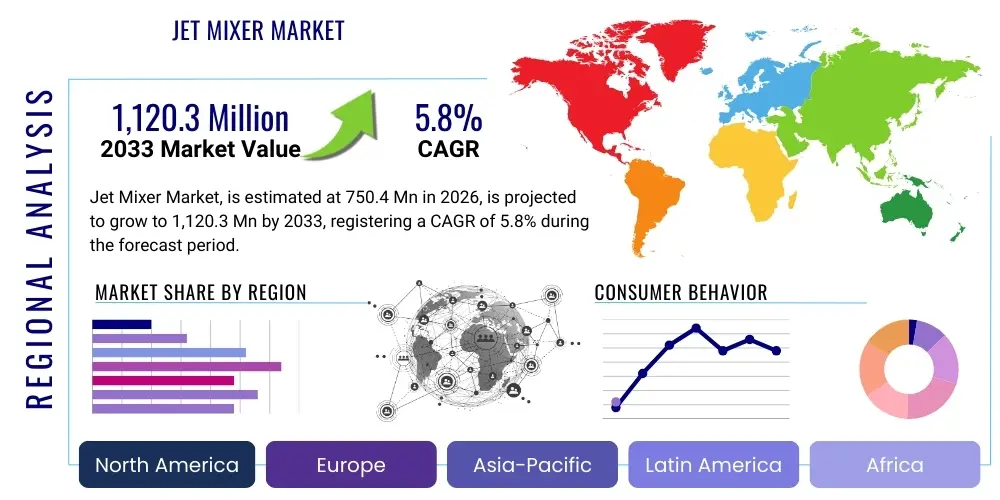

Jet Mixer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441698 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Jet Mixer Market Size

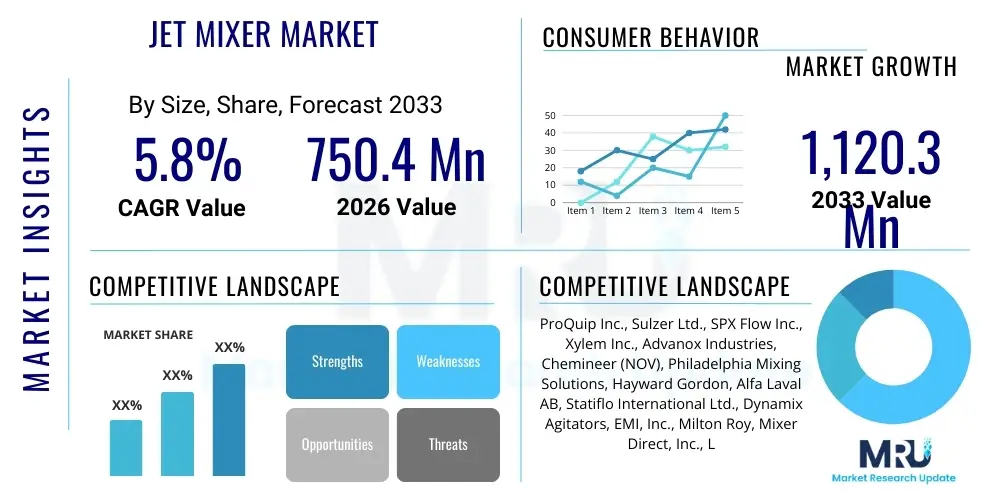

The Jet Mixer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 750.4 million in 2026 and is projected to reach USD 1,120.3 million by the end of the forecast period in 2033.

Jet Mixer Market introduction

The Jet Mixer Market encompasses the global trade of high-efficiency mixing equipment designed to achieve homogenization, dispersion, and suspension through the generation of high-velocity fluid jets. These mixers utilize principles of kinetic energy transfer, where a pump drives the fluid through one or more specialized nozzles, creating powerful jets that induce intense circulation and turbulence within the vessel. This method is highly effective for applications requiring rapid blending, tank cleaning, or maintaining solids in suspension, often proving more energy-efficient and maintenance-friendly than traditional mechanical agitators, particularly in large tanks or processes involving hazardous materials. The primary applications span crucial industrial sectors, including chemical processing, pharmaceuticals, food and beverage manufacturing, and municipal and industrial wastewater treatment, where consistency and throughput are critical operational metrics.

Jet mixers offer distinct operational benefits, suchiling the elimination of moving parts inside the tank, which significantly reduces the risk of seal failure and contamination, thereby lowering maintenance overheads and enhancing process integrity, especially important in sterile or sensitive environments. The ability to install these units externally or semi-submerged allows for easier servicing and retrofit into existing infrastructure without lengthy downtime. The market's growth is fundamentally driven by the escalating demand for sustainable and efficient mixing solutions across the process industries, coupled with stringent regulatory standards governing product quality and environmental compliance. Furthermore, the rising adoption of sophisticated fluid dynamics modeling (CFD) aids manufacturers in designing optimized jet mixer configurations tailored to specific rheological challenges, broadening their applicability in complex industrial workflows.

Jet Mixer Market Executive Summary

The global Jet Mixer Market is experiencing robust growth driven by accelerating industrialization in emerging economies and the imperative for operational efficiency improvements across established process industries. Current business trends indicate a strong pivot toward modular, skid-mounted jet mixing systems that facilitate rapid deployment and scalability, particularly favored by contract manufacturing organizations (CMOs) in the pharmaceutical and specialty chemical sectors. Technology advancements are focusing on integrating smart sensors and remote monitoring capabilities into jet mixer systems, aligning with Industry 4.0 principles, to provide real-time performance data, predictive maintenance alerts, and optimized energy consumption profiles. This integration enhances system reliability and reduces total cost of ownership, making modern jet mixers a highly compelling investment.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market segment, fueled by massive investments in infrastructure development, rapid expansion of the chemical and petrochemical industries, and increasing emphasis on advanced wastewater treatment facilities in countries like China and India. North America and Europe, while mature, maintain significant market share, characterized by high adoption rates of sophisticated, high-pressure jet mixing solutions and a strong regulatory push towards sustainable industrial practices. Segment trends reveal that the Submersible Jet Mixer category is gaining traction due to its ease of installation and suitability for large-volume municipal applications, while the Chemical Processing and Water Treatment sectors remain the dominant end-users, continually requiring reliable and powerful mixing capabilities for handling high-viscosity and high-solids media.

AI Impact Analysis on Jet Mixer Market

User inquiries regarding AI's influence on the Jet Mixer Market primarily center on predictive maintenance schedules, optimization of mixing cycles, and the potential for autonomous control systems. Key concerns often revolve around whether AI algorithms can effectively model complex, non-Newtonian fluid behaviors accurately enough to justify full system automation, and the required investment in sensor infrastructure and data processing capabilities. Users are highly interested in how AI can minimize energy wastage during mixing processes, especially for batch operations where parameters frequently change. The overriding expectation is that AI integration will transform jet mixing from a process optimized through empirical testing to one managed via highly precise, data-driven real-time adjustments, ultimately leading to superior product consistency and reduced operational expenditure.

The implementation of Artificial Intelligence and Machine Learning (ML) algorithms is poised to revolutionize the operation and maintenance lifecycle of jet mixing equipment. AI-driven predictive maintenance utilizes historical operational data, vibration analysis, and motor current signatures to forecast potential mechanical failures, allowing operators to schedule maintenance precisely before catastrophic failure occurs. This capability dramatically improves uptime and extends the lifespan of expensive components, directly addressing major operational restraints in large-scale continuous processes. Furthermore, ML models can ingest real-time fluid property data—such as viscosity, temperature, and concentration gradients—to dynamically adjust pump speed, nozzle configuration, and mixing duration. This precision control ensures that the minimum energy required is expended to achieve the desired homogeneity, leading to substantial energy savings compared to static, pre-programmed operating protocols.

Beyond maintenance and efficiency, AI contributes significantly to process optimization by enabling digital twinning of the mixing vessel. Computational Fluid Dynamics (CFD) models, augmented by ML, can accurately simulate the impact of various jet configurations and operating conditions on mixing effectiveness, identifying dead zones or insufficient circulation points before physical trials. This virtual testing environment drastically accelerates research and development cycles for new mixing applications and allows end-users to fine-tune existing systems without expensive, time-consuming physical experimentation. The impact moves the market toward highly customized, performance-guaranteed solutions, increasing the technical barriers to entry and favoring manufacturers who invest heavily in sophisticated software and integration capabilities.

- AI-driven Predictive Maintenance: Reduces unplanned downtime and operational costs by forecasting equipment failure.

- Dynamic Mixing Optimization: Adjusts jet parameters (pressure, flow) in real-time based on fluid property analysis, maximizing energy efficiency.

- Digital Twinning & Simulation: AI-enhanced CFD models accelerate R&D and process validation by accurately predicting mixing performance.

- Autonomous Control Systems: Enables self-regulating jet mixer operations, maintaining desired product quality metrics without manual intervention.

- Enhanced Data Analytics: Processes sensor data to provide deeper insights into fluid behavior and energy consumption patterns.

DRO & Impact Forces Of Jet Mixer Market

The Jet Mixer Market is significantly driven by stringent global environmental regulations mandating efficient treatment of industrial and municipal wastewater, where jet mixers are indispensable for sludge conditioning and chemical equalization basins. Furthermore, the expanding pharmaceutical and biotechnology sectors demand high-purity, scalable mixing solutions that minimize contamination risks, capabilities inherent to jet mixing technology due to the absence of in-tank seals and shafts. However, the market faces considerable restraints, notably the relatively high initial capital investment required for high-pressure pumping systems and specialized nozzle assemblies compared to conventional impeller mixers. Additionally, the effectiveness of jet mixers can be severely hampered in extremely high-viscosity or highly shear-sensitive applications, limiting penetration into certain specialized chemical or food processing segments.

Key opportunities within the market are predominantly tied to technological advancements and geographic expansion. The development of advanced materials, such as specialized polymers and corrosion-resistant alloys, is enabling jet mixers to operate effectively in highly aggressive chemical environments, opening up opportunities in specialized chemical manufacturing and mining. Furthermore, the growing trend toward decentralized wastewater treatment systems in developing regions presents a fertile ground for market penetration, as jet mixers offer compact, low-maintenance solutions suitable for remote or modular plants. Manufacturers are also focusing on offering integrated mixing packages, including pumping units, controls, and ancillary components, simplifying procurement and installation for end-users.

The impact forces influencing the market trajectory are multifaceted. The pervasive force of industrial automation (Industry 4.0) necessitates jet mixers that are easily integrated into plant-wide control systems, driving demand for smart, connected equipment. The competitive intensity among manufacturers forces continuous innovation in nozzle design and fluid dynamics modeling to achieve higher mixing efficiency and lower energy footprints, establishing efficiency as a critical purchasing criterion. Moreover, fluctuating raw material costs, particularly for stainless steel and specialized alloys used in construction, exert inflationary pressure on pricing, forcing manufacturers to optimize their supply chains and manufacturing processes to maintain competitive pricing structures while ensuring superior product durability and performance.

Segmentation Analysis

The Jet Mixer Market segmentation provides a granular understanding of the diverse application landscape and technological variations that define the industry structure. Key segments are analyzed based on the type of installation, the operating mechanism, the material of construction, and the specific end-use application. Understanding these segments is crucial for manufacturers to tailor their product offerings, sales strategies, and R&D investments toward areas exhibiting the highest growth potential or requiring specialized technical expertise. The market shows distinct demand patterns across segments; for instance, submersible units dominate municipal applications due to ease of handling, while top-entry units are preferred in highly controlled environments like pharmaceutical processing.

Detailed analysis of the market segments indicates that the chemical processing segment holds the largest revenue share, primarily due to the constant need for mixing large volumes of aggressive chemicals under various temperature and pressure conditions. Conversely, the Food and Beverage segment is anticipated to witness the highest growth rate, driven by increasing focus on hygienic mixing solutions and the expansion of continuous processing lines. Technologically, the segment based on the Operating Principle, particularly Venturi Jet Mixers, is expected to see increased adoption owing to their superior performance in gas dispersion and liquid-liquid extraction processes. This segmented view allows stakeholders to identify niche opportunities, such as compact jet mixers for laboratory scale or specialized high-shear systems for complex nano-suspension manufacturing.

- By Type:

- Submersible Jet Mixers

- Side-Entry Jet Mixers

- Top-Entry Jet Mixers

- By Operating Principle:

- Venturi Jet Mixers (Eductors)

- High-Impact Nozzle Systems

- Circulating Tank Mixers

- By Material of Construction:

- Stainless Steel (304, 316L)

- Specialty Alloys (Hastelloy, Titanium)

- Plastics and Polymers (FRP, PVC)

- By Application:

- Chemical Processing

- Pharmaceutical & Biotechnology

- Food & Beverage

- Water and Wastewater Treatment

- Pulp and Paper

- Oil & Gas

Value Chain Analysis For Jet Mixer Market

The value chain for the Jet Mixer Market begins with upstream activities involving the sourcing of raw materials, primarily specialized metals like stainless steel (316L for corrosion resistance) and high-performance alloys. Key upstream challenges include managing price volatility and securing reliable supply chains for critical components such as high-precision pumps, nozzles, and sophisticated sealing mechanisms, especially those required for high-pressure or sanitary applications. Manufacturers often engage in strategic partnerships with specialized pump suppliers to ensure the integration of high-efficiency fluid delivery systems, which are foundational to the jet mixer's performance. Quality control and material certification at this stage are paramount, particularly for equipment destined for regulated industries like pharmaceuticals.

The midstream activities encompass the core manufacturing processes, including precision machining of nozzles, fabrication of the tank shell and mounting hardware, and the assembly and testing of the final mixing system. Optimization of this phase involves advanced manufacturing techniques, such as additive manufacturing for complex nozzle geometries and rigorous computational fluid dynamics (CFD) modeling during the design phase to validate performance before physical prototyping. The distribution channel is bifurcated into direct sales and indirect channels. Direct distribution is common for large, customized, and high-value industrial projects, allowing manufacturers to provide specialized technical consultation and post-installation support directly to the end-user. Indirect channels, involving authorized distributors, system integrators, and engineering, procurement, and construction (EPC) firms, dominate sales for standard units and regional market penetration, leveraging local expertise and inventory.

Downstream activities center on installation, commissioning, maintenance, and aftermarket services. The profitability of the value chain is increasingly shifting toward these service segments, as sophisticated jet mixers require expert technical assistance for optimal operation and longevity. Direct engagement with end-users through service contracts ensures optimal performance and provides manufacturers with invaluable feedback for future product iterations. Potential customers rely heavily on the manufacturer's ability to provide comprehensive training and readily available spare parts, particularly high-wear items like pump impellers and gaskets, solidifying the importance of a robust, service-oriented distribution network that can rapidly address operational issues globally.

Jet Mixer Market Potential Customers

The primary customers for jet mixing technology are large-scale industrial operators and utility providers whose core processes rely on efficient fluid management, blending, or solid suspension. In the chemical sector, potential buyers include petrochemical refineries, polymer manufacturers, and specialty chemical producers who require mixers capable of handling corrosive or hazardous media safely and reliably. These customers prioritize equipment longevity, process scalability, and adherence to strict safety standards, often necessitating mixers built from exotic materials or featuring explosion-proof certifications. The complexity of their processes often leads them to seek highly customized mixing solutions rather than off-the-shelf products, focusing on total lifecycle costs and operational guarantees.

Another significant group of potential customers resides in the municipal and industrial water and wastewater treatment sectors. Municipalities and large industrial parks utilize jet mixers extensively in equalization basins, anaerobic digesters, and sludge storage tanks to maintain homogeneity, prevent sedimentation, and optimize chemical dosing. For these buyers, key considerations include low maintenance requirements, high energy efficiency for continuous operation, and robustness against abrasive materials or high solid content. The demand here is driven by population growth and increasing regulatory oversight regarding effluent quality, spurring consistent investment in upgrading and expanding existing treatment infrastructure to handle larger volumes efficiently.

The pharmaceutical and biotechnology industries represent a high-value customer segment, focusing on sterile environments and precise scalability. Companies involved in vaccine production, fermentation, and buffer preparation require sanitary-designed jet mixers (often 316L stainless steel with high surface finish) that can assure gentle but effective mixing while meeting strict Good Manufacturing Practices (GMP) and cleanability requirements (CIP/SIP compatibility). These customers value technical documentation, validation support, and systems that minimize shear stress to protect sensitive biological components. Their purchasing decisions are heavily influenced by the ability of the jet mixer to integrate seamlessly into validated production lines and maintain rigorous batch-to-batch consistency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 750.4 Million |

| Market Forecast in 2033 | USD 1,120.3 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ProQuip Inc., Sulzer Ltd., SPX Flow Inc., Xylem Inc., Advanox Industries, Chemineer (NOV), Philadelphia Mixing Solutions, Hayward Gordon, Alfa Laval AB, Statiflo International Ltd., Dynamix Agitators, EMI, Inc., Milton Roy, Mixer Direct, Inc., Lightnin (SPX Flow). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Jet Mixer Market Key Technology Landscape

The technological landscape of the Jet Mixer Market is fundamentally characterized by advancements in fluid dynamics modeling, nozzle design optimization, and materials science. The core innovation lies in leveraging Computational Fluid Dynamics (CFD) to accurately simulate complex flow patterns and optimize jet trajectory and velocity within diverse tank geometries. Modern jet mixer manufacturers utilize sophisticated CFD software to minimize energy consumption while ensuring maximum volumetric coverage and eliminating dead zones, a capability essential for guaranteeing product homogeneity and process consistency, particularly in large-scale reactors and storage vessels. This data-driven approach allows for the creation of application-specific nozzle arrays, moving away from generic designs to highly efficient, custom-engineered solutions that meet exacting performance standards.

A critical technology trend involves the transition toward smarter, connected mixing systems, driven by the principles of the Industrial Internet of Things (IIoT). Modern jet mixers are increasingly equipped with integrated sensors that monitor operational parameters such as pump vibration, motor temperature, power draw, and even in-situ process conditions like fluid velocity near the nozzle or sediment depth. This real-time data is essential for implementing the aforementioned AI-driven predictive maintenance programs and for enabling remote diagnostic capabilities, which significantly reduces the need for physical inspections and improves safety in hazardous environments. The integration of Variable Frequency Drives (VFDs) with advanced control logic also allows operators to dynamically adjust mixing intensity based on the stage of the batch process, ensuring energy is only expended when required for critical mixing tasks.

Furthermore, innovation in material science is expanding the operational envelope of jet mixers. The use of highly corrosion-resistant materials, such as Duplex stainless steels, specific high-nickel alloys (e.g., Hastelloy C-276), and specialized composite materials, enables jet mixers to withstand extremely acidic, caustic, or abrasive media found in mining, chemical incineration, and demanding polymer production processes. The development of specialized coatings and non-metallic linings for the wetted parts ensures chemical inertness and minimizes the risk of product contamination, a non-negotiable requirement for high-purity sectors. These material innovations are crucial for extending equipment lifespan and reducing lifecycle costs, reinforcing the jet mixer's position as a reliable, long-term mixing solution across harsh industrial environments.

Regional Highlights

- North America (NA): This region represents a mature yet highly lucrative market segment, characterized by stringent environmental regulations, particularly concerning municipal and industrial wastewater treatment (driven by EPA standards). High adoption rates are seen in the pharmaceutical and chemical sectors, which demand high-specification, customized jet mixing solutions integrated with sophisticated automation systems. The presence of major industry players and substantial R&D investment ensures continuous technological advancement and a strong preference for durable, high-efficiency equipment.

- Europe: Europe maintains a strong market presence, propelled by the robust specialty chemical manufacturing base in countries like Germany and the strict enforcement of EU directives on industrial emissions and water quality. Emphasis here is placed on energy efficiency, reflected in high demand for VFD-controlled jet mixers and systems designed for minimal carbon footprint. Western European countries are rapidly adopting IIoT capabilities for asset performance management of their installed jet mixer base.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, driven by rapid industrial expansion, urbanization, and critical infrastructure development, particularly in China, India, and Southeast Asia. Massive investments in water infrastructure and the relocation of chemical and pharmaceutical manufacturing bases to the region are fueling demand for cost-effective, scalable jet mixing solutions. While price sensitivity is present, the growing complexity of industrial effluent requires increasingly sophisticated jet mixer technology.

- Latin America (LATAM): Growth in LATAM is primarily linked to the resource extraction industries (Oil & Gas, Mining) and the expansion of the food and beverage sector. Demand for jet mixers supports processes like slurry handling, oil blending, and fermentation. Market adoption is gradual but steady, often contingent on large-scale infrastructure projects and foreign direct investment in processing plants.

- Middle East and Africa (MEA): The MEA region's market dynamics are heavily influenced by large petrochemical projects, desalination plants, and water reuse initiatives, especially in the Gulf Cooperation Council (GCC) countries. Jet mixers are critical for brine dilution and large-scale chemical blending operations. Investments are high-value but concentrated in specific industrial hubs, demanding extreme corrosion resistance due to challenging operational climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Jet Mixer Market.- ProQuip Inc.

- Sulzer Ltd.

- SPX Flow Inc.

- Xylem Inc.

- Advanox Industries

- Chemineer (NOV)

- Philadelphia Mixing Solutions

- Hayward Gordon

- Alfa Laval AB

- Statiflo International Ltd.

- Dynamix Agitators

- EMI, Inc.

- Milton Roy

- Mixer Direct, Inc.

- Lightnin (SPX Flow)

- Ekato Group

- MixMor

- Pulsair Systems, Inc.

- Indco, Inc.

- Sharpe Mixers

Frequently Asked Questions

Analyze common user questions about the Jet Mixer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary operational advantages of jet mixers over traditional mechanical agitators?

Jet mixers offer superior advantages including zero in-tank moving parts, which eliminates seal failure risks, reduces maintenance costs, and prevents product contamination. They provide highly effective mixing and solids suspension in very large or deep tanks, often with greater energy efficiency than conventional top-entry impeller systems, particularly in non-shear-sensitive applications.

Which industrial sectors are the largest consumers of jet mixing technology?

The largest consuming sectors are Water and Wastewater Treatment (for sludge conditioning and equalization), Chemical Processing (for blending and dilution of aggressive media), and the Pharmaceutical/Biotechnology industry, where jet mixers are valued for their hygienic design and ability to ensure rigorous batch uniformity without compromising product purity.

How is the efficiency of a jet mixer system typically measured and optimized?

Efficiency is measured by assessing the power required versus the achieved degree of homogeneity (uniformity) or the Critical Suspension Velocity (Cs) required to lift solids off the tank bottom. Optimization is achieved through Computational Fluid Dynamics (CFD) modeling of nozzle placement and design, coupled with real-time adjustments via Variable Frequency Drives (VFDs) to match mixing energy expenditure precisely to the process requirements.

What key factors influence the selection of a jet mixer based on material construction?

Selection is primarily determined by the corrosivity and temperature of the fluid being mixed. Standard selection defaults to Stainless Steel (316L) for most sanitary and general chemical applications. For highly aggressive chemicals (acids/bases) or high-temperature environments, specialized materials like Hastelloy, Titanium, or high-performance plastics are required to ensure long-term equipment integrity and prevent process contamination.

What role does Artificial Intelligence (AI) play in modern jet mixer operation and maintenance?

AI plays a crucial role in enabling predictive maintenance by analyzing sensor data to anticipate pump or nozzle failure, maximizing uptime. Furthermore, AI algorithms are used for dynamic process optimization, adjusting pump flow rates in real-time based on fluid property changes to ensure consistent mixing quality while minimizing overall energy consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager