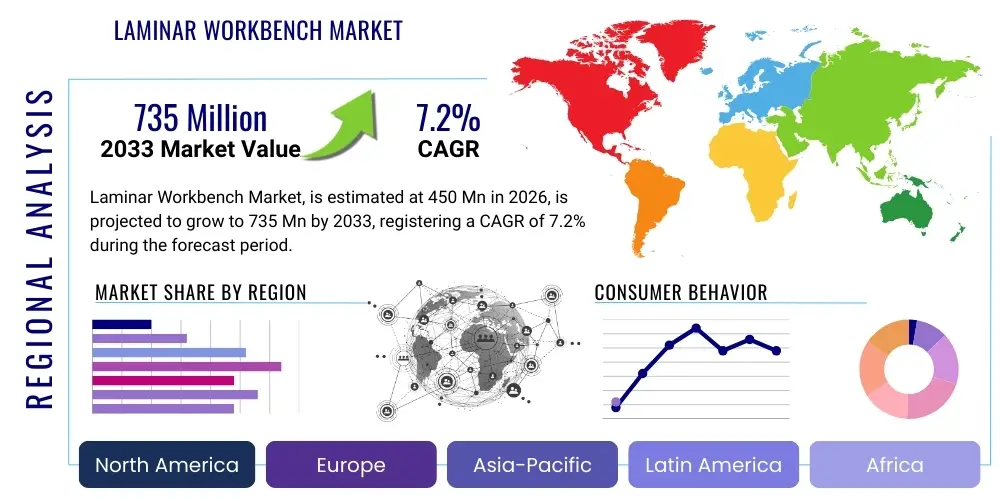

Laminar Workbench Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440803 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Laminar Workbench Market Size

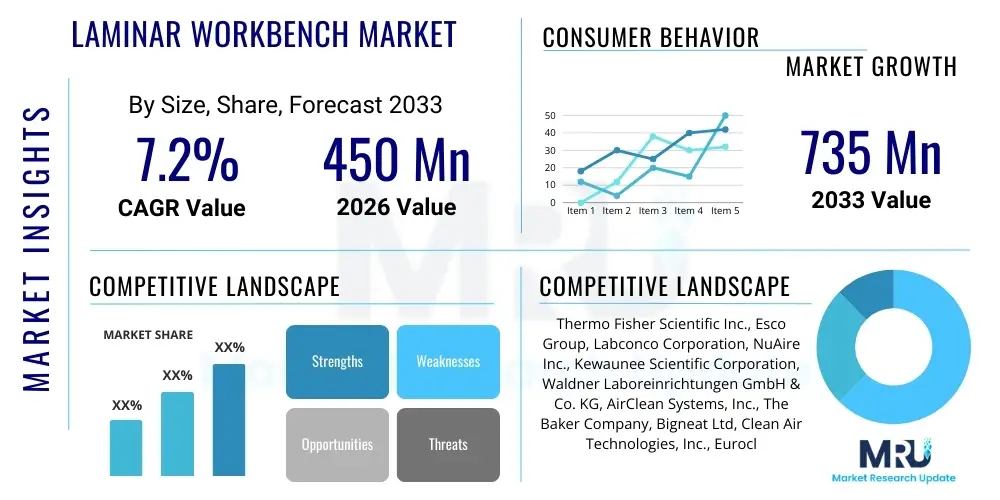

The Laminar Workbench Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 735 Million by the end of the forecast period in 2033.

Laminar Workbench Market introduction

The Laminar Workbench Market encompasses the global industry for specialized laboratory equipment designed to create an aseptic and particulate-free working environment. These critical instruments are indispensable in scientific research, clinical diagnostics, and industrial production where maintaining sterility and preventing contamination are paramount. A laminar workbench, often referred to as a laminar flow cabinet or clean bench, operates by continuously directing filtered air over the work surface in a unidirectional, smooth, and parallel flow. This constant stream of purified air effectively flushes out airborne contaminants, protecting sensitive samples, processes, and products from external particulate matter and microbial ingress. The market's growth is inherently tied to the expansion of industries reliant on precise contamination control, including pharmaceuticals, biotechnology, and advanced materials.

The primary function of a laminar workbench is to provide an isolated, controlled environment for sterile operations, safeguarding both the material being handled and, in some configurations, the operator. These workbenches utilize High-Efficiency Particulate Air (HEPA) filters, and in more demanding applications, Ultra-Low Particulate Air (ULPA) filters, to capture 99.97% of airborne particles 0.3 micrometers in diameter or larger. The air flow can be either horizontal, where air moves from the back of the cabinet towards the user, or vertical, where air moves downwards from the top of the cabinet to the work surface. Key components include a fan or blower for air movement, a pre-filter to extend the life of the main filter, and the HEPA or ULPA filter itself. Constructed typically from stainless steel or epoxy-coated steel, these units are designed for easy cleaning and resistance to common laboratory chemicals, ensuring longevity and compliance with hygiene standards.

Major applications for laminar workbenches span across diverse scientific and industrial sectors, including pharmaceutical compounding, cell culture, plant tissue culture, electronic component assembly, and forensic analysis. In pharmaceutical and biotechnology companies, they are crucial for aseptic filling, media preparation, and cell line manipulation. Healthcare facilities utilize them for sterile drug compounding, particularly in hospital pharmacies, to prevent microbial contamination of parenteral nutrition solutions and chemotherapy drugs. Academic and research institutions deploy laminar workbenches for microbiological studies, virology research, and general laboratory testing that requires a sterile environment. The benefits of using a laminar workbench are numerous, primarily revolving around superior contamination control, enhanced product quality, increased reproducibility of experimental results, and a degree of user protection from process-generated aerosols. Driving factors for market expansion include escalating investments in life sciences R&D, increasingly stringent regulatory requirements for product sterility and manufacturing environments, and the global surge in demand for biotechnological products, advanced therapies, and personalized medicine.

Laminar Workbench Market Executive Summary

The Laminar Workbench Market is experiencing robust growth driven by continuous advancements in biotechnology, pharmaceuticals, and healthcare, alongside a heightened global focus on laboratory safety and product integrity. Key business trends indicate a shift towards energy-efficient models, integrated digital controls for monitoring and diagnostics, and customizable designs to meet diverse research and manufacturing needs. Manufacturers are increasingly incorporating features such as variable airflow control, ergonomic designs, and advanced filtration technologies to enhance user experience and operational efficiency. The market is also seeing a rise in demand for cost-effective solutions without compromising performance, particularly in emerging economies, fostering innovation in materials and manufacturing processes. These evolving preferences underscore a competitive landscape where product differentiation through technological superiority and customer service is paramount for market leaders.

Regionally, the market exhibits dynamic growth patterns, with North America and Europe traditionally dominating due to strong R&D infrastructure, significant pharmaceutical investments, and strict regulatory frameworks governing sterile environments. However, the Asia Pacific region is rapidly emerging as a pivotal growth engine, propelled by expanding biotechnology and pharmaceutical industries, increasing government funding for scientific research, and growing healthcare expenditure in countries like China, India, and Japan. Latin America and the Middle East & Africa are also demonstrating nascent growth, driven by improvements in healthcare infrastructure and increasing adoption of advanced laboratory practices. These regional trends reflect a global imperative for contamination control, indicating a geographically diversified market with ample opportunities for localized manufacturing and distribution strategies.

Segmentation trends within the laminar workbench market reveal distinct preferences and growth drivers across various product types and end-user industries. Vertical laminar flow workbenches are gaining traction due to their enhanced user protection capabilities, making them a preferred choice for applications involving hazardous biological materials, though they are not biological safety cabinets. Horizontal flow workbenches remain popular for non-hazardous applications where sample protection is the primary concern. In terms of end-users, the pharmaceutical and biotechnology sectors continue to be the largest consumers, fueled by the accelerating pace of drug discovery, vaccine development, and biopharmaceutical manufacturing. Academic and research institutes represent another significant segment, driven by an expanding base of scientific inquiries and educational demands. There is also a growing demand for specialized units tailored for electronics, semiconductors, and food testing, reflecting the diverse need for ultra-clean environments across multiple high-tech industries.

AI Impact Analysis on Laminar Workbench Market

The integration of Artificial Intelligence (AI) into laboratory environments, particularly impacting equipment like laminar workbenches, is a burgeoning area generating significant user inquiry and anticipation. Common questions revolve around how AI can enhance the functionality, efficiency, and safety of these critical devices. Users are keenly interested in predictive maintenance capabilities, seeking to understand if AI can anticipate filter changes, fan malfunctions, or airflow deviations before they impact operations. There is also a strong curiosity regarding AI's potential for smart monitoring, including real-time environmental analysis, automated contamination detection, and intelligent alarm systems that go beyond basic threshold alerts. Furthermore, users explore how AI can integrate laminar workbenches into broader laboratory automation ecosystems, optimizing workflows, tracking usage patterns, and ensuring compliance through data-driven insights. The overarching themes include leveraging AI for proactive issue resolution, enhancing operational intelligence, and contributing to more reliable and precise sterile environments.

- AI-powered predictive maintenance algorithms for critical components like HEPA/ULPA filters and blowers, minimizing downtime.

- Integration of AI for real-time airflow monitoring and self-adjustment, optimizing energy consumption and maintaining consistent laminar flow.

- Smart sensors coupled with AI to detect subtle contamination risks, providing early warnings and improving sterility assurance.

- Automated compliance logging and reporting, utilizing AI to track operational parameters and simplify regulatory audits.

- AI-driven optimization of workflow within the laminar workbench, suggesting ideal placement of materials for improved efficiency and reduced turbulence.

- Enhanced user training and onboarding through AI-guided interactive simulations for proper sterile technique within the workbench.

- Data analytics platforms leveraging AI to analyze usage patterns, environmental conditions, and maintenance history for strategic asset management.

DRO & Impact Forces Of Laminar Workbench Market

The Laminar Workbench Market is significantly shaped by a combination of inherent drivers, palpable restraints, and emerging opportunities, all acting as dynamic impact forces within the competitive landscape. Primary drivers include the continuous and escalating investment in research and development activities across biotechnology, pharmaceutical, and life sciences sectors, which inherently necessitates controlled, sterile environments. The stringent regulatory standards imposed by bodies such as the FDA, EMA, and other national health agencies for sterile manufacturing and laboratory practices also compel widespread adoption of laminar workbenches to ensure product safety and integrity. Furthermore, ongoing technological advancements in filtration systems, motor efficiency, and digital control interfaces enhance the appeal and utility of modern laminar workbenches, driving replacement cycles and new installations.

Conversely, several factors restrain market growth. The high initial capital investment required for purchasing advanced laminar workbenches, coupled with the recurring costs associated with maintenance, filter replacement, and energy consumption, can be prohibitive for smaller laboratories or institutions with limited budgets. The requirement for skilled personnel to operate and maintain these sophisticated pieces of equipment also poses a challenge, particularly in regions with a shortage of trained professionals. Moreover, the emergence of alternative sterile solutions, such as isolators and restricted access barrier systems (RABS) in very high-containment or large-scale aseptic processing applications, presents a potential constraint, as these systems offer higher levels of sterility assurance for specific use cases, though often at a significantly greater cost and complexity.

Opportunities within the market largely stem from the expansion into emerging economies, where burgeoning healthcare infrastructure, increasing government support for scientific research, and growing pharmaceutical manufacturing bases are creating new demand. The trend towards customized laminar workbenches tailored to specific applications, such as specialized ergonomic designs or integration with advanced robotics for automated laboratory processes, also presents significant growth avenues. Furthermore, the development of eco-friendly and energy-efficient models with lower operational costs and reduced environmental impact is becoming a key differentiator, appealing to sustainability-conscious organizations. These opportunities underscore a dynamic market that is responsive to both global industry trends and specific user needs, pushing manufacturers towards innovation in design, functionality, and sustainability.

Segmentation Analysis

The Laminar Workbench Market is meticulously segmented based on various critical parameters, offering a granular view of market dynamics and catering to diverse industrial and research requirements. These segmentations allow for a deeper understanding of product preferences, application-specific demands, and regional consumption patterns, providing valuable insights for market participants and strategic planning. The core segmentations reflect the fundamental design characteristics of the workbenches, the end-user industries they serve, the specific functions they enable, and the type of filtration technology employed, each with distinct growth trajectories and competitive landscapes.

- By Type

- Horizontal Laminar Workbench

- Vertical Laminar Workbench

- By End-User

- Pharmaceutical & Biotechnology Companies

- Healthcare Sector (Hospitals, Clinics, Diagnostic Labs)

- Academic & Research Institutes

- Electronics & Semiconductors Industry

- Food & Beverage Industry

- Forensic Laboratories

- Others (e.g., Veterinary Labs, Environmental Testing)

- By Application

- Sterile Compounding

- Cell Culture & Tissue Culture

- Aseptic Filling & Packaging

- Microbiological & Virological Studies

- Plant Tissue Culture

- Laboratory Testing & Experimentation

- Non-Hazardous Sample Preparation

- By Filter Type

- HEPA Filter

- ULPA Filter

Value Chain Analysis For Laminar Workbench Market

A comprehensive value chain analysis for the Laminar Workbench Market illuminates the sequence of activities that transform raw materials into a finished product delivered to the end-user, highlighting critical stages from upstream procurement to downstream distribution and after-sales support. The upstream segment involves the sourcing and processing of essential raw materials and components, which include high-grade stainless steel or epoxy-coated steel for the cabinet structure, specialized HEPA and ULPA filters, efficient blowers and motors, sophisticated electronic controls, and various ancillary components such as lighting, gauges, and safety interlocks. Key suppliers in this phase are typically specialized manufacturers of filtration media, fan technologies, and precise electronic control units, whose quality and innovation directly impact the final product's performance and reliability. Establishing strong relationships with reputable and consistent suppliers is paramount for maintaining product quality, managing costs, and ensuring a stable supply chain.

The core manufacturing stage involves the assembly, integration, and rigorous testing of these components into the final laminar workbench units. This process requires precision engineering, skilled labor, and adherence to strict quality control protocols to ensure that each unit meets specified airflow patterns, filtration efficiency, and safety standards. Following manufacturing, the downstream analysis encompasses the distribution, sales, installation, and crucial after-sales support services. Distribution channels for laminar workbenches are typically multi-faceted, involving both direct sales to large institutional clients and indirect sales through a network of specialized distributors, laboratory equipment suppliers, and regional dealers. These distributors play a vital role in market penetration, particularly in geographically diverse or emerging markets, by providing local sales support, logistics, and sometimes initial installation and calibration services.

Direct sales strategies are often employed for large volume purchases or highly customized solutions, allowing manufacturers to maintain direct relationships with key clients and gain deeper insights into their specific needs. This approach enables greater control over the sales process, pricing, and service delivery. Conversely, indirect channels leverage the established networks and market expertise of distributors, extending market reach and providing local representation. Regardless of the channel, comprehensive after-sales services, including warranty support, preventative maintenance contracts, filter replacement services, and technical troubleshooting, are critical for customer satisfaction and long-term market competitiveness. The effectiveness of the entire value chain, from material procurement to post-purchase support, directly influences brand reputation, customer loyalty, and ultimately, market share within the competitive laminar workbench industry.

Laminar Workbench Market Potential Customers

The Laminar Workbench Market caters to a diverse and expanding base of potential customers who critically rely on controlled, sterile environments for their operations, making these pieces of equipment indispensable across a multitude of scientific, medical, and industrial applications. The primary end-users are concentrated within the life sciences and healthcare sectors, where the need for contamination control is non-negotiable for ensuring product integrity, experimental reproducibility, and patient safety. Pharmaceutical and biotechnology companies represent a cornerstone of demand, utilizing laminar workbenches extensively for aseptic drug compounding, media preparation, cell culture manipulation, gene therapy research, and the development of vaccines and biologics. These organizations operate under stringent regulatory guidelines, making the consistent performance and reliability of laminar workbenches crucial for compliance and product efficacy.

Beyond the core life sciences, academic and research institutions constitute another significant segment of potential customers. Universities, public research laboratories, and private R&D centers globally invest in laminar workbenches for a broad spectrum of scientific investigations, including microbiology, molecular biology, virology, immunology, and plant tissue culture. These environments often require versatile and robust equipment that can support various experimental protocols while maintaining high standards of sterility. The continuous funding for scientific research, coupled with the global push for innovation in various scientific disciplines, ensures sustained demand from this sector. The academic community's role in training future scientists and technicians also perpetuates the understanding and demand for such fundamental laboratory equipment.

Furthermore, the healthcare sector, encompassing hospitals, clinics, and diagnostic laboratories, represents a critical customer base, particularly for applications like sterile intravenous admixture preparation and chemotherapy compounding in hospital pharmacies. These facilities rely on laminar workbenches to prevent microbial contamination of critical medications, thereby safeguarding patient health and complying with pharmaceutical compounding standards. The electronics and semiconductor industries also represent a niche yet significant segment, where ultra-clean environments are essential for assembling sensitive microelectronic components to prevent particulate contamination that could compromise device performance. Other emerging customer segments include forensic laboratories, veterinary clinics, and some specialized food and beverage quality control labs that require aseptic conditions for specific testing procedures. The pervasive need for contamination control across a wide array of high-precision and sensitive industries ensures a broad and growing customer base for laminar workbenches.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 735 Million |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific Inc., Esco Group, Labconco Corporation, NuAire Inc., Kewaunee Scientific Corporation, Waldner Laboreinrichtungen GmbH & Co. KG, AirClean Systems, Inc., The Baker Company, Bigneat Ltd, Clean Air Technologies, Inc., Euroclone S.p.A., Cruma S.A., Jeio Tech Co., Ltd., Flow Science, Angelantoni Life Science, Basan GmbH, BINDER GmbH, Opticap GmbH, Zhejiang Fuxia Medical Technology Co., Ltd., Steril Solution |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laminar Workbench Market Key Technology Landscape

The technological landscape of the Laminar Workbench Market is characterized by continuous innovation aimed at enhancing efficiency, safety, ergonomic design, and user-friendliness, while simultaneously reducing operational costs and environmental impact. At the core of these advancements is sophisticated filtration technology, with HEPA (High-Efficiency Particulate Air) filters being the standard and ULPA (Ultra-Low Particulate Air) filters offering even higher retention rates for minute particles, critical for the most demanding applications. Beyond the filters themselves, the design of the filtration system, including filter loading mechanisms and gasket seals, is continuously refined to prevent bypass leakage and ensure maximal particulate removal efficiency throughout the filter's lifespan. These filtration systems are often coupled with advanced fan and motor technologies.

Modern laminar workbenches increasingly feature energy-efficient DC ECM (Electronically Commutated Motor) blowers, which offer superior performance, quieter operation, and significantly lower power consumption compared to traditional AC motors. This not only translates to reduced running costs but also contributes to a more sustainable laboratory environment, aligning with global green initiatives. Integrated microprocessor control systems are another pivotal technological advancement, allowing for precise control over airflow velocity, digital display of operational parameters, filter life monitoring, and sophisticated alarm systems for deviations in performance. These intelligent control panels often include programmable features, allowing users to optimize settings for different applications and schedule maintenance alerts.

Further technological integration includes ergonomic design features such as adjustable work surfaces, LED lighting that minimizes glare and heat generation, and quiet operation levels that improve user comfort and reduce fatigue during long working hours. Connectivity features, such as USB ports or Ethernet connections, are also emerging, enabling data logging, remote monitoring, and integration with broader laboratory information management systems (LIMS) for enhanced operational oversight and compliance. Some advanced models incorporate interlocking systems for accessories or automatic sash closure mechanisms, further enhancing safety and preventing contamination risks. The overarching trend is towards "smart" workbenches that offer not just aseptic conditions but also intelligent monitoring, energy efficiency, and seamless integration into the automated laboratory of the future, all contributing to safer, more efficient, and more reliable research and manufacturing processes.

Regional Highlights

- North America: This region holds a significant share of the Laminar Workbench Market, driven by robust R&D spending in the pharmaceutical and biotechnology sectors, the presence of numerous leading research institutions, and stringent regulatory frameworks. The United States, in particular, showcases a high adoption rate due to substantial government and private sector investments in life sciences, advanced healthcare infrastructure, and a strong culture of innovation in laboratory technologies. Canada also contributes significantly, supported by its growing biopharmaceutical industry and a commitment to scientific advancement. The region is characterized by a demand for high-end, technologically advanced, and compliant laminar workbenches.

- Europe: Europe represents another key market, propelled by a well-established pharmaceutical industry, a strong academic research base, and widespread adoption of Good Manufacturing Practices (GMP) and other regulatory standards. Countries such as Germany, the UK, France, and Switzerland are at the forefront, with significant investments in drug discovery, advanced therapies, and clinical research. The European market emphasizes energy efficiency, ergonomic design, and integration with laboratory automation, reflecting a mature market focused on sustainable and efficient laboratory operations. Funding from the European Union for research initiatives further stimulates market growth.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for laminar workbenches, fueled by rapid industrialization, increasing healthcare expenditure, and burgeoning biotechnology and pharmaceutical sectors in countries like China, India, Japan, and South Korea. These nations are experiencing a surge in contract research and manufacturing organizations (CROs and CMOs), coupled with growing government support for local R&D initiatives. The demand is driven by the need for modern laboratory infrastructure, an expanding patient base, and the increasing focus on localized drug development and manufacturing capabilities. The region also presents significant opportunities for both established international players and local manufacturers.

- Latin America: The Laminar Workbench Market in Latin America is experiencing gradual growth, primarily driven by improving healthcare infrastructure, increasing investments in pharmaceutical manufacturing, and expanding academic and research activities in countries such as Brazil, Mexico, and Argentina. Governments and private entities are increasingly focusing on modernizing laboratory facilities to meet international standards, especially in the context of vaccine production and local drug manufacturing. However, economic volatility and limited R&D budgets in some areas can present challenges, leading to a demand for cost-effective yet reliable solutions.

- Middle East and Africa (MEA): This region is an emerging market for laminar workbenches, with growth spurred by increasing investments in healthcare infrastructure, particularly in the GCC countries, and a growing emphasis on local pharmaceutical production and scientific research. Efforts to diversify economies away from oil dependency are leading to greater funding for science and technology parks. South Africa, in particular, has a relatively developed research landscape. The market here is characterized by a growing awareness of the importance of contamination control in clinical, pharmaceutical, and academic settings, often supported by international partnerships and technology transfer initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laminar Workbench Market.- Thermo Fisher Scientific Inc.

- Esco Group

- Labconco Corporation

- NuAire Inc.

- Kewaunee Scientific Corporation

- Waldner Laboreinrichtungen GmbH & Co. KG

- AirClean Systems, Inc.

- The Baker Company

- Bigneat Ltd

- Clean Air Technologies, Inc.

- Euroclone S.p.A.

- Cruma S.A.

- Jeio Tech Co., Ltd.

- Flow Science

- Angelantoni Life Science

- Basan GmbH

- BINDER GmbH

- Opticap GmbH

- Zhejiang Fuxia Medical Technology Co., Ltd.

- Steril Solution

Frequently Asked Questions

Analyze common user questions about the Laminar Workbench market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a laminar workbench?

A laminar workbench, or laminar flow cabinet, is a laboratory enclosure that provides a contamination-free work environment by directing filtered, unidirectional air over the work surface, protecting sensitive materials from airborne particulates and microorganisms. It uses HEPA or ULPA filters to achieve sterility.

What are the main applications of laminar workbenches?

Laminar workbenches are primarily used for sterile compounding in pharmacies, cell and tissue culture, aseptic filling, plant tissue culture, and general laboratory testing where sample protection from environmental contamination is crucial, particularly in pharmaceutical, biotechnology, and academic research settings.

What is the difference between horizontal and vertical laminar flow?

Horizontal laminar flow workbenches direct filtered air horizontally from the back of the cabinet across the work surface towards the user, offering excellent product protection. Vertical laminar flow workbenches move filtered air downwards from the top of the cabinet to the work surface, providing both product and a degree of user protection from fumes generated within the cabinet, although they are not biosafety cabinets.

How often should HEPA filters in a laminar workbench be changed?

The frequency of HEPA filter changes depends on usage, air quality of the environment, and manufacturer recommendations, but typically ranges from 3 to 5 years under normal operating conditions. Regular performance testing, such as HEPA filter integrity testing (DOP test), helps determine the optimal replacement schedule and ensures continued efficacy.

What regulations govern the use of laminar workbenches?

The use of laminar workbenches is governed by various international and national standards, including ISO 14644 for cleanrooms and associated controlled environments, NSF/ANSI 49 for Biosafety Cabinetry (though laminar workbenches are not biosafety cabinets, some principles overlap for airflow), and industry-specific guidelines such as USP <797> and USP <800> for sterile compounding in pharmacies. Adherence ensures product quality, user safety, and regulatory compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager