas, urban development, and utility expansion; Demand for highly durable gloves resistant to extreme heat and UV exposure; Market development dependent on localized safety mandates and major project timelines.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Insulated Electrical Gloves Market.- Honeywell International Inc.

- Salisbury by Honeywell

- CATU (a division of Sicame Group)

- 3M Company

- Dipped Products PLC (DPL)

- Regeltex

- GB Industries

- Hubbell Incorporated (Chance)

- Saf-T-Gard International, Inc.

- Ansell Ltd.

- Midas Safety

- Secura B.V.

- Protective Industrial Products (PIP)

- Elsec

- Boddingtons Electrical Ltd.

- Sorbent International

- Novax

- Binaca

- Jiangsu Haian Rubber Co. Ltd.

- Cementex Products Inc.

- Marigold Industrial

- Skylotec GmbH

- LION Safety

- Arco Limited

- Dupont de Nemours, Inc. (Material Supplier)

Frequently Asked Questions

Analyze common user questions about the Insulated Electrical Gloves market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the most crucial factor driving demand in the Insulated Electrical Gloves Market?

The primary driver is the stringent and continuously evolving global regulatory landscape concerning occupational safety in high-voltage environments, such as those mandated by OSHA (USA) and IEC (international standards), compelling mandatory use, routine testing, and timely replacement of certified electrical PPE.

How often must insulated electrical gloves be tested for safety compliance?

Insulated electrical gloves must undergo rigorous dielectric testing periodically, typically every six months, regardless of their usage frequency, according to standards such as ASTM D120 and IEC 60903. This ensures the integrity of the insulation barrier remains intact and compliant with specified voltage ratings.

Which material type is dominant, and what are the advantages of composite gloves?

Natural rubber latex remains the dominant material due to its superior dielectric properties and excellent flexibility. Composite gloves, however, are gaining traction as they integrate the necessary electrical insulation with mechanical reinforcement, offering improved resistance against cuts, tears, and punctures compared to traditional rubber gloves.

What is the market impact of the growth of the Electric Vehicle (EV) industry?

The EV industry significantly boosts the demand for lower voltage classes (Class 00 and Class 0) of insulated gloves, which are essential for manufacturing, servicing, and maintaining high-voltage battery systems (typically 400V to 800V DC) utilized in electric vehicles, creating a new, specialized end-user segment.

Which geographic region presents the highest growth opportunity for insulated electrical gloves?

The Asia Pacific (APAC) region is projected to exhibit the highest growth rate, driven by massive investments in electricity infrastructure expansion, rapid industrialization, and the increasing implementation of formalized safety standards in major economies like China and India, shifting procurement towards certified, high-quality safety equipment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager