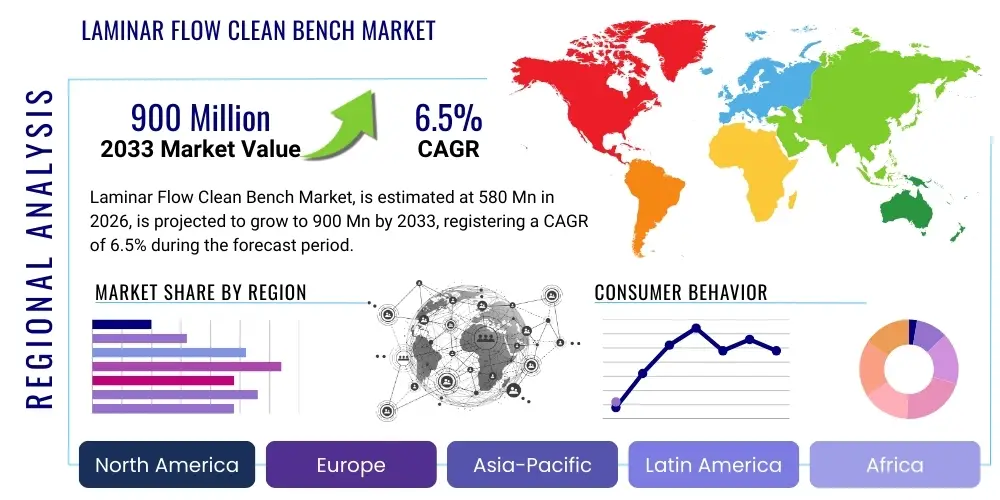

Laminar Flow Clean Bench Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443604 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Laminar Flow Clean Bench Market Size

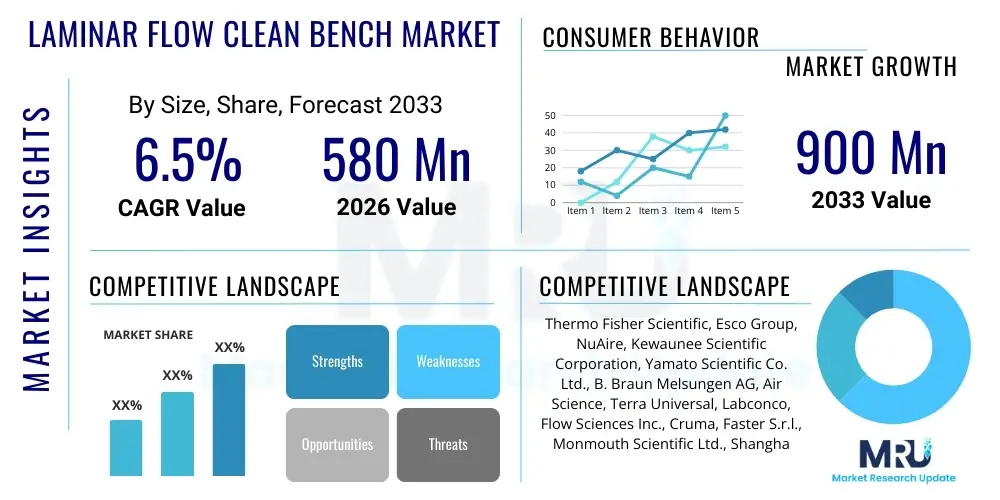

The Laminar Flow Clean Bench Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 580 million in 2026 and is projected to reach USD 900 million by the end of the forecast period in 2033.

Laminar Flow Clean Bench Market introduction

The Laminar Flow Clean Bench Market encompasses specialized laboratory equipment designed to create an aseptic, particle-free working environment crucial for sensitive scientific and manufacturing processes. A laminar flow clean bench, often referred to as a laminar flow hood, operates by directing air through a High-Efficiency Particulate Air (HEPA) or Ultra-Low Penetration Air (ULPA) filter, ensuring a unidirectional, constant stream of filtered air across the workspace. This flow pattern prevents particulate matter, aerosols, and microbial contamination from entering the critical work area, thereby protecting samples, products, and processes from external contaminants. The foundational principle relies on maintaining an ISO Class 5 or better environment within the enclosure, supporting applications that demand stringent cleanliness standards where product protection, rather than personnel protection, is the primary concern. Technological advancements are continuously enhancing filtration efficiency, reducing operational noise, and improving ergonomic designs, making these benches indispensable in modern research and industrial settings.

Product differentiation within this market segment largely revolves around airflow orientation, size customization, and integration of advanced monitoring systems. Horizontal laminar flow benches push filtered air towards the user, which is ideal for working with sensitive electronic components or non-hazardous samples, minimizing direct contact risk from the bench surface. Conversely, vertical laminar flow benches direct air downwards onto the work surface and exhaust it through the base, often providing a more contained environment suitable for tissue culture preparation and non-pathogenic microbiological work. Major applications are concentrated in industries requiring precise environmental control, including biotechnology, pharmaceutical manufacturing, clinical pathology, electronics assembly, and medical device fabrication. The increasing complexity of genetic engineering, cell therapy research, and the stringent regulatory mandates governing cleanroom procedures globally are significantly driving the demand for reliable and high-performance laminar flow clean benches.

Driving factors for sustained market growth include the global expansion of the biopharmaceutical sector, catalyzed by increased funding for life sciences research and development, particularly in emerging economies. The benefits of utilizing laminar flow systems—such as minimizing batch contamination, improving experimental reproducibility, and extending the shelf life of sensitive materials—provide a compelling value proposition for end-users. Furthermore, the necessity for specialized, isolated workstations to handle non-hazardous materials under highly controlled conditions, particularly those subject to regulatory frameworks like Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP), cements the critical role of these benches. The market is also experiencing tailwinds from the burgeoning cell and gene therapy sector, which requires ultra-clean environments for cultivation and manipulation, pushing manufacturers to innovate features such as automated sterilization cycles and integrated airflow sensors for enhanced operational compliance and safety.

Laminar Flow Clean Bench Market Executive Summary

The Laminar Flow Clean Bench Market is experiencing robust expansion driven primarily by accelerated investment in the global pharmaceutical and biotechnology industries, particularly focusing on sterile compounding and advanced therapy medicinal products (ATMPs). Current business trends indicate a shift towards modular and customizable solutions, enabling laboratories to integrate clean benches seamlessly into existing infrastructure while meeting dynamic throughput requirements. Manufacturers are prioritizing energy-efficient designs and incorporating digital monitoring capabilities, such as real-time pressure sensing and remote diagnostics, to address the growing demand for sustainable and compliant operations. Geographically, the market trajectory is highly influenced by regulatory harmonization efforts in key regions, with North America and Europe maintaining dominant positions due to established R&D ecosystems and stringent quality control standards, while the Asia Pacific region is demonstrating the highest CAGR, propelled by expanding contract manufacturing organizations (CMOs) and government initiatives supporting local drug production.

Segment trends highlight the dominance of horizontal flow benches in non-hazardous applications such as optics and microelectronics, valuing accessibility and unobstructed airflow paths. However, the vertical flow segment is gaining traction within the life sciences due to its suitability for processes requiring higher levels of downward protection over the work surface, often conforming better to certain containment requirements. The application segmentation underscores the indispensable role of these benches in clinical diagnostics and drug discovery, sectors which are continually expanding their capacity and reliance on controlled environments for reproducible results. Furthermore, the market is witnessing increased adoption of benches featuring antimicrobial coatings and advanced material construction, specifically stainless steel, which facilitates rigorous cleaning and sterilization protocols necessary for maintaining aseptic conditions in critical pharmaceutical operations, thereby directly addressing concerns regarding cross-contamination risk.

Regional dynamics reveal that the Asia Pacific market, led by China, India, and South Korea, is becoming a pivotal manufacturing hub, attracting significant foreign investment in bioprocessing infrastructure, which directly stimulates demand for clean bench installations. In established markets like the United States and Germany, replacement cycles and technological upgrades—focusing on compliance with updated ISO standards (e.g., ISO 14644)—are the primary drivers. The competitive landscape remains moderately consolidated, with major global players emphasizing innovation in filtration technology (e.g., introduction of energy-saving DC motors and longer-lasting ULPA filters) and ergonomic design to capture market share. Overall, the executive outlook forecasts sustained growth, contingent upon continued regulatory enforcement for quality control in sterile environments and the unrelenting global pursuit of new pharmaceuticals and diagnostic tools, solidifying the clean bench as a fundamental tool in high-precision laboratory work.

AI Impact Analysis on Laminar Flow Clean Bench Market

User queries regarding the impact of Artificial Intelligence (AI) on the Laminar Flow Clean Bench Market frequently center on the potential for AI to optimize operational efficiency, enhance predictive maintenance, and ensure superior regulatory compliance. Key themes identified include the integration of machine learning algorithms for real-time monitoring of air velocity, filter loading, and particle count data, moving beyond traditional static alarms to dynamic risk assessment. Users are keenly interested in how AI can minimize human error during critical aseptic processes performed within the bench, potentially through automated parameter adjustment or sophisticated anomaly detection that anticipates failures before they occur. The underlying expectation is that AI integration will transform the clean bench from a passive containment barrier into an active, intelligent workstation capable of self-optimization and providing comprehensive digital documentation essential for 21st-century quality assurance protocols.

The integration of AI modules within laminar flow benches promises to revolutionize how these crucial pieces of equipment are managed and validated. AI algorithms can process vast datasets related to environmental parameters, user behavior (e.g., frequency of door opening, movement within the work zone), and filter lifespan, establishing precise baseline operational profiles. When deviations occur, the AI system can not only alert the user but also suggest corrective actions or automatically adjust motor speeds to maintain laminar conditions despite external influences. This level of predictive control significantly enhances the reliability of sensitive research and manufacturing processes, reducing the incidence of costly batch failures linked to unforeseen environmental fluctuations or filter degradation. Furthermore, AI-driven digital twins of the clean bench environment allow for simulated testing of protocols, improving standard operating procedures (SOPs) before physical execution, thereby optimizing resource utilization and overall operational throughput.

Beyond operational optimization, AI significantly addresses concerns related to regulatory reporting and compliance inherent in the use of clean benches within GMP environments. Advanced analytical tools powered by machine learning can automatically compile comprehensive audit trails, documenting every measured parameter, operational adjustment, and maintenance event in a tamper-proof digital log. This capability dramatically simplifies validation processes and speeds up regulatory submissions by providing transparent, data-backed evidence of environmental control efficacy. The market expects that AI integration will lead to a new generation of "smart" clean benches that minimize downtime through predictive servicing schedules, optimize energy consumption based on usage patterns, and ultimately ensure a consistently higher level of contamination control confidence compared to legacy analog systems, thereby increasing the value proposition for high-stakes pharmaceutical and clinical applications.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast HEPA/ULPA filter exhaustion and fan motor failures, minimizing unexpected downtime.

- Real-time Environmental Optimization: Machine learning algorithms automatically adjust fan speed and flow rates to maintain ISO classification despite ambient changes.

- Enhanced Digital Compliance Documentation: Automated generation of audit trails and validation reports based on continuous, real-time data monitoring.

- Process Anomaly Detection: Identifying subtle deviations in airflow or particle counts indicative of contamination risk or procedural error.

- Ergonomic and Workflow Optimization: Analyzing user interaction patterns to suggest improvements in SOPs and bench layout.

DRO & Impact Forces Of Laminar Flow Clean Bench Market

The Laminar Flow Clean Bench Market is fundamentally shaped by a combination of accelerating drivers, persistent restraints, emerging opportunities, and competitive impact forces. The primary drivers are the exponential growth in global pharmaceutical R&D spending, particularly in cell and gene therapy—which mandates ultra-clean handling—and the increasingly strict global regulatory environment requiring verifiable aseptic conditions for manufacturing and testing. Restraints include the high initial capital investment required for installing advanced cleanroom infrastructure, including the benches themselves, which can be prohibitive for smaller research facilities or those in developing economies, coupled with the ongoing operational costs associated with frequent filter replacements and calibration checks. Opportunities abound in modular clean bench designs, integration with smart monitoring technologies (IoT and AI), and catering to specialized niche applications such as nano-fabrication and high-throughput screening. The overall impact forces compel manufacturers towards continuous innovation in energy efficiency, compliance robustness, and cost-effectiveness to secure sustained market penetration in diverse global contexts.

Key drivers creating momentum include the worldwide rise in healthcare expenditures and the subsequent expansion of clinical diagnostics laboratories that rely on clean environments to ensure the integrity of patient samples and test results. Furthermore, the necessity for localized drug manufacturing capabilities, spurred by geopolitical shifts and supply chain vulnerabilities, encourages investment in regional biomanufacturing facilities, all of which require extensive installations of clean benches. However, market growth is often restricted by the challenge of training specialized personnel capable of operating and maintaining these sensitive systems correctly; procedural errors by poorly trained staff can compromise the aseptic environment, leading to costly material loss. Additionally, product obsolescence driven by rapid technological advances, particularly in filtration and motor technology, means organizations must frequently assess the need for upgrades to maintain compliance with evolving standards like ISO 14644, presenting a structural restraint on long-term capital planning.

The strategic opportunities for market expansion reside in exploiting untapped potential within emerging markets in Southeast Asia and Latin America, where governmental initiatives are actively promoting scientific research infrastructure development. Customization for niche markets, such as specialized benches for robotics integration in automated laboratories, represents a high-value opportunity. Impact forces intensify competitive rivalry, driving companies to differentiate through superior after-sales service, extended warranty periods, and enhanced ergonomic features that improve user comfort and reduce the risk of contamination caused by operator fatigue. Regulatory impact is perhaps the most forceful external factor, as strict enforcement by agencies like the FDA and EMA dictates the technical specifications and validation requirements for all equipment used in sterile environments, ensuring that only vendors who prioritize quality and compliance can thrive in this highly regulated sector, thereby reinforcing the imperative for continuous quality improvement.

Segmentation Analysis

The Laminar Flow Clean Bench Market is comprehensively segmented across several crucial parameters including product type, airflow direction, application, and end-user, providing a granular view of market dynamics and adoption patterns. Analyzing these segments is critical for understanding market demand drivers, tailoring product development efforts, and formulating targeted marketing strategies. The market exhibits distinct preferences based on the intended use; for instance, end-users in electronics manufacturing typically favor horizontal flow benches for surface protection, whereas pharmaceutical compounding centers often require vertical flow benches for enhanced work zone containment. This segmentation reveals heterogeneous growth rates, with advanced segments such as personalized medicine applications driving higher demand for customized, compact laminar flow solutions, contrasting with steady demand from traditional industrial sectors.

Segmentation by product type typically distinguishes between standard models, compact/benchtop models, and customized large-scale units. Compact benches are gaining popularity in academic research and small-scale diagnostics where space optimization is paramount, while customized units address the specific volumetric and integration needs of high-throughput industrial processes, such as packaging or assembly lines within a cleanroom environment. The airflow direction segmentation, differentiating between horizontal and vertical flow, remains foundational, reflecting the fundamental choice between primary product protection (horizontal) and slightly improved containment/downward protection (vertical). Understanding this foundational distinction allows manufacturers to position their product lines effectively based on the risk profile and procedural requirements of the target customer base, ensuring that the selected bench configuration optimally supports the sterile nature of the work being conducted.

The application segment provides insights into industry-specific demand, ranging from cell culture and microbiological analysis to precision instrument calibration and semiconductor manufacturing. The pharmaceutical segment, inclusive of sterile drug preparation and quality control testing, dominates the market share due to stringent regulatory demands and high-volume usage. End-user segmentation further refines the demand analysis, covering hospitals and clinical laboratories, academic and research institutes, and industrial entities (e.g., electronics, food and beverage). The increasing modernization of hospital pharmacies for sterile intravenous (IV) compounding, often regulated by standards such as USP <797>, ensures sustained growth in the hospital sector, while academic institutions represent a steady, replacement-driven demand source focused on budget-friendly and versatile equipment suitable for diverse research projects.

- By Product Type:

- Standard Laminar Flow Benches

- Benchtop/Compact Laminar Flow Benches

- Customized Large-Scale Units

- By Airflow Direction:

- Horizontal Laminar Flow Benches

- Vertical Laminar Flow Benches

- By Application:

- Cell Culture and Tissue Processing

- Microbiological Testing

- Sterile Compounding (Pharmaceutical)

- Electronics and Semiconductor Manufacturing

- Precision Instrument Assembly

- By End-User:

- Pharmaceutical and Biotechnology Companies

- Hospitals and Clinical Laboratories

- Academic and Research Institutions

- Industrial Entities (Non-Pharma)

Value Chain Analysis For Laminar Flow Clean Bench Market

The value chain for the Laminar Flow Clean Bench Market begins with the upstream suppliers of critical components, primarily focusing on high-grade materials and specialized filtration media. Upstream analysis involves raw material providers supplying stainless steel (essential for aseptic surfaces), specialized HEPA/ULPA filter media (e.g., borosilicate microfibers), and electronic components such as blowers, motors (increasingly energy-efficient DC motors), and control systems. The quality and reliability of these upstream inputs directly dictate the performance and longevity of the final product, especially the efficiency of the filtration system. Strong supplier relationships are necessary to ensure a stable supply of materials that meet stringent quality and regulatory standards, particularly concerning particle shedding and chemical resistance, which are paramount in controlled environments. Efficiency in procurement and inventory management at this stage is crucial for managing the final cost of the clean bench.

The midstream phase involves the manufacturing and assembly of the clean benches, encompassing design, fabrication, testing, and certification. Manufacturers must adhere to international standards (e.g., ISO 14644, ANSI/ASHRAE 110) during the production process, implementing rigorous quality control measures, including factory acceptance testing (FAT) to verify air velocity profiles and leak integrity before shipment. Downstream activities focus on distribution, sales, installation, validation, and post-sales service. The distribution channel is often complex, utilizing a mix of direct sales teams for major contracts (e.g., large pharmaceutical plant installations) and indirect channels through specialized scientific equipment distributors and local dealers who provide essential regional support, installation expertise, and faster response times for maintenance calls. The effectiveness of the downstream supply chain, particularly the ability to provide reliable validation (IQ/OQ/PQ) and calibration services, profoundly influences customer satisfaction and repeat business.

The structure of the distribution channel impacts market accessibility and cost structure. Direct sales offer higher margins and closer customer feedback loops but require significant investment in a dedicated sales and service infrastructure. Indirect channels leverage the existing networks and technical competencies of regional partners, facilitating rapid market entry and penetration in geographically diverse regions. Given the technical nature and regulatory importance of the equipment, distributors often need specialized training to perform initial setup and routine maintenance, acting as certified service providers. Furthermore, the increasing trend toward digital integration and IoT necessitates that the value chain extends to software and data service providers, ensuring that remote monitoring and predictive maintenance features are adequately supported throughout the life cycle of the clean bench, further emphasizing the interconnectedness of manufacturing and post-sales service in this market.

Laminar Flow Clean Bench Market Potential Customers

The primary potential customers for Laminar Flow Clean Benches span a diverse range of sectors, all united by the need for meticulous contamination control in their processes. The largest segment of end-users are entities within the biopharmaceutical and clinical health sectors. Pharmaceutical and biotechnology companies rely heavily on these benches for critical steps in drug discovery, quality control testing, and sterile compounding, adhering strictly to current Good Manufacturing Practices (cGMP). Clinical laboratories, particularly those involved in high-complexity testing, molecular diagnostics, and specialized pathological work, utilize clean benches to protect reagents, cultures, and patient samples from airborne particulates, thereby maintaining the integrity and reproducibility of test results. The necessity for these controlled environments is non-negotiable in regulated health science fields, making these organizations the most reliable and high-volume buyers.

Academic and governmental research institutions represent another crucial customer segment. University science departments, national research laboratories, and governmental testing centers (e.g., public health labs) require clean benches for fundamental research in microbiology, genomics, cell biology, and materials science. While procurement cycles in this segment may be longer, driven by grant funding and institutional budget allocation, the demand is steady and essential for training the next generation of scientists and conducting foundational scientific inquiry. These customers often prioritize versatility, reliability, and ease of use, frequently opting for mid-range vertical flow models suitable for various non-hazardous biological applications. The educational sector often drives bulk orders when establishing new laboratory facilities or upgrading aging infrastructure to meet contemporary safety standards.

Beyond life sciences, industrial customers in high-precision manufacturing sectors constitute a growing market. Electronics and semiconductor manufacturers require ultra-clean environments, often utilizing horizontal flow benches, to assemble microchips, sensors, and delicate electronic components where even microscopic dust particles can cause catastrophic failure. Similarly, industries involved in optics, aerospace component fabrication, and specialized material processing also utilize laminar flow technology to ensure product quality and dimensional integrity. These industrial end-users prioritize high throughput compatibility, low vibration, and customization for integration into assembly line infrastructure, representing a premium segment focused on minimizing operational defects caused by environmental contamination. Therefore, the potential customer base ranges from highly regulated medical environments to precision-focused industrial settings, all requiring guaranteed particle-free workspaces.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 580 Million |

| Market Forecast in 2033 | USD 900 Million |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Esco Group, NuAire, Kewaunee Scientific Corporation, Yamato Scientific Co. Ltd., B. Braun Melsungen AG, Air Science, Terra Universal, Labconco, Flow Sciences Inc., Cruma, Faster S.r.l., Monmouth Scientific Ltd., Shanghai Boxun Industrial Co., LTD, Ruskinn Technology Ltd., BIOBASE Group, Wuxi Fude Technology Co., Ltd., AirClean Systems, Sheldon Manufacturing, Inc., Dagard. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laminar Flow Clean Bench Market Key Technology Landscape

The technology landscape of the Laminar Flow Clean Bench Market is continuously evolving, driven by the imperative to enhance energy efficiency, improve filtration performance, and integrate sophisticated monitoring and control systems. The foundational technology remains the High-Efficiency Particulate Air (HEPA) filter, or increasingly, the Ultra-Low Penetration Air (ULPA) filter, capable of trapping 99.99% of particles down to 0.3 micrometers or even smaller. Current innovation focuses heavily on optimizing the motor and fan system. The shift from traditional AC motors to energy-efficient electronically commutated (EC) DC motors is a major technological trend. EC motors offer variable speed control, reduced power consumption, and lower operational noise, significantly decreasing the total cost of ownership (TCO) for end-users, which is a major purchasing criterion in large-scale laboratory and manufacturing environments where multiple units operate continuously. This motor optimization supports compliance with green building standards and sustainability goals prevalent across developed economies.

Beyond core filtration and airflow mechanics, the integration of advanced digital technologies is redefining the functional capabilities of clean benches. Modern units incorporate microprocessors and sophisticated sensors for real-time monitoring of critical parameters, including differential pressure across the filters, air velocity uniformity, and operational hour logging. These smart systems facilitate proactive maintenance and ensure regulatory compliance by providing continuous data streams. Moreover, the connectivity enabled by Internet of Things (IoT) frameworks allows for remote diagnostic checks, data logging, and integration with Laboratory Information Management Systems (LIMS). This level of connectivity transforms the clean bench from an isolated piece of equipment into a networked asset, improving data integrity and streamlining quality assurance processes, which is particularly vital for GxP environments that require comprehensive digital record-keeping.

Material science innovation also plays a critical role, focusing on surfaces that minimize particle generation and facilitate effective decontamination. Work surfaces are typically constructed from seamless, medical-grade stainless steel to resist chemical corrosion and microbial growth. Manufacturers are exploring antimicrobial coatings and innovative joint designs to reduce areas where contaminants can accumulate. Furthermore, ergonomic considerations are being addressed through adjustable work heights, integrated task lighting that minimizes glare, and low-noise operation, recognizing that user comfort directly impacts procedural accuracy and adherence to sterile techniques. The overall technology trajectory is moving towards fully validated, self-optimizing clean benches that offer enhanced performance guarantees and reduced lifetime operating costs, ensuring the integrity of highly sensitive materials and processes in modern scientific applications.

Regional Highlights

- North America: This region, encompassing the United States and Canada, holds the largest market share due to its well-established, heavily funded biopharmaceutical industry, leading academic research infrastructure, and the presence of major key players. Stringent regulatory frameworks imposed by the FDA, driving continuous demand for high-compliance, validated equipment for drug development and manufacturing, solidify its dominance. The US market is characterized by frequent technology upgrades and high adoption rates of advanced, integrated clean bench solutions, particularly in cell therapy and advanced diagnostics.

- Europe: Europe represents the second-largest market, fueled by robust investments in biotechnology, strong government support for scientific innovation (e.g., Horizon Europe programs), and the concentration of major global pharmaceutical companies in countries like Germany, Switzerland, and the UK. The implementation of strict EU GMP standards and ISO regulations ensures steady demand for reliable, certified laminar flow technology. The trend here leans toward sustainability, driving demand for energy-efficient EC motor-equipped benches.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region globally, primarily driven by rapid industrialization, increasing healthcare expenditure, and the relocation of manufacturing bases (CMOs/CDMOs) to countries such as China, India, and South Korea. Government initiatives to promote local pharmaceutical production and establish advanced research centers are major catalysts. Demand in APAC is characterized by price sensitivity coupled with increasing emphasis on basic quality certification, making customized, cost-effective standard models highly competitive.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, propelled by infrastructure modernization in clinical laboratories and emerging pharmaceutical markets in Brazil and Mexico. Market growth is constrained by fluctuating economic conditions and import tariffs, leading to a preference for locally manufactured or regional distributor-supplied equipment that offers competitive pricing and localized service support.

- Middle East and Africa (MEA): Growth in the MEA region is accelerating, primarily concentrated in the Gulf Cooperation Council (GCC) countries investing heavily in developing advanced medical and research city initiatives, aiming to reduce reliance on imported pharmaceuticals. The demand is project-based, linked to the establishment of new state-of-the-art hospitals and bioscience research parks, focusing on high-specification equipment meeting international standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laminar Flow Clean Bench Market.- Thermo Fisher Scientific

- Esco Group

- NuAire

- Kewaunee Scientific Corporation

- Yamato Scientific Co. Ltd.

- B. Braun Melsungen AG

- Air Science

- Terra Universal

- Labconco

- Flow Sciences Inc.

- Cruma

- Faster S.r.l.

- Monmouth Scientific Ltd.

- Shanghai Boxun Industrial Co., LTD

- Ruskinn Technology Ltd.

- BIOBASE Group

- Wuxi Fude Technology Co., Ltd.

- AirClean Systems

- Sheldon Manufacturing, Inc.

- Dagard

Frequently Asked Questions

What is the primary function of a Laminar Flow Clean Bench in a laboratory setting?

The primary function of a laminar flow clean bench is to create a highly controlled, particulate-free working environment (typically ISO Class 5) by filtering air through a HEPA or ULPA filter and directing it over the work surface in a unidirectional, laminar stream. This ensures protection for sensitive samples, products, and processes from airborne contamination, critical for applications like cell culture and sterile compounding.

How do horizontal and vertical laminar flow benches differ in terms of airflow and application?

Horizontal laminar flow benches direct filtered air parallel to the work surface, towards the user, offering maximum product protection and preventing particulate buildup on the surface. They are ideal for non-hazardous materials and precision assembly. Vertical laminar flow benches direct filtered air downward onto the work surface, exhausting through the front access opening or grilles, providing a slightly more contained environment suitable for biological work where product protection and minor work zone containment are necessary, provided the material is not pathogenic.

Which regulatory standards govern the use and validation of laminar flow clean benches?

The performance and validation of laminar flow clean benches are primarily governed by international standards such as ISO 14644 (specifically ISO Class 5 for the work zone) and operational standards like current Good Manufacturing Practice (cGMP) in the pharmaceutical industry. Additionally, standards like NSF/ANSI 49, though often associated with biosafety cabinets, provide relevant guidelines for airflow uniformity, pressure monitoring, and leak testing essential for validating clean bench efficacy.

What is driving the growing demand for energy-efficient DC motors in clean bench technology?

The growing demand for electronically commutated (EC) DC motors is driven by the need for reduced operational costs, enhanced sustainability, and precise airflow control. EC motors consume significantly less energy than traditional AC motors, generate less heat, and offer variable speed capabilities, allowing systems to dynamically adjust flow rates while maintaining laminar conditions with minimal noise, aligning with global green laboratory initiatives and lowered total cost of ownership (TCO).

How is the Asia Pacific region influencing the future growth trajectory of the Laminar Flow Clean Bench Market?

The Asia Pacific region is influencing market growth significantly due to escalating investment in domestic biomanufacturing and research infrastructure, particularly in India, China, and South Korea. This expansion, driven by government policies promoting local drug production and medical device assembly, translates into high volume demand for new installations. This region is projected to exhibit the highest Compound Annual Growth Rate (CAGR) globally throughout the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager