Line Striping Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442983 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Line Striping Machines Market Size

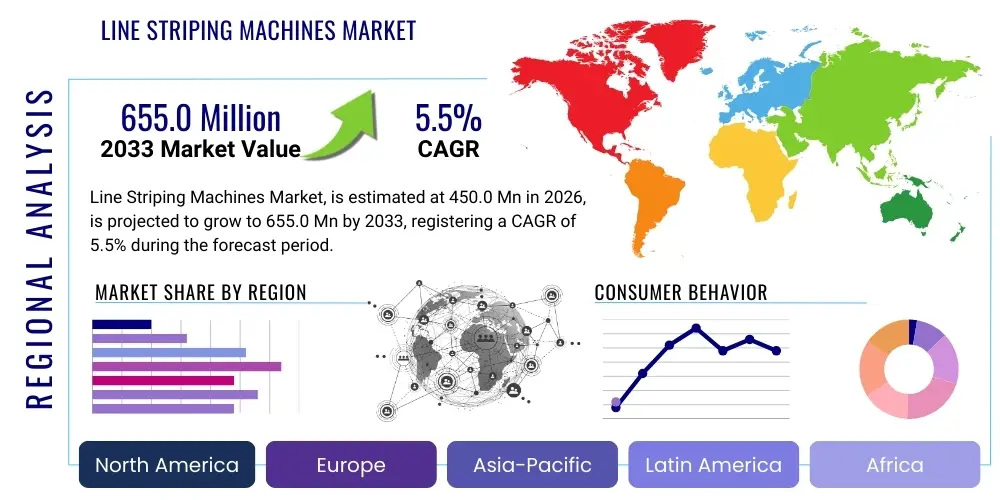

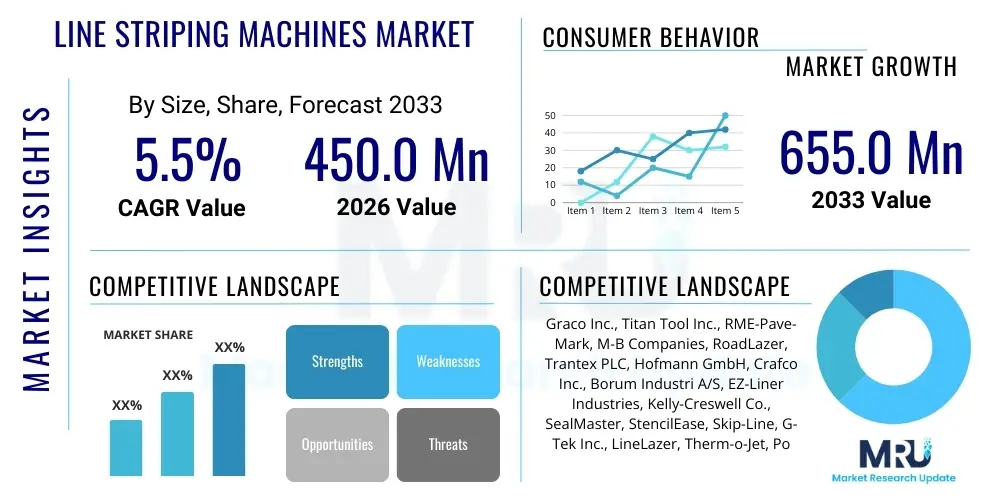

The Line Striping Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 450.0 million in 2026 and is projected to reach USD 655.0 million by the end of the forecast period in 2033.

Line Striping Machines Market introduction

The Line Striping Machines Market encompasses the sales and utilization of specialized equipment designed for applying paint, thermoplastic, or other marking materials onto surfaces such as roads, parking lots, sports fields, airports, and warehouse floors. These machines range from manual push models suitable for small jobs to highly sophisticated, truck-mounted hydraulic systems capable of high-volume, precision application on major highways and runways. The fundamental requirement for clear, durable surface markings across various infrastructure sectors drives the consistent demand for these specialized tools, making them indispensable in construction, maintenance, and public safety initiatives globally.

Line striping machines are categorized primarily by the application method, including airless sprayers, conventional air sprayers, and specialized extrusion equipment for thick materials like thermoplastics. Modern versions prioritize operational efficiency, reduced material waste, and compliance with stringent environmental regulations regarding volatile organic compounds (VOCs). The product description centers on robust engineering, precision control systems (often computerized), and ergonomics, ensuring consistent line width and paint thickness regardless of surface texture or external conditions. Key components involve high-pressure pumps, material reservoirs, advanced nozzle technologies, and guidance systems that ensure straight and accurate markings.

Major applications of line striping machines span public infrastructure maintenance (highways, municipal roads), commercial property management (parking garages, shopping centers), and recreational facility upkeep (tennis courts, running tracks). The primary benefits derived from using specialized machinery over manual methods include significantly increased speed of application, superior durability and quality of the finished line, substantial cost savings through optimized material usage, and enhanced worker safety by minimizing manual exposure to traffic. Market growth is primarily driven by continuous global investment in urban infrastructure, strict adherence to traffic safety standards necessitating reflective and visible markings, and the ongoing expansion of logistics centers requiring internal floor marking.

Line Striping Machines Market Executive Summary

The global Line Striping Machines Market is experiencing robust expansion driven by urbanization trends and intensified infrastructure development, particularly across emerging economies in the Asia Pacific region. Business trends reflect a clear shift toward advanced, automated machinery offering enhanced precision and sustainability. Manufacturers are focusing heavily on integrating GPS guidance systems, telematics for fleet management, and hybrid/electric power sources to address escalating labor costs and environmental mandates. This technological pivot is fostering competition based not solely on machine capacity but on smart features that optimize paint usage and adherence to complex regulatory line specifications. The market structure remains moderately fragmented, with specialized manufacturers competing on innovation and robust after-sales service.

Regionally, North America and Europe maintain dominance due to established highway networks, stringent safety regulations (mandating frequent remarking), and high adoption rates of premium, automated equipment. However, the fastest growth trajectory is observed in Asia Pacific, propelled by large-scale government infrastructure projects in countries like China and India, focusing on new road construction and airport expansion. Latin America and the Middle East also represent promising segments, spurred by investments in smart city projects and rapidly expanding logistics hubs. This geographical diversification necessitates localized product offerings, especially regarding material compatibility (e.g., high-temperature resistance in the Middle East).

Segment trends highlight the dominance of airless stripers due to their efficiency and versatility, although thermoplastic extruders command a significant value share owing to their application in high-durability highway markings. The power source segment is rapidly transitioning, with internal combustion engine (ICE) machines gradually yielding market share to battery-operated and hybrid models, particularly in confined or indoor environments where emissions are critical concerns. The end-user spectrum shows robust demand from professional paving and marking contractors who seek high-performance, durable machines capable of maximizing uptime and handling diverse contract requirements efficiently.

AI Impact Analysis on Line Striping Machines Market

Common user questions regarding AI's influence in the Line Striping Machines Market predominantly center on how Artificial Intelligence and Machine Learning (ML) can enhance the precision, autonomy, and material efficiency of striping operations. Key concerns revolve around the feasibility and cost of integrating complex navigational AI (similar to autonomous driving) into specialized construction equipment, ensuring regulatory compliance for autonomous roadwork, and the capacity of AI systems to interpret variable environmental factors such as surface inconsistencies, existing faded lines, or dynamic traffic flow. Users are keenly interested in predictive maintenance facilitated by AI, aiming to maximize machine uptime and reduce unforeseen operational failures during critical contracting periods. The consensus suggests high expectation for AI to fundamentally shift striping from a semi-manual, high-variability process to a fully automated, high-precision task.

AI's primary transformative role is anticipated in optimizing machine operation parameters in real-time. ML algorithms can analyze data streams from sensors (Lidar, cameras, GPS) to dynamically adjust paint flow rates, nozzle pressure, and speed based on the precise material requirements for a given road surface type and curvature. This level of optimization minimizes material waste—a significant cost component—and ensures markings meet strict reflection and durability specifications consistently, regardless of operator experience. Furthermore, AI-driven computer vision systems can significantly improve the quality control process by autonomously detecting, documenting, and correcting line imperfections immediately after application, thereby reducing the need for costly rework and improving overall project throughput.

Looking ahead, the integration of generative AI in planning phases allows contractors to model complex marking layouts (e.g., airport runways or specialized intersection designs) and simulate the application process to identify potential issues before deployment. This strategic use of AI enhances both safety and efficiency. While full autonomy for large-scale highway striping faces regulatory hurdles, AI-enhanced assistance systems (A-DAS) that provide sophisticated guidance, collision avoidance, and material consumption forecasting are already becoming standard features on high-end machinery, solidifying AI as a crucial differentiator for leading manufacturers.

- Autonomous navigation for precise, pre-mapped line application.

- Predictive maintenance schedules reducing machine downtime.

- Real-time material flow optimization based on surface feedback.

- AI-enhanced quality assurance using computer vision for instant defect detection.

- Integration of machine learning for optimizing thermoplastic heating cycles.

- Enhanced operator guidance systems and collision avoidance in live traffic.

- Simulation and generative modeling for complex striping project planning.

DRO & Impact Forces Of Line Striping Machines Market

The dynamics of the Line Striping Machines Market are significantly influenced by a compelling set of Driving factors, operational Restraints, and latent Opportunities that collectively shape market trajectories and competitive positioning. Key drivers include stringent governmental regulations mandating clear, retroreflective road markings to enhance traffic safety globally, coupled with massive, sustained investment in road infrastructure development and maintenance, particularly in rapidly urbanizing regions. These regulatory and infrastructural pressures ensure a consistent, non-discretionary demand for reliable striping equipment. Counterbalancing these drivers are significant restraints, notably the high initial capital investment required for advanced, automated equipment, which can be prohibitive for smaller contracting firms, and the inherent volatility in raw material costs, specifically paint and thermoplastic compounds, which impacts the profitability of both machine usage and material supply.

Opportunities for market expansion are largely tied to technological advancements and niche application development. The transition toward sustainable and environmentally compliant marking materials (e.g., low-VOC paints, solvent-free compounds) presents an opportunity for manufacturers to innovate specialized machinery capable of handling these new formulations efficiently. Furthermore, the burgeoning demand for highly durable, long-lasting pavement markings in high-traffic areas, such as using specialized extruded thermoplastics or preformed tapes, stimulates R&D in heavy-duty, high-capacity machines. The growing adoption of airless striping technology, which offers superior precision and reduced overspray, also provides substantial growth pathways within the commercial and airport sectors.

The impact forces within the market are predominantly driven by technological parity, regulatory stringency, and economic cycles. Regulatory changes related to road safety standards (e.g., mandated minimum reflectivity standards) force rapid equipment upgrades. Simultaneously, the force of technological innovation, particularly the race toward automation and integration of GPS/GNSS guidance, pressures companies to continuously invest in R&D to remain competitive. Economically, governmental budget allocations for public works directly correlate with market demand, making the sector susceptible to large-scale, public spending decisions. These forces collectively dictate pricing strategies, market entry barriers, and the speed of technology adoption across different geographic regions.

Segmentation Analysis

The Line Striping Machines Market is comprehensively segmented based on technology, power source, application, and end-user, enabling a granular understanding of market dynamics and targeted strategic planning. The segmentation by technology, including airless, conventional, and specialized extruders, reveals preference trends concerning efficiency and material type. Power source segmentation is vital, reflecting the industry's shift towards sustainability with classifications like internal combustion engines (ICE), electric/battery, and hydraulic systems. Application-based segmentation provides insight into high-growth sectors such as highway maintenance versus niche areas like sports field marking. Finally, end-user categorization differentiates between large professional contractors, government agencies, and small municipal or facility management operators, each possessing distinct procurement requirements and purchasing power profiles.

- By Technology:

- Airless Stripers

- Conventional Air Spray Stripers

- Thermoplastic Extrusion Machines

- Ride-on/Truck Mounted Systems

- Others (e.g., Taping Machines)

- By Power Source:

- Internal Combustion Engine (ICE) Powered

- Battery/Electric Powered

- Hydraulic Powered

- By Application:

- Road and Highway Marking

- Parking Lot and Commercial Facility Marking

- Airport and Runway Marking

- Sports Field Marking

- Warehouse and Industrial Floor Marking

- By End User:

- Professional Paving Contractors

- Government and Municipal Agencies

- Facility Management and Institutional Users

- Rental Fleets

Value Chain Analysis For Line Striping Machines Market

The value chain for the Line Striping Machines Market commences with upstream analysis, focusing on the sourcing of critical raw materials and components, including specialized metals (steel and aluminum), polymers for housing and seals, and complex electronic components necessary for control boards, GPS systems, and pumps. Key upstream suppliers include manufacturers of high-pressure pumps (diaphragm and piston pumps), precision nozzles, engines (gasoline or diesel), and electric motors. Efficiency and quality in the upstream segment are crucial, as pump reliability directly dictates machine performance and longevity. Strategic relationships with specialized component providers are essential for mitigating supply chain risks and ensuring the integration of cutting-edge technology, particularly regarding advanced pressure regulation systems.

The central phase involves the manufacturing and assembly of the striping machines. Manufacturers focus on design engineering, optimizing machine ergonomics, durability, and paint delivery precision. Rigorous quality control and adherence to safety standards, such as those governing pressure vessel integrity, are paramount. The distribution channel is bifurcated into direct and indirect routes. Direct sales are common for high-value, customized, truck-mounted systems sold directly to large governmental agencies or top-tier contractors, allowing manufacturers to maintain tight control over pricing and customer support. Indirect distribution, involving specialized equipment dealers and rental companies, dominates the sales of smaller, walk-behind, and mid-range airless stripers, leveraging the established regional networks of these partners for warehousing, service, and localized sales support.

Downstream analysis focuses on the end-user, primarily professional contractors and municipal bodies responsible for infrastructure maintenance. Their procurement decisions are heavily influenced by total cost of ownership (TCO), machine reliability, and the availability of responsive local service and replacement parts. The aftermarket segment, encompassing maintenance, repairs, and the sale of consumables (nozzles, filters, hoses), constitutes a significant revenue stream. This robust service requirement further strengthens the role of indirect distribution channels. The overall value chain emphasizes technology transfer from component suppliers to machine manufacturers, and efficient, localized support from distributors to maximize machine uptime for the demanding professional end-users.

Line Striping Machines Market Potential Customers

The core customer base for Line Striping Machines is highly diverse, spanning various sectors responsible for maintaining marked surfaces critical to safety and logistics. Professional paving and marking contractors represent the largest segment, acting as primary buyers who require high-capacity, durable, and technologically advanced machines to fulfill large-scale public and private infrastructure contracts efficiently. These customers prioritize machine speed, material versatility (handling paint, thermoplastics, and epoxy), and minimal maintenance requirements to maximize operational profitability. Their purchasing decisions are often tied to specific project requirements and fleet standardization.

Governmental and municipal agencies, including departments of transportation (DOTs), public works departments, and military facilities, form another crucial customer group. These entities often procure heavy-duty, truck-mounted systems for large-scale highway and airport runway maintenance. Their requirements emphasize longevity, compliance with strict regulatory specifications (such as ASTM or federal highway standards), and increasingly, adherence to environmental sustainability metrics. Procurement is typically conducted through formalized bidding processes, favoring suppliers who offer proven reliability and comprehensive service agreements.

Furthermore, facility management professionals, institutional users (universities, large hospitals), and operators of commercial properties (shopping centers, large corporate campuses) constitute a growing segment for smaller, more maneuverable striping units, particularly battery-powered or walk-behind airless sprayers. These buyers seek ease of use, lower emissions for indoor applications (e.g., parking garages, warehouses), and sufficient durability for intermittent, non-professional use. The rental market also serves as a significant buyer, purchasing machines for short-term leasing to smaller contractors and facility managers, further diversifying the distribution landscape and increasing overall machine utilization rates across the industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.0 million |

| Market Forecast in 2033 | USD 655.0 million |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Graco Inc., Titan Tool Inc., RME-Pave-Mark, M-B Companies, RoadLazer, Trantex PLC, Hofmann GmbH, Crafco Inc., Borum Industri A/S, EZ-Liner Industries, Kelly-Creswell Co., SealMaster, StencilEase, Skip-Line, G-Tek Inc., LineLazer, Therm-o-Jet, PowerMark, RoadPrintz, LineBoss. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Line Striping Machines Market Key Technology Landscape

The Line Striping Machines Market is characterized by continuous technological evolution aimed at improving precision, durability, and operational efficiency while minimizing environmental impact. A key area of innovation is in fluid delivery systems, specifically the move towards advanced airless spray technology, which utilizes high pressure to atomize paint, resulting in sharper, more consistent line edges and significantly reduced overspray compared to traditional air spray methods. This technology maximizes material utilization and ensures compliance with strict line geometry standards, a critical factor for highway applications. Furthermore, the integration of advanced sensors and real-time electronic pressure control systems allows operators to dynamically adjust settings based on speed and surface condition, maintaining superior application quality even under varying operational circumstances.

Another dominant technology trend involves advanced guidance and automation systems. High-end, truck-mounted machines now routinely incorporate Global Navigation Satellite System (GNSS) or high-precision GPS (HP-GPS) technology, often supplemented by Lidar and Inertial Measurement Units (IMUs), to ensure millimeter-level accuracy for complex road patterns, airport markings, and longitudinal lines. This shift towards digitally mapped and computer-controlled striping is crucial for optimizing workflows, eliminating the need for manual pre-marking (chalking), and enabling precise re-striping of faded lines. The move towards semi-autonomous and fully autonomous capabilities, particularly in controlled environments like airports, is leveraging these precision technologies to reduce reliance on human intervention and mitigate associated labor safety risks.

Sustainability and material innovation are driving the third major technology thrust. The market is seeing increased adoption of thermoplastic extrusion equipment, which applies molten material for extremely durable, long-lasting markings, requiring sophisticated heating and temperature control technologies to ensure consistent application viscosity. Concurrently, there is a substantial focus on developing reliable battery-powered and hybrid-electric stripers, addressing the demand for low-emission machines suitable for indoor warehousing, tunnels, and environmentally sensitive areas. These electric systems require innovations in battery longevity and power management to sustain the high-pressure demands of airless pumps while ensuring acceptable operational durations for professional contractors.

Regional Highlights

- North America: North America holds a dominant position in the Line Striping Machines Market, characterized by extensive, well-established highway networks and rigorous maintenance schedules mandated by federal and state transportation departments. The region is a primary adopter of high-end, automated, and truck-mounted striping systems featuring advanced GPS guidance. Strict governmental standards regarding pavement marking reflectivity and durability necessitate frequent repainting and continuous investment in high-performance equipment, particularly in the U.S. and Canada. The region also exhibits high demand for airless technology across commercial and municipal applications, supported by a strong presence of key global manufacturers and a mature rental market ecosystem.

- Europe: Europe is a mature market driven by high environmental consciousness and strong commitments to road safety (Vision Zero initiatives). European demand is characterized by a strong preference for efficient, low-emission equipment, accelerating the adoption of electric and hybrid striping machines, particularly in urban centers and controlled zones. Germany, the UK, and France are key contributors, driven by stringent quality standards for thermoplastic and cold plastic markings. Furthermore, European manufacturers often lead innovation in specialized machinery designed for complex urban intersections and high-durability reflective markings.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by massive public investments in infrastructure development, including new highway construction, airport expansions, and the growth of logistics and industrial parks in countries like China, India, and Southeast Asia. The demand here is dual-natured: high capacity, durable machines for national highways, and cost-effective, maneuverable stripers for rapidly expanding municipal and commercial spaces. While price sensitivity is higher, there is a rapid uptake of modern technology to meet international safety and quality benchmarks, presenting significant opportunities for global suppliers.

- Latin America: This region presents substantial growth potential, linked to increasing urbanization and necessary upgrades to aging road infrastructure. Market growth is stimulated by the need to implement modern traffic safety measures. Procurement often relies on government tender processes, with emphasis placed on reliable, easy-to-maintain equipment. Brazil and Mexico are primary markets, with rising demand for both standard paint stripers and specialized thermoplastic equipment as road networks expand and safety standards gradually increase.

- Middle East and Africa (MEA): Growth in the MEA region is driven primarily by large-scale infrastructure projects, including smart city developments and new airport construction, particularly in the GCC countries (Saudi Arabia, UAE). The unique challenge of extreme heat necessitates specialized machinery capable of handling high-temperature thermoplastic materials and robust cooling systems. Africa's market remains fragmented but shows promise due to development bank-funded road projects focusing on connecting major economic hubs, driving demand for essential, durable striping equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Line Striping Machines Market.- Graco Inc.

- Titan Tool Inc.

- RME-Pave-Mark

- M-B Companies

- RoadLazer

- Trantex PLC

- Hofmann GmbH

- Crafco Inc.

- Borum Industri A/S

- EZ-Liner Industries

- Kelly-Creswell Co.

- SealMaster

- StencilEase

- Skip-Line

- G-Tek Inc.

- LineLazer

- Therm-o-Jet

- PowerMark

- RoadPrintz

- LineBoss

Frequently Asked Questions

Analyze common user questions about the Line Striping Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What types of line striping machines are most effective for highway use?

For high-volume highway use, truck-mounted thermoplastic extrusion machines are most effective due to their high production speed and the superior durability of thermoplastic materials. Airless stripers are also used for paint, often integrated into large, automated systems with GPS guidance for maximum precision.

How does battery-powered striping technology benefit contractors?

Battery-powered striping machines offer key benefits including zero emissions, significantly lower noise levels, and reduced maintenance needs compared to ICE-powered models. This makes them ideal for indoor applications (warehouses, garages) and urban areas with strict noise and air quality regulations.

What is the primary factor driving demand for line striping equipment globally?

The primary factor driving global demand is increasing government investment in infrastructure maintenance and expansion, coupled with stringent, non-negotiable traffic safety regulations that mandate clear, retroreflective, and highly visible pavement markings on all public roads and facilities.

Which region shows the highest growth potential for line striping machines?

The Asia Pacific (APAC) region exhibits the highest growth potential, propelled by rapid urbanization and massive government expenditure on new road networks, airports, and industrial infrastructure projects across major economies like China and India.

How is AI impacting the efficiency of modern line striping operations?

AI impacts efficiency through the integration of precise guidance systems (HP-GPS), real-time material flow optimization, and predictive maintenance diagnostics. These AI-enhanced features minimize paint waste, improve line consistency, and maximize machine uptime during critical paving seasons.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager