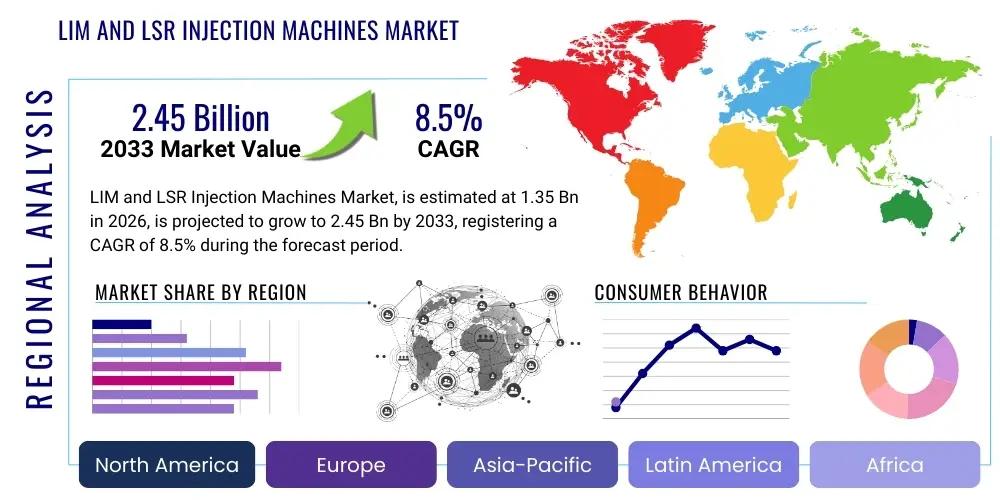

LIM and LSR Injection Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440737 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

LIM and LSR Injection Machines Market Size

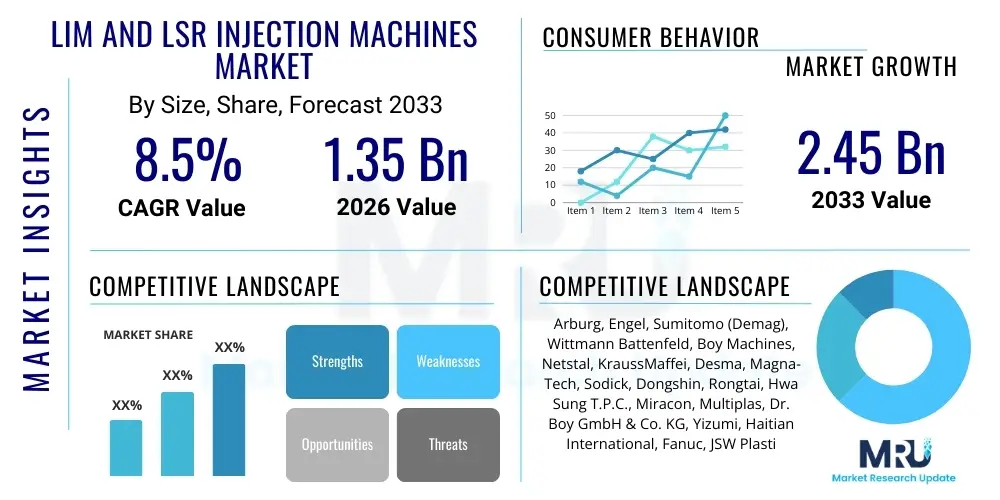

The LIM and LSR Injection Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.35 billion in 2026 and is projected to reach USD 2.45 billion by the end of the forecast period in 2033.

LIM and LSR Injection Machines Market introduction

The Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) Injection Machines Market encompasses specialized equipment designed for precision processing of two-component liquid silicone rubbers. These machines are engineered to handle the unique rheological properties of LSR, offering controlled mixing, dosing, and injection into molds under specific temperature and pressure conditions. Their capability to produce highly complex geometries with tight tolerances makes them indispensable in various high-growth industries demanding robust, biocompatible, and durable components. The inherent properties of LSR, such as excellent thermal stability, chemical resistance, electrical insulation, and superior elasticity, position these machines at the forefront of advanced manufacturing.

Major applications for LIM and LSR injection machines span critical sectors including medical devices, automotive components, consumer electronics, and industrial seals. In the medical field, these machines are crucial for manufacturing implantable devices, surgical instruments, and fluid transfer systems due to LSR's biocompatibility and sterilization resistance. For the automotive industry, they produce seals, gaskets, and sensor housings that can withstand extreme temperatures and harsh operating environments. The electronics sector leverages them for producing waterproof seals, keypads, and connectors, capitalizing on LSR's excellent insulation properties and tactile feel.

The primary benefits of utilizing LIM and LSR injection machines include high-volume production capabilities with exceptional repeatability, reduced material waste through precise dosing, and the ability to achieve intricate designs with superior surface finish. These machines facilitate automation, leading to lower labor costs and increased manufacturing efficiency. Driving factors for market growth include the escalating demand for miniaturized, high-precision components across industries, the continuous innovation in medical technology, and the automotive sector's increasing shift towards electric vehicles requiring advanced sealing and insulating solutions. Furthermore, the growing adoption of Industry 4.0 principles, integrating automation and data analytics into manufacturing processes, further propels the demand for these sophisticated injection molding systems.

LIM and LSR Injection Machines Market Executive Summary

The LIM and LSR Injection Machines Market is experiencing robust expansion, primarily fueled by the escalating demand for high-performance elastomers in critical applications across diverse industries. Business trends indicate a strong focus on automation, digitalization, and integration of smart manufacturing principles to enhance productivity and reduce operational costs. Manufacturers are increasingly investing in advanced machine features such as closed-loop control systems, robotic automation, and energy-efficient designs to meet the stringent requirements of precision molding and sustainability. Strategic alliances and collaborations between machine manufacturers and material suppliers are also becoming prevalent, aimed at developing optimized solutions for specific end-use applications and pushing the boundaries of LSR processing capabilities.

Regional trends reveal Asia Pacific as the leading and fastest-growing market, driven by expanding manufacturing bases, particularly in China, India, and Southeast Asian countries. This growth is underpinned by substantial investments in medical device production, automotive manufacturing, and consumer electronics assembly in these regions. North America and Europe continue to be significant markets, characterized by a focus on high-value, specialized applications, technological innovation, and stringent regulatory environments that demand superior quality and performance. Latin America, the Middle East, and Africa are emerging markets, showing increasing adoption as industrialization and healthcare infrastructure develop, presenting new growth opportunities for market players.

Segment trends highlight the medical device and automotive industries as primary consumers of LIM and LSR injection machines, accounting for the largest market shares. Within the medical segment, the demand for implantable components, diagnostic devices, and surgical tools made from biocompatible LSR is a significant driver. In the automotive sector, the push for electric vehicles (EVs) and autonomous driving systems is intensifying the need for durable, heat-resistant seals, connectors, and insulating components, thereby boosting the adoption of these machines. Furthermore, the electronics and consumer goods segments are also contributing to market growth, driven by the requirement for durable, aesthetically pleasing, and high-performance silicone parts for various products, indicating a diversified yet specialized market landscape.

AI Impact Analysis on LIM and LSR Injection Machines Market

User inquiries regarding AI's impact on the LIM and LSR Injection Machines Market frequently center on its potential to revolutionize manufacturing efficiency, product quality, and operational intelligence. Key themes include the application of AI for predictive maintenance to minimize downtime, optimization of molding parameters for enhanced yield and reduced waste, and intelligent quality control systems capable of real-time defect detection. Users are keenly interested in how AI can facilitate greater automation, enable more precise control over complex processes, and ultimately contribute to cost reduction and faster time-to-market for high-precision LSR components. Expectations also revolve around AI's role in streamlining design-for-manufacturability processes and adapting to dynamic production demands.

- AI-driven predictive maintenance for minimizing machine downtime and optimizing service schedules, enhancing overall equipment effectiveness (OEE).

- Real-time process optimization through machine learning algorithms that adjust injection parameters (temperature, pressure, speed) for consistent part quality and reduced material scrap.

- Enhanced quality control systems utilizing computer vision and AI for automated defect detection, ensuring compliance with stringent industry standards, especially in medical and automotive sectors.

- Smart factory integration enabling seamless data exchange between LIM/LSR machines and broader manufacturing execution systems (MES) for holistic production management.

- AI-assisted mold design and simulation, accelerating product development cycles and optimizing mold geometries for improved flow characteristics and reduced cycle times.

- Automated root cause analysis for production anomalies, allowing for quicker problem resolution and continuous process improvement.

- Adaptive production scheduling and resource allocation driven by AI, optimizing machine utilization and responding dynamically to changes in demand or supply chain disruptions.

DRO & Impact Forces Of LIM and LSR Injection Machines Market

The LIM and LSR Injection Machines Market is propelled by several significant drivers. A primary driver is the increasing demand for high-performance elastomers in various industries, where LSR's unique properties like excellent heat resistance, biocompatibility, and electrical insulation are critical. The expansion of the medical device industry, driven by an aging global population and advancements in healthcare technology, necessitates the precise manufacturing of LSR components for implantable devices, surgical tools, and drug delivery systems. Furthermore, the automotive sector's shift towards electric vehicles (EVs) and autonomous driving requires lightweight, durable, and highly reliable sealing and insulating components, substantially boosting the adoption of advanced LSR molding solutions. The integration of Industry 4.0 technologies, emphasizing automation, data exchange, and smart manufacturing, also serves as a strong catalyst for market growth, as modern LIM/LSR machines are designed for seamless integration into connected production environments.

Despite robust growth, the market faces certain restraints. The high initial capital investment required for LIM and LSR injection machines, molds, and auxiliary equipment can be a significant barrier for small and medium-sized enterprises (SMEs). The complexity of processing LSR materials, which demands specialized expertise in machine operation, mold design, and material handling, often leads to a shortage of skilled labor, thereby impacting productivity and increasing operational costs. Additionally, the volatility in raw material prices for liquid silicone rubber can affect manufacturing costs and profit margins for machine manufacturers and component producers alike. Stringent regulatory requirements, particularly in the medical and aerospace sectors, necessitate rigorous validation and testing, adding to the development timeline and overall cost of new products and processes.

Opportunities within the market are abundant and diverse. Emerging markets in Asia Pacific, Latin America, and the Middle East and Africa present significant untapped potential due to their rapidly developing industrial infrastructure, increasing healthcare spending, and growing automotive production capacities. The trend towards customization and specialized product development offers lucrative niches for manufacturers capable of producing bespoke LSR components with unique properties or complex geometries. Furthermore, the growing emphasis on sustainable manufacturing practices creates opportunities for machines that offer energy efficiency, waste reduction, and the ability to process bio-based or recyclable silicone materials. Innovations in multi-component molding, where LSR is combined with other plastics or metals, are also opening new application areas and market segments.

Impact forces influencing the LIM and LSR Injection Machines Market include rapid technological advancements, which constantly introduce more precise, automated, and integrated molding solutions. Regulatory changes, particularly in healthcare and automotive safety standards, directly affect product design and manufacturing processes, driving demand for machines capable of meeting these stringent requirements. Global economic conditions and trade policies can impact investment decisions, raw material supply chains, and market access. Lastly, the competitive landscape, characterized by both established global players and agile regional manufacturers, fosters continuous innovation and competitive pricing, benefiting end-users with a wider array of advanced machine options and capabilities.

Segmentation Analysis

The LIM and LSR Injection Machines market is comprehensively segmented to provide a detailed understanding of its diverse landscape and growth dynamics across various parameters. These segmentations are critical for analyzing market trends, identifying key growth areas, and understanding the competitive environment. The market can be broadly categorized based on machine type, clamping force, application, and end-use industry, each reflecting distinct operational capabilities and demand drivers. This granular analysis allows for a precise evaluation of market potential within specific niches and helps stakeholders align their strategies with prevailing market demands.

- By Type:

- Horizontal Injection Machines: Predominantly used for general-purpose molding, offering ease of automation and integration.

- Vertical Injection Machines: Ideal for insert molding and specialized applications requiring precise alignment.

- C-Frame Injection Machines: Compact design, often used for smaller components and specialized processes.

- Multi-component/Two-Shot Injection Machines: Capable of molding different materials or colors in a single cycle.

- By Clamping Force:

- Less than 100 Ton: Suited for small, precision parts and medical applications.

- 100-300 Ton: Mid-range machines for a broad array of applications, balancing precision and capacity.

- More than 300 Ton: Used for larger parts, high-volume production, and complex molds, particularly in automotive.

- By Application:

- Sealing Components: Gaskets, O-rings, membranes used across industries.

- Medical Components: Catheters, syringes, medical diaphragms, surgical components.

- Electrical & Electronic Components: Connectors, keypads, sensor housings, insulation.

- Optical Components: Lenses, light guides, optical seals.

- Consumer Goods: Baby products, kitchenware, wearables.

- Automotive Components: Gaskets, seals, sensor housings, wire harnesses, lighting components.

- Industrial Components: Diaphragms, bellows, valve seals, protective covers.

- By End-Use Industry:

- Healthcare & Medical Devices: Driven by biocompatibility and sterilization requirements.

- Automotive: Focus on durability, heat resistance, and sealing for EVs and traditional vehicles.

- Electronics: Emphasis on insulation, waterproof capabilities, and tactile properties.

- Consumer Goods: Demand for soft-touch, durable, and aesthetically pleasing silicone parts.

- Industrial: Applications requiring chemical resistance, temperature stability, and elasticity.

Value Chain Analysis For LIM and LSR Injection Machines Market

The value chain for the LIM and LSR Injection Machines Market begins with upstream activities, primarily involving the raw material suppliers and component manufacturers. Raw material suppliers provide the foundational liquid silicone rubber (LSR) compounds, which are crucial to the entire process. These suppliers focus on developing advanced LSR formulations that offer specific properties like enhanced tear strength, improved transparency, or specialized curing characteristics. Complementing this, component manufacturers supply critical parts for the injection machines themselves, including hydraulic systems, electrical control units, clamping units, injection units, and specialized screws and barrels designed for LSR processing. The quality and innovation at this upstream stage directly influence the performance and capabilities of the final injection molding machines.

Moving downstream, the value chain encompasses the core activities of LIM and LSR injection machine manufacturing, followed by distribution channels and ultimately, the end-users. Machine manufacturers engage in research and development, design, assembly, and testing of these highly specialized machines. They focus on incorporating advanced technologies such as Industry 4.0 integration, energy-efficient designs, multi-component molding capabilities, and sophisticated control systems to meet evolving customer demands. After manufacturing, these machines are delivered to end-users through a combination of direct and indirect distribution channels. Direct sales involve direct engagement between the machine manufacturer and large industrial clients, often accompanied by extensive customization and after-sales support. Indirect channels involve distributors, agents, and system integrators who facilitate sales to a broader range of customers, particularly in diverse geographical regions or for specialized niche applications.

The final stage of the value chain involves the end-users and the critical after-sales support and services that maintain machine performance and longevity. End-users are the companies across various industries—such as medical, automotive, electronics, and consumer goods—that utilize these machines to produce their final LSR components. Their specific requirements drive the demand for certain machine features and capabilities. Post-sale, support services, including installation, training, maintenance, spare parts supply, and technical assistance, are essential to ensure optimal machine operation and customer satisfaction. The efficiency and responsiveness of these downstream activities are pivotal for sustained market growth, as robust support systems enhance customer loyalty and facilitate the adoption of new technologies in the LIM and LSR injection molding sector.

LIM and LSR Injection Machines Market Potential Customers

The primary potential customers for LIM and LSR Injection Machines are manufacturers and specialized molding companies across a spectrum of high-precision, high-performance industries. Within the healthcare sector, medical device manufacturers constitute a significant customer base. These companies require machines capable of producing implantable components, surgical instruments, diagnostic equipment parts, and drug delivery systems from biocompatible LSR. Their demand is driven by the need for exceptionally high quality, sterility, and compliance with stringent regulatory standards, making precision LIM/LSR machines indispensable for their operations. This segment continuously seeks machines offering high repeatability, intricate molding capabilities, and comprehensive process validation.

Another major segment of potential customers is the automotive industry, particularly manufacturers of vehicle components and their Tier 1 and Tier 2 suppliers. With the escalating trend towards electric vehicles (EVs), there is an amplified demand for LSR parts such as battery seals, cable glands, sensor housings, and various sealing components that can withstand extreme temperatures, vibrations, and harsh environmental conditions. Traditional automotive applications like engine gaskets, vibration dampeners, and lighting components also continue to drive demand. These customers prioritize machines that offer high throughput, robust automation, and the capability to produce durable, long-lasting parts that contribute to vehicle safety and performance.

Beyond medical and automotive, the electronics and consumer goods industries represent substantial potential customer bases. In electronics, companies manufacturing connectors, keypads, seals for waterproof devices, and various sensor encapsulation utilize LIM and LSR injection machines due to LSR's excellent electrical insulation, tactile properties, and environmental sealing capabilities. For consumer goods, particularly baby products, kitchenware, and wearables, manufacturers seek machines to produce soft-touch, durable, and aesthetically pleasing silicone components. These segments often require machines that can handle high-volume production while maintaining consistent quality and offering flexibility for various product designs and material grades. Additionally, the industrial sector, encompassing manufacturers of fluidic systems, seals, and diaphragms for diverse industrial equipment, also forms a crucial part of the potential customer landscape, driven by the need for chemical resistance, temperature stability, and long operational lifespans.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.35 billion |

| Market Forecast in 2033 | USD 2.45 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Arburg, Engel, Sumitomo (Demag), Wittmann Battenfeld, Boy Machines, Netstal, KraussMaffei, Desma, Magna-Tech, Sodick, Dongshin, Rongtai, Hwa Sung T.P.C., Miracon, Multiplas, Dr. Boy GmbH & Co. KG, Yizumi, Haitian International, Fanuc, JSW Plastic Machinery |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

LIM and LSR Injection Machines Market Key Technology Landscape

The technological landscape of the LIM and LSR Injection Machines market is characterized by continuous innovation aimed at enhancing precision, efficiency, and automation. A predominant trend is the widespread adoption of all-electric and hybrid machine architectures. All-electric machines offer superior energy efficiency, quieter operation, and significantly higher precision and repeatability in injection and clamping movements compared to traditional hydraulic systems. This precision is critical for maintaining tight tolerances required in medical and automotive components, leading to reduced material waste and improved part quality. Hybrid machines combine the strengths of electric and hydraulic systems, providing a balance of power, speed, and energy savings for diverse applications, making them a versatile choice for many manufacturers.

Advancements in control systems and automation are also central to the evolving technology landscape. Modern LIM/LSR machines integrate sophisticated closed-loop control systems that allow for real-time monitoring and adjustment of critical parameters such as injection pressure, temperature, and shot volume. This ensures consistent process stability and product quality, especially crucial for sensitive materials like LSR. Furthermore, the integration of robotic automation for part removal, insert loading, and post-molding processes significantly boosts overall production efficiency, reduces manual labor, and minimizes contamination risks, particularly important in cleanroom environments. These automated solutions contribute directly to higher throughput and lower operational costs, aligning with Industry 4.0 principles.

Multi-component molding capabilities and advanced material handling systems represent another key technological frontier. Multi-component machines enable the simultaneous injection of different LSR grades or the combination of LSR with other materials (e.g., thermoplastics or metal inserts) in a single molding cycle. This allows for the creation of highly complex functional parts with varied material properties, expanding application possibilities. Concurrently, advancements in dosing and mixing technologies ensure precise, air-free, and consistent delivery of the two-component LSR material, which is vital for preventing defects and achieving optimal material properties in the final part. These technologies, combined with smart sensors for condition monitoring and data analytics, collectively enhance machine intelligence, predictive maintenance capabilities, and overall manufacturing excellence in the LIM and LSR injection molding sector.

Regional Highlights

- North America: This region is a mature market driven by the robust growth of the medical device industry, stringent quality standards, and significant investments in advanced manufacturing technologies. The U.S. leads in adopting sophisticated LIM and LSR injection machines for high-precision components, especially in healthcare, aerospace, and specialized automotive applications. Canada and Mexico also contribute, with increasing demand in automotive and electronics manufacturing.

- Europe: Europe represents a key market, particularly Germany, Switzerland, and Austria, known for their strong engineering capabilities and focus on high-quality, high-performance manufacturing. The region benefits from substantial R&D investments, a strong automotive sector (especially in electric vehicles), and a prominent medical device industry. Strict regulatory environments drive demand for advanced, reliable, and precise molding solutions.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for LIM and LSR injection machines, led by China, Japan, South Korea, and India. Rapid industrialization, expanding manufacturing bases, and significant foreign direct investment contribute to this growth. The region's booming electronics, automotive (including EV production), and burgeoning medical device sectors are primary demand drivers. Cost-effectiveness and increasing domestic demand for high-quality goods further fuel market expansion.

- Latin America: This region is an emerging market showing consistent growth, primarily driven by the expansion of the automotive and consumer goods industries in countries like Brazil and Mexico. Increasing foreign investment in manufacturing facilities and a growing middle class with rising disposable incomes are stimulating demand for advanced production technologies, including LIM and LSR injection machines.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth, with increasing investments in industrialization and healthcare infrastructure. Countries like Saudi Arabia, UAE, and South Africa are witnessing a rise in demand for high-quality industrial seals, automotive components, and medical devices. Economic diversification efforts and government initiatives to boost local manufacturing are expected to drive further adoption of these specialized machines.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the LIM and LSR Injection Machines Market.- Arburg GmbH + Co KG

- Engel Austria GmbH

- Sumitomo (SHI) Demag Plastics Machinery GmbH

- Wittmann Battenfeld GmbH

- Boy Machines, Inc.

- Netstal Maschinen AG (KraussMaffei Group)

- KraussMaffei Technologies GmbH

- Desma Tec GmbH

- Magna-Tech, LLC

- Sodick Co., Ltd.

- Dongshin Hydraulic Co., Ltd.

- Rongtai Technology (China) Co., Ltd.

- Hwa Sung T.P.C. Co., Ltd.

- Miracon Co., Ltd.

- Multiplas Eng. & Mfg. Inc.

- Dr. Boy GmbH & Co. KG

- Yizumi Precision Machinery Co., Ltd.

- Haitian International Holdings Limited

- Fanuc Corporation

- JSW Plastic Machinery Inc.

Frequently Asked Questions

Analyze common user questions about the LIM and LSR Injection Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of LIM and LSR injection machines?

LIM and LSR injection machines are specialized systems designed for precision molding of liquid silicone rubber into complex parts. They ensure accurate mixing, dosing, and injection of two-component LSR materials to produce components with high quality, durability, and specific properties for various industries.

Which industries are the major end-users of LIM and LSR injection machines?

The primary end-user industries include medical devices (for biocompatible implants and surgical tools), automotive (for seals, gaskets, and EV components), electronics (for waterproof seals and connectors), and consumer goods (for durable and soft-touch silicone products).

What are the key benefits of using LIM and LSR injection molding technology?

Key benefits include high precision and repeatability, ability to produce complex geometries, excellent material properties (heat resistance, biocompatibility), efficient high-volume production, reduced material waste, and potential for extensive automation, leading to lower labor costs and consistent quality.

How does AI impact the LIM and LSR Injection Machines market?

AI significantly impacts the market by enabling predictive maintenance, optimizing molding parameters in real-time for improved quality, enhancing automated defect detection through computer vision, and streamlining overall production efficiency, leading to smarter and more reliable manufacturing processes.

What are the main drivers and restraints for market growth?

Major drivers include the increasing demand for high-performance elastomers, growth in medical device and automotive (especially EV) sectors, and Industry 4.0 adoption. Restraints include high initial investment costs, the need for skilled labor, raw material price volatility, and stringent regulatory compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager