Lightweight Steel Frames Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442591 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Lightweight Steel Frames Market Size

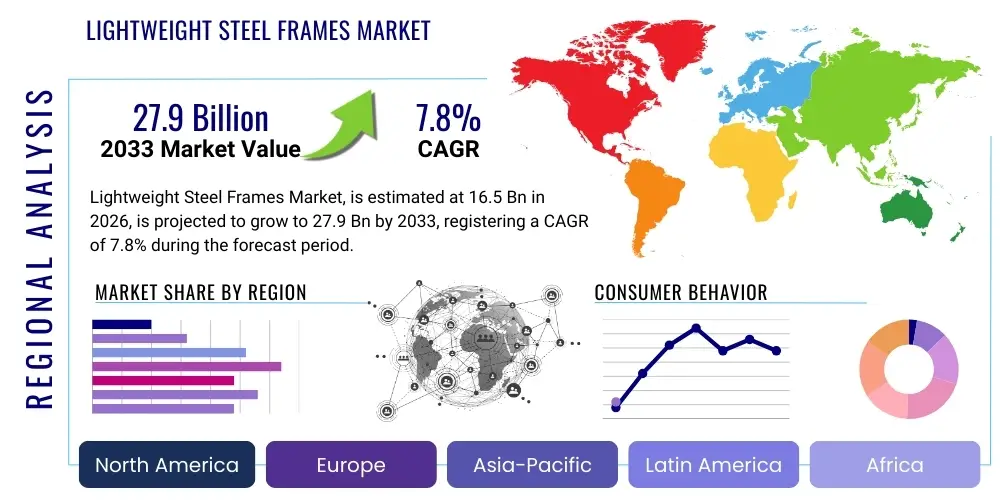

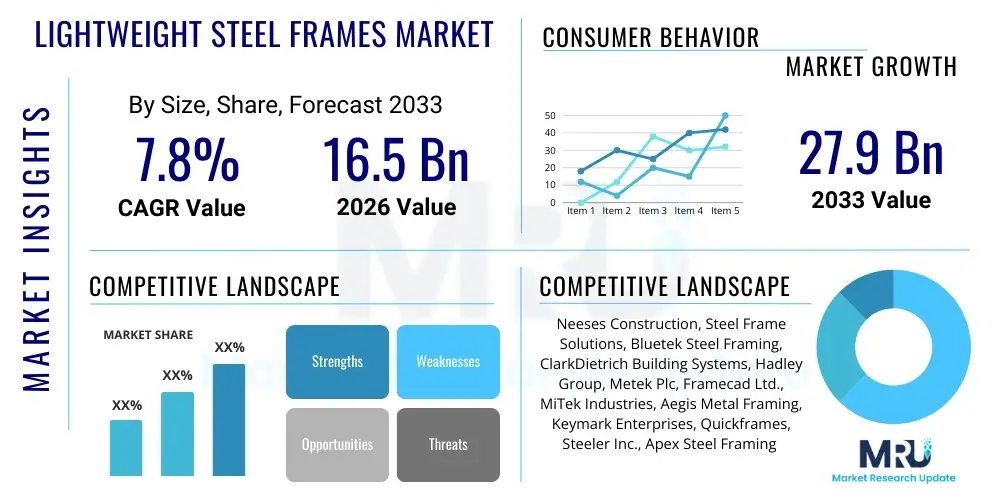

The Lightweight Steel Frames Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $16.5 Billion in 2026 and is projected to reach $27.9 Billion by the end of the forecast period in 2033.

Lightweight Steel Frames Market introduction

The Lightweight Steel Frames (LSF) Market encompasses the design, manufacture, and deployment of structural elements constructed from cold-formed steel (CFS) sections, primarily used in residential, commercial, and industrial construction sectors globally. LSF technology offers a compelling alternative to traditional heavy construction methods, such as concrete and timber framing, due to its superior strength-to-weight ratio, high dimensional stability, and intrinsic non-combustibility. These frames, often fabricated off-site using highly accurate computer numerical control (CNC) machinery, facilitate rapid on-site assembly, significantly reducing construction timelines and associated labor costs. The versatility of LSF allows for complex architectural designs and superior thermal performance when integrated with modern insulation systems, positioning it as a key technology in sustainable building initiatives and high-density urban development where speed and efficiency are paramount.

Product descriptions within the LSF market typically involve frame systems categorized by thickness, coating, and application—including load-bearing walls, internal partitions, floor joists, and roof trusses. Major applications span low-rise residential structures, mid-rise commercial buildings, modular housing units, and specialized applications such as seismic retrofitting and prefabricated school or medical facilities. The intrinsic benefits of LSF, such including enhanced durability, resistance to pests like termites, and recyclability, align strongly with modern construction standards emphasizing life-cycle assessment and environmental responsibility. Furthermore, the precision manufacturing process minimizes material waste and ensures compliance with stringent building codes, particularly those related to structural integrity and fire safety in densely populated urban areas.

Key driving factors accelerating market adoption include the increasing global demand for affordable and rapid housing solutions, particularly in developing economies experiencing rapid urbanization. Additionally, favorable regulatory environments in North America and Europe mandating high energy efficiency standards and promoting sustainable building practices continue to bolster LSF uptake. The technological shift toward modular and prefabricated construction, where LSF serves as the ideal structural backbone, further fuels market growth. Economic considerations, such as the volatility in timber prices and the long-term cost savings associated with steel’s longevity and low maintenance requirements, solidify the market's trajectory toward sustained expansion across diverse construction verticals.

Lightweight Steel Frames Market Executive Summary

The global Lightweight Steel Frames (LSF) market is undergoing robust expansion, characterized by significant shifts towards prefabricated and off-site manufacturing processes. Business trends reveal substantial investment in automation technologies, particularly CNC roll-forming machines, which enhance production speed and accuracy while reducing labor dependency. Strategic partnerships between steel suppliers, specialized fabricators, and large-scale construction firms are becoming prevalent, creating integrated supply chains capable of handling large infrastructure and housing projects. Furthermore, sustainability is emerging as a dominant business driver, with companies focusing on optimizing material use and highlighting steel's 100% recyclability to appeal to environmentally conscious developers and government tenders. This operational streamlining and focus on green credentials define the current competitive landscape, prioritizing efficient delivery mechanisms and certified material sourcing.

Regional trends indicate North America and Europe maintain maturity in LSF adoption, driven by stringent energy efficiency codes and sophisticated logistics infrastructure supporting modular construction. The Asia Pacific (APAC) region, however, represents the fastest-growing market segment, primarily propelled by rapid urbanization, massive infrastructure spending in countries like China and India, and the urgent need for quick, resilient housing solutions following natural disasters. Conversely, growth in Latin America and the Middle East & Africa (MEA) is accelerating, albeit from a lower base, supported by government initiatives aimed at modernizing construction practices and diversifying away from traditional methods to meet ambitious housing targets. The varied pace of growth necessitates regionally tailored marketing and product specifications, especially concerning seismic resilience standards prevalent in parts of APAC and Latin America.

Segment trends highlight the dominance of the residential sector, which relies heavily on LSF for low-to-mid-rise housing and internal partitioning systems due to its cost-effectiveness and speed. However, the commercial segment, including offices, hotels, and retail spaces, is showing rapidly increasing adoption, driven by the structural flexibility and long-span capabilities afforded by light gauge steel trusses. Technology-wise, integration with Building Information Modeling (BIM) software is becoming standard, enabling precise clash detection, material optimization, and streamlined project management from design conceptualization through installation. This digital integration is crucial for maintaining market competitiveness and appealing to sophisticated engineering and architectural firms seeking efficiency gains across complex project lifecycles.

AI Impact Analysis on Lightweight Steel Frames Market

Common user questions regarding AI's influence on the Lightweight Steel Frames (LSF) Market frequently revolve around automation in design and manufacturing, predictive supply chain management, and optimizing structural performance. Users are keen to understand how AI can reduce material waste, shorten fabrication lead times, and enhance structural integrity assessment, especially concerning seismic and wind loading scenarios. Key themes include the implementation of generative design algorithms to optimize framing layouts for maximum material efficiency, the use of machine learning (ML) in predicting maintenance needs for fabrication equipment, and leveraging AI-driven logistics platforms to ensure timely delivery of prefabricated components to increasingly complex construction sites. The prevailing expectation is that AI integration will lead to unprecedented levels of precision and efficiency, fundamentally transforming the traditional, often manually intensive, design and fabrication phases into fully digitalized processes.

- AI optimizes structural design using generative algorithms to minimize steel weight while maintaining required load capacity.

- Machine learning enhances precision manufacturing by predicting and correcting machine tolerances in real-time on CNC roll formers.

- Predictive analytics improve supply chain resilience, forecasting steel price volatility and optimizing inventory levels.

- AI-powered visual inspection systems automate quality control, identifying fabrication defects with high accuracy before shipment.

- BIM integration with AI algorithms streamlines clash detection and project scheduling, reducing on-site delays.

- Enhanced energy performance modeling uses AI to design LSF systems integrated with advanced façade and insulation materials for optimal thermal efficiency.

DRO & Impact Forces Of Lightweight Steel Frames Market

The market for Lightweight Steel Frames is primarily propelled by compelling drivers centered on construction efficiency, sustainability mandates, and demographic shifts. Key drivers include the global imperative for rapid and affordable housing, especially in metropolitan areas grappling with housing shortages, which LSF's speed of construction directly addresses. Furthermore, increasing regulatory emphasis on energy efficiency and green building certifications, such as LEED and BREEAM, favors steel framing due to its high recyclability and reduced material waste compared to traditional building materials. The low weight of the frames also reduces foundation costs and makes them ideal for additions to existing structures or construction in areas with challenging soil conditions. These combined economic and environmental incentives create a strong pull factor for adoption across both developed and emerging markets.

However, the market faces significant restraints that temper its growth trajectory. The most pronounced restraint is the lack of widespread skilled labor capable of designing, fabricating, and assembling LSF systems efficiently in certain geographies, contrasting sharply with the established trades for timber and concrete construction. Secondly, the initial cost of high-precision roll-forming machinery required for LSF manufacturing represents a substantial capital barrier to entry for smaller enterprises. Moreover, while steel is non-combustible, structural protection against high temperatures is required, necessitating additional fireproofing measures that can sometimes add complexity and cost to the final structure, thus impacting the overall construction budget and project timeline.

Opportunities for market expansion are vast, particularly through technological innovation and penetration into untapped sectors. The integration of LSF with modular and prefabricated construction represents a significant opportunity, allowing for the standardization of components and further economies of scale. There is also potential in specialized applications such as seismic strengthening of existing buildings and the construction of disaster relief housing, where LSF's resilience and speed are invaluable. Impact forces, such as the increasing global focus on climate resilience and the volatility of lumber prices, strongly influence market dynamics. The persistent volatility in the cost of raw steel, coupled with ongoing trade tariffs, remains a major impact force requiring strategic sourcing and hedging by key market participants to maintain competitive pricing and stable supply chains necessary for large-scale, sustained market growth.

Segmentation Analysis

The Lightweight Steel Frames (LSF) Market is comprehensively segmented based on material type, product form, application, and end-user, providing a granular view of market dynamics and adoption patterns across various sectors. Material segmentation often differentiates between high-tensile steel and standard galvanized steel, reflecting varying structural requirements and corrosion protection needs. Product form segmentation distinguishes between floor joists, wall panels, roof trusses, and specialized connectors, each catering to specific structural roles. Application segmentation is crucial for understanding demand trends across diverse project types, ranging from single-family homes to large-scale commercial complexes. End-user categorization helps in targeting specific buyer behaviors and regulatory landscapes, focusing on the distinct needs of residential, commercial, and industrial developers.

- By Type:

- Cold-Formed Steel (CFS)

- Light Gauge Steel (LGS)

- By Product Form:

- Wall Panels (Load-bearing and Non-load-bearing)

- Floor Joists and Beams

- Roof Trusses

- Structural Components (Bracing, Connections, Studs, Tracks)

- By Application:

- Residential Construction (Low-rise, Mid-rise, Multi-family housing)

- Commercial Construction (Office Buildings, Retail, Hospitality)

- Industrial Construction (Warehouses, Factories)

- Specialized Structures (Modular Buildings, Temporary Housing, Educational Facilities)

- By End-User:

- Contractors and Builders

- Architects and Engineers

- Property Developers

- Government and Public Works Agencies

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (U.K., Germany, France, Italy, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Lightweight Steel Frames Market

The value chain for the Lightweight Steel Frames (LSF) market begins with the upstream segment, dominated by steel manufacturers and suppliers of galvanized coils. This phase involves sourcing high-quality iron ore, producing steel, and applying zinc coatings to ensure corrosion resistance, a critical attribute for LSF longevity. Key activities at this stage include refining metallurgical processes, negotiating commodity pricing, and ensuring the delivery of steel coils meeting precise specifications (e.g., yield strength and thickness) required for cold forming. Efficiency and quality control at the upstream level are paramount, as the properties of the raw material directly influence the structural integrity and durability of the finished frame components. Suppliers who offer advanced high-tensile steel alloys gain a competitive edge by enabling lighter and stronger frame designs.

The midstream segment involves specialized fabricators who transform the steel coils into finished LSF components using highly automated CNC roll-forming machines. This stage incorporates sophisticated design software, often integrated with BIM, to translate architectural plans into detailed framing instructions, optimizing material usage and minimizing waste. Fabrication encompasses precise cutting, punching, dimpling, and labeling of components ready for assembly. Distribution channels play a critical role here; direct channels involve large fabricators selling and delivering proprietary framing systems directly to major construction contractors or property developers, ensuring full control over product quality and installation support. Indirect channels involve utilizing third-party distributors or local dealers, which is common for smaller or custom projects, providing broader regional reach but potentially adding layers of logistical complexity.

The downstream activities involve on-site assembly, installation, and integration of the LSF structure with other building systems (e.g., cladding, insulation, services). This phase requires specialized training for assembly crews to ensure the frames are erected according to engineering specifications and local building codes. End-users, including developers and facility owners, benefit from the speed and accuracy of LSF installation, which significantly shortens the overall construction schedule. A critical aspect of the downstream segment is post-installation support and inspection services to ensure compliance and structural performance, thereby completing the value loop. The efficiency of the entire chain relies heavily on the seamless flow of digital information, from initial design optimization in the midstream to rapid assembly validation in the downstream phase, maximizing the inherent benefits of prefabrication.

Lightweight Steel Frames Market Potential Customers

Potential customers for Lightweight Steel Frames (LSF) are diverse, encompassing a wide spectrum of the construction industry seeking efficiency, durability, and sustainability advantages over traditional building methods. The primary segment comprises large-scale property developers focusing on residential housing, particularly multi-family apartments, high-density complexes, and planned communities. These buyers prioritize the rapid construction cycles and predictable quality offered by LSF, which allows them to accelerate project delivery, manage costs effectively, and quickly monetize their investments. Furthermore, developers in areas prone to seismic activity or harsh weather conditions favor LSF for its superior resilience and engineering reliability, reducing long-term maintenance liabilities and insurance costs associated with structural damage.

Another significant customer base includes specialized contractors and general builders engaged in commercial projects such as budget hotels, student accommodation, retail outlets, and offices up to ten stories high. For these buyers, LSF provides structural flexibility that accommodates varied interior layouts and large spans, while the reduced overall structural weight minimizes the burden on foundations, a crucial factor in urban infill developments. Government entities and public works agencies also represent key customers, particularly for public projects such as schools, hospitals, modular military housing, and disaster relief shelters, where the need for speed, standardized quality, and deployment agility is paramount. These institutional buyers value the long life cycle and fire resistance inherent in steel construction.

The growing market for modular and prefabricated construction firms forms a rapidly expanding pool of potential customers. These companies rely almost exclusively on LSF as the backbone of their standardized building modules, enabling mass production in factory settings. Finally, individual homeowners undertaking custom builds or renovation projects, particularly those focused on adding upper stories or large extensions, are increasingly utilizing LSF due to its ease of handling, clean construction process, and suitability for narrow sites. Effective market penetration requires LSF providers to tailor their offerings—from bespoke engineering services for developers to standardized component kits for builders—addressing the distinct scale and sophistication requirements of each customer segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $16.5 Billion |

| Market Forecast in 2033 | $27.9 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Neeses Construction, Steel Frame Solutions, Bluetek Steel Framing, ClarkDietrich Building Systems, Hadley Group, Metek Plc, Framecad Ltd., MiTek Industries, Aegis Metal Framing, Keymark Enterprises, Quickframes, Steeler Inc., Apex Steel Framing Systems, SureFrame, Trachte Building Systems, Scottsdale Construction Systems, Steel Network Inc., Stramit Corporation, USG Corporation, Genesis Steel Framing |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lightweight Steel Frames Market Key Technology Landscape

The core technology underpinning the Lightweight Steel Frames (LSF) market is advanced cold-formed steel (CFS) manufacturing, primarily executed through Computer Numerical Control (CNC) roll-forming machines. These state-of-the-art machines integrate design software directly with the fabrication process, allowing for the precise production of galvanized steel sections with intricate dimensions, specific web and flange profiles, and pre-punched holes for services and connections. Technological innovation focuses heavily on enhancing the automation and versatility of these machines, enabling rapid changeovers between different profiles and minimizing human intervention. This shift towards high-speed, automated production lines ensures extremely tight tolerances, which is crucial for the seamless assembly of prefabricated modules on site, fundamentally differentiating LSF from traditional site-built framing methods. Furthermore, the development of proprietary connection systems and high-strength fasteners is integral, optimizing the structural performance and ease of installation of the LSF components.

A transformative technology influencing the LSF sector is the widespread adoption of Building Information Modeling (BIM). BIM platforms allow architects and engineers to create highly detailed, three-dimensional digital models of the entire structure, integrating the LSF system with mechanical, electrical, and plumbing (MEP) services early in the design phase. This level of integration facilitates 'design for manufacturing and assembly' (DFMA), significantly reducing conflicts, material wastage, and redesign costs during construction. Advanced software tools now incorporate structural analysis algorithms optimized for CFS behavior, allowing for precise engineering calculations related to buckling, shear, and load distribution. The seamless data exchange between the BIM model and the CNC fabrication machinery is the technological linchpin that delivers the speed and accuracy promise of modern LSF construction, driving down the overall project lifecycle duration from concept to completion.

Furthermore, materials science advancements are continually impacting the LSF market, specifically through improved galvanization and protective coatings designed to enhance corrosion resistance and durability, especially in coastal or harsh industrial environments. Research is also focused on developing stronger, yet lighter, steel alloys that maintain structural integrity while reducing the overall material mass, leading to further cost savings in transportation and foundation requirements. Emerging technologies, such as the application of robotics in automated assembly both in the factory and potentially on the construction site, are poised to further revolutionize the labor dynamics of the market. These robotics solutions aim to address the persistent skilled labor shortage while simultaneously improving the precision and consistency of the final installed product, solidifying LSF's position as a technologically advanced and scalable construction methodology for the future global market.

Regional Highlights

- North America (U.S., Canada): This region is a mature and leading adopter of Lightweight Steel Frames, driven by stringent energy efficiency codes, high labor costs favoring prefabrication, and significant commercial construction activity. The U.S. market benefits from robust infrastructure investment and a strong regulatory push towards disaster-resilient construction, particularly in coastal and high-wind zones, where LSF offers superior performance. Canada sees steady adoption, especially in low-to-mid-rise multi-family housing, leveraging LSF for speed and sustainability credentials.

- Europe (U.K., Germany, France): Europe is characterized by a high focus on sustainable building (Net-Zero mandates) and retrofitting existing structures. The U.K. is a key market, utilizing LSF extensively in modular housing and multi-story extensions due to density constraints. Germany emphasizes precision engineering and thermal performance, favoring LSF integration with high-performance insulation systems. Regulatory support for off-site construction further stimulates demand across the continent.

- Asia Pacific (APAC - China, India, Japan): APAC is the fastest-growing market due to rapid urbanization, massive housing shortages, and frequent seismic activity demanding resilient building materials. China and India are experiencing explosive growth, propelled by government investments in infrastructure and the urgent need for fast-to-erect, durable housing. Japan utilizes LSF primarily for its excellent performance in earthquake zones and high precision manufacturing standards.

- Latin America: Market growth is moderate but accelerating, primarily focused on affordable housing initiatives and large-scale public works projects. Adoption is driven by the need for structurally sound, non-combustible alternatives in seismically active areas, though economic instability and varying regulatory frameworks remain challenges.

- Middle East & Africa (MEA): This region is increasingly exploring LSF as part of ambitious national diversification and infrastructure development plans, particularly in the GCC countries. LSF offers advantages in hot climates due to its ability to support highly insulated envelopes and its resistance to pests, which is a key concern in certain African nations. Implementation of advanced construction methods is central to regional modernization efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lightweight Steel Frames Market.- Neeses Construction

- Steel Frame Solutions

- Bluetek Steel Framing

- ClarkDietrich Building Systems

- Hadley Group

- Metek Plc

- Framecad Ltd.

- MiTek Industries

- Aegis Metal Framing

- Keymark Enterprises

- Quickframes

- Steeler Inc.

- Apex Steel Framing Systems

- SureFrame

- Trachte Building Systems

- Scottsdale Construction Systems

- Steel Network Inc.

- Stramit Corporation

- USG Corporation

- Genesis Steel Framing

Frequently Asked Questions

Analyze common user questions about the Lightweight Steel Frames market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary sustainability advantages of Lightweight Steel Frames?

Lightweight Steel Frames (LSF) offer significant sustainability benefits, primarily due to steel's 100% recyclability, which drastically reduces landfill waste. Furthermore, LSF manufacturing minimizes construction site waste, and its inherent dimensional stability allows for superior thermal envelope designs, leading to significant energy savings over the building's lifespan.

How do Lightweight Steel Frames compare to traditional timber framing in terms of cost and speed?

While the initial material cost of LSF can sometimes be higher than raw timber, the overall project cost is often lower due to dramatically accelerated construction timelines, reduced on-site labor requirements, and less material wastage. LSF precision manufacturing facilitates rapid assembly, delivering structures faster and offering long-term savings through increased durability and reduced maintenance.

Is the Lightweight Steel Frames market resilient to fluctuations in raw material prices?

The LSF market is moderately sensitive to steel price volatility, but market players mitigate this through long-term supplier contracts, material hedging, and optimizing design to minimize material usage. The structural efficiency of LSF often means less material is needed compared to heavy structural steel, enhancing cost control despite commodity price fluctuations.

What is the maximum height feasible for structures built using Lightweight Steel Frame technology?

LSF is generally most economically viable for low-to-mid-rise buildings, typically up to 10 stories. However, when integrated as infill or secondary structures within a primary concrete or heavy steel frame, LSF can be used in much taller structures, providing lightweight, non-load-bearing wall systems and enhanced flexibility for internal configurations.

What role does BIM play in optimizing the Lightweight Steel Frames construction process?

Building Information Modeling (BIM) is crucial for LSF optimization, enabling engineers to design highly accurate models that integrate framing components with MEP services. This integration ensures efficient material optimization, eliminates on-site clashes before fabrication begins, and directly feeds data to CNC machinery, thereby maximizing prefabrication benefits and ensuring smooth, rapid assembly.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager