Low Chlorine Epoxy Resin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442111 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Low Chlorine Epoxy Resin Market Size

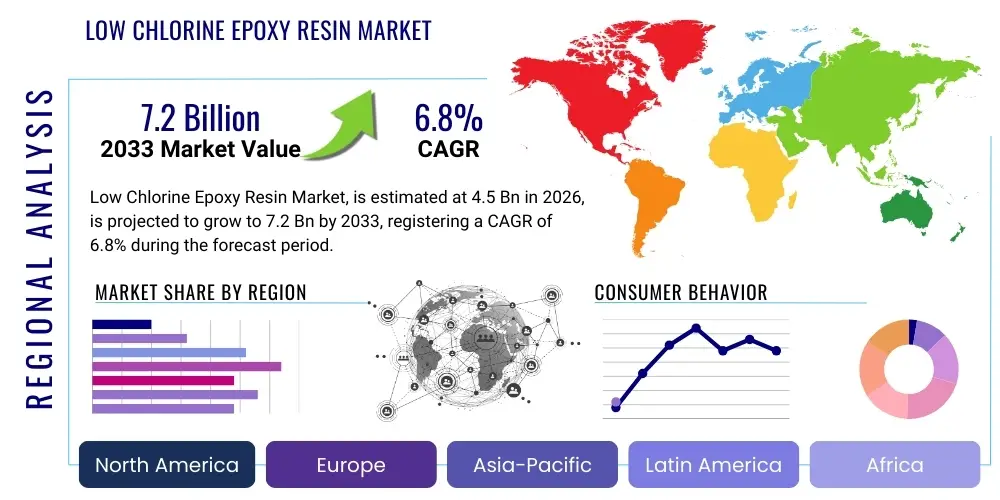

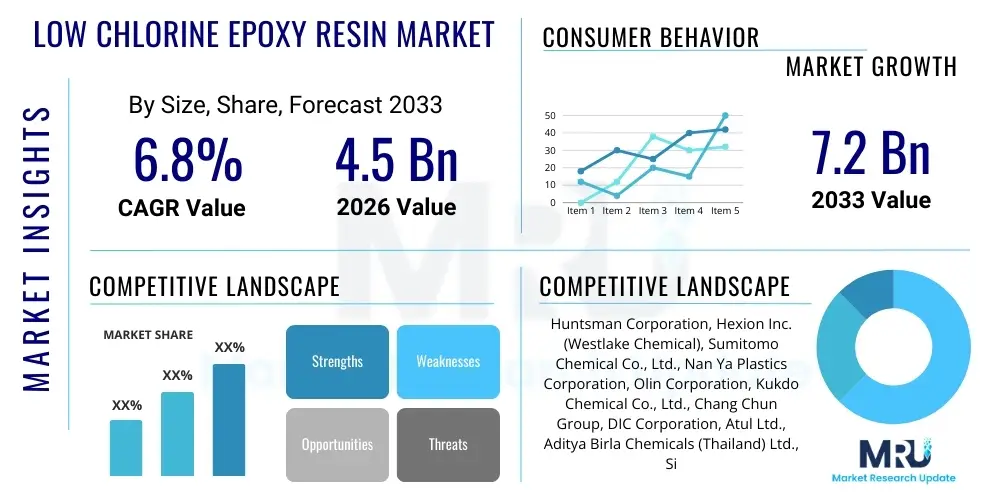

The Low Chlorine Epoxy Resin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033.

Low Chlorine Epoxy Resin Market introduction

Low Chlorine Epoxy Resins are specialty chemical compounds characterized by extremely low levels of hydrolyzable and total chlorine content, typically measured in parts per million (ppm). These resins are critical for high-performance applications, especially in the electronics, aerospace, and advanced protective coatings sectors, where the presence of even trace amounts of chlorine can lead to detrimental effects such as corrosion, electrical leakage, or reduced thermal stability. The demand for these high-purity materials is fundamentally driven by stringent regulatory requirements and the continuous miniaturization and performance enhancement of electronic components, necessitating exceptional reliability and longevity.

The primary product characteristic differentiating low chlorine epoxy resins from standard epoxy materials is their superior purity, which is achieved through specialized manufacturing processes, including extensive washing and purification steps. Key applications include encapsulation compounds for semiconductors, adhesives for flexible circuits, laminates for printed circuit boards (PCBs), and specialized protective coatings utilized in harsh environments. The intrinsic benefits of low chlorine content—namely enhanced dielectric properties, improved thermal reliability, and superior resistance to moisture and ion migration—position these resins as indispensable materials in critical infrastructure and high-tech manufacturing.

Driving factors for this market expansion include the exponential growth of the global semiconductor industry, particularly in Asia Pacific, coupled with the accelerating adoption of electric vehicles (EVs) which rely heavily on sophisticated electronics and robust battery encapsulation materials. Furthermore, the increasing complexity of aerospace and defense systems demands materials capable of operating under extreme stress without degradation, thus reinforcing the market for ultra-high purity epoxy formulations. Regulatory push towards halogen-free products also subtly favors low chlorine resins as an interim or complementary solution for compliance.

Low Chlorine Epoxy Resin Market Executive Summary

The Low Chlorine Epoxy Resin Market is poised for substantial growth, propelled by robust business trends centered on technological advancements in high-reliability applications and the expansion of smart infrastructure globally. Manufacturers are intensely focused on developing customized resin systems that offer specific performance attributes, such as ultra-low viscosity for vacuum casting or enhanced glass transition temperatures (Tg) for high-thermal-stress environments. The shift towards sustainable chemical processes, minimizing the environmental footprint of production, also represents a critical business vector, with leading firms investing heavily in process optimization to maintain competitive advantage in purity and consistency.

Regionally, the Asia Pacific (APAC) market dominates the consumption landscape, primarily due to the concentration of global semiconductor manufacturing hubs and massive investments in consumer electronics and automotive electrification, particularly in countries like China, South Korea, and Taiwan. While North America and Europe remain key centers for research, development, and high-specification applications (aerospace/defense), APAC’s rapid industrial scaling dictates overall volume growth. Emerging regional trends involve increasing demand from Latin America for robust infrastructure coatings and specialized protective applications in energy sectors.

Segment trends highlight the dominance of the coating and composite segments, though the encapsulation and molding compounds segment, vital for microelectronics, is projected to exhibit the highest Compound Annual Growth Rate (CAGR). Segmentation by purity level (e.g., <500 ppm, <200 ppm, and <100 ppm) clearly indicates a premiumization trend, with ultra-low chlorine variants commanding higher prices due to their necessity in advanced semiconductor packaging. Furthermore, the segmentation based on resin type, primarily Bisphenol A and Bisphenol F derivatives, shows increased R&D focus on novolac-based low chlorine resins for superior thermal performance.

AI Impact Analysis on Low Chlorine Epoxy Resin Market

User queries regarding the impact of Artificial Intelligence (AI) on the Low Chlorine Epoxy Resin Market frequently revolve around three core themes: enhancing quality control and purity assurance, optimizing complex formulation processes, and predicting material performance under varied application conditions. Users are particularly interested in how AI and machine learning (ML) algorithms can be deployed to manage the intricate purification stages during manufacturing, ensuring consistent hydrolyzable chlorine levels below critical thresholds without manual intervention. Furthermore, there is significant interest in using AI for predictive maintenance in manufacturing equipment, minimizing contamination risks, and accelerating the development cycle for novel, ultra-low chlorine resin chemistries needed for next-generation microchips and advanced power electronics.

- AI-driven optimization of polymerization kinetics and purification processes, ensuring trace impurity levels are consistently met, thereby reducing batch-to-batch variability.

- Predictive quality control (PQC) systems utilizing sensor data to monitor feedstock quality and real-time reaction parameters, minimizing the risk of high chlorine contamination early in the synthesis cycle.

- Machine Learning models accelerating R&D by simulating the long-term aging and performance of complex resin formulations in extreme thermal and electrical environments, drastically cutting down physical testing time.

- Supply chain risk mitigation using AI to track the provenance and certification of low chlorine precursors, enhancing traceability and compliance for sensitive end-use sectors like aerospace.

- Automated defect detection in coated or encapsulated components, leveraging computer vision to identify micro-cracks or voids potentially caused by material imperfections, including residual chlorine deposits.

DRO & Impact Forces Of Low Chlorine Epoxy Resin Market

The Low Chlorine Epoxy Resin Market dynamics are shaped by powerful drivers, strict restraints, and lucrative opportunities. A major driver is the relentless demand for high-reliability electronics, particularly in 5G infrastructure, advanced driver-assistance systems (ADAS), and high-power modules, where material integrity directly correlates with system longevity and performance. The inherent purity of these resins prevents galvanic corrosion and ionic migration, making them mandatory for encapsulation and bonding critical components. Coupled with this is the global push towards miniaturization, which increases power density and thermal stress, demanding highly stable and pure encapsulation materials. These forces collectively create a strong upward trajectory for market growth.

However, the market faces significant restraints. The production process for low chlorine epoxy resins is inherently more complex and capital-intensive than standard epoxy manufacturing, requiring specialized washing equipment and cleanroom conditions to maintain purity, resulting in significantly higher manufacturing costs. This increased cost can limit adoption in non-critical or volume-driven applications where conventional epoxies suffice. Furthermore, the volatility of raw material prices (e.g., Bisphenol A and Epichlorohydrin), coupled with complex regulatory hurdles regarding chemical handling and disposal, presents ongoing logistical and economic challenges for manufacturers, potentially constraining supply growth.

Opportunities abound in emerging application areas, particularly the rapid scaling of renewable energy systems (solar and wind power components) and the transition to high-voltage battery systems in EVs, both requiring robust, chemically stable insulation and protection. The development of next-generation low-chlorine bio-based or renewable epoxy systems offers a major opportunity for market differentiation and meeting long-term sustainability goals. The increasing utilization of advanced composites in infrastructure and aerospace, demanding traceable purity in resin matrices, provides additional avenues for market expansion, particularly for resins certified below 100 ppm.

Segmentation Analysis

The Low Chlorine Epoxy Resin Market is comprehensively segmented based on Resin Type, Purity Level, Application, and End-Use Industry, providing a granular view of demand drivers and market penetration across various sectors. Analyzing these segments is critical for stakeholders to identify high-growth niches and tailor product development strategies. The inherent need for ultra-high purity in specific applications dictates the value and volume of each segment, illustrating a clear dichotomy between standard industrial coatings and specialized microelectronic materials.

- By Resin Type:

- Bisphenol A (BPA) Low Chlorine Epoxy Resin

- Bisphenol F (BPF) Low Chlorine Epoxy Resin

- Novolac Low Chlorine Epoxy Resin

- Others (Aliphatic, Cycloaliphatic)

- By Purity Level:

- <500 ppm

- <200 ppm

- <100 ppm

- Ultra-Low Chlorine (<50 ppm)

- By Application:

- Coatings and Paints (Protective, Marine, Automotive)

- Composites (Aerospace, Wind Energy)

- Adhesives and Sealants

- Encapsulation and Molding Compounds (Electronics)

- Laminates and Prepregs (PCBs)

- By End-Use Industry:

- Electronics and Electrical

- Automotive and Transportation (EV Batteries)

- Aerospace and Defense

- Construction and Infrastructure

- Marine and Offshore

- Industrial and General Manufacturing

Value Chain Analysis For Low Chlorine Epoxy Resin Market

The value chain for the Low Chlorine Epoxy Resin Market is highly specialized, beginning with the complex upstream procurement and processing of high-purity raw materials. Key precursors, primarily Bisphenol A, Epichlorohydrin (ECH), and various hardeners, must meet exceptionally strict purity standards before synthesis. Upstream players, including petrochemical suppliers, focus on delivering pharmaceutical-grade or electronics-grade ECH to minimize potential chlorine contamination from the outset. The manufacturing stage is critical, involving precise reaction conditions and extensive post-synthesis purification techniques, such as solvent washing or specialized filtration, to strip away residual chlorine compounds and maintain hydrolyzable chlorine below the required ppm level.

Midstream activities involve formulation and compounding, where specialized chemical manufacturers blend the purified epoxy base resin with specific additives, fillers, and curing agents to create final products tailored for end-use applications (e.g., molding compounds with tailored rheology or highly filled thermal interface materials). This formulation stage adds significant value by imparting key performance characteristics like thermal conductivity, flame retardancy, and specific viscosity profiles. The quality control mechanisms at this stage are stringent, relying on advanced analytical techniques (e.g., titration and chromatography) to certify the low chlorine content of the final product before distribution.

The downstream distribution channel is bifurcated into direct sales and indirect routes. Due to the highly technical nature and critical application areas (e.g., semiconductor packaging), major manufacturers often employ direct distribution models, engaging technical sales teams to work closely with large-scale end-users (Tier 1 electronics manufacturers, major aerospace companies) to ensure product specifications are met exactly. Indirect channels utilize specialized chemical distributors and regional agents, particularly for smaller volume orders or geographically dispersed general industrial applications (coatings, composites). The efficiency of this downstream network, ensuring proper handling and storage (preventing moisture ingress), is vital for maintaining the integrity and certified purity of the high-value resin throughout its lifecycle.

Low Chlorine Epoxy Resin Market Potential Customers

The primary consumers and end-users of Low Chlorine Epoxy Resins are enterprises operating in industries where material reliability, resistance to corrosion, and superior dielectric performance are non-negotiable prerequisites. Semiconductor fabricators and outsourced semiconductor assembly and test (OSAT) providers represent the largest and most demanding customer segment, utilizing these resins for critical die attach, wire bonding, and comprehensive encapsulation of microchips, memory modules, and complex sensors. These buyers require resins certified at ultra-low chlorine levels (<100 ppm) to ensure the long-term functioning of electronic devices, particularly in harsh or humid conditions, mitigating the risk of component failure due to ionic impurities.

Another major customer segment resides within the Electric Vehicle (EV) manufacturing ecosystem and related power electronics sectors. Customers here include battery module manufacturers and power inverter producers who utilize low chlorine epoxy materials for potting, casting, and sealing high-voltage components, offering excellent thermal management and electrical insulation while preventing internal corrosion. The demand from these customers is rapidly escalating as global EV production scales, prioritizing material safety and durability under continuous high-power cycling.

Furthermore, aerospace, defense contractors, and specialized infrastructure builders constitute critical buyers. Aerospace companies require low chlorine resins for manufacturing lightweight, high-strength composite components (e.g., aircraft primary structures, radomes) and for specialized protective coatings capable of resisting extreme temperature variations and harsh chemical exposure. In the infrastructure domain, customers in oil and gas, marine, and chemical processing industries purchase these resins for high-performance tank linings, piping coatings, and structural adhesives where corrosion prevention is paramount for asset integrity and operational safety, justifying the premium price point.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Huntsman Corporation, Hexion Inc. (Westlake Chemical), Sumitomo Chemical Co., Ltd., Nan Ya Plastics Corporation, Olin Corporation, Kukdo Chemical Co., Ltd., Chang Chun Group, DIC Corporation, Atul Ltd., Aditya Birla Chemicals (Thailand) Ltd., Sika AG, Kureha Corporation, BASF SE, Toray Industries Inc., Mitsui Chemicals Inc., Nippon Kayaku Co., Ltd., Altana AG, CVC Thermoset Specialties. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Chlorine Epoxy Resin Market Key Technology Landscape

The technological landscape of the Low Chlorine Epoxy Resin Market is focused intensely on chemical engineering innovations that facilitate meticulous purification and enhance performance characteristics without compromising low chlorine integrity. A primary area of technological advancement is the development of continuous washing and purification systems, moving beyond traditional batch processes. These continuous systems, often incorporating highly efficient membrane separation and specialized solvent recovery units, are designed to significantly reduce processing time and minimize potential contamination points, ensuring that hydrolyzable chlorine remains in the ultra-low ppm range consistently across massive production volumes necessary for the electronics industry.

Another crucial technological frontier involves advanced analytical and quality assurance protocols. Manufacturers are adopting high-precision analytical techniques, such as Ion Chromatography (IC) and specialized titrimetric methods, which allow for the accurate measurement of trace quantities of ionic contaminants, including chloride ions, down to single-digit ppm levels. The integration of inline sensors and statistical process control (SPC) systems ensures real-time monitoring of residual chlorine during synthesis and post-treatment, enabling instantaneous process adjustments to maintain quality. This analytical rigor is essential for securing the necessary certifications required by aerospace and defense standards (e.g., MIL-SPEC).

Furthermore, innovation is centered on developing novel curing agents and formulation technologies that are compatible with the high-purity resin base. Traditional hardeners can sometimes introduce contaminants. Therefore, R&D efforts are focused on high-purity anhydride and amine curing agents that are free of latent acidic or ionic impurities. Moreover, sophisticated blending technologies are being employed to ensure uniform dispersion of functionalized fillers (e.g., high-purity silica or alumina) into the low chlorine matrix, critical for achieving enhanced thermal conductivity and reduced coefficient of thermal expansion (CTE) required for advanced thermal interface materials and semiconductor molding compounds.

Regional Highlights

The geographic distribution of the Low Chlorine Epoxy Resin Market exhibits high correlation with global manufacturing hubs for electronics and specialized industrial production. Asia Pacific (APAC) dominates the global market both in terms of production capacity and consumption volume, driven overwhelmingly by its status as the world’s primary center for semiconductor fabrication, PCB manufacturing, and burgeoning Electric Vehicle (EV) assembly. Countries like China, Taiwan, South Korea, and Japan represent massive end-use demand for ultra-low chlorine encapsulation compounds and laminates, necessitated by the sheer volume and technological sophistication of their consumer electronics and automotive output. Government initiatives supporting high-tech manufacturing further solidify APAC's leading position, demanding continuous high-volume supply of specialized resins.

North America and Europe constitute mature markets characterized by steady, high-value demand focused heavily on stringent aerospace, defense, and high-reliability industrial applications. In North America, demand is particularly strong within the military and commercial aviation sectors for composite materials and advanced protective coatings that require guaranteed purity and long-term chemical resistance. European consumption is robust across the renewable energy sector (wind turbine blades utilizing specialized composites) and sophisticated industrial infrastructure projects. While volume growth in these regions is typically lower than APAC, the average selling price (ASP) of resins used here is higher due to the extremely demanding performance specifications and regulatory adherence, such as REACH compliance.

The Middle East and Africa (MEA) and Latin America (LATAM) markets are emerging rapidly, primarily driven by large-scale infrastructure and energy sector investments. In the MEA region, the massive oil and gas and marine industries require low chlorine protective coatings to safeguard critical assets against severe corrosion in highly saline and abrasive environments. LATAM, notably Brazil and Mexico, shows increasing demand tied to automotive manufacturing expansion and local infrastructure development. Though currently smaller, these regions represent significant future opportunities for specialized coating and composite applications as industrialization progresses and safety standards rise, requiring reliable, corrosion-resistant chemical solutions.

- Asia Pacific (APAC): Market leader due to semiconductor manufacturing concentration, massive EV production scaling, and rapid urbanization demanding specialized high-purity materials for electronics and infrastructure.

- North America: Strong demand from the aerospace and defense sectors for high-specification composites and encapsulation, focusing on R&D and premium-priced, certified materials.

- Europe: Key consumer in renewable energy (wind power composites), high-end automotive, and industrial protective coatings, characterized by strict environmental regulations (REACH).

- Middle East & Africa (MEA): Growing segment driven by extensive infrastructure projects, particularly in oil, gas, and marine sectors where anti-corrosion, low chlorine coatings are essential for asset protection.

- Latin America (LATAM): Emerging market primarily driven by expansion in the automotive industry and localized construction projects requiring reliable and durable epoxy-based structural components and protective systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Chlorine Epoxy Resin Market.- Huntsman Corporation

- Hexion Inc. (Westlake Chemical)

- Sumitomo Chemical Co., Ltd.

- Nan Ya Plastics Corporation

- Olin Corporation

- Kukdo Chemical Co., Ltd.

- Chang Chun Group

- DIC Corporation

- Atul Ltd.

- Aditya Birla Chemicals (Thailand) Ltd.

- Sika AG

- Kureha Corporation

- BASF SE

- Toray Industries Inc.

- Mitsui Chemicals Inc.

- Nippon Kayaku Co., Ltd.

- Altana AG

- CVC Thermoset Specialties

- Jiangsu Sanmu Group Co., Ltd.

- Kolon Industries, Inc.

Frequently Asked Questions

Analyze common user questions about the Low Chlorine Epoxy Resin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of Low Chlorine Epoxy Resin?

The primary advantage is superior resistance to corrosion and electrical leakage, particularly crucial in sensitive electronic assemblies. High chlorine content leads to ionic contamination, which accelerates corrosion of metal components and degrades dielectric performance, issues mitigated effectively by maintaining chlorine levels typically below 500 ppm or even lower for microelectronics.

Which end-use industry is the largest consumer of ultra-low chlorine (<100 ppm) resins?

The Electronics and Electrical industry, specifically the semiconductor packaging and printed circuit board (PCB) laminate manufacturing sectors, is the largest consumer of ultra-low chlorine epoxy resins. These purity levels are mandated for high-reliability components, ensuring device longevity and performance stability in advanced microprocessors and memory chips.

How does the production of low chlorine resins differ from standard epoxy manufacturing?

Low chlorine resin production involves extensive, multi-stage post-synthesis purification steps, such as rigorous washing and specialized filtration, to remove residual hydrolyzable chlorine compounds. This process requires higher capital investment, specialized cleanroom environments, and more stringent quality control protocols compared to standard epoxy synthesis.

What is the expected CAGR for the Low Chlorine Epoxy Resin Market between 2026 and 2033?

The Low Chlorine Epoxy Resin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven largely by the global expansion of electric vehicle manufacturing and the sustained demand for high-reliability electronic components in 5G and IoT applications.

What role do Bisphenol F and Novolac resins play in the low chlorine market?

Bisphenol F and Novolac derivatives are utilized extensively in the low chlorine segment when enhanced thermal stability and chemical resistance are required. Novolac-based low chlorine resins, in particular, are favored for high-temperature applications and specialized electronic encapsulation where superior Glass Transition Temperature (Tg) is a critical performance parameter.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager