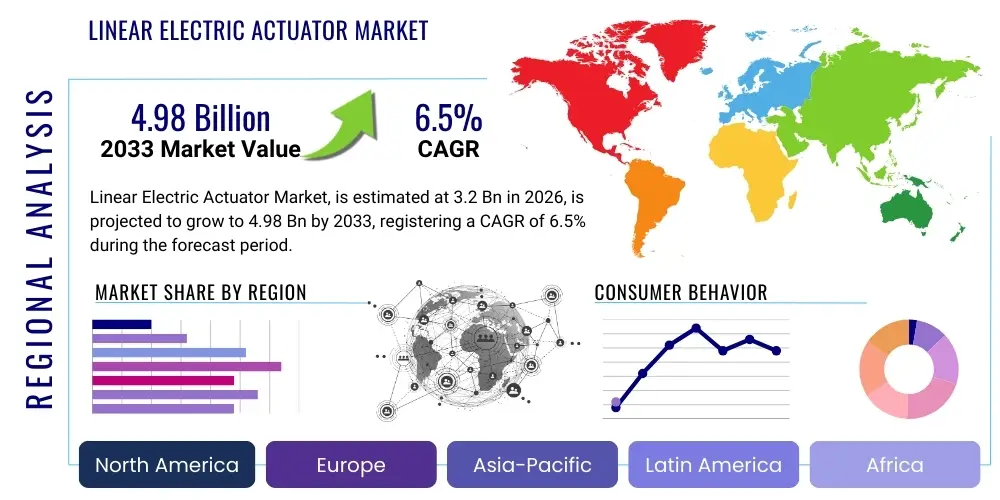

Linear Electric Actuator Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441747 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Linear Electric Actuator Market Size

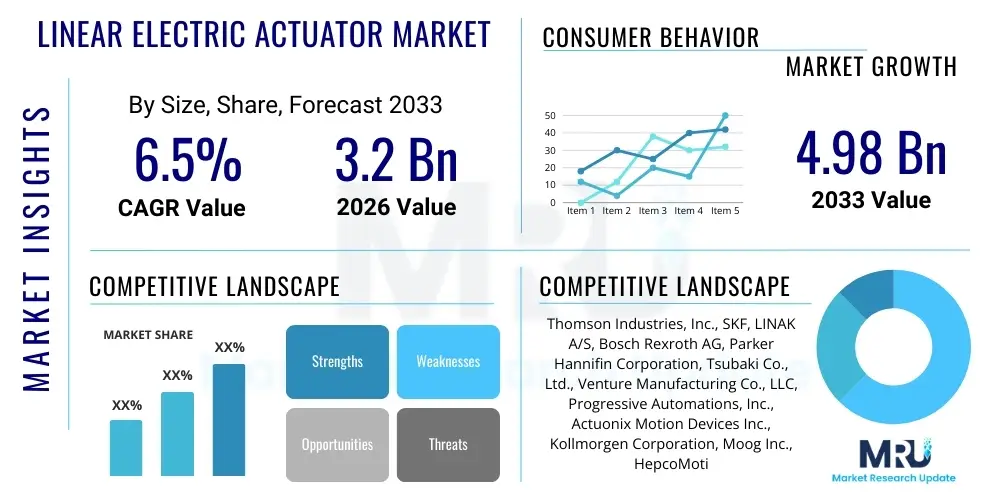

The Linear Electric Actuator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 3.2 Billion in 2026 and is projected to reach USD 4.98 Billion by the end of the forecast period in 2033.

Linear Electric Actuator Market introduction

Linear Electric Actuators (LEAs) represent sophisticated electromechanical mechanisms engineered to convert the rotational motion generated by an electric motor—typically AC, DC, or stepper—into precise, straight-line (linear) displacement. These devices are fundamentally replacing older hydraulic and pneumatic systems across various industries due to their unparalleled accuracy, inherent energy efficiency, superior controllability, and lower long-term operational costs. Key applications span a vast spectrum, encompassing high-speed material handling systems in logistics, intricate positioning tasks in semiconductor manufacturing, patient positioning and critical fluid control in advanced medical devices, and robust utility control in the energy sector. The core benefits derived from their implementation include highly repeatable positioning (often within micron levels), simplified integration via standardized digital communication protocols, minimal maintenance requirements, and full programmatic control over speed, force, and acceleration profiles. Market growth is fundamentally driven by the accelerating global transition towards smart manufacturing and Industry 4.0 paradigms, where data-driven control and optimized resource utilization are paramount operational mandates.

Linear Electric Actuator Market Executive Summary

The global market for Linear Electric Actuators demonstrates a powerful upward trend, significantly influenced by macroeconomic shifts toward automated efficiency and resource sustainability. Business trends highlight a strong industry focus on developing integrated solutions, where actuators are sold as part of a complete motion package featuring integrated drives, controllers, and predictive maintenance software, increasing the barriers to entry for simpler, component-only providers. Technological innovation is centering on achieving higher force density within smaller footprints, necessitating advances in motor technology and mechanical screw design. Regional trends reveal that while North America and Europe continue to adopt high-precision, customized solutions in specialized sectors like aerospace and medical, the Asia Pacific region dictates the overall market volume growth, driven by massive investments in standardized factory automation and electric vehicle production capacity. Segment trends confirm that Ball Screw Actuators maintain the largest share due to their versatility and cost-effectiveness, though the Roller Screw segment is experiencing the fastest revenue growth due to its superior capacity for heavy-duty, continuous operation.

AI Impact Analysis on Linear Electric Actuator Market

End-user interest regarding the incorporation of Artificial Intelligence (AI) into Linear Electric Actuator systems focuses heavily on achieving autonomous optimization and mitigating operational risks associated with mechanical wear. Common questions query the feasibility of using embedded AI modules to process complex operational data—such as high-frequency vibration signatures and instantaneous current spikes—to create highly accurate Remaining Useful Life (RUL) predictions. Users are concerned about whether AI integration will necessitate complete hardware overhauls or if it can be implemented through advanced firmware updates and centralized cloud-based analytics platforms. The consensus expectation is that AI must enhance the actuator's core performance attributes, specifically its repeatability and reliability, beyond the capabilities of traditional Proportional-Integral-Derivative (PID) control loops, especially in dynamic, highly variable load applications where manual tuning is inefficient or impossible.

The practical integration of AI is transforming actuator lifecycle management and energy optimization. AI algorithms are adept at analyzing complex multivariate data streams generated by the actuator, learning the characteristic "fingerprint" of normal operation under specific load profiles, duty cycles, and temperatures. When deviations occur, the AI system can classify the fault type (e.g., bearing degradation, screw wear, or misalignment) with far greater accuracy and speed than human analysts or simple threshold-based monitoring systems. This capability drastically reduces unscheduled downtime, optimizing maintenance schedules to ensure components are replaced precisely when necessary, maximizing both productivity and the component’s operational lifespan. Furthermore, AI contributes significantly to reducing energy waste by ensuring the actuator uses only the necessary torque and speed for the required task, factoring in real-time friction and load variables to operate at peak electrical efficiency.

Beyond diagnostics, AI is crucial for enhancing motion control in highly coupled, multi-axis systems, common in six-axis robots and synchronized industrial press applications. In these scenarios, slight variations in one actuator's performance can cascade, affecting the entire system's precision. AI systems provide predictive control by learning the dynamic interactions between axes and compensating for potential errors before they manifest, ensuring ultra-precise path following and coordinated movement across multiple components. This requires robust computational capacity at the edge level, leading to the development of higher-performance actuator controllers featuring dedicated microprocessors capable of running complex neural networks. As the market matures, AI integration will become a standardized feature, highly valued for its ability to enable truly adaptive and self-correcting automation environments essential for bespoke manufacturing and flexible production lines.

- AI enables predictive maintenance by analyzing vibration, temperature, and current draw data to forecast component wear.

- Optimization of motion profiles for energy efficiency and reduced mechanical stress.

- AI facilitates self-calibration and automated error correction in dynamic environments.

- Enhanced quality control through real-time analysis of positional accuracy and force application consistency.

- Improved coordination and synchronization in complex multi-axis automation systems.

DRO & Impact Forces Of Linear Electric Actuator Market

The Linear Electric Actuator market expansion is fundamentally driven by the global imperative for enhanced manufacturing precision and the ongoing adoption of smart factory concepts, collectively known as Industry 4.0, which mandates high levels of data exchange and centralized control over physical assets. The inherent high efficiency and low maintenance requirements of electric actuators, contrasted with the environmental concerns and operational complexity associated with hydraulic systems, further accelerate this transition. Constraints primarily revolve around the high capital expenditure required for initial system integration and the technological limitations faced by electric systems in specific ultra-heavy-duty environments where traditional hydraulic cylinders still offer a superior force-to-size ratio and mechanical simplicity. However, ongoing R&D in roller screw technology and high-power density motors is gradually eroding this performance barrier, creating opportunities for electric actuators in previously inaccessible segments.

Segmentation Analysis

The Linear Electric Actuator market is intricately categorized to reflect the vast array of applications and performance requirements found across industrial and specialized sectors. Segmentation based on the screw mechanism—Ball Screw, Lead Screw, or Roller Screw—determines the actuator’s suitability for high speed, high load, or cost-sensitive applications, respectively. Further differentiation is achieved through segmentation by end-use industry, where sectors such as Medical (demanding sterile, silent operation) and Aerospace (requiring extreme reliability and redundancy) often command premium pricing and specialized certification, contrasting with the high-volume, standardized needs of the general industrial automation segment. The technological segments, particularly those involving advanced motor types like Brushless DC (BLDC), are seeing the most rapid technological advancement, focusing on optimizing duty cycles and integrating sophisticated electronic control systems to meet dynamic industrial needs.

- By Product Type:

- Lead Screw Actuators

- Ball Screw Actuators

- Roller Screw Actuators

- Belt-Driven Actuators

- By Force:

- Low Force (< 500 N)

- Medium Force (500 N – 50 kN)

- High Force (> 50 kN)

- By End-Use Industry:

- Industrial Automation and Factory Equipment

- Automotive (including EVs and Off-Highway)

- Medical and Healthcare

- Aerospace and Defense

- Construction and Mining

- Energy and Utilities (e.g., Solar Trackers)

- Packaging and Material Handling

- By Mechanism:

- AC Motor Actuators

- DC Motor Actuators (Brushed and Brushless)

- Stepper Motor Actuators

Value Chain Analysis For Linear Electric Actuator Market

The Linear Electric Actuator value chain commences with the procurement of highly specified raw materials, which dictates foundational performance characteristics. Upstream suppliers deliver precision-rolled stainless steel for actuator rods, high-purity copper wiring for motor windings, advanced magnet materials (e.g., Neodymium), and specialized thermoplastics for lightweight housing components designed for durability and thermal management. A critical upstream dependency lies in the reliable sourcing of microcontrollers, power transistors, and advanced encoder ICs, primarily from semiconductor firms. Volatility in global semiconductor supply chains directly impacts the production capacity and cost structures of high-end smart actuators, emphasizing the need for robust risk management and dual-sourcing strategies for electronic components to ensure continuous manufacturing flow.

The manufacturing and assembly phase constitutes the core value addition, where intellectual property related to mechanical design, motor control algorithms, and thermal management is leveraged. Key midstream activities involve highly automated processes for winding motors, precise grinding and finishing of ball and roller screws to achieve sub-micron tolerances, and the integration of feedback sensors and proprietary control electronics. Certification and rigorous testing—including accelerated life testing, ingress protection (IP) rating verification, and electromagnetic compatibility (EMC) testing—are essential for market entry, particularly for segments like medical devices (e.g., ISO 13485) and aerospace, adding significant assurance and value before the product reaches the market. Efficient logistics management is crucial here, as actuator components often involve complex, multi-stage manufacturing across different specialized facilities before final integration.

Downstream market penetration relies heavily on the effectiveness of distribution and post-sale support. Direct sales channels are maintained for complex, large-volume industrial projects where customization (e.g., specific stroke lengths, specialized mounting) and close engineering consultation are necessary. Conversely, indirect channels—comprising global industrial distributors, Value-Added Resellers (VARs), and authorized system integrators—are essential for reaching the fragmented SME market and providing localized technical support. These integrators often bundle actuators with complementary motion components (drives, HMI screens) to offer complete solutions. Providing comprehensive application engineering support, swift repair services, and accessible spare parts logistics forms a critical part of the downstream offering, significantly influencing customer satisfaction and long-term loyalty in a competitive market environment characterized by high customer expectations for equipment reliability and extended Mean Time Between Failures (MTBF).

Linear Electric Actuator Market Potential Customers

The breadth of potential customers for Linear Electric Actuators is defined by the universal requirement for controlled, precise linear movement, extending far beyond traditional factory settings. Primary high-volume buyers are sophisticated machinery OEMs, particularly those specializing in packaging, food and beverage processing, and high-speed logistics. These customers are driven by throughput, requiring actuators that can operate reliably under continuous, often demanding, conditions and satisfy stringent hygienic design standards (e.g., wash-down capabilities and FDA compliance for food contact zones). System integrators serving large automotive assembly plants constitute another major segment, procuring large batches of standardized, networked actuators for welding lines, painting booths, and powertrain assembly, prioritizing communication robustness and ease of integration into existing factory networks.

In the specialized sectors, aerospace and defense customers represent a high-value, low-volume segment. These buyers, including airframe manufacturers and military vehicle builders, require extremely robust, highly redundant electric actuators for flight control surfaces, landing gear actuation, and satellite alignment systems. Their purchasing decisions are primarily governed by performance characteristics under extreme temperature variations, adherence to rigorous regulatory standards (e.g., DO-160), and proven reliability metrics, often leading to custom, highly engineered actuator solutions with significant upfront R&D investment. The medical sector, comprising manufacturers of imaging equipment (CT scanners, MRIs) and surgical systems, seeks ultra-quiet, non-magnetic (for MRI compatibility), and certified sterile actuators, demonstrating a preference for vendors capable of providing extensive documentation and quality assurance throughout the product lifecycle.

The emerging market of ergonomic and comfort applications, including office furniture OEMs (standing desks, ergonomic chairs) and smart home technology providers (automated window systems, hidden storage lifts), represents a growing, price-sensitive customer base. While these applications require lower force and speed, they demand high aesthetic integration, exceptionally low noise levels (silent operation), and competitive pricing achievable through high-volume standardization. Finally, infrastructure and utility providers represent customers for environmental control systems, utilizing ruggedized, weather-proof actuators (high IP ratings) for dam gates, massive HVAC damper control in commercial buildings, and critical valve control in water treatment and power generation facilities, emphasizing longevity, minimal field maintenance, and secure remote monitoring capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.2 Billion |

| Market Forecast in 2033 | USD 4.98 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thomson Industries, Inc., SKF, LINAK A/S, Bosch Rexroth AG, Parker Hannifin Corporation, Tsubaki Co., Ltd., Venture Manufacturing Co., LLC, Progressive Automations, Inc., Actuonix Motion Devices Inc., Kollmorgen Corporation, Moog Inc., HepcoMotion, Exlar Corporation (Curtiss-Wright), Tolomatic, Inc., TiMOTION Technology Co., Ltd., Phoenix Contact, ABB, Beckhoff Automation, Siemens AG, IAI Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Linear Electric Actuator Market Key Technology Landscape

The contemporary technology landscape of Linear Electric Actuators is defined by relentless pursuit of higher power density and control intelligence, moving the components from simple motion devices to integral cyber-physical systems. A foundational shift involves the advanced electronic control technology, specifically the utilization of digital signal processors (DSPs) and Field-Programmable Gate Arrays (FPGAs) to manage complex motor control algorithms, enabling finer tuning of torque delivery, minimized current ripple, and ultimately, significantly improved positional accuracy and speed. This electronic sophistication is tightly coupled with advancements in permanent magnet motor technology, especially rare-earth magnets, allowing motors to generate higher torque within smaller physical envelopes, crucial for miniaturization trends in robotics and compact medical equipment where space optimization is critical.

Mechanically, the adoption of planetary roller screws is a significant technological differentiator, particularly in the high-load segment. Unlike traditional ball screws, roller screws utilize rollers instead of balls, dramatically increasing the contact area between the screw and the nut. This structural difference not only triples the dynamic load capacity but also extends the operational lifespan in high-cycle applications, offering a viable electric alternative to medium-scale hydraulic cylinders. Furthermore, advancements in specialized coatings and lubrication systems (e.g., self-lubricating plastics and proprietary surface treatments) are reducing internal friction and wear, allowing actuators to handle higher acceleration and speed limits while simultaneously reducing the need for intensive preventative maintenance and reducing overall noise signature, a key requirement for indoor and medical environments.

Connectivity and security are increasingly vital technological layers. Modern actuators utilize standardized industrial Ethernet protocols (such as EtherCAT for determinism and high speed) which facilitate real-time bidirectional data exchange, enabling precise synchronization in multi-axis systems and facilitating advanced diagnostics. Crucially, as actuators become networked components of the Industrial Internet of Things (IIoT), manufacturers are embedding cybersecurity features, including encrypted communication protocols and secure boot processes, to protect against unauthorized access or tampering, which is critical for safety-critical applications in infrastructure and defense. The development of specialized firmware supporting sophisticated control loops, coupled with secure remote diagnostic capabilities, cements the actuator’s role as an intelligent, secure, and fully traceable component within the interconnected industrial ecosystem, driving the need for continual software updates and robust digital infrastructure.

Regional Highlights

North America maintains a prominent position in the Linear Electric Actuator market, primarily driven by high demand for specialized, high-performance solutions in the aerospace, defense, and advanced medical sectors. The market here is characterized by early adoption of new technologies, such as actuators featuring integrated AI for predictive maintenance and EtherCAT communication for ultra-fast, deterministic control. The robust manufacturing base, coupled with significant governmental and private investment in next-generation robotics and automation, ensures sustained demand for high-specification, reliable, and energy-efficient electromechanical systems. Regulatory emphasis on workplace safety and energy conservation also compels industries to upgrade existing pneumatic installations to precise electric equivalents, supporting premium pricing models for technologically superior products.

The Asia Pacific (APAC) region, currently the epicenter of global manufacturing expansion, is projected to command the largest market share and exhibit the highest growth rate throughout the forecast period. This dominance stems from relentless industrialization, particularly in China, South Korea, and Southeast Asian nations, where massive factory construction and modernization projects demand millions of actuators annually for general automation, assembly, and testing equipment. The rapid expansion of the Electric Vehicle (EV) supply chain across APAC requires massive quantities of medium-to-high-force actuators for battery handling, robotic assembly, and final vehicle testing. While cost remains a significant competitive factor, the rising importance of quality and speed in export-focused economies is increasingly shifting demand towards reliable ball screw and brushless DC motor actuators.

Europe represents a mature and technologically advanced market, heavily influenced by the German concept of Industry 4.0, focusing on hyper-efficient, highly connected, and modular production systems. The region shows strong demand for actuators that comply with stringent European Union environmental and safety regulations, prioritizing low noise, high energy efficiency, and ease of recycling. The market is particularly strong in the automotive manufacturing sector (excluding basic assembly, focusing on high-precision engine and chassis component fabrication), as well as in demanding logistics and pharmaceutical automation, where traceability and validated performance are non-negotiable. Latin America and the Middle East & Africa are developing rapidly, with market growth tied to heavy infrastructure projects, resource extraction modernization, and the nascent growth of localized manufacturing hubs, generally favoring ruggedized and mechanically simple electric actuators that offer reliability in challenging, remote operating environments.

- Asia Pacific (APAC): Dominates market growth, driven by expansion in manufacturing, automotive, and electronics industries; focus on cost-effective, high-volume production; led by China, Japan, and South Korea.

- North America: High penetration in aerospace, medical robotics, and precision engineering; emphasis on IoT integration and high-performance, specialized solutions.

- Europe: Strong market for high-precision, energy-efficient solutions; driven by Germany (Industry 4.0) and Scandinavia (sustainable manufacturing); high regulatory compliance standards.

- Latin America (LATAM): Growing demand fueled by infrastructure projects, mining, and agricultural automation; characterized by increasing adoption of ruggedized systems.

- Middle East and Africa (MEA): Emerging market driven by oil & gas sector automation and diversification into manufacturing; significant potential in renewable energy projects (solar trackers).

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Linear Electric Actuator Market.- Thomson Industries, Inc.

- SKF

- LINAK A/S

- Bosch Rexroth AG

- Parker Hannifin Corporation

- Tsubaki Co., Ltd.

- Venture Manufacturing Co., LLC

- Progressive Automations, Inc.

- Actuonix Motion Devices Inc.

- Kollmorgen Corporation

- Moog Inc.

- HepcoMotion

- Exlar Corporation (Curtiss-Wright)

- Tolomatic, Inc.

- TiMOTION Technology Co., Ltd.

- Phoenix Contact

- ABB

- Beckhoff Automation

- Siemens AG

- IAI Corporation

Frequently Asked Questions

Analyze common user questions about the Linear Electric Actuator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the replacement of hydraulic actuators with electric linear actuators?

The primary driver is the superior energy efficiency and precision control offered by electric actuators. Unlike hydraulic systems, electric actuators do not leak oil, require less maintenance, and provide highly repeatable, programmable motion profiles, which are essential for modern closed-loop control systems and compliance with strict industrial environmental standards. This shift results in lower total cost of ownership (TCO) and enhanced operational cleanliness.

How does the choice between a ball screw and a roller screw actuator impact performance?

Ball screw actuators are commonly used for general industrial applications requiring high speeds and medium loads, offering good efficiency and moderate lifespan. Roller screw actuators are the high-performance choice, preferred for extreme performance scenarios involving heavy, continuous loads, high duty cycles, and exceptional durability, as they offer significantly higher force transmission capability and a substantially extended operational lifespan due to increased rolling element contact area.

Which end-use industry segment is expected to show the highest growth rate during the forecast period?

The Medical and Healthcare segment, alongside the burgeoning Electric Vehicle (EV) manufacturing sector, is projected to exhibit the highest Compound Annual Growth Rate. This accelerated growth is fueled by the widespread global deployment of high-precision surgical robotics, advanced diagnostic equipment (like MRI/CT machines), and the rapid transition to electric powertrains and assembly lines requiring reliable, high-speed motion control components.

What role does integrated sensor technology play in smart linear actuators?

Integrated sensor technology, encompassing high-resolution position encoders, internal force sensors, and temperature monitors, transforms standard actuators into smart, connected devices. This enables immediate, accurate closed-loop control, facilitates predictive maintenance by monitoring component health, and ensures seamless, real-time data communication with centralized Industrial IoT (IIoT) platforms for enhanced process monitoring and optimization.

What challenges does the Linear Electric Actuator market face in penetrating heavy-duty applications?

The main challenge remains the high initial investment cost, especially for high-force electric systems, and the difficulty in efficiently replicating the extreme shock resistance and high power-to-size ratio traditionally provided by large hydraulic cylinders in specific ultra-heavy-duty industrial and mobile applications. However, continuous R&D into specialized roller screw mechanisms is increasingly bridging this performance gap.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager