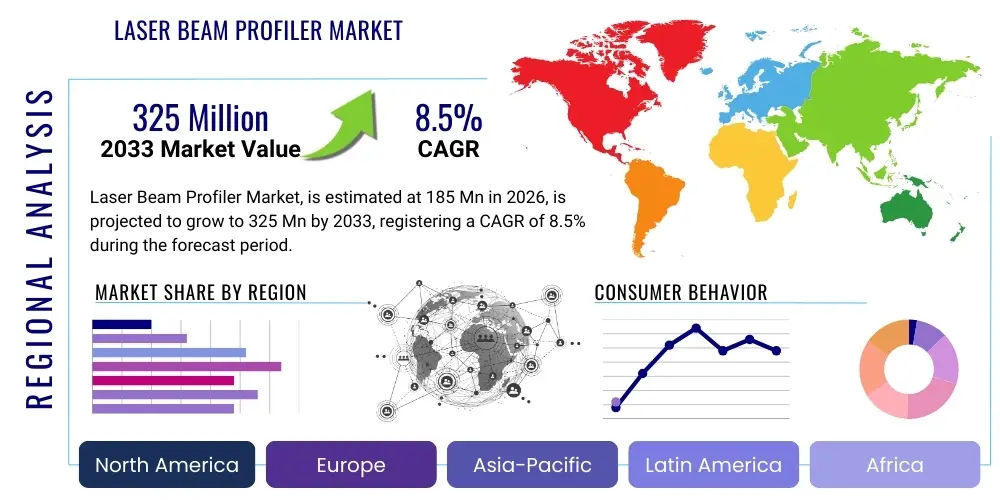

Laser Beam Profiler Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443035 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Laser Beam Profiler Market Size

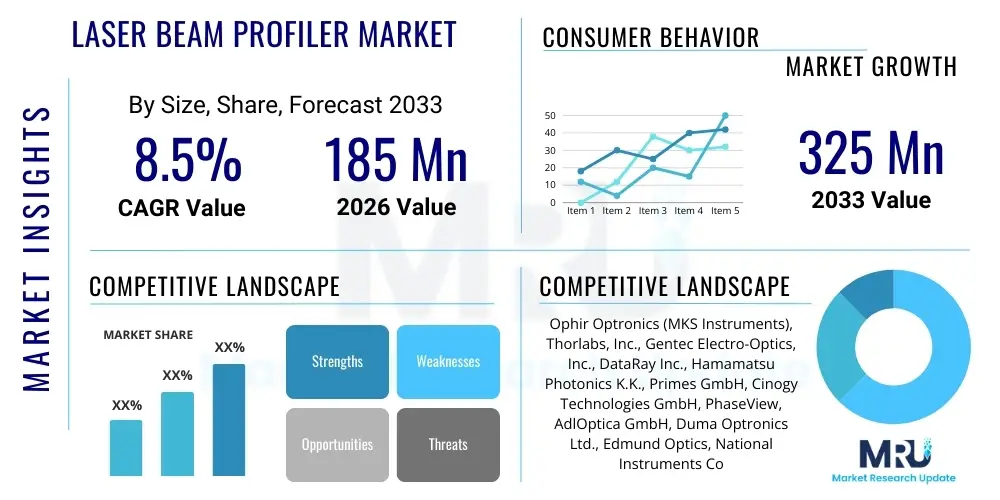

The Laser Beam Profiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 185 Million in 2026 and is projected to reach USD 325 Million by the end of the forecast period in 2033.

Laser Beam Profiler Market introduction

The Laser Beam Profiler Market encompasses instruments and systems designed to measure the spatial intensity distribution, or profile, of a laser beam. These measurements are critical for ensuring optimal performance, consistency, and quality control across diverse applications, particularly those requiring extreme precision, such as micro-machining, medical surgery, semiconductor fabrication, and advanced scientific research. Laser beam profilers analyze key beam parameters including beam width, beam shape (e.g., Gaussian, top-hat), beam divergence, and beam quality (M²), providing essential feedback necessary for system alignment, calibration, and long-term stability monitoring. The increasing adoption of high-power and ultrafast lasers in industrial settings is directly fueling the demand for sophisticated profiling solutions that can withstand high fluence levels while delivering accurate, real-time data.

Products within this market range significantly in terms of technology, including CCD/CMOS camera-based profilers, scanning slit profilers, knife-edge profilers, and pyroelectric arrays, each suited for different wavelength ranges, power levels, and beam sizes. Camera-based systems offer high spatial resolution and are predominantly used for continuous wave (CW) and pulsed lasers operating in the visible and near-infrared spectra. Conversely, scanning slit profilers offer superior dynamic range and are often favored for very small beam diameters or applications demanding high precision for beam width measurements, while pyroelectric arrays are essential for mid- to far-infrared wavelengths, where traditional silicon or InGaAs sensors are ineffective.

The primary benefits derived from using laser beam profilers include improved process yield, reduced material wastage, enhanced product reliability, and regulatory compliance, particularly in regulated industries like medical device manufacturing and aerospace. Driving factors for market expansion include the proliferation of Industry 4.0 initiatives necessitating automated quality assurance, the rapid expansion of optical communication technologies, and substantial investments in quantum computing and advanced research facilities globally. As laser systems become more complex, integrating precise, robust, and software-driven profiling capabilities is becoming mandatory rather than optional.

Laser Beam Profiler Market Executive Summary

The Laser Beam Profiler Market is characterized by robust growth, driven primarily by escalating demand from high-precision manufacturing sectors and burgeoning research and development activities in photonics. A significant business trend involves the shift towards highly integrated, compact, and plug-and-play profiling systems, facilitated by advances in sensor technology and faster processing capabilities. Vendors are increasingly focusing on developing software solutions that provide complex mathematical analysis and predictive maintenance features, allowing users to move beyond simple beam spot measurement to comprehensive beam propagation characterization (M² measurements) in industrial environments. Strategic collaborations between profiler manufacturers and laser system integrators are becoming crucial to offer seamless, embedded solutions for OEM customers.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, attributed to the massive concentration of semiconductor fabrication plants, automotive manufacturing, and consumer electronics production hubs, particularly in China, Japan, South Korea, and Taiwan. These regions utilize high volumes of lasers in processes like cutting, welding, drilling, and lithography, creating continuous demand for quality control instruments. North America and Europe, while representing mature markets, maintain high revenue shares driven by significant governmental and private funding into advanced research, defense technologies, and specialized medical device manufacturing, demanding high-end, customized profiler solutions.

Segment-wise, the CCD/CMOS Camera-Based Profilers segment retains the largest market share due to its versatility, high resolution, and cost-effectiveness for visible and near-infrared lasers. However, the Scanning Slit Profilers segment is anticipated to exhibit rapid growth, especially in applications requiring highly accurate beam width measurements and compatibility with extremely high-power continuous wave (CW) lasers, where camera-based solutions often struggle with saturation or heat dissipation. Application trends indicate that industrial material processing remains the dominant end-user category, although the medical and life sciences segment is projected to show the highest CAGR, driven by the expanding use of surgical lasers and ophthalmology equipment requiring rigorous quality checks.

AI Impact Analysis on Laser Beam Profiler Market

Common user inquiries concerning AI's integration into the Laser Beam Profiler Market primarily revolve around questions regarding automated system alignment, predictive capabilities for laser drift, and the ability of AI algorithms to process and interpret massive datasets generated by high-repetition-rate laser systems. Users are keen to understand how AI can minimize human intervention in repetitive calibration tasks, thereby improving operational efficiency and throughput in industrial settings. Concerns often touch upon the required computational overhead, the standardization of training data for varied beam profiles, and the reliability of AI-driven optimization feedback loops in mission-critical applications.

Based on this analysis, the key themes summarizing user expectations are optimization, automation, and predictive maintenance. Users anticipate AI transforming profiling from a diagnostic tool into a proactive control element. AI is expected to enable real-time, closed-loop feedback systems that automatically adjust laser parameters (such as optics, mirrors, or power levels) to maintain a predefined optimal beam profile, even in the presence of thermal drift or external disturbances. This move from passive measurement to active, intelligent control is the core value proposition of AI in this domain, substantially reducing downtime and ensuring continuous process quality.

Furthermore, AI-powered image recognition and anomaly detection algorithms are essential for managing the complexity of non-Gaussian beam profiles and detecting subtle defects or changes that a human operator or traditional threshold-based software might miss. By analyzing long-term trends in beam quality metrics (like M² variation over time), AI can predict component failure or required maintenance schedules for the laser source or the associated optics, transitioning maintenance from reactive to truly predictive, thereby maximizing the lifespan and efficiency of expensive laser systems.

- Enables fully automated, closed-loop beam alignment and optimization processes.

- Facilitates real-time anomaly detection in complex, high-repetition-rate laser pulses.

- Provides predictive maintenance alerts for laser source drift or optical degradation based on historical beam quality data.

- Enhances data interpretation and classification of non-standard or custom beam shapes using deep learning algorithms.

- Improves M² measurement speed and accuracy by optimizing data acquisition and fit algorithms.

DRO & Impact Forces Of Laser Beam Profiler Market

The dynamics of the Laser Beam Profiler Market are significantly influenced by a combination of influential Drivers (D), inherent Restraints (R), and compelling Opportunities (O), which collectively define the Impact Forces shaping industry evolution. A primary Driver is the global adoption of Industry 4.0 and smart manufacturing paradigms, which mandate highly accurate, traceable, and automated quality control for every stage of laser-based processes. Coupled with this is the rapid expansion of high-power industrial fiber and diode lasers used in cutting-edge applications, requiring sophisticated profilers capable of handling extreme intensity while delivering sub-micron precision.

Conversely, the market faces constraints, most notably the high initial cost associated with advanced profiling systems, particularly those designed for specialized wavelengths (e.g., EUV, deep UV) or high-energy measurement (pyroelectric arrays), which acts as a barrier to entry for smaller enterprises or research labs with limited capital budgets. Additionally, the complexity inherent in accurately characterizing exotic beam shapes and ensuring reproducible calibration across different environmental conditions requires highly specialized technical expertise, often creating a dependency on vendor support and increasing operational overhead.

The predominant Opportunities lie in the burgeoning fields of LiDAR technology for autonomous vehicles and advanced medical diagnostics, both of which rely heavily on precisely engineered and characterized laser beams. Furthermore, the development of compact, portable, and wireless profilers tailored for field service applications presents a significant avenue for market expansion beyond traditional laboratory settings. The overall impact force is strongly positive, driven by the fundamental necessity of precision metrology in modern photonics, making profilers indispensable tools for maintaining global manufacturing standards and advancing scientific discovery.

Segmentation Analysis

The Laser Beam Profiler Market is comprehensively segmented based on technology, end-user industry, measurement method, and regional geography, allowing for a detailed understanding of market dynamics and specialized application requirements. Technology segmentation distinguishes between the fundamental methods used to capture the beam profile, directly correlating system choice with required wavelength, power handling capacity, and spatial resolution. End-user segmentation reveals the dominant sectors driving revenue, indicating where critical quality control using lasers is most prevalent, such as in semiconductor, automotive, and medical fields.

Within the technology landscape, camera-based profilers (CCD/CMOS) dominate due to their ability to provide high-resolution, 2D images of the beam shape, making them highly suitable for low to medium-power visible and near-IR applications. Scanning slit and knife-edge methods, while offering lower complexity and robustness against high power, are preferred where precise M² measurements and high-dynamic range are critical, often serving the needs of high-power material processing centers and military applications. Pyroelectric arrays are essential niche segments, ensuring that mid- and far-infrared lasers, crucial for defense and certain industrial heating processes, can also be accurately profiled.

The increasing complexity of laser systems necessitates diverse profiling solutions, ensuring that whether a user requires real-time monitoring of a continuous wave fiber laser or the analysis of ultrafast picosecond pulses, an appropriate technological solution exists. This structural segmentation aids both manufacturers in focusing R&D efforts and end-users in selecting the optimal system to meet stringent quality and performance standards required in their specific operational environment.

- By Technology:

- CCD/CMOS Camera-Based Profilers

- Scanning Slit Profilers

- Knife-Edge Profilers

- Pyroelectric Array Profilers

- Others (E.g., Virtual Profilers, Phosphor-coated sensors)

- By Application:

- Industrial Material Processing (Cutting, Welding, Marking, Drilling)

- Medical and Aesthetics (Surgery, Ophthalmology, Dermatology)

- Research and Scientific (Physics, Chemistry, Biology, Quantum)

- Defense and Aerospace (Targeting, Ranging, Directed Energy)

- Telecommunications and Optical Storage

- By Measurement Type:

- Continuous Wave (CW) Laser Profiling

- Pulsed Laser Profiling (Nanosecond, Picosecond, Femtosecond)

- By Spectral Range:

- UV and Deep UV

- Visible and Near-Infrared (NIR)

- Mid-Infrared (MIR) and Far-Infrared (FIR)

Value Chain Analysis For Laser Beam Profiler Market

The value chain for the Laser Beam Profiler Market begins with upstream suppliers providing critical components, notably high-resolution sensor arrays (CCD, CMOS, Pyroelectric materials), advanced optical components (lenses, filters, attenuators), and specialized microprocessors. The quality and performance of these upstream components directly dictate the accuracy, dynamic range, and speed of the final profiler system. Key challenges in this stage include securing a reliable supply of highly specialized, low-noise sensors and maintaining stringent quality control over optical element manufacturing to minimize aberration and distortion in the acquired beam image.

The central manufacturing stage involves the system integration, calibration, and software development by the profiler vendors. This phase adds substantial value through proprietary algorithms for beam fitting (e.g., M² calculation), thermal management design for high-power profilers, and user interface development focused on ease of use and compliance reporting. Distribution channels are typically a mix of direct sales teams catering to large industrial OEMs and specialized research institutes, and indirect channels relying on technical distributors or representatives who possess deep knowledge of regional laser applications and integration needs. The distributor network is essential for providing localized technical support and initial product setup.

Downstream analysis focuses on end-users across industrial, medical, and scientific applications. The after-sales service, which includes periodic calibration, software updates, and technical training, forms a critical part of the value proposition, ensuring the long-term reliability and accuracy of the measurement systems. The efficiency of this value chain is increasingly reliant on minimizing latency between measurement and feedback, particularly as profilers become integrated components within automated production lines, demanding robust connectivity and real-time data processing capabilities.

Laser Beam Profiler Market Potential Customers

Potential customers for laser beam profilers are primarily organizations where the consistency and quality of a laser beam are paramount for their final product yield, research integrity, or service reliability. The largest group constitutes industrial manufacturers involved in micro-machining, additive manufacturing (3D printing), and electronics fabrication, including semiconductor companies using lasers for lithography, annealing, and dicing processes. These users require profilers for continuous monitoring to prevent costly production failures caused by beam drift or degradation, linking measurement quality directly to revenue generation.

Another crucial customer segment is represented by scientific research institutions, universities, and national laboratories engaged in cutting-edge physics experiments, materials science, and quantum technology development. These customers often utilize highly specialized, ultra-fast or high-energy lasers, necessitating profilers capable of handling complex temporal and spatial characteristics. For these researchers, the profiler is an essential diagnostic tool for optimizing experimental setups and validating theoretical models related to light-matter interaction.

Furthermore, the medical device and aesthetics industry forms a rapidly growing customer base. Manufacturers of surgical lasers, dermatological systems, and diagnostic tools must comply with strict regulatory standards (e.g., FDA, CE marking), mandating consistent beam quality documentation for patient safety and efficacy. These end-users demand highly reliable, easy-to-use profilers that can perform rapid, standardized quality checks before deployment and during routine maintenance cycles. Lastly, defense contractors and aerospace firms use profilers to ensure the precision and stability of directed energy weapons, targeting systems, and advanced remote sensing apparatus.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185 Million |

| Market Forecast in 2033 | USD 325 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ophir Optronics (MKS Instruments), Thorlabs, Inc., Gentec Electro-Optics, Inc., DataRay Inc., Hamamatsu Photonics K.K., Primes GmbH, Cinogy Technologies GmbH, PhaseView, AdlOptica GmbH, Duma Optronics Ltd., Edmund Optics, National Instruments Corp., CVI Laser Optics, Greenlight Optics, Holo/Or Ltd., Laser Components GmbH, SCANTEAM, Teledyne FLIR, Toptica Photonics, Coherent Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Beam Profiler Market Key Technology Landscape

The technological landscape of the Laser Beam Profiler Market is defined by continuous innovation aimed at increasing measurement speed, spatial resolution, dynamic range, and compatibility across diverse laser parameters, especially concerning high-power and ultrafast laser sources. A primary technological focus is the optimization of sensor technology, particularly the evolution of CCD and CMOS sensors to handle higher frame rates and reduce noise floor, allowing for rapid, accurate analysis of high-repetition-rate pulsed lasers. Non-contact measurement techniques, such as those employing advanced adaptive optics or wavefront sensors integrated with profiling capability, are gaining traction, providing a means to measure beam quality without physically intercepting or attenuating the beam, which is critical for extremely high-power industrial applications.

Furthermore, significant advancements are centered around software and data processing capabilities. Modern profilers are highly integrated with proprietary software offering extensive analysis features, including automated M² measurements, beam propagation modeling, and compliance reporting tools tailored to ISO standards. The integration of powerful processing units allows for real-time calculation of complex metrics, minimizing latency in closed-loop feedback systems used in precision manufacturing. The trend toward miniaturization is also highly evident, with manufacturers developing compact, USB-powered, and wireless profiling heads designed for easy integration into machine vision systems and space-constrained OEM environments, enhancing portability and ease of field deployment.

The challenge of profiling ultra-fast (femtosecond and picosecond) lasers has driven innovation in specialized techniques, such as the use of advanced pulse stretching and temporal-to-spatial mapping methods, ensuring accurate characterization of these beams crucial for applications like two-photon microscopy and highly precise micro-ablation. For infra-red profiling, improvements in microbolometer and pyroelectric array technologies have enhanced sensitivity and resolution across the MIR and FIR spectra. Overall, the technological trajectory is moving towards integrated smart systems that combine measurement, analysis, and active laser control through sophisticated algorithms and robust hardware interfaces, driving higher automation levels in quality control across all photonics-enabled industries.

Regional Highlights

- Asia Pacific (APAC): APAC commands the leading share and is the fastest-growing market globally. This dominance is fundamentally driven by the region's status as the global manufacturing hub, particularly for semiconductors, consumer electronics, and automotive components. Countries like China, South Korea, and Taiwan invest heavily in laser material processing technologies, necessitating mandatory beam profiling for quality assurance. Government initiatives promoting high-tech manufacturing and increased R&D spending in quantum optics and optical communications further solidify APAC's market position, characterized by high volume demand for affordable and reliable profiler solutions.

- North America: North America represents a mature yet highly valuable market, characterized by demand for high-end, technologically advanced profiling systems. Growth is sustained by substantial governmental and private sector investment in defense technologies (directed energy), advanced medical device manufacturing, and cutting-edge academic research, including fusion energy and advanced lithography. The presence of major laser and photonics companies and a strong emphasis on compliance with quality standards (e.g., ISO 11146 for M² measurement) ensures consistent demand for premium, highly accurate beam profilers and related software solutions.

- Europe: Europe holds a significant market share, fueled by a strong industrial base, particularly in Germany (precision engineering and automotive), and robust scientific research in countries like the UK and France. The region focuses heavily on industrial automation (Industry 4.0) and sustainable manufacturing, where laser processing efficiency is paramount. European regulations promoting quality control and traceability in production processes necessitate the use of accurate and frequently calibrated laser beam profiling equipment. The region shows strong adoption of specialized systems for metrology and customized high-power laser applications.

- Latin America (LATAM): The LATAM market is nascent but exhibits moderate growth, primarily driven by expanding medical aesthetics sectors and increasing industrial automation in key economies like Brazil and Mexico. The demand focuses mainly on standard, reliable profiling solutions for established industrial lasers and a growing need for technical support infrastructure.

- Middle East and Africa (MEA): The MEA market is the smallest contributor but shows potential, particularly in the UAE and Saudi Arabia due to investments in diversification, including defense modernization and the establishment of high-tech research centers. Demand is currently sporadic and highly dependent on large-scale infrastructure and defense procurement projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Beam Profiler Market.- Ophir Optronics (MKS Instruments)

- Thorlabs, Inc.

- Gentec Electro-Optics, Inc.

- DataRay Inc.

- Hamamatsu Photonics K.K.

- Primes GmbH

- Cinogy Technologies GmbH

- PhaseView

- AdlOptica GmbH

- Duma Optronics Ltd.

- Edmund Optics

- National Instruments Corp.

- CVI Laser Optics

- Greenlight Optics

- Holo/Or Ltd.

- Laser Components GmbH

- SCANTEAM

- Teledyne FLIR

- Toptica Photonics

- Coherent Corp.

Frequently Asked Questions

Analyze common user questions about the Laser Beam Profiler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a laser beam profiler in industrial settings?

The primary function is to measure and analyze the spatial intensity distribution, beam width, and M² beam quality parameter of a laser, ensuring the laser system maintains optimal performance, consistency, and alignment necessary for high-precision manufacturing processes such as cutting, welding, and micromachining, thereby maximizing process yield.

Which technology segment dominates the Laser Beam Profiler Market?

The CCD/CMOS Camera-Based Profilers segment typically dominates the market, offering high spatial resolution and versatility for measuring CW and pulsed lasers in the visible and near-infrared spectral ranges. Their advanced software integration and relatively high affordability for standard applications drive their widespread adoption across research and industrial quality control.

How does the integration of AI impact laser beam profiling accuracy and efficiency?

AI significantly enhances efficiency by enabling automated, closed-loop optimization systems that maintain beam quality in real-time, compensating for environmental or thermal drift without human intervention. AI also improves accuracy in data interpretation and predictive maintenance by analyzing complex beam profiles and long-term performance trends.

What are the key drivers for market growth in the Asia Pacific region?

The key drivers in APAC include the immense concentration of semiconductor fabrication facilities, robust consumer electronics manufacturing hubs, and large-scale industrial automation initiatives (Industry 4.0), all requiring stringent laser quality control systems to ensure high-volume, defect-free production.

What is the main challenge when profiling high-power or ultra-fast pulsed lasers?

The main challenge is managing extreme energy density and preventing sensor saturation or damage, requiring specialized components like highly attenuating optics (for high power) and advanced triggering/synchronization mechanisms combined with specialized measurement techniques (for ultra-fast pulses) to accurately capture the transient beam characteristics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Laser Beam Profiler Market Size Report By Type (190-1100 nm, 1440-1605 nm, Others (800-1700 nm, etc.)), By Application (Research Institute, Industry, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Industry Laser Beam Profiler Market Statistics 2025 Analysis By Application (Manufacturing, Semiconductor), By Type (190-1100 nm, 1440-1605 nm), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager