Lime Juice Concentrate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441220 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Lime Juice Concentrate Market Size

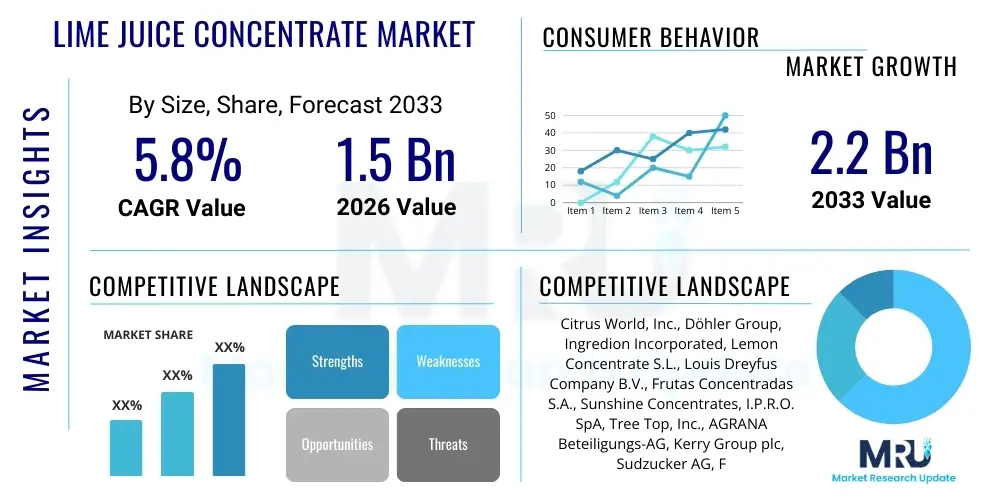

The Lime Juice Concentrate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $2.75 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by the expanding food and beverage industry globally, coupled with a rising consumer preference for natural, less processed ingredient alternatives compared to artificial flavorings. The versatility of lime juice concentrate in various applications, ranging from ready-to-drink beverages to culinary enhancements and confectioneries, solidifies its indispensable role in the modern ingredient supply chain.

Market expansion is also supported by increasing investments in advanced processing technologies, particularly those focused on enhancing quality parameters such as Brix levels, acidity, and color retention during concentration and storage. Manufacturers are prioritizing supply chain efficiency and implementing stringent quality control measures to meet the rigorous demands of international regulatory standards and sophisticated B2B buyers. Furthermore, the shift in consumption patterns towards exotic and tropical flavors, especially in Western markets, significantly boosts the demand for authentic lime products, thereby driving the concentrate segment over traditional fresh lime usage due to cost-effectiveness and year-round availability.

The stability provided by concentrated formats offers significant logistical and storage advantages, minimizing spoilage and optimizing shipping costs, which is crucial for international trade. This economic efficiency makes lime juice concentrate highly attractive to large-scale industrial users, including global soft drink manufacturers and flavor houses. Despite fluctuations in raw lime harvests caused by unpredictable climate patterns, the inherent benefit of concentration—which allows for large volume storage during peak harvest—mitigates supply risk, ensuring continuous operational capacity for end-user industries throughout the year. The established infrastructure for sourcing, processing, and distribution across key producing regions, such as Mexico, Brazil, and India, underpins the market's robust future outlook.

Lime Juice Concentrate Market introduction

The Lime Juice Concentrate Market encompasses the production, distribution, and consumption of processed lime juice where a significant portion of the water content has been removed, increasing the Brix level and extending shelf life. This product serves as a fundamental ingredient across numerous industrial applications, offering the distinct, natural acidic flavor profile of fresh limes in a concentrated, highly stable, and easily transportable format. Major applications span the entirety of the food and beverage industry, including carbonated soft drinks, cocktails and mocktails, fruit beverages, sauces, marinades, baking, and dessert preparations. The market is defined by stringent quality standards related to total acidity, volatile oil content, and soluble solids, ensuring end-product consistency for large manufacturing operations globally.

The primary benefits driving the market adoption include superior cost management compared to using fresh fruit, reduced storage requirements due to minimized volume, and the assurance of flavor consistency regardless of seasonal variation in raw fruit quality or availability. For industrial buyers, the concentrate format simplifies manufacturing processes, allowing for precise dilution and formulation integration. Key driving factors include the global surge in demand for ready-to-drink (RTD) beverages that incorporate natural fruit flavors, the increasing popularity of ethnic cuisines requiring authentic citrus notes, and sustained growth in the convenience food sector. Furthermore, clean label trends encourage the use of natural concentrates over artificial flavorings and acids, providing a significant structural uplift to demand.

The intrinsic challenges related to sourcing and processing fresh limes, such as volatility in crop yields due to climate change and regional agricultural regulations, are expertly managed through the concentration process. This method allows processors to purchase large volumes of fruit during peak season, stabilize the juice, and supply users reliably year-round, thereby smoothing out price and supply fluctuations for downstream partners. The technological advancements in ultrafiltration and evaporation techniques continue to improve the concentrate's quality, minimizing heat damage to delicate flavor compounds and ensuring maximum vitamin and nutrient retention, thereby supporting the product's premium positioning in health-conscious segments.

Lime Juice Concentrate Market Executive Summary

The Lime Juice Concentrate Market is experiencing robust expansion, fundamentally driven by shifts in global consumer preferences toward natural and ethnically inspired flavors, necessitating stable sourcing of high-quality citrus ingredients. Business trends highlight strategic vertical integration among leading processors, extending from grove management to advanced bottling and blending facilities, aiming to secure raw material supply and optimize cost structures. There is a discernible trend towards producing specialized concentrates, such as organic or not-from-concentrate (NFC) blends, catering to niche premium segments that prioritize provenance and minimal processing. Competitive strategy focuses heavily on achieving sustainability certifications and transparency in sourcing to align with corporate social responsibility goals and consumer demand for ethical products, significantly influencing procurement decisions across multinational corporations.

Regionally, North America and Europe remain the largest consumers, attributed to mature industrial beverage sectors and high disposable incomes supporting premium flavor experimentation in food service and retail. However, the Asia Pacific (APAC) region is poised for the fastest growth, primarily fueled by rapid urbanization, Westernization of dietary patterns, and the massive expansion of the non-alcoholic beverage industry in populous nations like China and India. Production dominance remains concentrated in Latin America, particularly Mexico and Brazil, which benefit from favorable climate and established processing infrastructure, while regions like Southeast Asia are emerging as vital secondary production hubs, diversifying the global supply landscape and mitigating geopolitical risk inherent in concentrated supply chains.

Segment trends reveal that the 400 GPL (Grams Per Liter) acidity segment dominates the market due to its versatility and standard use in industrial applications, balancing flavor intensity with cost efficiency. Application-wise, the beverage industry holds the largest share, constantly innovating with new flavor combinations utilizing lime concentrate as a tart base or complementary note. The fastest-growing segments, however, are found in the specialized food preparations sector, including high-end sauces, dressings, and culinary ready-meals, where consumers seek complexity and authenticity. Retail sales of smaller concentrated formats for home use are also witnessing an uplift, reflecting consumer interest in scratch cooking and home mixology, further fragmenting the market and requiring diverse packaging strategies from suppliers.

AI Impact Analysis on Lime Juice Concentrate Market

User queries regarding the impact of Artificial Intelligence (AI) on the Lime Juice Concentrate Market frequently center on optimizing agricultural yields, enhancing processing efficiency, and improving supply chain resilience against climate variability. Consumers and industry professionals are keenly interested in how predictive AI models can forecast raw lime availability and pricing volatility, allowing processors to make informed procurement decisions months in advance. A common theme is the expectation that AI-driven quality control systems will replace manual sampling, ensuring highly precise measurements of Brix, acidity, and potential contaminants, thereby standardizing concentrate quality across batches and regions. Concerns often revolve around the high initial investment required for implementing sophisticated AI and IoT infrastructure in agricultural settings, particularly in developing nations that form the backbone of raw material supply, and the associated need for upskilling the existing workforce to manage these new digital platforms effectively.

The primary summary emerging from these themes is that AI integration is not merely an optional upgrade but is becoming a critical component for maintaining a competitive edge through efficiency, sustainability, and quality assurance. AI is expected to revolutionize grove management using satellite imagery and drone monitoring to predict disease outbreaks, optimize irrigation schedules, and calculate precise harvest timing, maximizing yield per acre and minimizing resource waste. In the processing plant, machine learning algorithms will be deployed to fine-tune evaporation and filtration parameters, minimizing energy consumption while preserving the delicate flavor profiles and nutritional integrity of the concentrate, leading to better product differentiation and reduced operational expenditure.

Ultimately, users anticipate that AI will facilitate a more responsive and transparent global citrus supply chain, providing real-time tracking of concentrate shipments, dynamic inventory management based on predicted downstream demand, and automated compliance checks against diverse international food safety regulations. This enhanced visibility and automation will enable faster response to unforeseen disruptions, such as shipping delays or crop failures, drastically reducing risk for global buyers and stabilizing the notoriously volatile commodity pricing structure associated with agricultural inputs. The successful deployment of these technologies will require collaborative platforms linking farmers, processors, distributors, and end-users under a unified, AI-managed data ecosystem.

- AI-driven predictive analytics for raw lime harvest forecasting and yield optimization.

- Implementation of machine vision systems for automated quality control and grading of fresh limes entering processing facilities.

- Optimization of concentration processes (evaporation/filtration) using machine learning to minimize energy use and maximize flavor retention.

- Enhanced supply chain visibility and traceability through AI-managed blockchain platforms for ethical sourcing validation.

- Automated dynamic pricing models based on real-time global supply, demand, and freight cost data.

- Robotics and automation in sorting, peeling, and packaging lines to increase throughput and reduce labor dependency.

DRO & Impact Forces Of Lime Juice Concentrate Market

The dynamics of the Lime Juice Concentrate Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively channeled by various impact forces ranging from regulatory scrutiny to evolving consumer health trends. Key drivers include the exponential growth in the global beverage industry, particularly flavored waters, functional drinks, and alcoholic mixers, all of which rely heavily on consistent citrus bases. Furthermore, the sustained clean label movement encourages manufacturers to substitute synthetic additives with natural fruit concentrates. Conversely, the market faces significant restraints, chiefly characterized by the inherent volatility and price fluctuations of raw lime crops, heavily influenced by adverse weather events and geopolitical instability in major producing regions, leading to unpredictable input costs for processors. The high dependency on specific agricultural geographies creates critical supply vulnerabilities, necessitating robust risk mitigation strategies for long-term buyers.

Opportunities for growth are substantial, particularly in the expansion into high-value functional food sectors, such as immune-boosting supplements and fortified beverages, capitalizing on the natural Vitamin C content of lime juice. Furthermore, leveraging advanced extraction and concentration technologies allows processors to create differentiated products, such as organic, single-origin, or specific varietal concentrates (e.g., Persian or Key Lime), tapping into premium segments willing to pay a surplus for distinct quality attributes. The development of advanced, low-temperature processing methods presents an opportunity to deliver superior flavor profiles that closely mimic fresh juice, enhancing consumer acceptance and widening the product’s application scope beyond traditional industrial uses into high-end culinary arts and artisanal product manufacturing. Strategic partnerships between concentrate producers and global flavor houses further accelerate innovation in new product formulations.

The primary impact forces include stringent governmental regulations concerning food safety, residue limits (pesticides), and international trade tariffs, which directly affect operational costs and market access. Economic impact forces, such as changes in global commodity prices and transportation costs (especially ocean freight), fundamentally influence the final price point and competitiveness of the concentrate. Additionally, social impact forces, specifically the increasing consumer awareness regarding sustainable sourcing and labor practices in agriculture, necessitate costly compliance and certification, exerting pressure on producers to invest in ethical supply chains. Technological innovation acts as a force multiplier, mitigating some restraints by improving yield reliability and processing efficiency, thereby stabilizing supply and offering competitive advantages to early adopters of sophisticated automation and quality assurance systems.

Segmentation Analysis

The Lime Juice Concentrate Market is intricately segmented based on Acidity Level, Application, Product Form, and Distribution Channel, reflecting the diverse requirements of industrial, retail, and food service users. Segmentation by acidity level, typically measured in grams per liter (GPL) of citric acid, is crucial as it determines the product's functional utility in formulations, dictating the required dilution ratios and final flavor characteristics. The application segmentation demonstrates the widespread utility of the product, with the beverage industry constituting the largest consumer base, followed by dairy, confectionery, and savory food sectors, each demanding specific concentrate specifications regarding color, clarity, and preservative use. Understanding these segment dynamics is paramount for market players to tailor production capabilities and marketing strategies effectively.

Detailed analysis of the segments reveals distinct growth drivers. For instance, the high-acidity segment (above 500 GPL) often targets institutional and industrial applications where high potency and efficiency are prioritized, such as chemical processing or large-volume industrial compounding. Conversely, the low-acidity, higher Brix concentrates are favored in specific food preparations where a smoother, less aggressive tartness is desired, such as baked goods or certain dairy products. The evolution of the retail segment is notable, driven by consumer demand for convenient, smaller-format packaging (Product Form) suitable for direct home consumption, often positioning the product as a shelf-stable alternative to fresh lime juice for cocktails and cooking, demanding stringent packaging quality and shelf-appeal.

Distribution segmentation highlights the dominance of the B2B channel, where large volumes of concentrate are moved directly from processors to industrial manufacturers, facilitated by specialized logistics and storage solutions (e.g., bulk drums, tankers). However, the growing importance of third-party distributors and specialized ingredient suppliers is providing greater market access for mid-sized processors and reaching smaller end-users in fragmented markets. Strategic growth often involves penetrating the food service sector (restaurants, hotels) through specialized wholesalers who manage inventory and delivery logistics suited to high-turnover hospitality environments, requiring consistent quality and reliable batch sizes, thereby ensuring comprehensive market coverage across all potential buying points.

- By Acidity Level:

- 400 GPL (Grams Per Liter)

- 500 GPL

- 600 GPL and Above

- By Application:

- Beverages (Soft Drinks, Juices, Alcoholic Mixers)

- Confectionery and Bakery

- Dairy and Desserts

- Sauces, Dressings, and Marinades

- Food Service and Institutional Use

- By Product Form:

- Frozen Concentrate

- Aseptic/Ambient Concentrate (Shelf-Stable)

- By Distribution Channel:

- B2B (Direct Industrial Sales)

- Retail (Supermarkets, Hypermarkets)

- Food Service Distributors

Value Chain Analysis For Lime Juice Concentrate Market

The Value Chain for the Lime Juice Concentrate Market begins with upstream activities centered around raw material cultivation, primarily the sourcing of fresh limes (Key Limes, Persian Limes). This stage involves complex agricultural management, including farming, harvesting, and initial transport to processing centers. Critical upstream factors include climate vulnerability, seed quality, labor availability, and agricultural yield volatility, which directly dictate the processor's input cost and supply security. Major processors often engage in contract farming or acquire their own groves to exert greater control over quality, timing, and sustainable practices, thereby mitigating price risk associated with fluctuating open market purchases. Efficiency at this stage is crucial for maintaining competitive concentrate pricing.

The core processing stage involves cleaning, extraction, pasteurization, and concentration using advanced techniques such as vacuum evaporation or reverse osmosis to remove water content, achieving the desired Brix level and acidity. This stage is capital-intensive, requiring specialized machinery and significant energy input. Midstream activities also include quality control checks, such as testing for residual solvents and ensuring microbiological safety, before the concentrate is standardized and packaged into drums or bulk containers. Effective waste management (utilizing lime peel and pulp for essential oils or animal feed) contributes significantly to the processor's profitability and environmental sustainability profile. Innovation in processing technology directly impacts the final product's quality, particularly flavor fidelity and color retention.

Downstream activities focus on distribution, marketing, and final consumption. The distribution channel is bifurcated into direct B2B sales to large industrial customers (Coca-Cola, PepsiCo, major flavor houses) and indirect sales through specialized ingredient distributors who cater to smaller manufacturers, food service, and retail sectors. Direct distribution emphasizes large volume, long-term contracts, and customized specifications, while indirect channels require robust inventory management and flexible delivery schedules. The final consumption point sees the concentrate utilized across the immense diversity of the food and beverage landscape. Success in the downstream sector relies on strong customer relationships, technical support for formulation integration, and efficient global logistics to ensure timely, cold-chain-compliant delivery where necessary.

Lime Juice Concentrate Market Potential Customers

The primary potential customers and end-users of lime juice concentrate span across various sectors that necessitate consistent, high-quality, and cost-effective citrus ingredients. The most significant customer segment remains the global beverage industry, encompassing manufacturers of carbonated soft drinks, bottled water flavor enhancers, sports and functional drinks, and alcoholic beverage mixers (e.g., margarita mixes, ready-to-drink cocktails). These large-scale users require substantial volumes of concentrate with guaranteed specifications regarding GPL, color, and clarity, often signing multi-year supply contracts to ensure uninterrupted production capacity, making stability and supply assurance critical procurement criteria.

A rapidly expanding customer base resides within the prepared food and institutional food service sectors. This includes manufacturers of savory products such as salad dressings, marinades, ethnic sauces (e.g., Asian and Latin American cuisines), and specialized seasonings, where lime’s acidic profile is essential for preservation and flavor balance. Food service companies, including major restaurant chains and catering operators, utilize bulk concentrate for consistency in recipes and efficiency in kitchen operations, bypassing the labor and storage constraints associated with fresh limes. The rise of centralized commissaries and ghost kitchens further amplifies this demand for standardized ingredient inputs.

Furthermore, the pharmaceutical and nutraceutical industries represent a niche but high-value customer segment. Lime concentrate is used as a natural source of Vitamin C and bioflavonoids in dietary supplements and certain medicinal preparations, often requiring concentrates that meet rigorous quality standards, including low microbiological counts and specific chemical purity levels. The retail segment, which packages smaller consumer-friendly formats, also constitutes a vital customer segment, purchasing large volumes of concentrate for repacking and direct sale to the general public for home cooking and beverage preparation, relying heavily on brand visibility and shelf life optimization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $2.75 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Citrus Systems, Inc., Döhler GmbH, Lemon Concentrate S.L., Prodalim Group, Louis Dreyfus Company B.V., Symrise AG, Archer Daniels Midland Company (ADM), Sunshine Concentrates, Inc., S. A. F. Or. S.p.A., Cutrale Citrus Juices USA, Inc., Tree Top, Inc., Ventura Coastal, Citrus World, Inc., AGRANA Beteiligungs-AG, Iprona S.p.A., Furest S.A., Ingredion Incorporated, Kerr Concentrates Inc., Sudzucker AG, and LiDestri Food and Drink. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lime Juice Concentrate Market Key Technology Landscape

The technological landscape within the Lime Juice Concentrate Market is characterized by continuous innovation focused primarily on efficiency, quality preservation, and energy reduction during the concentration process. The primary technology utilized is multi-effect vacuum evaporation, which efficiently removes water at lower temperatures, minimizing thermal degradation of flavor and nutrients. However, modern processors are increasingly adopting membrane technologies, such as Reverse Osmosis (RO) and Nanofiltration (NF). RO allows for partial water removal with significantly less heat exposure than traditional evaporation, resulting in a 'premium' concentrate with superior volatile flavor retention and a profile closer to fresh juice, justifying a higher selling price in discerning industrial markets.

Furthermore, advances in quality control and analytical instrumentation are vital. Processors leverage High-Performance Liquid Chromatography (HPLC) and Gas Chromatography (GC) to accurately measure key chemical markers, including D-Limonene content, total acidity, and Brix levels, ensuring concentrates meet exact customer specifications. Non-thermal processing techniques, such as High-Pressure Processing (HPP) and Pulsed Electric Fields (PEF), are also emerging, particularly for 'Not-From-Concentrate' (NFC) products, but their application is increasingly being explored for concentrate processing to further enhance microbiological safety and extend shelf stability without reliance on high heat, which can be detrimental to the delicate citrus flavor components and natural colorants.

Supply chain technology, including IoT sensors for real-time temperature and humidity monitoring during transport and storage, is crucial for maintaining the quality integrity of bulk concentrate shipments, particularly frozen variants. Moreover, the integration of enterprise resource planning (ERP) systems with agricultural data (e.g., weather patterns, yield mapping) allows for superior forecasting and optimized operational scheduling, reducing waste and maximizing resource utilization throughout the entire vertical chain, from grove to final blending. This technological convergence enables processors to offer greater transparency and reliability, which are critical differentiators in the highly competitive bulk ingredients market, moving the industry towards highly efficient, data-driven manufacturing processes.

Regional Highlights

- North America: North America, led by the United States, represents a mature but highly dynamic consumer market for lime juice concentrate. The robust demand is fueled by the massive consumption of ready-to-drink beverages, especially soda, flavored waters, and the surging popularity of tequila-based cocktails and hard seltzers, where lime is a signature flavor. The region benefits from established industrial formulation capabilities and high consumer awareness regarding product quality and labeling standards. Regulatory adherence, particularly regarding pesticide residues and organic certification, is a significant determinant for market entry. High competition among leading beverage corporations drives continuous product innovation, creating steady demand for premium and specialized concentrates.

- Europe: Europe is characterized by a strong emphasis on clean label ingredients, sustainability, and stringent food safety standards (EFSA guidelines). Western European countries, particularly Germany, the UK, and France, are major consumers, utilizing concentrate extensively in the confectionery, savory sauces, and natural juice industries. There is a notable growth trend in the organic lime concentrate segment, catering to the strong European consumer preference for certified ecological products. Supply chain stability is critical for European buyers who rely heavily on imports from Latin America and, increasingly, from Mediterranean suppliers.

- Asia Pacific (APAC): APAC is the fastest-growing market, driven by rising disposable incomes, rapid urbanization, and the expanding presence of global fast-food and beverage chains. Countries like China, India, and Australia are witnessing a steep increase in demand for Westernized processed foods and beverages. While price sensitivity remains a factor in certain emerging economies, the adoption of packaged drinks and convenience foods provides vast opportunities. Local production capabilities are developing, but much of the high-quality concentrate is still imported, posing logistical challenges that are gradually being overcome through investment in cold chain infrastructure.

- Latin America (LATAM): Latin America, specifically Mexico and Brazil, functions as the primary global production hub for lime juice concentrate due to optimal climatic conditions and abundant raw material supply. While a major exporter, internal consumption is also strong, driven by local beverage consumption (e.g., concentrated juices and Aguas Frescas). The region’s market dynamics are heavily influenced by agricultural yields and seasonal weather patterns, making it the focal point for price discovery and global supply management. Investment in local processing technology is critical for regional players seeking to compete globally on quality and efficiency.

- Middle East and Africa (MEA): The MEA region shows emerging potential, driven by growing populations and increasing sophistication in the retail food and beverage landscape, particularly in the UAE, Saudi Arabia, and South Africa. Demand is concentrated in the hotel, restaurant, and catering (HORECA) sector and in packaged non-alcoholic drinks. Religious and cultural consumption patterns influence product development, often favoring non-alcoholic and exotic juice blends. Supply relies almost exclusively on imports, placing a premium on reliable shipping and long shelf life concentrates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lime Juice Concentrate Market.- Citrus Systems, Inc.

- Döhler GmbH

- Lemon Concentrate S.L.

- Prodalim Group

- Louis Dreyfus Company B.V.

- Symrise AG

- Archer Daniels Midland Company (ADM)

- Sunshine Concentrates, Inc.

- S. A. F. Or. S.p.A.

- Cutrale Citrus Juices USA, Inc.

- Tree Top, Inc.

- Ventura Coastal

- Citrus World, Inc.

- AGRANA Beteiligungs-AG

- Iprona S.p.A.

- Furest S.A.

- Ingredion Incorporated

- Kerr Concentrates Inc.

- Sudzucker AG

- LiDestri Food and Drink

Frequently Asked Questions

Analyze common user questions about the Lime Juice Concentrate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Lime Juice Concentrate Market?

The primary factor driving market growth is the global expansion of the ready-to-drink (RTD) beverage industry, coupled with the persistent consumer shift towards natural flavoring agents, leading industrial users to favor concentrated lime juice over artificial acidulants and synthetic flavors for cost-effective and consistent formulations.

How does the volatile pricing of fresh limes impact concentrate producers?

Raw material price volatility, often caused by climate change or weather disruptions in major producing regions like Mexico and Brazil, represents a significant restraint. Producers mitigate this risk through strategic hedging, long-term contract farming, and maintaining high inventory reserves during peak harvest seasons to stabilize their input costs for year-round production.

Which geographical region holds the largest market share in the Lime Juice Concentrate Market?

North America and Europe currently hold the largest consumption shares due to their mature industrial food and beverage sectors, sophisticated demand for premium flavored products, and established supply chains for high-volume ingredient procurement and usage, though Asia Pacific exhibits the fastest growth trajectory.

What are the key differences between 400 GPL and 600 GPL lime concentrates?

The designation GPL (Grams Per Liter) refers to the total citric acid content, indicating the strength and acidity level. 600 GPL concentrate is significantly stronger, requiring greater dilution and offering higher efficiency in industrial applications where maximum potency is needed, whereas 400 GPL is a standard, versatile concentration often preferred for broader flavor balancing applications.

Is the use of Reverse Osmosis (RO) technology increasing in concentrate production?

Yes, Reverse Osmosis technology is increasingly adopted, particularly for premium concentrates. RO allows for water removal with minimal heat exposure compared to traditional evaporation, thus preserving more delicate volatile flavor compounds and yielding a higher quality, 'closer-to-fresh' juice profile sought after by high-end food and beverage manufacturers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager