KCL Buffer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441584 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

KCL Buffer Market Size

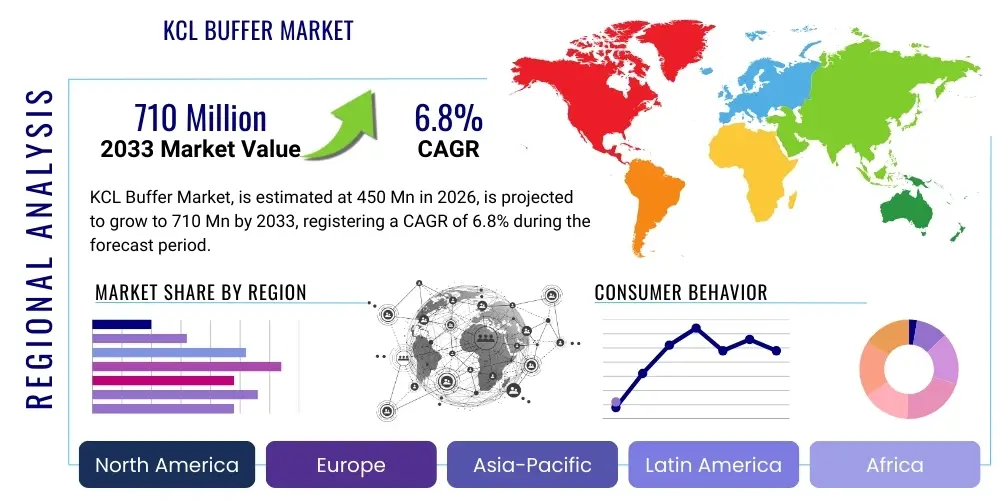

The KCL Buffer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $450 Million in 2026 and is projected to reach $710 Million by the end of the forecast period in 2033.

KCL Buffer Market introduction

KCL Buffer solutions, primarily comprised of potassium chloride dissolved in a solvent, often deionized water, serve as essential reagents across various scientific and industrial applications, most notably in electrochemistry. Their primary function is to maintain ionic strength and ensure electrical conductivity, particularly critical for the accurate functioning of pH electrodes and conductivity meters. These solutions are fundamental calibration standards, providing stability and reliability required for precise analytical measurements, which are indispensable in quality control within the chemical, pharmaceutical, and environmental monitoring sectors. The market encompasses a range of purity grades and concentrations tailored for specific technical requirements, from basic laboratory research to highly regulated industrial processes.

The core product in this market is the KCL storage and filling solution utilized for electrochemical sensors, such as reference electrodes. The efficacy of a pH electrode is heavily dependent on maintaining the hydration and ionic environment of its internal reference element, which KCL solutions provide. Furthermore, KCL buffers are vital components in specific biological and diagnostic assays where maintaining osmotic balance or serving as a background electrolyte is crucial. The high demand stemming from routine maintenance and calibration schedules across thousands of laboratories globally ensures a stable foundational market base for KCL buffers.

Driving factors for sustained market growth include stringent regulatory standards mandating frequent instrument calibration, particularly in pharmaceutical manufacturing (cGMP environments) and environmental testing. The continuous expansion of biotechnology and clinical diagnostics, which rely heavily on precise electrochemical measurements for sample analysis, further fuels demand. Moreover, advancements in sensor technology require increasingly high-purity and specialized buffer formulations, prompting innovation among manufacturers to meet these demanding specifications. The inherent need for consumable replacement, given the limited lifespan of reference solutions post-opening, sustains consistent market revenue flow.

KCL Buffer Market Executive Summary

The KCL Buffer market exhibits robust growth driven by accelerating demand in the pharmaceutical and biotechnology sectors, coupled with expanding environmental monitoring requirements worldwide. Business trends indicate a focus on developing ultra-high purity KCL solutions and ready-to-use calibration kits, streamlining laboratory workflows and enhancing measurement accuracy. Strategic partnerships between buffer manufacturers and instrument providers (e.g., pH meter manufacturers) are becoming prevalent to offer integrated solutions, enhancing market penetration and brand loyalty. Additionally, manufacturers are increasingly addressing sustainability concerns by offering bulk packaging and minimizing solvent waste, reflecting broader corporate responsibility trends.

Regional trends highlight North America and Europe as dominant markets, primarily due to established pharmaceutical industries and rigorous regulatory frameworks demanding frequent calibration and quality assurance. However, the Asia Pacific region, particularly China and India, is emerging as the fastest-growing market. This accelerated growth is attributed to massive investments in regional biotechnology research, expanding clinical diagnostic capabilities, and rapid industrialization requiring enhanced quality control measures. Specific challenges in emerging markets relate to establishing consistent cold-chain logistics for sensitive reagents, though localized production is mitigating some of these constraints.

Segmentation trends reveal strong growth in the High Concentration KCL buffer segment, often used in specialized ion-selective electrodes (ISEs) and industrial processes requiring high ionic strength stability. The USP Grade segment is experiencing disproportionately high revenue growth, directly correlated with the expansion of cGMP-compliant pharmaceutical production globally, where regulatory compliance necessitates the use of certified reagents. End-user demand is shifting towards sophisticated, pre-standardized buffer solutions that minimize preparation errors, thereby favoring premium product offerings. The adoption of automated liquid handling systems in large laboratories also dictates a preference for readily accessible, high-volume buffer supplies, influencing packaging and distribution channel strategies.

AI Impact Analysis on KCL Buffer Market

Common user questions regarding AI's impact on the KCL Buffer market primarily revolve around optimizing manufacturing processes, enhancing quality control accuracy, and predicting demand fluctuations. Users are concerned about how AI can ensure the highest levels of purity and consistency in batch production, given the critical role buffers play in highly sensitive measurements. Furthermore, inquiries focus on AI's potential in automating inventory management for laboratories and suppliers, minimizing waste, and reducing the incidence of using expired or improperly stored buffers. There is also significant interest in leveraging machine learning to analyze electrochemical data sets, potentially reducing the frequency of recalibration needed, which could subtly impact buffer consumption rates but improve overall laboratory efficiency and compliance reliability.

The primary influence of Artificial Intelligence (AI) in the KCL Buffer market manifests through operational efficiency improvements rather than direct product transformation. AI algorithms can be deployed in the manufacturing plant to monitor real-time synthesis parameters—such as mixing speed, temperature, and raw material purity—to predict and prevent batch deviations, ensuring unparalleled consistency across production runs. This leads to reduced waste and higher yield rates for specialized, high-purity grades required by pharmaceutical clients. Predictive maintenance schedules for complex purification and packaging machinery, managed by AI, minimize downtime and maintain a stable supply chain, which is critical for supporting large-scale end-users.

In the end-user environment, AI-driven laboratory information management systems (LIMS) utilize predictive analytics to forecast KCL buffer consumption based on scheduled testing volumes and calibration frequency history. This optimization ensures that laboratories maintain optimal stock levels, avoiding costly rush orders or the disposal of expired stock, enhancing financial and operational sustainability. Moreover, in advanced R&D settings, machine learning models analyze complex electrochemical data to optimize experimental conditions and potentially discover novel, more stable buffer compositions, although the fundamental chemistry of KCL remains largely stable and standardized. This integration facilitates a shift towards smarter, data-driven quality assurance practices across the analytical industry.

- AI-driven Quality Control: Enhanced real-time monitoring of batch consistency and purity during manufacturing, minimizing regulatory risks associated with reagent variability.

- Predictive Inventory Management: AI algorithms optimize supply chain logistics and laboratory stock levels, forecasting demand to reduce waste and ensure timely supply.

- Automated Calibration Systems: Integration of AI into analytical instruments to optimize calibration frequency, potentially extending the useful life of a buffer solution based on environmental and measurement drift data.

- Process Optimization: Machine learning models improve manufacturing energy efficiency and reduce operational costs associated with high-purity water production and mixing processes.

- R&D Acceleration: AI assists in analyzing performance data of various buffer formulations under stress conditions, accelerating the development of highly stable and specialized electrochemical reagents.

- Error Reduction: Utilization of AI in automated laboratory systems (robotics) ensures precise handling and dispensing of KCL buffers, minimizing human error in critical applications.

DRO & Impact Forces Of KCL Buffer Market

The dynamics of the KCL Buffer market are shaped by compelling drivers related to industrial growth and regulatory compliance, while simultaneously facing constraints concerning product stability and competitive intensity. The key drivers include the global expansion of pharmaceutical R&D, stringent quality control mandates across food and beverage safety, and increasing regulatory enforcement in environmental monitoring, all necessitating reliable calibration standards. Opportunities lie in the development of specialized, non-contaminating, and extended shelf-life buffer solutions, particularly for high-throughput automated systems. Conversely, restraints involve the commodity nature of basic KCL solutions leading to price sensitivity, the logistical challenges of ensuring long-term solution stability, and the environmental impact associated with chemical waste disposal.

The primary impact forces acting on this market include technological substitution pressure, particularly from advanced solid-state sensors that may require less frequent external calibration, and the stringent regulatory environment (e.g., FDA, EMA) which dictates usage and handling standards, thus controlling consumption patterns and acceptable quality metrics. Furthermore, the competitive rivalry among established chemical suppliers and localized reagent manufacturers exerts downward pressure on pricing, especially for generic KCL concentrations. The bargaining power of large pharmaceutical and clinical lab procurement groups is significant, demanding high-volume supply contracts at competitive rates and requiring robust certification documentation, driving continuous improvements in supply chain transparency and quality assurance practices.

Specific market drivers contributing to expansion involve the rising global prevalence of chronic diseases, spurring demand for clinical diagnostics that often rely on electrochemical measurements standardized by KCL solutions. Similarly, the growing complexity of water and wastewater treatment processes requires constant pH and conductivity checks, creating a perpetual market for these consumable reagents. Opportunities are also being realized through customizing buffers for novel applications, such as specialized forensic testing or niche industrial battery electrolytes, opening up higher-margin specialized segments. The impact of raw material cost volatility, especially high-purity potassium chloride, presents an ongoing operational challenge that necessitates sophisticated supply chain risk management strategies to maintain stable pricing structures for end-users.

Segmentation Analysis

The KCL Buffer market is systematically segmented based on various technical and commercial parameters, including the buffer concentration, the purity grade, the specific application, and the final end-user industry. Concentration segments differentiate between standard 3M and 4M solutions used widely for pH electrode filling and storage, and lower concentration solutions used for calibration or conductivity reference. Purity grade is crucial, distinguishing between cost-effective technical grades for general industrial use and highly certified USP/EP (United States Pharmacopeia/European Pharmacopeia) grades essential for regulated environments where zero contamination is paramount. Analyzing these segments helps manufacturers tailor marketing strategies and product portfolios to specific regulatory and technical customer needs, ensuring optimal market penetration and specialized value proposition delivery.

- By Concentration:

- Standard (3M/4M): Most commonly used for reference electrode filling and storage, optimizing ionic strength for longevity.

- Low Concentration (<1M): Used primarily for conductivity calibration standards and specific low-ionic-strength electrochemical applications.

- High Concentration (>4M): Specialized use in unique high-precision ISEs or high-salt matrix sample analysis.

- By Grade:

- Technical Grade: Suitable for general industrial, educational, and less stringent quality control processes.

- USP/EP Grade: Mandated for pharmaceutical production, biotechnology, and clinical diagnostics, requiring high certification and purity standards.

- ACS Grade: Used in higher-level academic research and analytical chemistry laboratories, offering verified quality.

- By Application:

- pH Electrode Filling and Storage: Core application ensuring the functional integrity and lifespan of pH sensors.

- Conductivity Calibration: Used as reference standards to verify the accuracy of conductivity meters.

- Reference Electrode Preparation: Essential for creating liquid junction potentials in various electrochemical setups.

- Biological Assays: Employed in specific media to maintain osmotic balance or serve as inert background electrolytes.

- By End-User:

- Pharmaceutical & Biotechnology: Largest consumer due to strict cGMP requirements for quality testing and R&D.

- Chemical and Petrochemical Industry: Routine quality control and process monitoring applications.

- Academic and Research Institutes: High volume of general laboratory experimentation and scientific studies.

- Environmental Testing and Monitoring: Water quality analysis, pollution control, and regulatory compliance checks.

- Clinical and Diagnostic Laboratories: Calibration and maintenance of diagnostic electrochemical equipment.

Value Chain Analysis For KCL Buffer Market

The KCL Buffer market value chain commences with the sourcing of ultra-pure raw materials, primarily high-grade potassium chloride salts and purified solvents, typically deionized or distilled water. Upstream activities focus intensely on material certification, ensuring raw potassium chloride meets stringent purity specifications (e.g., heavy metal content limitations) critical for producing USP or ACS grade buffers. Manufacturers often negotiate long-term contracts with specialized chemical producers to ensure a stable supply of certified materials, as raw material purity directly dictates the final product quality and, consequently, its ability to meet regulatory standards required by pharmaceutical end-users. Quality verification at this stage is a key competitive differentiator.

The transformation phase involves highly controlled manufacturing processes, including precise weighing, complex mixing under validated conditions, and multiple stages of filtration to remove particulate matter. Quality assurance (QA) protocols are integrated throughout the manufacturing line, involving rigorous testing for pH stability, conductivity, and ionic strength before packaging. Packaging operations, which fall under the direct channel, are optimized for stability, utilizing specialized, non-leaching plastic or glass containers to maintain solution integrity over extended shelf life. For the indirect channel, large distributors often purchase in bulk, requiring robust, standardized labeling and documentation for international shipping and regulatory adherence across different jurisdictions.

Downstream activities involve complex distribution networks. Direct sales channels are frequently employed for large pharmaceutical or industrial clients who require customized formulations, bulk volumes, and direct technical support from the manufacturer. Indirect channels, utilizing specialized chemical distributors, laboratory supply houses (such as Fisher Scientific or VWR), and e-commerce platforms, manage the vast majority of sales to smaller laboratories, academic institutions, and international markets. Effective distribution relies on maintaining inventory across strategic global hubs and ensuring rapid fulfillment, as buffer solutions are consumable, routine purchases critical to continuous laboratory operations. Sales and marketing efforts emphasize regulatory compliance documentation, product stability data, and competitive pricing strategies targeting routine procurement cycles.

KCL Buffer Market Potential Customers

Potential customers for KCL Buffer solutions span the entirety of the analytical and bio-scientific community, characterized by any organization reliant on precise electrochemical measurement, primarily pH and conductivity analysis. The largest and most lucrative segment consists of pharmaceutical and biotechnology firms, driven by mandatory quality control checks (e.g., verifying media pH in bioreactors, testing drug stability) and extensive R&D activities. These customers require high-volume, certified (USP/EP) solutions and often purchase based on technical compliance and long-term supplier reliability rather than merely price, making them highly valued accounts requiring detailed technical support and audited supply chain verification.

Another significant customer base includes academic and government research institutions, ranging from university chemistry departments to national environmental agencies. While generally more price-sensitive than the pharmaceutical industry, these customers maintain a consistent, high-volume demand for a wider range of grades (ACS and technical) necessary for diverse experimental setups, educational purposes, and publicly funded environmental monitoring projects. Clinical diagnostic laboratories, which utilize automated analyzers for blood gas and electrolyte measurements, represent a rapidly expanding customer segment. These labs demand pre-packaged, ready-to-use, and highly stable buffers integrated into diagnostic kits or calibration routines, emphasizing ease of use and long-term stability.

Furthermore, various industrial sectors constitute a stable customer base, including chemical processing plants, food and beverage manufacturers, and municipal water treatment facilities. In these settings, KCL buffers are essential for routine process optimization, regulatory compliance regarding effluent quality, and ensuring product safety (e.g., verifying fermentation pH, testing purity of chemical intermediates). These industrial customers prioritize stability in challenging operational environments and often purchase bulk volumes to support continuous, 24/7 monitoring systems, making the robustness of the packaging and ease of integration into industrial monitoring equipment crucial purchase considerations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $710 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Merck KGaA (MilliporeSigma), Agilent Technologies, Hanna Instruments, Mettler Toledo, Cole-Parmer, HORIBA Scientific, Reagecon, GFS Chemicals, Ricca Chemical Company, Oakton Instruments, Metrohm AG, PanReac AppliChem, VWR International, Hach Company, WTW (Xylem Analytics), LaMotte Company, YSI (Xylem Analytics), Spectrum Chemical, Avantor (VWR). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

KCL Buffer Market Key Technology Landscape

The technology landscape for the KCL Buffer market is centered less on radical product invention and more on the refinement of manufacturing precision, quality assurance protocols, and delivery systems. Key technological advancements relate to the sophisticated purification of raw water components, utilizing multi-stage reverse osmosis and deionization techniques to achieve resistivity levels required for ultra-high purity grades. Furthermore, precision metrology equipment, including certified master pH meters and conductivity bridges traceable to national standards (e.g., NIST), is essential for certifying the accuracy and traceability of every manufactured batch. This emphasis on traceable certification is the core technological differentiator, ensuring the buffers meet the demanding requirements of cGMP environments.

Another crucial technological aspect involves packaging innovation designed to maximize solution stability and shelf life. This includes the use of inert materials, hermetically sealed containers, and specialized dosing nozzles that minimize atmospheric contamination (e.g., CO2 absorption, which affects pH buffers) during storage and use. The integration of RFID or barcode technology into packaging facilitates enhanced inventory tracking and compliance documentation, especially vital for laboratories operating under stringent ISO 17025 or FDA regulations. The technological focus is moving towards "smart buffers" where the packaging itself interacts with automated laboratory instruments, providing immediate verification of calibration data and lot traceability, further reducing manual transcription errors.

Finally, the manufacturing environment utilizes advanced process control systems to maintain tight control over mixing temperatures and atmospheric conditions, preventing inconsistencies that could compromise ionic strength or purity. High-speed, validated filtration systems (often using sub-micron filters) ensure the removal of all particulate matter, crucial for protecting sensitive electrode junctions. For high-volume production, continuous manufacturing techniques are sometimes employed, leveraging automation to scale production while maintaining stringent quality control checks at every stage, representing a significant capital investment in operational technology aimed at achieving both efficiency and uncompromised purity standards necessary to compete in the highly regulated segments of the market.

Regional Highlights

- North America: This region maintains the largest market share, driven by a robust and heavily regulated pharmaceutical and biotechnology industry, particularly in the United States. High expenditure on R&D, coupled with mandatory FDA compliance requiring regular use of certified calibration standards like KCL buffers, sustains consistent, high-value demand. The presence of major analytical instrument manufacturers who often bundle KCL solutions with their products further strengthens this market. The focus here is on high-purity, pre-certified USP grade buffers.

- Europe: The European market is mature and characterized by strong environmental and clinical testing requirements. Germany, Switzerland, and the UK are key contributors, driven by established chemical manufacturing sectors and stringent EU directives on water quality monitoring (Water Framework Directive). Demand emphasizes European Pharmacopoeia (EP) certified products. Regulatory harmonization across the EU facilitates easier distribution, but intense competition among local manufacturers demands competitive pricing and efficient supply chain management.

- Asia Pacific (APAC): APAC is the fastest-growing regional market, fueled by rapid expansion in India, China, and South Korea's biopharma sectors and increasing governmental focus on environmental quality control. While price sensitivity remains a factor in basic research and industrial applications, the increasing adoption of Western regulatory standards (like cGMP) by local drug manufacturers is dramatically boosting demand for high-ppurity, internationally certified KCL buffers. Localized manufacturing is gaining traction to reduce import costs and lead times.

- Latin America: This region presents moderate but steady growth, largely dependent on imported reagents. Key markets include Brazil and Mexico, where growth in chemical and food processing industries drives demand for technical-grade and standard KCL buffers for routine quality checks. Market challenges involve complex import regulations and currency volatility, making local partnerships essential for effective distribution and technical support.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) states, driven by investments in water desalination and petrochemical industries, requiring process monitoring and quality control using electrochemical sensors. Pharmaceutical production is an emerging consumer segment. The market is fragmented, highly reliant on international suppliers, and focuses mainly on industrial-grade buffers and basic analytical applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the KCL Buffer Market.- Thermo Fisher Scientific

- Merck KGaA (MilliporeSigma)

- Agilent Technologies

- Hanna Instruments

- Mettler Toledo

- Cole-Parmer

- HORIBA Scientific

- Reagecon

- GFS Chemicals

- Ricca Chemical Company

- Oakton Instruments

- Metrohm AG

- PanReac AppliChem

- VWR International

- Hach Company

- WTW (Xylem Analytics)

- LaMotte Company

- YSI (Xylem Analytics)

- Spectrum Chemical

- Avantor (VWR)

- Macherey-Nagel

- LGC Standards

- Restek Corporation

- Sartorius AG

- ELGA LabWater

Frequently Asked Questions

Analyze common user questions about the KCL Buffer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of KCL Buffer solutions in laboratory settings?

KCL Buffer solutions, particularly 3M or 4M potassium chloride, are essential for maintaining the required ionic strength and electrical conductivity within the reference electrode of pH meters and other electrochemical sensors. This ensures stable and accurate liquid junction potential, which is fundamental for reliable analytical measurements, promoting sensor longevity and precision.

Why is USP or EP Grade KCL Buffer required in the pharmaceutical industry?

USP (United States Pharmacopeia) or EP (European Pharmacopoeia) Grade KCL Buffers are mandatory in cGMP (current Good Manufacturing Practice) pharmaceutical environments because they guarantee minimum levels of impurities and validated consistency. Regulatory agencies mandate the use of certified reagents to ensure the reliability and traceability of quality control data, minimizing risk of contamination in drug production processes.

How does the shelf life and storage of KCL buffers impact their market consumption?

The shelf life, typically ranging from one to five years depending on the formulation and packaging, necessitates regular replacement, driving consistent consumable demand. Improper storage (e.g., exposure to air causing CO2 absorption) can degrade the solution's properties, requiring more frequent replacement, thus increasing consumption and reinforcing the need for controlled inventory management in end-user labs.

Which geographical region is expected to demonstrate the highest growth rate for KCL Buffers?

The Asia Pacific (APAC) region, led by China and India, is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This acceleration is attributed to massive government and private investment in biotechnology research, expansion of local drug manufacturing capabilities, and increasingly stringent environmental quality standards adopted across industrial sectors in the region.

What are the key differences between KCL filling solution and standard pH calibration buffers?

KCL filling solutions are high-concentration (typically 3M/4M) electrolytes used to maintain the internal reference element of an electrode. Standard pH calibration buffers (e.g., pH 4, 7, 10), conversely, are dilute, pH-adjusted solutions used to standardize the electrode response against known values. While both are critical consumables, KCL solutions focus on electrode maintenance, whereas pH buffers focus on measurement accuracy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager