Lab Grinders Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441703 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Lab Grinders Market Size

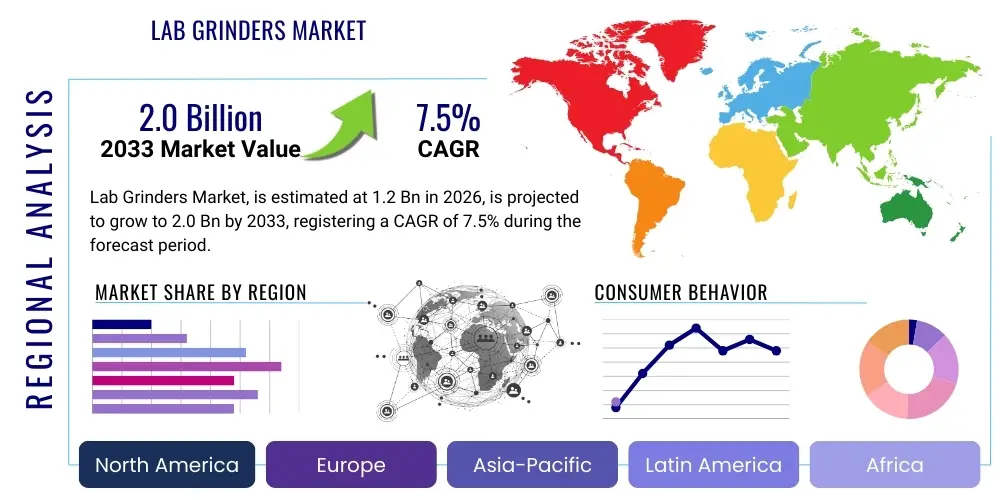

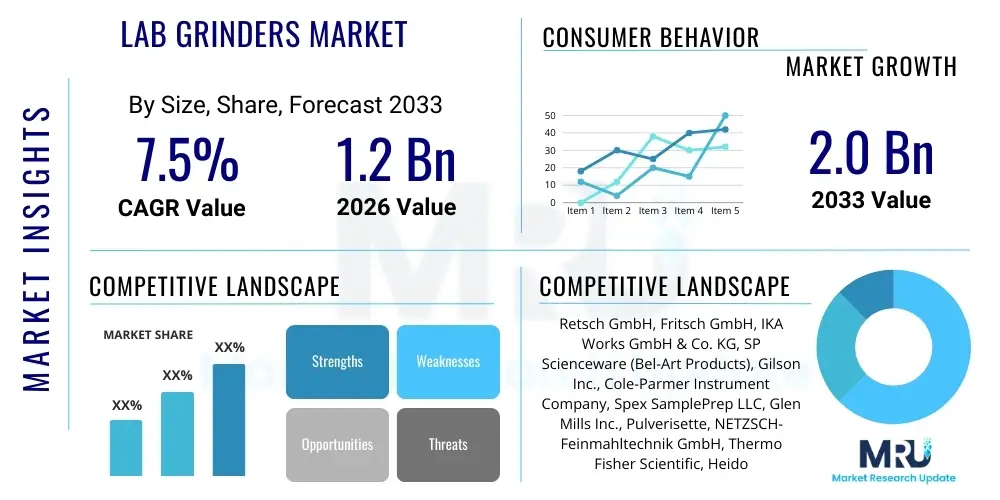

The Lab Grinders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $2.0 Billion by the end of the forecast period in 2033.

Lab Grinders Market introduction

The Lab Grinders Market encompasses the manufacturing, distribution, and utilization of specialized equipment designed for the mechanical reduction of particle size in laboratory settings. These devices are crucial for sample preparation across diverse scientific and industrial applications, including chemistry, material science, pharmaceuticals, biotechnology, geology, and environmental analysis. Product varieties range from simple mortar grinders and ball mills to advanced cutting, rotor, and cryogenic grinding systems, each optimized for specific sample types and required particle size distributions. The primary objective is to homogenize or comminute samples to ensure accurate, reproducible, and reliable downstream analysis, such as spectroscopy, chromatography, and microscopy.

Major applications of lab grinders include preparing biological tissues for DNA extraction, homogenizing pharmaceutical compounds for quality control testing, reducing geological cores for elemental analysis, and processing raw materials in R&D settings. The benefits of modern lab grinding technology are substantial, providing speed, precision, reduced contamination risk, and often the capability to process hard, brittle, elastic, or sensitive materials under controlled temperature conditions (e.g., cryo-grinding). These instruments are fundamental tools supporting research integrity and industrial process development globally.

The market is predominantly driven by the continuous expansion of R&D investment in life sciences, particularly in drug discovery and personalized medicine, coupled with increasingly stringent regulatory requirements for quality assurance in food safety and environmental testing. The growing demand for standardized sample preparation methodologies that ensure high throughput and minimize operator variability further fuels market growth. Furthermore, technological advancements leading to automated, multi-functional, and quieter grinding systems are enhancing operational efficiency and driving replacement demand across established scientific institutions.

Lab Grinders Market Executive Summary

The Lab Grinders Market exhibits robust business trends characterized by a shift towards high-throughput automation and specialized applications tailored for sensitive biological samples and nanotechnology research. Key market players are concentrating on developing intelligent grinders integrated with digital interfaces for protocol management and data logging, meeting the stringent requirements for traceability in regulated laboratories. There is a notable strategic focus on expanding product portfolios with cryo-grinding capabilities, essential for handling thermally sensitive materials, and planetary ball mills offering ultra-fine grinding capabilities crucial for advanced material science and battery research. Furthermore, sustainability initiatives are driving demand for energy-efficient models and consumables that minimize waste, reflecting broader corporate environmental responsibility goals across end-user industries.

Regionally, North America and Europe maintain dominance due to high levels of R&D expenditure, established infrastructure, and stringent quality control mandates in pharmaceutical and clinical sectors. However, the Asia Pacific (APAC) region is poised for the highest growth trajectory, propelled by massive government investment in scientific infrastructure, the rapid expansion of generic drug manufacturing hubs in countries like India and China, and increasing industrialization requiring enhanced quality testing capabilities. Latin America and MEA are showing steady, albeit slower, growth, driven primarily by investments in resource exploration (geology) and expanding academic research programs. Competitive intensity is high, requiring manufacturers to differentiate through superior application support and optimized service networks.

Segmentation trends indicate that ball mills and planetary grinders command a substantial share due to their versatility in processing hard and brittle materials, essential in mining and metallurgy, while cutting and rotor mills are gaining traction in the food and agricultural testing sectors for homogenizing fibrous samples. In terms of end-users, the pharmaceutical and biotechnology segments represent the largest consumer base, demanding specialized, contamination-free grinding solutions for drug formulation and analysis. Academic and government research institutions represent a stable, significant segment focusing on multi-purpose, robust instrumentation suitable for diverse exploratory research projects. This segmentation dynamic emphasizes the need for differentiated product offerings that address specific technical requirements related to sample volume, hardness, and required particle size range.

AI Impact Analysis on Lab Grinders Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Lab Grinders Market primarily revolve around the optimization of sample preparation protocols, predictive maintenance, and the integration of automated quality control. Users frequently question how AI algorithms can ensure reproducible particle size distribution (PSD) automatically, thereby eliminating the subjective optimization historically performed by experienced technicians. Key concerns also include the cybersecurity risks associated with integrating networked smart grinders and the cost-effectiveness of implementing AI-driven monitoring systems in smaller labs. Expectations are high concerning AI’s ability to predict instrument failure based on vibration analysis or motor load, minimizing unexpected downtime, which is particularly critical in high-throughput testing facilities where operational continuity is paramount. Additionally, researchers anticipate AI guiding the selection of optimal grinding parameters (speed, duration, material type) based on real-time sample characteristics, thus accelerating method development and validation processes, and leading to significant improvements in laboratory efficiency and data integrity.

- AI integration enables autonomous parameter optimization (e.g., grinding speed, time) based on real-time feedback mechanisms, ensuring consistent particle size distribution (PSD).

- Predictive maintenance algorithms use sensor data (vibration, temperature, motor current) to forecast potential component failure, maximizing uptime and reducing unplanned maintenance costs.

- Automated quality control systems utilize machine vision and deep learning to instantly verify sample homogeneity post-grinding, streamlining validation procedures.

- AI facilitates enhanced sample traceability by linking grinding metadata directly to LIMS/ELN systems, crucial for regulatory compliance in pharmaceuticals.

- Development of smart, self-diagnosing lab grinders reduces reliance on manual troubleshooting, increasing operational autonomy.

- AI algorithms assist in optimizing energy consumption during the grinding process, contributing to laboratory sustainability objectives.

DRO & Impact Forces Of Lab Grinders Market

The Lab Grinders Market is influenced by a powerful combination of Driving factors, Restraints, and Opportunities, collectively forming significant Impact Forces shaping its trajectory. The primary driver is the global increase in pharmaceutical and biotechnological R&D, requiring high-precision sample preparation for complex biological matrices and novel drug delivery systems. Restraints largely center on the high initial capital investment required for advanced, specialized cryo-grinding or ultra-fine milling systems, posing budgetary constraints, particularly for small-scale laboratories and academic spin-offs in developing nations. Opportunities are abundant in the development of multi-functional, modular systems that can adapt to various grinding methods (ball, cutting, mortar) using standardized interfaces, alongside the expansion into emerging fields like battery manufacturing and advanced ceramic production which necessitate highly specific particle comminution techniques. These factors collectively exert significant impact forces on pricing strategies, technological innovation cycles, and geographic market penetration, mandating continuous R&D investment for competitive relevance.

Segmentation Analysis

The Lab Grinders Market is strategically segmented across several critical dimensions, including product type, end-user application, operating mechanism, and geographical presence. Analyzing these segments is essential for understanding market dynamics, identifying high-growth niches, and formulating targeted business strategies. Product segmentation reveals a diverse landscape, ranging from robust, high-energy planetary ball mills favored in metallurgy and ceramics to sensitive, low-contaminant mortar grinders used in precise analytical chemistry. The inherent complexity of sample matrices (ranging from hard ores to delicate biological tissues) dictates the necessity for specialized grinding solutions, driving product diversification and technological sophistication. Furthermore, segmentation by capacity (benchtop vs. floor-standing industrial models) reflects the differing throughput needs of clinical diagnostic labs versus large centralized quality control facilities, influencing pricing and distribution channel focus.

The segmentation based on end-user industry highlights the diverse application requirements. The pharmaceutical and biotechnology sector, for instance, demands grinders capable of sterile operation and high reproducibility for drug formulation and dissolution testing, prioritizing traceability and compliance with GMP standards. Conversely, the academic and government research segment values versatility, ease of use, and cost-effectiveness for educational purposes and broad exploratory research. This diversity requires manufacturers to offer tailored features, documentation, and technical support specific to the regulatory and operational environments of each end-user group. The competitive edge is often gained by providing comprehensive application methodologies alongside the hardware, effectively solving specific sample preparation challenges.

A detailed segmentation analysis also reveals the impact of automation and digitalization. The growing adoption of automated robotic systems and integrated sample preparation workflows is creating a sub-segment for smart grinders that can communicate seamlessly with Laboratory Information Management Systems (LIMS). This trend is particularly pronounced in high-throughput screening environments and centralized biobanks. Consequently, manufacturers are investing in software development and connectivity features, transforming grinders from standalone instruments into integrated components of the modern digital laboratory ecosystem. This move towards 'Smart Lab' integration is expected to redefine the criteria for purchasing decisions, shifting focus from pure mechanical performance to overall system integration capabilities and data management features.

- By Product Type: Ball Mills, Planetary Ball Mills, Mortar Grinders, Rotor Mills, Cutting Mills, Disk Mills, Cryogenic Grinders, Vibratory Mills, High-Speed Homogenizers.

- By Operating Mechanism: Automated/Robotic Systems, Semi-Automated Systems, Manual Systems.

- By Application: Geological Sample Preparation, Pharmaceutical Formulation and Quality Control, Biotechnology and Life Sciences (Tissue Homogenization), Material Science (Nanoparticle Synthesis, Ceramics), Environmental Testing, Food and Agriculture Analysis, Mining and Metallurgy.

- By End-User: Pharmaceutical & Biotechnology Companies, Academic & Research Institutions, Clinical Diagnostic Laboratories, Food & Beverage Testing Labs, Environmental Testing Laboratories, Chemical & Petrochemical Industries.

- By Capacity: Benchtop Grinders (Low to Medium Volume), Floor-Standing Grinders (High Volume/Industrial).

Value Chain Analysis For Lab Grinders Market

The value chain for the Lab Grinders Market spans raw material sourcing, precision manufacturing, intricate distribution networks, and specialized end-user application support. Upstream activities involve the meticulous procurement of high-grade, corrosion-resistant materials, such as specialized stainless steel alloys, tungsten carbide, zirconium oxide ceramics, and advanced polymers necessary for creating robust grinding vessels, rotors, and contamination-free grinding beads. Precision engineering and strict adherence to stringent quality control standards, particularly ISO 9001 and specific industry guidelines (e.g., GMP for pharma and GLP for testing labs), are critically important in the manufacturing phase to ensure reproducibility and consistency of the critical particle size reduction process. Manufacturers are increasingly focused on integrating sophisticated electronic components, including variable speed motor controls, advanced sensor technology for temperature and pressure monitoring, and digital human-machine interfaces, which are essential for developing next-generation automated and intelligent lab grinders. Suppliers of highly specialized components, such as high-torque variable speed brushless motors and cryo-grinding accessories utilizing liquid nitrogen management systems, often hold significant market leverage due to the technical expertise and high specifications required for high-energy comminution processes.

The downstream segment focuses heavily on sophisticated, technically competent distribution channels and robust after-sales technical support. Direct distribution is common for high-value, highly complex, or customized instrument configurations, where manufacturers maintain direct sales forces and specialized application scientists to assist customers in complex installation procedures, critical calibration, and detailed method development for novel samples. This direct engagement is necessary to ensure optimal instrument performance and compliance with complex procedural requirements in highly regulated environments, such as pharmaceutical quality control laboratories or accredited geological testing facilities. Indirect distribution involves specialized laboratory equipment distributors, broad-line catalog houses, and increasingly optimized e-commerce platforms, which are particularly effective for standardized benchtop models, general-purpose instruments, and frequently replaced consumables (like grinding balls, sieves, and cleaning kits). These third-party channels provide extensive logistical reach into smaller research institutions and globally dispersed academic laboratories, requiring strong supply chain integration from the manufacturer.

The effective optimization of the distribution channel is paramount due to the global nature and specific technical requirements of scientific research. Direct channels facilitate deep client relationships and necessary knowledge transfer for complex high-throughput or highly specialized systems, emphasizing profound technical competence and consultative selling over sheer volume. Conversely, indirect channels, while offering broader immediate market access, necessitate robust inventory management systems and standardized, continuous training for reseller networks to ensure consistent product knowledge, application expertise, and service quality across diverse geographic regions and multiple regulatory landscapes. The strategic choice between direct and indirect distribution often depends on the maturity of the specific geographic market and the complexity of the product being sold; emerging markets often rely on strong local distributors who possess established logistical capabilities, existing customer relationships, and a deep understanding of regional regulatory nuances. Consequently, competitive differentiation in the Lab Grinders Market frequently lies not just in the foundational grinding technology itself, but equally in the efficiency, technical depth, responsiveness, and global reach of the entire post-manufacturing value chain, which includes comprehensive warranty management, specialized preventative maintenance contracts, and advanced application training programs for end-users operating in highly sensitive and data-driven testing environments.

Lab Grinders Market Potential Customers

Potential customers for the Lab Grinders Market encompass a wide array of entities across the scientific, industrial, and governmental sectors, all requiring precise and reproducible sample homogenization for subsequent analytical testing. The largest segment of end-users are pharmaceutical and biotechnology companies, which utilize these instruments extensively throughout the drug development lifecycle—from early-stage formulation research and solubility studies to final quality control testing of finished dosage forms. In these environments, grinders must meet rigorous specifications for cleanliness, particle size precision, and validation support to comply with global regulatory standards such as FDA and EMA guidelines. The shift towards biologics and personalized medicine further increases the demand for specialized, low-volume, contamination-free grinding systems for sensitive biological materials, including tissues and complex matrices for biomarker analysis.

Academic and government research institutions represent another crucial customer base. These organizations, including universities, national laboratories, and geological survey centers, require versatile and durable lab grinders suitable for a broad spectrum of research applications, including geological mapping, environmental toxicology, agricultural testing, and fundamental materials science research. Their purchasing decisions are often influenced by grant funding cycles, instrument longevity, ease of maintenance, and the ability of the device to accommodate diverse sample types. The educational component is also vital, requiring user-friendly interfaces and robust safety features suitable for student operation. Furthermore, national standards bodies and regulatory agencies often purchase these devices to establish and maintain reference material certifications and conduct inter-laboratory proficiency testing, emphasizing the need for absolute accuracy and low measurement uncertainty.

The industrial sector, particularly companies involved in mining and metallurgy, advanced ceramics, polymers, and food processing, forms the third major customer group. In metallurgy, grinders are essential for preparing metal ores and alloys for elemental analysis, ensuring quality and purity. The food and beverage industry uses high-speed cutting mills and homogenizers to prepare samples for nutritional content analysis, contamination detection, and quality assurance, often dealing with complex, high-moisture, or fibrous materials. The electronics and advanced materials sectors utilize planetary ball mills extensively for producing ultra-fine powders and nanoparticles necessary for next-generation components like specialized battery electrodes and high-performance semiconductors. These industrial applications demand instruments that offer high throughput, exceptional durability, and the capability to handle extremely hard or abrasive materials reliably over extended operational periods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $2.0 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Retsch GmbH, Fritsch GmbH, IKA Works GmbH & Co. KG, SP Scienceware (Bel-Art Products), Gilson Inc., Cole-Parmer Instrument Company, Spex SamplePrep LLC, Glen Mills Inc., Pulverisette, NETZSCH-Feinmahltechnik GmbH, Thermo Fisher Scientific, Heidolph Instruments GmbH & Co. KG, Sartorius AG, PerkinElmer Inc., Bio-Rad Laboratories, FLSmidth & Co. A/S, Hosokawa Micron Corporation, Analytik Jena GmbH, Buchi Corporation, Eppendorf AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lab Grinders Market Key Technology Landscape

The technological landscape of the Lab Grinders Market is characterized by a drive towards enhanced automation, increased versatility, and the development of specialized techniques to handle challenging sample matrices, reflecting the growing precision demands of modern scientific analysis. A primary area of innovation is the proliferation of cryogenic grinding technology, which utilizes liquid nitrogen to embrittle samples (such as plastics, biological tissues, and elastic polymers) before milling. This process preserves temperature-sensitive molecular structures, prevents sample degradation, and allows for the efficient processing of materials that are otherwise difficult to grind at ambient temperatures. Advancements in cryo-grinders include integrated, automated liquid nitrogen dosing systems and sophisticated temperature management controls that ensure safe operation and highly reproducible low-temperature conditions. This technology is critical for genomics, proteomics, and drug metabolism studies where sample integrity is non-negotiable, providing a key competitive differentiator for manufacturers specializing in life science applications.

Another dominant technological trend involves the integration of smart features and IoT connectivity across all product categories, from planetary ball mills to cutting mills. Modern lab grinders are increasingly equipped with embedded sensors for real-time monitoring of critical parameters, including motor torque, vibration intensity, processing temperature, and pressure within the grinding chamber. This data is utilized for advanced process control, allowing algorithms to automatically adjust grinding parameters to maintain a target energy input or particle size distribution dynamically. Furthermore, connectivity features enable seamless integration with Laboratory Information Management Systems (LIMS) and Electronic Lab Notebooks (ELNs), ensuring full data traceability and remote diagnostics capabilities. This digitalization effort significantly enhances laboratory compliance (especially in GMP/GLP environments), improves workflow efficiency by automating documentation, and supports the implementation of predictive maintenance protocols, reducing overall operational costs and minimizing unplanned downtime.

Material science and engineering innovations also play a crucial role in advancing lab grinder performance. Manufacturers are continuously exploring novel materials for grinding tools (vessels, balls, rotors) to minimize cross-contamination and abrasion, thereby extending instrument lifespan and ensuring sample purity. The use of highly wear-resistant ceramics (like silicon nitride and stabilized zirconia) and specialized polymers for pharmaceutical applications requiring inert contact surfaces is becoming standard. Furthermore, the mechanics of high-energy milling are being refined through computational modeling and simulation to optimize grinding kinetics, resulting in devices that achieve finer particle sizes (down to the sub-micron and nanometer range) more rapidly and with lower energy consumption. This focus on mechanical efficiency and specialized material compatibility is essential for supporting cutting-edge research in nanotechnology, advanced battery materials, and high-performance composites, positioning specialized grinding systems as indispensable tools in these rapidly evolving fields.

Regional Highlights

- North America: North America, particularly the United States, represents the largest and most technologically advanced market for lab grinders, driven by immense public and private investment in biotechnology, pharmaceutical R&D, and clinical diagnostics. The presence of major global pharmaceutical companies, leading academic research centers, and stringent FDA regulations necessitate the continuous adoption of highly precise, validated, and often automated grinding equipment. Demand is high for high-throughput sample preparation systems and specialized cryo-grinding instruments required for cutting-edge genomics and toxicology testing. The region maintains its market dominance through rapid adoption of smart laboratory technology and favorable funding environments for scientific infrastructure upgrades, ensuring sustained growth across all segments.

- Europe: Europe is a mature and highly competitive market, characterized by strong governmental support for fundamental research (Horizon Europe programs) and robust regulatory frameworks (EMA) governing pharmaceutical manufacturing and food safety. Countries like Germany, France, and the UK are key markets, showing high demand for versatile planetary ball mills used extensively in material science, ceramics research, and geological analysis. The emphasis here is often on high precision, reliability, and low energy consumption, aligned with regional sustainability goals. Furthermore, Europe is a major hub for the manufacturing and export of high-quality laboratory instruments, driving internal technological advancements and competitive pricing pressures.

- Asia Pacific (APAC): The APAC region is poised to exhibit the fastest growth over the forecast period, fueled by rapid industrialization, massive state-led investments in scientific R&D (especially in China, Japan, and South Korea), and the emergence of India and China as global pharmaceutical and contract research organization (CRO) manufacturing hubs. The increasing number of academic institutions, coupled with growing environmental concerns requiring enhanced environmental monitoring and food safety testing, drives volume sales of both benchtop and semi-automated grinders. While cost sensitivity remains a factor, the demand for specialized, high-performance equipment is rising sharply, necessitating local distribution support and tailored pricing strategies from international vendors.

- Latin America (LATAM): Growth in LATAM is primarily driven by investments in resource extraction (mining and geology) and expanding academic research sectors, particularly in Brazil and Mexico. The market generally favors reliable, robust, and cost-effective instrumentation, with a slower adoption rate for highly specialized, capital-intensive robotic systems. Geological sample preparation, particularly for precious metals and mineral analysis, forms a substantial segment, requiring heavy-duty disc mills and high-capacity ball mills. Market penetration is often challenging due to complex regulatory environments and logistical hurdles, requiring strong local partnerships for effective distribution and technical service provision.

- Middle East and Africa (MEA): The MEA market is gradually expanding, propelled by government initiatives aimed at diversifying economies beyond oil, leading to increased investment in localized healthcare infrastructure, food production, and specialized materials research (e.g., desalination technologies). The market size remains relatively smaller but is showing promising signs of growth, particularly in countries like Saudi Arabia and the UAE. Demand centers around basic laboratory infrastructure upgrades in universities and the establishment of new quality control laboratories in the growing regional petrochemical and pharmaceutical sectors, primarily focusing on general-purpose mortar and rotor mills.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lab Grinders Market.- Retsch GmbH

- Fritsch GmbH

- IKA Works GmbH & Co. KG

- SP Scienceware (Bel-Art Products)

- Gilson Inc.

- Cole-Parmer Instrument Company

- Spex SamplePrep LLC

- Glen Mills Inc.

- Pulverisette

- NETZSCH-Feinmahltechnik GmbH

- Thermo Fisher Scientific

- Heidolph Instruments GmbH & Co. KG

- Sartorius AG

- PerkinElmer Inc.

- Bio-Rad Laboratories

- FLSmidth & Co. A/S

- Hosokawa Micron Corporation

- Analytik Jena GmbH

- Buchi Corporation

- Eppendorf AG

Frequently Asked Questions

Analyze common user questions about the Lab Grinders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for specialized cryogenic lab grinders?

The primary driver is the necessity for sample preparation methods that preserve the molecular integrity and prevent thermal degradation of temperature-sensitive biological and polymeric materials (e.g., DNA, RNA, elastic polymers) required for accurate high-resolution analysis in biotechnology and materials science.

How do stringent regulatory standards impact the technological requirements for pharmaceutical lab grinders?

Stringent regulatory standards (like GMP and FDA guidelines) mandate high precision, operational consistency, minimal cross-contamination risk, and comprehensive data traceability, necessitating grinders with validated protocols, inert contact materials, and digital integration capabilities for automated data logging and audit trail generation.

Which geographical region is projected to experience the highest growth rate in the Lab Grinders Market?

The Asia Pacific (APAC) region is projected to experience the highest growth rate, driven by significant government investments in scientific research infrastructure, rapid expansion of the pharmaceutical and biotech industries, and increasing demand for environmental and food safety testing services.

What are the key technical differences between a planetary ball mill and a rotor mill in laboratory applications?

A planetary ball mill uses high-energy centrifugal forces to achieve ultra-fine particle size reduction and is ideal for extremely hard, brittle materials (e.g., ceramics, minerals). Conversely, a rotor mill utilizes impact and cutting forces and is typically used for rapid coarse to medium grinding of soft, fibrous, or medium-hard materials like food samples and plant tissues.

What role does IoT integration play in the latest generation of lab grinders?

IoT integration enables real-time remote monitoring of operating parameters, predictive maintenance alerts based on sensor data analysis, automated data transfer to LIMS for enhanced traceability, and the remote management of grinding protocols, significantly boosting laboratory efficiency and compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager