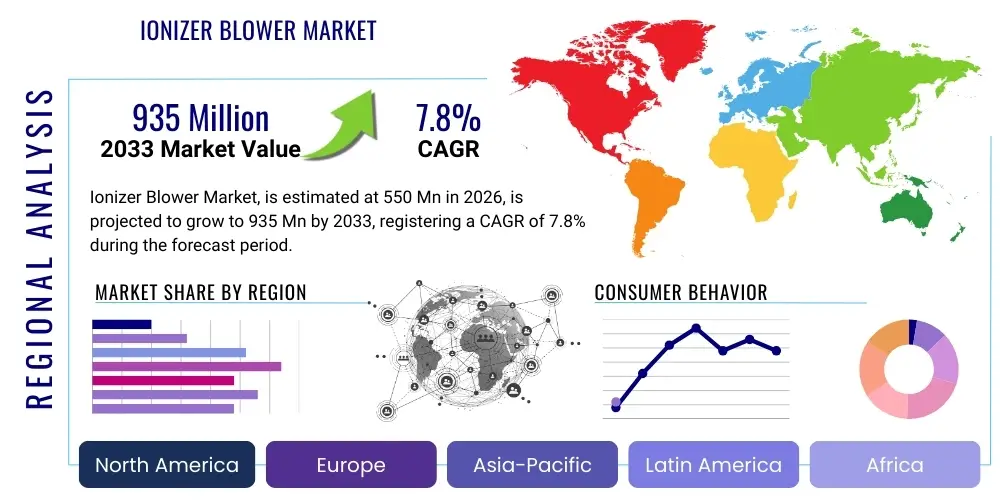

Ionizer Blower Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442149 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Ionizer Blower Market Size

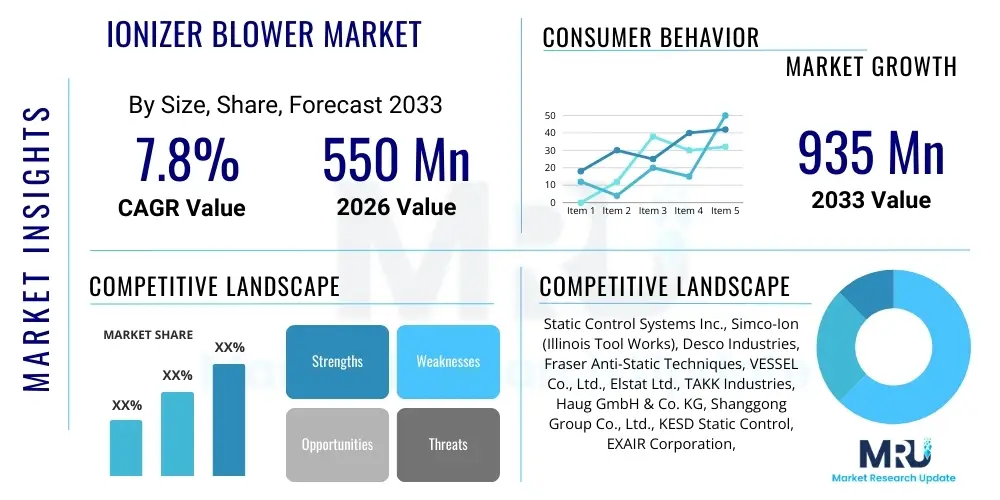

The Ionizer Blower Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $550 Million in 2026 and is projected to reach $935 Million by the end of the forecast period in 2033.

Ionizer Blower Market introduction

The Ionizer Blower Market encompasses specialized equipment designed to neutralize static electrical charges on surfaces and materials, particularly in sensitive manufacturing and controlled environments such as cleanrooms, electronics assembly, and pharmaceutical processing. These devices operate by generating a balanced stream of positive and negative ions, which are then propelled by a fan or blower across the target area. The primary function is to eliminate the detrimental effects of Electrostatic Discharge (ESD), which can cause catastrophic failure or latent defects in electronic components, or attract particulate contamination, thereby compromising product quality and operational efficiency in high-precision industries.

Ionizer blowers utilize various ionization technologies, including AC, DC, and Pulsed DC systems, each tailored for different application ranges, charge decay speeds, and environmental requirements. AC ionizers are often utilized for smaller, localized areas due to their simple design, while Pulsed DC systems offer superior ion balance and efficiency over larger areas or in environments requiring stringent decay time performance, characteristic of ISO Class 1 to Class 5 cleanrooms. The growing global demand for advanced semiconductor devices, microelectronics miniaturization, and the rigorous quality standards within the medical device manufacturing sector are collectively serving as the foundational driving forces for sustained market expansion. Furthermore, regulatory compliance related to ESD control (e.g., ANSI/ESD standards) mandates the implementation of effective static elimination solutions, cementing the indispensable role of ionizer blowers in modern industrial ecosystems.

Ionizer Blower Market Executive Summary

The Ionizer Blower Market is undergoing significant evolution driven by the rapid expansion of the semiconductor and display manufacturing industries across Asia Pacific, coupled with increasing automation integration in European and North American manufacturing hubs. Key business trends indicate a shift towards smarter, networked ionizer blowers featuring self-monitoring capabilities, remote diagnostics, and improved ion balance control mechanisms utilizing proprietary sensor technology. This technological push is focused on minimizing maintenance downtime and ensuring continuous adherence to ultra-low ESD standards critical for manufacturing 7nm and 5nm node technology chips. Competition remains intense, characterized by continuous innovation aimed at improving charge decay times and reducing the footprint of high-performance units for integration into increasingly compact production lines and sophisticated equipment.

Regionally, Asia Pacific maintains dominance, fueled by massive investments in new fab construction in China, South Korea, and Taiwan, which necessitates large-scale deployment of advanced ionization systems in controlled environments. North America and Europe demonstrate robust growth, primarily driven by the stringent quality demands of the aerospace, medical device, and specialized automotive electronics sectors, emphasizing high-reliability DC and Pulsed DC ionizers. Segment trends highlight the Pulsed DC technology segment as the fastest growing due to its superior performance in critical cleanroom applications, offering better ion coverage and precision required by advanced manufacturing processes. The Electronics & Semiconductor application segment remains the largest consumer, though the Pharmaceuticals & Medical Devices segment shows accelerating adoption rates due to the criticality of contamination control in sterile environments and during sensitive assembly procedures.

Overall, the market trajectory is positive, underpinned by macroeconomic trends favoring technological complexity and miniaturization across end-user industries. Strategic initiatives by leading market participants focus on vertical integration, geographical expansion into emerging manufacturing regions, and continuous R&D to enhance efficiency, reduce energy consumption, and ensure long-term stability of the ion balance output under varying ambient conditions. The market's resilience is tied directly to the global digital transformation and the increasing regulatory scrutiny on product quality and defect prevention in high-tech manufacturing.

AI Impact Analysis on Ionizer Blower Market

Common user questions regarding AI's impact on the Ionizer Blower Market often revolve around predictive maintenance, optimization of static control parameters, and integration capabilities within Industry 4.0 frameworks. Users are concerned with how AI can minimize human intervention in the calibration and maintenance process, asking if AI algorithms can anticipate ion emitter wear or ion balance drift before it impacts production quality. There is also significant interest in using machine learning to correlate environmental data (temperature, humidity, air flow) with ionization performance to achieve dynamic, real-time adjustments for optimal charge decay times across complex production floor layouts. Essentially, users expect AI to transition static control from a reactive maintenance task to a proactive, integrated component of intelligent manufacturing systems, ensuring zero defects related to ESD contamination.

AI’s influence is primarily manifested through enhancing the efficiency and reliability of ionizer blower systems by enabling smart monitoring and corrective action without manual input. Predictive maintenance models, built using historical performance data, environmental sensor inputs, and operational hours, allow manufacturers to schedule emitter pin cleaning or replacement precisely when needed, maximizing uptime and reducing unnecessary service calls. Furthermore, AI-driven algorithms can process complex datasets generated by an array of ionizer monitoring points across a large cleanroom facility, optimizing the overall ion delivery strategy to maintain uniform static control performance despite variations in equipment movement or material handling processes. This advanced analytical capability transforms standard ionization technology into a dynamic control system, crucial for highly automated manufacturing environments.

The implementation of AI/ML models is also facilitating the development of advanced control boards embedded within ionizer blowers, which can learn the optimal operational profile for specific production tasks. These systems learn to recognize patterns indicative of environmental changes or component degradation, adjusting voltage output or blower speeds instantaneously to maintain the required charge decay specifications (e.g., less than ±10V decay time). This evolution positions ionizer blowers not merely as standalone components but as critical data-generating endpoints in a comprehensive IoT manufacturing infrastructure, significantly elevating process control and yield rates, especially in high-volume, low-margin sectors like consumer electronics and memory fabrication.

- Implementation of predictive maintenance algorithms to forecast emitter pin degradation and maintenance schedules.

- Real-time dynamic ion balance adjustment utilizing machine learning based on ambient environmental conditions (temperature, humidity).

- Integration into manufacturing execution systems (MES) via IoT sensors for centralized performance monitoring and anomaly detection.

- Optimization of ion delivery patterns and flow rates across large-area coverage by analyzing air current models.

- Enhanced quality control by correlating ionizer performance data directly with product defect rates for root cause analysis.

- Automated self-calibration routines driven by AI to ensure continuous compliance with strict ISO/ESD standards.

DRO & Impact Forces Of Ionizer Blower Market

The Ionizer Blower Market is primarily driven by the unstoppable trend of electronic component miniaturization and the subsequent stringent requirements for electrostatic discharge (ESD) control in advanced manufacturing environments, particularly within the semiconductor and microelectronics industries. Miniaturization leads to lower voltage tolerances for sensitive components, making even minor static events catastrophic, thereby necessitating robust and precisely controlled ionization solutions. Restraints include the high initial cost associated with sophisticated Pulsed DC and networked ionizer systems, particularly for smaller manufacturing enterprises, coupled with the ongoing operational expenditure required for regular maintenance, calibration, and cleaning of emitter points to ensure optimal ion balance and performance stability. The constant need for specialized technical personnel to manage and validate these systems adds to the operational overhead, acting as a frictional constraint on rapid, widespread adoption in less regulated sectors.

Opportunities for market expansion are significant, particularly in emerging applications such as additive manufacturing (3D printing) where static electricity can disrupt powder handling and layering processes, and in the burgeoning field of flexible electronics and printed circuit board assembly where surface contamination risks are high. Furthermore, the global push toward Industry 4.0 and smart factory automation provides a substantial opportunity for manufacturers to integrate IoT-enabled ionizer blowers, offering remote monitoring and data analytics capabilities that add value beyond simple static elimination. These advanced units appeal directly to large corporations seeking comprehensive, automated solutions for quality control and process repeatability across global manufacturing footprints.

The impact forces influencing the market are multifaceted, driven externally by increasing global competition in high-tech manufacturing, forcing companies to adopt zero-defect policies, and internally by continuous technological innovation focused on improving ion output stability and decay time efficiency. Regulatory compliance, specifically adherence to international standards like IEC 61340 and ANSI/ESD S20.20, exerts a strong positive influence, mandating the use of validated static control measures. Conversely, the impact of fluctuating raw material costs, particularly for precision components and specialized plastics used in blower construction, can moderately affect pricing strategies and supply chain stability. The combined force of escalating performance demands from semiconductor manufacturers and proactive regulatory environments acts as the primary engine sustaining robust growth rates across all major geographic markets.

Segmentation Analysis

The Ionizer Blower Market is systematically segmented based on technological implementation, target application, and the specific environments in which they are deployed, providing a granular view of market demands and consumption patterns. The segmentation by type is crucial, distinguishing between simpler AC technologies and high-precision DC/Pulsed DC systems that cater to differing requirements for ion balance and charge decay speed. Application segmentation highlights the dominance of the electronics sector while identifying key growth areas such as pharmaceutical packaging and specialized coating processes. End-user categorization further refines the demand profile, differentiating needs between highly controlled cleanrooms and general industrial assembly lines, each requiring distinct form factors and performance metrics for static elimination equipment.

- By Type

- AC Ionizer Blower (Standard, Low-cost, localized coverage)

- DC Ionizer Blower (Improved ion balance, medium to large coverage)

- Pulsed DC Ionizer Blower (Superior ion balance, fastest decay time, critical cleanrooms)

- By Application

- Electronics & Semiconductor Manufacturing

- Automotive Assembly & Component Manufacturing

- Pharmaceuticals & Medical Devices (Sterile Packaging, Drug Filling)

- Food & Beverages Processing

- Packaging and Converting Industry

- Industrial Manufacturing (Plastics, Textiles, Optics)

- By End-User

- Cleanrooms (ISO Class 1 to 7)

- Assembly Lines and Workstations

- R&D Laboratories and Testing Facilities

- By Coverage Area

- Benchtop Ionizers

- Overhead Ionizers

- Nozzle/Gun Ionizers (Point-of-use)

Value Chain Analysis For Ionizer Blower Market

The value chain for the Ionizer Blower Market begins with upstream activities involving the sourcing of highly specialized raw materials and components, particularly high-precision metal alloys for emitter pins (e.g., tungsten or stainless steel), advanced ceramics and polymers for housing construction, and sophisticated power supply and control electronics. Key upstream suppliers include specialized manufacturers of high-voltage transformers, miniature fans/blowers designed for low vibration and clean operation, and sensor technology providers crucial for ion balance monitoring. The quality and purity of these sourced materials directly impact the long-term reliability and performance consistency of the final ionizer product, making strong supplier relationships and rigorous quality control at this stage paramount for mitigating manufacturing risks.

The midstream phase centers on the core manufacturing, assembly, and testing of the ionizer blower units. This involves complex processes such as high-voltage power supply integration, precision assembly of ion emitters and air flow systems, and extensive calibration procedures to meet specified ion balance (typically ±5V to ±20V) and charge decay time targets. Key competitive differentiators in this stage include proprietary ionization technologies (e.g., corona discharge vs. soft X-ray), robust quality assurance protocols, and the integration of smart features like self-monitoring diagnostics. Distribution channels are varied, encompassing direct sales models for large, highly customized cleanroom projects, and indirect channels relying on specialized industrial distributors, ESD control product wholesalers, and system integrators who bundle ionizer blowers with other cleanroom or assembly equipment.

Downstream activities focus on reaching the end-user, providing installation services, ongoing technical support, and critical maintenance and calibration services—often mandated annually to maintain compliance with ESD standards. Direct sales are prevalent when dealing with major semiconductor fabrication plants or pharmaceutical companies that require high volumes and complex system integration. Indirect channels are crucial for reaching smaller assembly operations and general industrial users. The effectiveness of the value chain relies heavily on the technical proficiency of the distribution network to educate customers on the nuanced differences between AC, DC, and Pulsed DC technologies and to correctly specify the appropriate ionizer solution based on the application's unique charge generation characteristics and sensitivity requirements.

Ionizer Blower Market Potential Customers

The primary end-users and potential buyers of ionizer blower systems are entities operating in environments where electrostatic discharge or particulate contamination poses a critical threat to product quality, yield, or operational safety. Leading customers are entrenched within the high-tech electronics manufacturing ecosystem, notably semiconductor foundries, printed circuit board (PCB) assembly houses, and specialized component manufacturers dealing with sensitive microchips, sensors, and magnetic storage media. These customers invest heavily in advanced ionization systems—typically Pulsed DC overhead or benchtop units—to maintain ISO Class 1 to Class 5 cleanroom integrity, ensuring charge decay times meet the most stringent industry specifications to protect components that are increasingly sensitive to minute static events.

A rapidly growing customer segment includes the pharmaceutical and medical device industries, encompassing manufacturers of sterile packaging, drug delivery systems, diagnostic equipment, and implantable devices. In these environments, static charges attract airborne particulates (dust, fibers) onto sterile surfaces, leading to product rejection and non-compliance with Good Manufacturing Practices (GMP). Ionizer blowers are critical for neutralizing charges on non-conductive surfaces like plastic components, packaging films, and glass vials during filling and assembly operations. The demand here is often focused on units that offer low particle generation and easy sterilization, making them suitable for aseptic processing zones and controlled non-shedding environments.

Furthermore, major automotive electronics manufacturers, aerospace and defense contractors, and specialized optics and display producers represent significant customer bases. The proliferation of complex electronic control units (ECUs) and sensor arrays in modern vehicles necessitates dedicated ESD control in automotive assembly lines. Potential customers in the industrial sector also include packaging and converting companies, textile manufacturers, and plastics processors, who utilize ionizer blowers to eliminate static buildup that causes material jamming, shock hazards for operators, and poor print quality. The purchasing decisions of all these end-users are driven by risk mitigation, regulatory compliance, and the imperative to maximize production yield rates and component reliability in mission-critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million |

| Market Forecast in 2033 | $935 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Static Control Systems Inc., Simco-Ion (Illinois Tool Works), Desco Industries, Fraser Anti-Static Techniques, VESSEL Co., Ltd., Elstat Ltd., TAKK Industries, Haug GmbH & Co. KG, Shanggong Group Co., Ltd., KESD Static Control, EXAIR Corporation, Meech International, Koga Electric, Keyence Corporation, Q-Lab Corporation, Prostat Corporation, Alpha Laboratories, NRD Static Control, TDK Corporation, 3M Company (Specific Static Control Division). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ionizer Blower Market Key Technology Landscape

The technological landscape of the Ionizer Blower Market is dominated by corona discharge technology, categorized primarily into AC, DC, and Pulsed DC ionization methods, each utilizing high voltage to create positive and negative ions from ambient air molecules. AC ionization, the oldest and simplest method, uses a single high-voltage power source (50/60 Hz) applied to the emitter pins, generating alternating bursts of positive and negative ions. While cost-effective, AC systems suffer from slower ion decay times and are often less effective in maintaining zero-balance over large distances due to recombination of ions, limiting their use primarily to small, localized benchtop applications or non-critical industrial environments where high precision is not required. Technological advancement in AC systems focuses mainly on increasing the frequency to reduce the ion pulse period and improve balance.

In contrast, DC ionization utilizes separate high-voltage sources for positive and negative emitters, resulting in a continuous, steady stream of charged ions. Standard DC systems offer improved ion balance and wider coverage compared to AC, making them suitable for overhead applications in larger workstations. However, the most advanced technological segment is Pulsed DC ionization, which employs a highly controlled, cyclical output of positive and negative ions, managed by sophisticated electronic controls. This pulsing mechanism significantly reduces ion recombination, allowing for rapid charge neutralization and highly stable ion balance (often maintained within ±5V of zero) even over extended distances and varying air flow conditions. Pulsed DC technology is mandatory in high-purity cleanrooms (e.g., semiconductor Fabs) due to its superior performance in achieving extremely fast charge decay times required by ultra-sensitive components.

Recent innovations in the technological landscape include the integration of proprietary sensor feedback loops, often referred to as "auto-balancing" technology. These systems incorporate sensors (e.g., capacitive or field meters) that continuously measure the ion balance at a designated monitoring point and instantly transmit data back to the blower's control board. The board then dynamically adjusts the high voltage output of the positive or negative channels to compensate for any imbalance caused by environmental drift or emitter wear. This capability ensures continuous, verified compliance with critical ESD standards without manual intervention. Furthermore, manufacturers are focusing on integrating network connectivity (Ethernet, Wi-Fi) into new models, facilitating remote monitoring, data logging, and integration into centralized factory management systems, reflecting the overarching trend toward smart, interconnected manufacturing infrastructure.

Regional Highlights

Regional dynamics within the Ionizer Blower Market are characterized by differential growth rates and specific technology adoption patterns driven by the concentration of high-tech manufacturing, regulatory stringency, and general industrial output across major economic zones.

- Asia Pacific (APAC): Dominates the global market share and is projected to exhibit the highest growth rate. This is directly attributable to the colossal manufacturing base, particularly the massive investment and expansion in semiconductor fabrication (memory, logic chips), flat panel displays, and consumer electronics assembly in countries such as China, Taiwan, South Korea, and Japan. The stringent requirements of new-generation Fabs necessitate high-volume adoption of advanced Pulsed DC ionizer blowers and networked overhead systems, making APAC the primary driver for technological demand.

- North America: Represents a mature yet technologically sophisticated market, driven by high-reliability sectors including aerospace and defense, advanced medical devices, and specialized R&D facilities. Demand is focused on high-performance, validated ionizer systems capable of meeting rigorous military and institutional quality standards. The region leads in the adoption of AI-enabled, self-monitoring ionizer systems and integration into complex manufacturing execution systems (MES).

- Europe: Characterized by strong growth in the automotive electronics, industrial automation, and specialized pharmaceutical manufacturing sectors (especially Germany, Switzerland, and Ireland). European companies prioritize energy efficiency, long-term stability, and compliance with stringent EU safety and environmental regulations (e.g., RoHS, REACH), driving demand for high-quality, reliable DC and Pulsed DC blowers with certified calibration traceability.

- Latin America (LATAM): A developing market primarily focused on general industrial assembly and lower-tier electronics manufacturing. The market penetration of advanced ionization technologies is relatively lower compared to mature regions, with higher demand for cost-effective AC and standard DC benchtop units. Growth is moderate, tied primarily to foreign direct investment in electronics and automotive component assembly in Mexico and Brazil.

- Middle East and Africa (MEA): Currently holds the smallest market share, with demand concentrated in energy, petrochemicals (where static charge poses explosion risks), and nascent high-tech manufacturing hubs in the UAE and Saudi Arabia. Market growth is sporadic and dependent on government-backed initiatives to diversify economies away from oil, fostering small-scale electronics assembly and specialized industrial operations that require basic static control measures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ionizer Blower Market.- Static Control Systems Inc.

- Simco-Ion (Illinois Tool Works)

- Desco Industries

- Fraser Anti-Static Techniques

- VESSEL Co., Ltd.

- Elstat Ltd.

- TAKK Industries

- Haug GmbH & Co. KG

- Shanggong Group Co., Ltd.

- KESD Static Control

- EXAIR Corporation

- Meech International

- Koga Electric

- Keyence Corporation

- Q-Lab Corporation

- Prostat Corporation

- Alpha Laboratories

- NRD Static Control

- TDK Corporation

- 3M Company (Specific Static Control Division)

Frequently Asked Questions

Analyze common user questions about the Ionizer Blower market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the difference between AC, DC, and Pulsed DC ionizer blowers?

AC ionizers alternate between positive and negative ion generation on a single emitter, suitable for small areas and general industrial use. DC ionizers use separate emitters for continuous positive and negative output, offering better balance over larger areas. Pulsed DC is the most advanced, using controlled cycles to minimize ion recombination, achieving superior, rapid ion balance (near zero volts) critical for semiconductor cleanrooms (ISO Class 1-5).

How often should ionizer blowers be calibrated and maintained?

Ionizer blowers should be calibrated and performance-verified typically every 6 to 12 months, depending on the criticality of the application and internal quality standards (such as ANSI/ESD S20.20 compliance). Regular maintenance involves cleaning the emitter pins (to remove contamination that causes ion imbalance) and verifying the charge decay time and offset voltage using a calibrated plate monitor.

Which industries are the primary drivers of demand for high-performance ionizer blowers?

The semiconductor manufacturing industry is the primary driver, specifically due to the need for ultra-clean, static-free environments for producing advanced microchips (7nm, 5nm nodes). Other key drivers include specialized medical device manufacturing, automotive electronics production, and optics/display panel fabrication, all requiring strict contamination and ESD control.

What is 'ion balance' and why is it crucial for static control?

Ion balance, or offset voltage (Vo), is the net voltage measured in the ionized air stream, ideally zero volts (or near-zero, e.g., ±5V). It is crucial because a consistent imbalance means the ionizer is predominantly generating one polarity of charge, potentially leaving a detrimental static charge on materials. High-performance ionizers utilize auto-balancing technology to maintain this critical balance dynamically.

How is AI integrating into modern Ionizer Blower systems?

AI is enabling intelligent, networked ionizer systems capable of predictive maintenance, forecasting emitter wear, and dynamically adjusting ion output based on real-time environmental data (humidity, temperature) to maintain optimal charge decay performance. This integration supports centralized remote monitoring and quality control within Industry 4.0 frameworks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager