Lifting Tong Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443209 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Lifting Tong Market Size

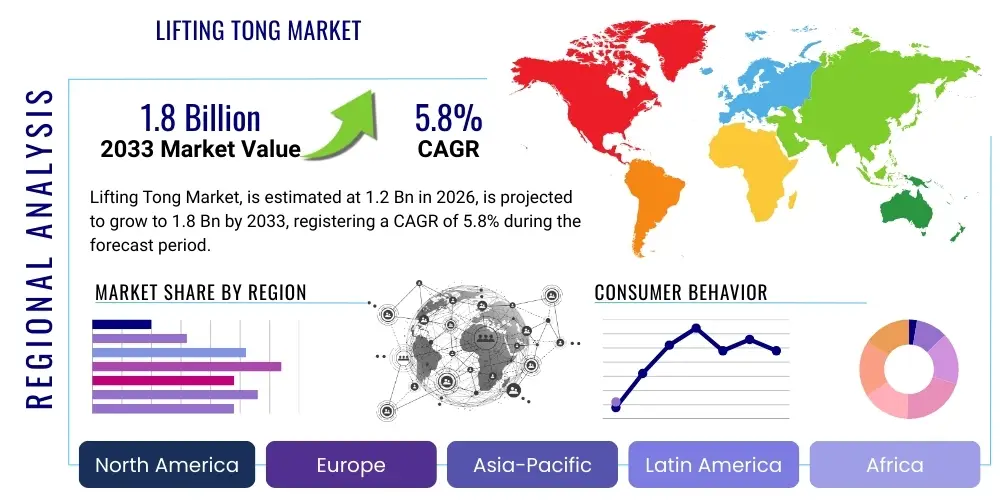

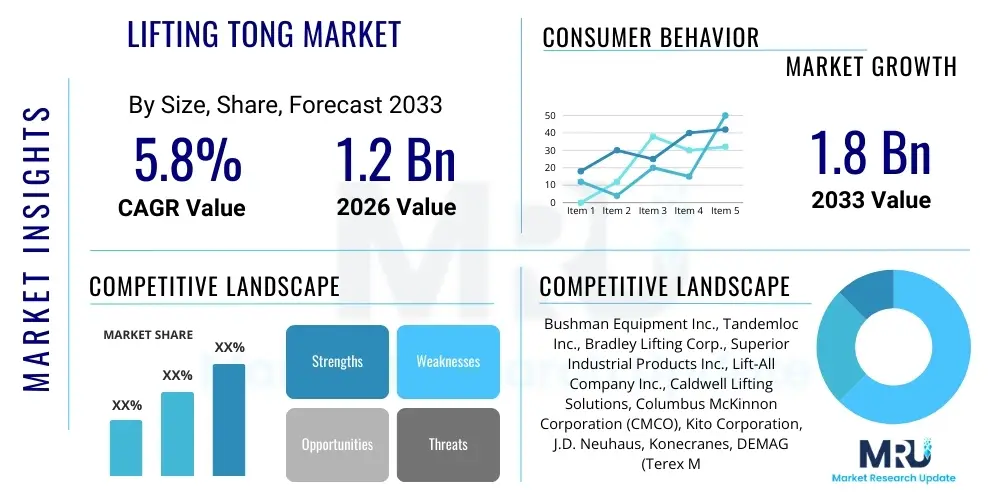

The Lifting Tong Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.8 Billion by the end of the forecast period in 2033.

Lifting Tong Market introduction

The Lifting Tong Market encompasses specialized material handling equipment designed for securely gripping, lifting, and transporting heavy, often irregularly shaped, objects in industrial settings. These mechanical devices provide a reliable, hands-free method for material transfer, significantly enhancing workplace safety and operational efficiency. The primary function of a lifting tong is to distribute the load evenly, ensuring stability and preventing damage to the material being moved. They are crucial components in infrastructure-heavy industries where massive loads, such as steel coils, concrete slabs, pipes, and billets, are routinely handled. The fundamental mechanism often involves a scissor or gravity-operated clamping action, adapting automatically to the load size within its operational range. Different designs, such as vertical coil tongs, slab tongs, and pipe tongs, are optimized for specific industrial loads.

Major applications for lifting tongs span critical sectors including metallurgy, construction, shipbuilding, precast concrete manufacturing, and general heavy logistics. In the steel industry, tongs are indispensable for handling hot and cold rolled coils and slabs within processing plants and storage yards, where high temperatures and significant weight necessitate robust, specialized tools. The benefits of deploying advanced lifting tongs include reduced manual labor requirements, minimized risk of dropped loads, increased speed of material throughput, and compliance with stringent occupational safety standards. Modern tongs often integrate sensors and locking mechanisms to further guarantee load integrity during movement, contributing to overall operational excellence and asset protection.

Driving factors propelling market expansion include rapid urbanization, leading to increased demand for steel and construction materials, particularly in the Asia Pacific region. Furthermore, the global emphasis on workplace safety mandates the replacement of outdated or manual lifting methods with certified, reliable tong systems. Technological advancements, such as the integration of remote operation capabilities and weight monitoring systems, are also boosting adoption, making specialized tongs a critical investment for industries focused on maximizing efficiency and adhering to global manufacturing standards.

Lifting Tong Market Executive Summary

The global Lifting Tong Market is exhibiting steady growth, primarily driven by the robust recovery and expansion of the global industrial and manufacturing sectors, especially metallurgy and infrastructure development. Key business trends indicate a strong move towards automated and semi-automated lifting solutions, favoring tongs integrated with modern crane systems and IoT technologies for real-time monitoring of load capacity and operational status. Manufacturers are focusing on developing tongs constructed from high-strength, lightweight alloys to increase efficiency and durability while adhering to increasingly strict load safety certifications. Furthermore, customization is a significant trend, with end-users demanding specialized tong designs capable of handling unique geometries found in specialized manufacturing, such as aerospace components or specialized piping infrastructure.

Regionally, the Asia Pacific (APAC) dominates the market, largely due to massive infrastructure projects in China and India, coupled with high steel production volumes in the region. North America and Europe maintain strong market positions characterized by high adoption rates of premium, safety-compliant, and technologically advanced tongs, often mandated by strict regulatory frameworks like OSHA and CE standards. Emerging economies in Latin America and the Middle East & Africa (MEA) are seeing accelerated growth as industrialization projects and oil and gas sector investments necessitate reliable heavy material handling equipment, creating lucrative opportunities for market penetration by established global vendors.

In terms of segmentation, the material type segment (e.g., steel, concrete, pipe) and the operation type segment (e.g., automatic, semi-automatic, manual) are the primary differentiators shaping market dynamics. Automatic lifting tongs, which eliminate the need for an operator to physically engage the clamping mechanism, are experiencing the fastest growth due to efficiency gains and improved safety performance. The Coil Tong sub-segment remains dominant owing to the sheer volume of steel coil production worldwide, while the Slab Tong segment is also expanding robustly driven by the construction and heavy manufacturing industries.

AI Impact Analysis on Lifting Tong Market

User queries regarding the impact of Artificial Intelligence (AI) on the Lifting Tong Market primarily revolve around themes of predictive maintenance, autonomous operation, and enhanced safety monitoring. Users are keenly interested in how AI can move lifting tongs beyond simple mechanical functionality into intelligent material handling systems. Specific concerns include the feasibility of AI-driven defect detection during lifting, optimizing crane paths based on real-time load distribution, and minimizing equipment downtime through predictive analytics derived from sensor data embedded in the tongs. Expectations center on AI integrating the tongs seamlessly into broader smart factory ecosystems, providing immediate diagnostics, automating load measurement, and ultimately reducing the potential for human error and catastrophic failure during critical lifting operations. The integration of AI aims to standardize lifting protocols and enhance compliance tracking.

- AI-Driven Predictive Maintenance: Utilizing sensor data from tongs (strain, temperature, cycle count) to forecast component failure, minimizing unexpected downtime.

- Autonomous Operation Integration: Enabling tongs to interact with AI-controlled automated guided vehicles (AGVs) and cranes for fully robotic material transfer sequences.

- Real-Time Load Optimization: AI algorithms assessing load eccentricity and dynamically adjusting lifting parameters to ensure stability and prevent load slippage.

- Enhanced Safety Protocols: AI systems analyzing video feeds and sensor input to instantly detect unsafe lifting practices or environment hazards, triggering automated stops or warnings.

- Digital Twin Modeling: Creating virtual replicas of tong components to simulate stress scenarios, aiding in the design of more robust and durable products.

- Inventory Management Automation: Tongs equipped with vision systems and AI recognition capabilities automatically logging and verifying the material being moved into inventory systems.

DRO & Impact Forces Of Lifting Tong Market

The Lifting Tong Market is fundamentally influenced by the strong growth drivers rooted in global industrialization and infrastructure development, which necessitate the efficient and safe movement of heavy materials. Restraints include the high initial capital investment required for specialized, high-capacity automatic tongs, particularly for smaller manufacturing enterprises, alongside the technical challenge of standardizing tong interfaces across diverse industrial crane systems. Opportunities are significantly present in the development of lightweight, composite material tongs for specialized applications like aerospace, and the integration of IoT and remote monitoring capabilities to enhance operational safety and traceability. The major impact forces driving change are stringent global safety regulations (especially in developed nations), the rising cost of industrial labor necessitating automation, and technological evolution focusing on smart, connected lifting devices.

Key drivers include the global push towards automation in heavy industries, aiming to reduce dependency on manual labor and increase handling precision. Robust economic growth in emerging markets fuels massive construction and infrastructure programs, directly boosting demand for high-capacity steel and slab handling tongs. Additionally, the increasing stringency of occupational safety and health regulations worldwide forces end-users to upgrade legacy equipment with certified, modern lifting tongs that incorporate advanced safety features such as automatic locks and overload indicators. The necessity for higher throughput in modern manufacturing environments also compels companies to invest in faster, automatic tong systems.

Conversely, the market faces restraints such as the volatility in raw material costs, particularly steel and high-grade alloys used in tong construction, which can impact final product pricing and profit margins. Furthermore, the specialized nature of many lifting tongs requires high maintenance expertise and costs, potentially deterring widespread adoption among companies lacking specialized technical teams. The complexity of designing custom tongs for non-standard loads presents a technical hurdle and lengthens the procurement cycle. Despite these challenges, the significant opportunities presented by technological hybridization—combining mechanical strength with digital intelligence—are poised to outweigh the restraints, driving sustained medium-to-long-term growth.

Segmentation Analysis

The Lifting Tong Market is meticulously segmented based on key functional, structural, and application characteristics to provide a clear understanding of varied demand patterns across industries. Key segmentation criteria include the type of material handled, the operational mechanism, the load capacity, and the specific application environment. This granular analysis allows manufacturers to tailor product development and marketing strategies precisely to the needs of heavy industries such such as steel, pipe manufacturing, and precast concrete construction. Understanding these segments is crucial for identifying high-growth niches, particularly the shift towards fully automated systems designed for high-volume, repetitive tasks where safety and efficiency are paramount concerns.

- By Product Type:

- Coil Tongs (Vertical & Horizontal)

- Slab Tongs

- Billet/Bloom Tongs

- Pipe Tongs

- Pallet Tongs

- Drum & Barrel Tongs

- Sheet & Plate Tongs

- Custom/Specialty Tongs

- By Operation Type:

- Automatic Tongs (Motorized or Gravity Operated Self-Locking)

- Semi-Automatic Tongs

- Manual Tongs

- By End-Use Industry:

- Steel & Metal Processing

- Construction & Infrastructure

- Logistics & Warehousing

- Shipbuilding

- Oil & Gas (Pipeline Handling)

- Precast Concrete Manufacturing

- Automotive

- By Capacity:

- Low Capacity (Up to 5 Tons)

- Medium Capacity (5 Tons to 25 Tons)

- High Capacity (Above 25 Tons)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Lifting Tong Market

The value chain for the Lifting Tong Market begins with the upstream activities centered on the procurement and processing of high-grade raw materials, predominantly specialized steel alloys, high-tensile strength metals, and sometimes composite materials for lighter applications. Critical upstream suppliers include specialized steel mills and forging companies that produce the robust components necessary to withstand immense loads and harsh operational environments. Quality control and material certification at this stage are paramount, as the integrity of the raw material directly affects the safety rating and durability of the final product. The manufacturing phase involves precision engineering, welding, assembly of complex mechanical linkages, and the integration of electronic components for modern automatic systems, requiring specialized engineering expertise and stringent adherence to manufacturing standards like ISO and relevant safety mandates.

Midstream activities involve the actual fabrication and assembly, including surface treatments (e.g., protective coatings, galvanization) and rigorous load testing procedures. Distribution channels for lifting tongs are generally bifurcated into direct sales and indirect sales. Direct channels are commonly used for high-capacity, customized, or integrated systems, where manufacturers work closely with large end-users (like major steel producers or large infrastructure contractors) to ensure the tong seamlessly integrates with existing crane and material handling infrastructure. This often involves commissioning, training, and long-term service agreements provided directly by the original equipment manufacturer (OEM).

Indirect distribution relies heavily on specialized industrial equipment distributors, regional material handling solution providers, and authorized dealers. These intermediaries play a crucial role in serving smaller and medium-sized enterprises (SMEs), offering local inventory, installation services, and rapid maintenance support. Downstream analysis focuses on the end-users—steel mills, ports, construction sites—and the necessary post-sale services, including scheduled inspections, preventative maintenance, spare parts supply, and certification renewal services. The efficiency of the distribution network and the reliability of after-sales support are significant factors determining competitive success in the market, particularly in global regions where logistics are complex.

Lifting Tong Market Potential Customers

Potential customers for the Lifting Tong Market are overwhelmingly concentrated in industries that handle substantial volumes of heavy, semi-finished, or finished goods that require safe and controlled vertical or horizontal movement. The primary customer base resides within the metallurgy sector, specifically steel production facilities, aluminum smelters, and non-ferrous metal processing plants, where equipment such as coil tongs and slab tongs are indispensable tools in core operations. These clients require high-capacity, durable equipment capable of operating continuously in high-temperature, dusty environments.

Another critical customer segment is the infrastructure and construction industry, encompassing precast concrete manufacturers who use specialized tongs for handling massive concrete pipes and wall sections, and large construction companies involved in bridge or building construction that require lifting beams and heavy structural components. Furthermore, the global logistics sector, including major port operators and specialized warehousing facilities, represents a growing customer base, utilizing general-purpose tongs and pallet tongs for optimized material flow.

The oil and gas industry also forms a specialized customer group, particularly for companies involved in pipeline laying and maintenance, demanding rugged pipe tongs designed for secure handling of various diameter pipes across challenging terrains. Ultimately, any industrial entity that aims to minimize manual handling risks, maximize operational throughput, and comply with strict safety regulations represents a high-potential customer for modern, certified lifting tong systems, creating a diverse but specific target market focused on heavy industrial application.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bushman Equipment Inc., Tandemloc Inc., Bradley Lifting Corp., Superior Industrial Products Inc., Lift-All Company Inc., Caldwell Lifting Solutions, Columbus McKinnon Corporation (CMCO), Kito Corporation, J.D. Neuhaus, Konecranes, DEMAG (Terex Material Handling), Dongqi Crane Group, Hyster-Yale Materials Handling, Vacuum Lifters, Weissenfels Tongs, Acco Material Handling Solutions, Peerless Industrial Group, Spanco Inc., Munck Cranes, Europress S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lifting Tong Market Key Technology Landscape

The current technology landscape of the Lifting Tong Market is characterized by a significant transition from purely mechanical devices to smart, sensor-integrated systems designed to maximize safety, durability, and operational intelligence. The core material technology focuses on high-strength, low-alloy (HSLA) steel and advanced structural composites to reduce the tong's self-weight while maintaining or exceeding rated load capacity. This is critical for maximizing the usable payload of overhead cranes. Furthermore, advanced manufacturing techniques, such as precision CNC machining and robotic welding, ensure tighter tolerances and higher structural integrity, which are essential for prolonged use in demanding industrial environments where cyclical loading is common.

A major technological trend is the integration of Industrial Internet of Things (IIoT) sensors directly into the tong structure. These sensors monitor vital operational parameters including clamping force, load weight, temperature, lift cycles, and structural strain. This data is wirelessly transmitted to a central monitoring system or crane PLC, enabling real-time diagnostics and condition monitoring. The use of self-locking mechanisms, often gravity or cam-operated, has become standard in automatic tongs to ensure that the load cannot be inadvertently released, significantly improving safety protocols and adherence to safety norms such as ASME B30.20 standards.

Moreover, the development of specialized protective coatings and heat-resistant materials allows certain tongs to operate reliably in extreme environments, such as handling molten or semi-molten materials in foundries and steel mills. Remote operation and control technologies, including radio-controlled actuators, allow operators to engage and disengage the tongs from a safe distance, further minimizing personnel exposure to hazardous areas. This shift toward intelligent, connected tongs represents the future of material handling, offering features like automatic identification of material dimensions and weight verification before lifting is authorized, thereby preventing accidental overloading and ensuring compliance with stringent operational limits.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market, driven primarily by extensive investments in infrastructure, urbanization, and the region's dominance in global steel production (especially China, India, and Japan). The high volume of manufacturing activities and increasing adoption of modern material handling equipment due to rising labor costs fuel robust demand for both standard and high-capacity automatic coil and slab tongs.

- North America: Characterized by high technological adoption and stringent safety regulations, the North American market focuses on replacing older, less efficient equipment with premium, certified, and smart lifting solutions. Growth is steady, supported by consistent demand from the oil & gas sector and the manufacturing revitalization initiatives focused on modernizing existing industrial plants.

- Europe: The European market emphasizes innovation, sustainability, and adherence to strict CE marking and safety standards. Western Europe shows strong demand for automatic tongs and highly specialized equipment for the automotive and advanced manufacturing sectors. Eastern Europe is experiencing growth driven by industrial expansion and modernization efforts, catching up with Western safety benchmarks.

- Middle East & Africa (MEA): Growth in MEA is highly correlated with capital investments in energy infrastructure, massive construction projects (particularly in the GCC states), and port expansion initiatives. Demand is high for durable, heavy-duty pipe tongs and slab handling solutions suitable for large-scale logistics and oil exploration activities.

- Latin America (LATAM): This region offers moderate growth potential, stimulated by renewed investment in mining, metallurgy, and construction, particularly in Brazil and Mexico. The market is price-sensitive but shows increasing recognition of the long-term benefits of safety-compliant, reliable lifting equipment over cheaper, lower-quality alternatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lifting Tong Market.- Bushman Equipment Inc.

- Tandemloc Inc.

- Bradley Lifting Corp.

- Superior Industrial Products Inc.

- Lift-All Company Inc.

- Caldwell Lifting Solutions

- Columbus McKinnon Corporation (CMCO)

- Kito Corporation

- J.D. Neuhaus

- Konecranes

- DEMAG (Terex Material Handling)

- Dongqi Crane Group

- Hyster-Yale Materials Handling

- Vacuum Lifters

- Weissenfels Tongs

- Acco Material Handling Solutions

- Peerless Industrial Group

- Spanco Inc.

- Munck Cranes

- Europress S.p.A.

- Pewag Group

- Harrington Hoists, Inc.

- Lifting Gear Hire (LGH)

- OZ Lifting Products

- R & M Materials Handling, Inc.

- Verlinde (P. K. B.)

Frequently Asked Questions

Analyze common user questions about the Lifting Tong market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Lifting Tong Market?

The market growth is primarily driven by escalating global infrastructure spending, the increasing need for operational efficiency through automation in heavy industries, and the enforcement of stricter global occupational safety regulations mandating certified, hands-free material handling solutions like advanced automatic lifting tongs.

How does the operation type (automatic vs. manual) impact market share and future growth?

Automatic lifting tongs, utilizing mechanisms such as motorized or gravity-operated self-locking systems, currently command a significant and growing market share. Their growth trajectory is higher than manual tongs due to superior safety features, reduced cycle times, and minimal human interaction required, which directly addresses rising industrial labor costs and efficiency mandates.

Which end-use industry is the largest consumer of lifting tongs globally?

The Steel and Metal Processing Industry is the largest consumer, requiring high volumes of specialized coil tongs (both vertical and horizontal) and slab tongs for handling hot and cold material across continuous production lines, storage yards, and transportation hubs. Their heavy, continuous operational demands necessitate robust, high-capacity equipment.

What role does technology play in modern lifting tong design and safety?

Modern lifting tongs integrate advanced technologies such as IIoT sensors for real-time load monitoring, predictive maintenance data collection, and safety compliance checks. These smart systems often feature remote control capabilities and advanced material construction (HSLA steel) to enhance durability, reduce downtime, and ensure adherence to rigorous safety standards like ASME B30.20.

Why is the Asia Pacific region projected to be the fastest-growing market for lifting tongs?

The APAC region's accelerated growth is attributed to rapid urbanization, massive government-backed infrastructure projects (roads, railways, power plants), and the concentration of the world's largest steel and cement manufacturing base, particularly in China and India, which creates immense, sustained demand for heavy material handling solutions.

The Lifting Tong Market, while mature in its core mechanical functionality, is experiencing a resurgence fueled by digital transformation and industrial safety mandates. The long-term stability of the market is underpinned by the essential nature of material handling in foundational industries, meaning that as long as steel is produced and infrastructure is built, specialized lifting tongs will remain indispensable tools. Market participants are increasingly differentiating themselves not merely on lifting capacity, but on the integrated intelligence and safety certifications of their products. This shift ensures that procurement decisions are increasingly weighted towards total cost of ownership, including factors like reduced maintenance frequency and enhanced worker safety, rather than just initial purchase price. The push for customization, particularly for handling novel materials or complex industrial assemblies, requires manufacturers to maintain highly flexible design and engineering capabilities. This technical requirement acts as a barrier to entry for smaller, less experienced competitors, consolidating market strength among established players with proven track records in reliability and safety compliance.

Furthermore, global supply chain volatility and geopolitical shifts have placed renewed emphasis on regional manufacturing capabilities. Companies are exploring diversified sourcing strategies for high-grade steel and mechanical components to mitigate risks associated with single-source reliance, ensuring continuity of production for these critical pieces of industrial equipment. Environmental, Social, and Governance (ESG) criteria are also beginning to influence procurement, with end-users favoring manufacturers who can demonstrate reduced energy consumption in their manufacturing processes and provide documentation detailing the recyclability of the tong materials at the end of their lifecycle. This focus on sustainable manufacturing is slowly transitioning from a niche requirement to a standard expectation, particularly in European and North American markets.

The service sector attached to the Lifting Tong Market, encompassing inspection, repair, re-certification, and training, is growing exponentially. Given the extreme safety criticality of lifting heavy loads, regulatory bodies demand periodic, rigorous examination and re-certification of all lifting gear. This provides a steady, high-margin revenue stream for OEMs and specialized service providers. Companies that can offer comprehensive, tech-enabled service packages, including remote diagnostic capabilities utilizing the embedded IIoT data, are gaining a competitive edge. This integrated service model ensures that the lifting equipment maintains peak performance and regulatory compliance throughout its operational lifespan, further solidifying the relationship between manufacturer and end-user and promoting loyalty within the highly specialized industrial segment.

Capacity-wise, the high-capacity segment (above 25 tons) is experiencing robust demand due to the global trend of scaling up industrial processes—larger steel mills, bigger ships, and higher capacity logistics hubs all necessitate specialized, powerful lifting solutions. These heavy-duty tongs represent significant capital expenditure but offer unmatched efficiency gains. Conversely, the low-to-medium capacity segments are seeing rapid technology adoption, especially the switch from manual clamps to compact automatic tongs for general warehouse operations and lighter fabrication tasks, driven by small-to-medium enterprises (SMEs) seeking cost-effective automation improvements without the massive infrastructure overhaul required by heavy industry. This bifurcated demand structure sustains growth across the entire capacity spectrum.

Geographically, while APAC remains the volume leader, the maturity of the North American and European markets pushes innovation. These regions are the earliest adopters of technologies like AI-driven failure prediction and augmented reality (AR) support tools for maintenance, setting the benchmarks for safety and operational complexity that developing markets will eventually adopt. Market penetration strategies in MEA and LATAM are focused on competitive pricing coupled with reliable, localized after-sales support to overcome skepticism about high initial investment costs. Successful penetration in these regions requires thorough understanding of local lifting standards and regulatory differences, as compliance documentation is a non-negotiable requirement for high-value industrial tenders.

Finally, competition within the Lifting Tong Market is intense, particularly in the standard product categories. Differentiation is increasingly achieved through specialization and vertical integration. Companies offering full material handling solutions—from the crane system down to the end effector (the tong)—provide superior value propositions to large industrial customers seeking integrated, single-vendor accountability. Mergers and acquisitions are likely to continue as key players consolidate expertise in specialized tong types (e.g., pipe handling or extreme temperature applications) and acquire critical digital capabilities to enhance their IIoT integration and software offerings, ensuring their continued relevance in the rapidly evolving landscape of smart manufacturing and industrial automation.

The specialized nature of lifting tongs demands continuous engineering excellence and materials science innovation. For example, in the handling of hot materials, manufacturers are constantly seeking alloys that exhibit superior resistance to thermal fatigue and high creep strength. This focus on material science ensures that the safety factor of the equipment remains consistent even under the most punishing operational conditions. The convergence of metallurgical expertise and modern sensor technology allows for the creation of tongs that not only lift safely but also provide valuable operational data, turning a simple mechanical tool into a data-generating asset critical for optimizing the entire material flow process. The regulatory environment acts as a constant catalyst for improvement; failure to comply with updated safety standards immediately renders equipment obsolete, creating a steady replacement market for innovative products.

Looking ahead, the evolution of the supply chain itself is influencing product development. The demand for just-in-time manufacturing and reduced warehousing costs means that materials often need to be moved more quickly and precisely within constrained spaces. This necessitates the development of more compact, agile tongs that maintain high lifting capacities. Furthermore, the advent of specialized composite materials, while still niche, offers future potential for reducing tong weight, which directly translates into increased crane efficiency and reduced structural stress on the supporting infrastructure. This forward-looking approach to materials and structural design is crucial for manufacturers aiming to maintain a leading edge in the competitive industrial equipment sector. Customer education on the proper selection, usage, and maintenance of specialized tongs is also a growing service requirement, as incorrect usage remains a leading cause of industrial accidents, underscoring the importance of comprehensive training programs offered by leading vendors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager