Low Temperature Sealing Glass Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442808 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Low Temperature Sealing Glass Market Size

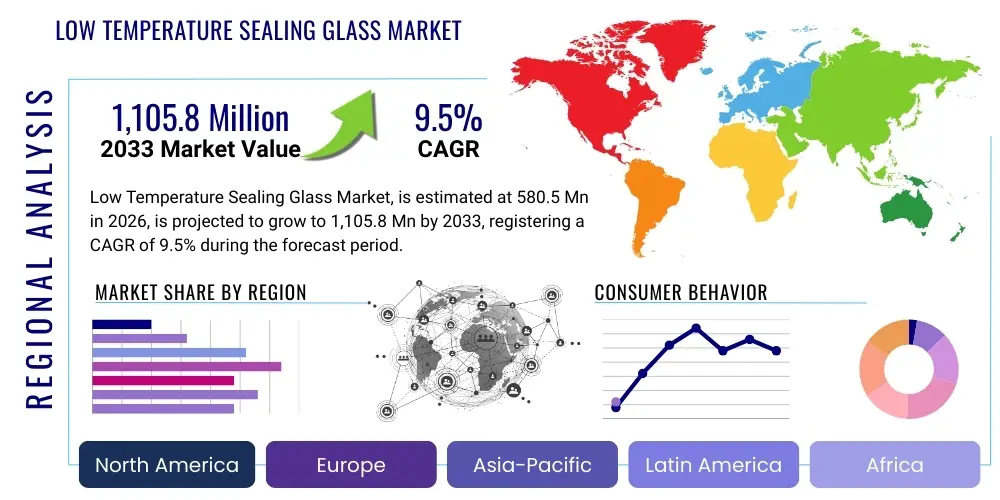

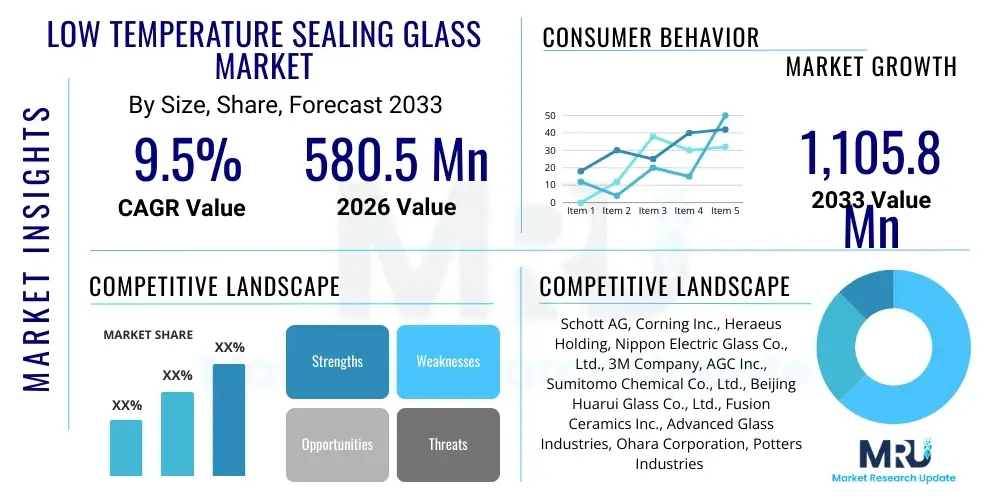

The Low Temperature Sealing Glass Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 580.5 Million in 2026 and is projected to reach USD 1,105.8 Million by the end of the forecast period in 2033.

Low Temperature Sealing Glass Market introduction

Low Temperature Sealing Glass, often referred to as frit glass or sealing compounds, encompasses specialized glass materials designed to form hermetic seals at temperatures significantly lower than traditional high-temperature glass or soldering processes. These materials typically feature high concentrations of elements like bismuth, vanadium, or zinc, which drastically lower the melting and softening points, enabling robust sealing below 550°C, and often even below 450°C. This characteristic is critical for integrating sensitive electronic components, particularly those incorporating temperature-sensitive organic materials or silicon wafers, where exposure to excessive heat could degrade performance or induce structural failures. The fundamental benefit of employing these sealing solutions lies in achieving long-term reliability and environmental protection—shielding delicate devices from moisture, oxygen, and contaminants—while maintaining compatibility with diverse substrate materials, including metals, ceramics, and other glasses, through careful matching of the coefficient of thermal expansion (CTE).

The primary applications driving the demand for low temperature sealing glass are concentrated within high-growth technological sectors, notably Solid Oxide Fuel Cells (SOFC), where reliable seals are essential for operational integrity at intermediate temperatures, and advanced display technologies like Organic Light-Emitting Diodes (OLEDs), which require stringent encapsulation barriers against moisture degradation. Additionally, the proliferation of miniaturized and complex sensor devices and semiconductor packaging relies heavily on these specialized glasses to ensure airtight packaging without damaging sensitive internal circuitry. The market growth is substantially driven by the increasing complexity and density of microelectronics, demanding higher performance encapsulation, alongside the global emphasis on sustainable energy solutions utilizing fuel cell technology and high-efficiency solar photovoltaic cells, all of which mandate high-quality, temperature-tolerant sealing methods. The inherent advantages of low temperature processing—reduced energy consumption, broader material compatibility, and improved manufacturing yield—solidify its crucial role in modern industrial fabrication processes across several critical verticals.

Low Temperature Sealing Glass Market Executive Summary

The global Low Temperature Sealing Glass Market is experiencing robust expansion driven fundamentally by accelerating technological evolution in advanced electronics and sustainable energy systems, particularly in the Asia-Pacific region, which dominates both production capacity and consumption. Current business trends indicate a significant shift towards lead-free and cadmium-free compositions, necessitated by stringent global environmental regulations, specifically the Restriction of Hazardous Substances (RoHS) directive. Manufacturers are heavily investing in Bismuth-based and Vanadium-based sealing glasses, focusing on optimizing the Coefficient of Thermal Expansion (CTE) match to novel substrates such as advanced ceramics and flexible polymers, thereby broadening application scope in next- generation flexible OLEDs and high-density semiconductor interconnects. The market is characterized by intense competition focused on proprietary formulations that offer superior chemical resistance and mechanical strength under operational stress, defining the competitive edge in high-reliability applications like aerospace sensors and implantable medical devices. Strategic alliances between raw material suppliers and end-product integrators are becoming increasingly common to streamline the supply chain and ensure material quality consistency, crucial for maintaining high manufacturing yields in sensitive electronic assembly processes.

Segment trends reveal that the Solid Oxide Fuel Cells (SOFC) application segment exhibits the highest growth potential, largely due to governmental incentives supporting cleaner energy infrastructure and the increasing adoption of micro-combined heat and power (CHP) systems, requiring durable, long-lasting seals capable of withstanding thermal cycling. Geographically, North America and Europe maintain strong market shares, primarily fueled by mature automotive electronics and stringent regulatory frameworks demanding high-specification sensor packaging; however, APAC, led by manufacturing hubs in China, South Korea, and Japan, commands the largest market share, driven by massive investments in OLED display production and semiconductor fabrication. The primary challenge remains the cost sensitivity associated with high-purity raw materials, especially Bismuth compounds, necessitating continuous innovation in powder preparation and sintering techniques to reduce processing costs and improve scalability. Furthermore, the market structure is moving toward customized sealing solutions, recognizing that a universal glass composition is insufficient for the diverse CTE and chemical requirements presented by emerging applications, thus favoring agile R&D capabilities among key market players.

AI Impact Analysis on Low Temperature Sealing Glass Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Low Temperature Sealing Glass Market commonly revolve around themes of predictive material science, accelerated formulation discovery, and optimization of manufacturing processes. Key concerns include whether AI can effectively model complex glass transition temperatures and CTE matching dynamics across diverse material combinations, and if machine learning algorithms can minimize defects during the critical sintering phase, especially in high-volume production environments like OLED encapsulation lines. Users express high expectations for AI’s role in identifying novel, lead-free low-temperature compositions that meet regulatory compliance while maintaining performance parity with traditional counterparts, often asking about AI-driven digital twin simulation capabilities for thermal stress testing. Furthermore, a substantial interest exists in leveraging AI for supply chain resilience, predicting raw material price fluctuations (e.g., Bismuth Oxide), and optimizing inventory management for specialized glass frit powders, ensuring consistent supply for high-stakes applications like medical implants and aerospace components.

AI’s influence is rapidly transitioning the low temperature sealing glass industry from empirical, trial-and-error R&D methods to data-driven, predictive material engineering. By utilizing sophisticated neural networks trained on vast datasets of glass composition, particle size distribution, viscosity profiles, and resulting mechanical properties, manufacturers can simulate millions of potential formulations digitally, drastically reducing laboratory time and resource expenditure required for new product development. In manufacturing, AI-powered computer vision systems are increasingly deployed for real-time quality control during the screen printing and thermal bonding stages, identifying minute defects such as voids or improper wetting before costly downstream failures occur, enhancing overall yield and product reliability, which is paramount for sensitive components like SOFC stacks and high-resolution displays. This capability allows for immediate feedback loop adjustments in sintering furnace settings or material deposition parameters, thus minimizing variability and adhering strictly to highly demanding specifications for hermeticity and durability in harsh operating environments.

- Accelerated formulation discovery using machine learning models to predict optimal low-temperature compositions and CTE match parameters.

- AI-driven simulation of thermal cycling stress and mechanical failure prediction, reducing physical prototyping requirements.

- Enhanced quality control through real-time AI computer vision for defect detection during glass frit deposition and sintering processes.

- Optimization of complex manufacturing parameters (e.g., heating rate, dwell time, atmosphere control) in large-scale furnace operations using predictive analytics.

- Improved supply chain management and predictive sourcing of specialized, high-purity raw materials such as Bismuth and Vanadium oxides.

- Development of digital twins for simulating entire sealing processes, ensuring seamless integration into high-volume semiconductor and display manufacturing lines.

DRO & Impact Forces Of Low Temperature Sealing Glass Market

The dynamics of the Low Temperature Sealing Glass Market are governed by a complex interplay of driving forces, restraining factors, and strategic opportunities that collectively shape its trajectory and competitive landscape. Key drivers center around the technological advancements in next-generation electronic devices, particularly the miniaturization trend in semiconductor packaging and the explosive growth in high-efficiency display technologies like OLEDs, both of which mandate highly reliable, temperature-sensitive sealing solutions. Furthermore, the global push towards sustainable energy sources provides a significant impetus, as the widespread commercialization of Solid Oxide Fuel Cells (SOFCs) and advanced photovoltaic (PV) modules critically depends on durable, intermediate-temperature hermetic sealing to ensure long operational lifespans and efficiency. The ongoing regulatory shift towards lead-free materials, while initially a technical challenge, ultimately serves as a powerful market driver, compelling innovation towards superior, environmentally compliant Bismuth and Vanadium-based glass compositions, thereby fostering a higher value proposition for advanced sealing solutions.

However, the market growth is moderately constrained by several factors, most notably the high cost and sensitivity of the raw materials required for manufacturing high-performance low temperature frits, particularly the reliance on Bismuth oxide, which can be subject to volatile pricing and supply chain complexities. Another significant restraint is the technical challenge of achieving perfect Coefficient of Thermal Expansion (CTE) matching across extremely diverse substrate materials—a failure to match CTE precisely results in internal stress buildup, leading to seal failure or component degradation, requiring substantial R&D expenditure to overcome. Opportunities abound, particularly in the emerging fields of flexible electronics and implantable medical devices, which demand ultra-low temperature processing (below 300°C) and bio-compatible sealing solutions, opening avenues for novel polymer-glass composite development. The opportunity to integrate low temperature sealing glasses with advanced packaging techniques, such as wafer-level packaging (WLP) and 3D integration, promises substantial market expansion, catering to the ever-increasing demand for dense, high-performance electronic assemblies across the automotive, aerospace, and defense sectors, where reliability under extreme conditions is non-negotiable.

Segmentation Analysis

The Low Temperature Sealing Glass Market is highly segmented across composition types, diverse application fields, and various end-use industries, reflecting the need for highly specialized material properties tailored to specific thermal and chemical environments. Compositional segmentation—including Bismuth-based, Vanadium-based, and Phosphate-based glasses—is crucial as the chemical makeup dictates the key operational characteristics such as softening point, viscosity, and chemical durability. Bismuth-based glasses currently dominate due to their excellent wetting properties and ultra-low sintering temperatures, essential for OLED encapsulation, while Vanadium-based glasses are gaining traction in SOFC applications due to their improved chemical resistance in reducing atmospheres. The market's structural complexity highlights the necessity for material science innovation to bridge the gap between regulatory requirements (lead-free) and demanding performance metrics (high hermeticity, thermal cycling stability).

- By Composition: Bismuth-based, Vanadium-based, Phosphate-based, Zinc Oxide based, Others (Tellurite, Borosilicate-based).

- By Application: Solid Oxide Fuel Cells (SOFC), OLED Displays/Encapsulation, Semiconductor Packaging (MEMS/Sensors), Photovoltaics (PV), Automotive Electronics, Medical Devices (Implants, Diagnostics).

- By End-Use Industry: Electronics and Semiconductor, Energy Storage and Generation, Automotive and Transportation, Medical and Healthcare, Aerospace and Defense.

Value Chain Analysis For Low Temperature Sealing Glass Market

The value chain for the Low Temperature Sealing Glass Market is highly specialized, beginning with the upstream sourcing and refining of high-purity metal oxides, predominantly Bismuth Oxide (Bi2O3), Vanadium Oxide (V2O5), and various proprietary fluxing agents. This upstream stage is critical, as the purity and particle size distribution of the precursor materials directly influence the glass's final properties, including its flow behavior, sealing temperature, and hermetic reliability. Key suppliers in this phase must adhere to stringent quality control standards, given that even trace impurities can compromise the functionality in high-stakes applications like microelectronics and SOFCs. The core manufacturing process involves melting the raw materials at high temperatures, followed by quenching, grinding, and milling to produce fine glass frit powder, which is then formulated into pastes or preforms suitable for specific customer sealing techniques (e.g., screen printing or dispensing).

Midstream activities involve the formulation and preparation of the final sealing product, where specialized companies convert the raw glass frit into ready-to-use compounds such as solvent-based pastes, tapes, or pre-formed gaskets. This stage requires significant expertise in rheology control and organic vehicle chemistry to ensure optimal printability, deposition accuracy, and binder burnout characteristics during the sealing process. The downstream distribution channel is bifurcated into direct sales to large Original Equipment Manufacturers (OEMs)—such as major OLED display manufacturers or Tier 1 automotive suppliers—and indirect sales through highly technical distributors who provide localized support, customization, and technical integration services for smaller, specialized end-users (e.g., custom sensor manufacturers or medical device companies). Direct distribution is favored for large volume, standardized products, whereas complex or custom applications rely heavily on technical distributors who possess the necessary application knowledge to integrate the sealing solution effectively within the customer’s unique assembly line, ensuring the required hermeticity and longevity.

Low Temperature Sealing Glass Market Potential Customers

The primary consumers and end-users of Low Temperature Sealing Glass are entities operating within technological sectors requiring robust, hermetic encapsulation of temperature-sensitive components. Major potential customers include global leaders in consumer electronics and display manufacturing, specifically companies specializing in OLED and QLED production, where the glass serves as the fundamental moisture and oxygen barrier critical for device longevity and luminous stability. Semiconductor fabricators and MEMS (Micro-Electro-Mechanical Systems) sensor manufacturers constitute another significant customer base, utilizing these glasses for wafer-level packaging (WLP) and the sealing of accelerometers, gyroscopes, and pressure sensors that are integral to automotive safety systems and IoT devices. The demand from these high-tech manufacturers is driven by the need for processes that minimize thermal budget while achieving exceptionally high levels of reliability and compliance with standards such as MIL-STD or specific industry qualifications for shock and vibration.

Beyond traditional electronics, a rapidly expanding customer segment is found within the sustainable energy sector, predominantly Solid Oxide Fuel Cell (SOFC) system developers and manufacturers. These companies require low temperature sealing glasses to effectively bond interconnect plates and sealing frames within the fuel cell stack, ensuring efficient gas separation and prevention of gas crossover while withstanding prolonged exposure to high temperatures (albeit intermediate, typically 600°C–800°C, requiring glasses with high chemical stability and CTE matching to ceramic components) and reducing atmospheres over thousands of operational hours. Furthermore, the medical device industry, particularly producers of implantable medical electronics (e.g., pacemakers, neurostimulators), represents a premium customer segment, where the demand for ultra-reliable, bio-compatible, and hermetic seals is paramount for patient safety and device function, leading them to prioritize specialized, tested low-temperature glass-ceramic composites despite the higher material costs associated with stringent certification requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 580.5 Million |

| Market Forecast in 2033 | USD 1,105.8 Million |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schott AG, Corning Inc., Heraeus Holding, Nippon Electric Glass Co., Ltd., 3M Company, AGC Inc., Sumitomo Chemical Co., Ltd., Beijing Huarui Glass Co., Ltd., Fusion Ceramics Inc., Advanced Glass Industries, Ohara Corporation, Potters Industries LLC, Shenzhen Sunwin Glass Co., Ltd., Ferrotec Corporation, Shanghai Haorui Optical Materials Co., Ltd., Sichuan Xingfa Glass Co., Ltd., Hebei Huide Glass Co., Ltd., Shin-Etsu Chemical Co., Ltd., Materion Corporation, Ametek Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Temperature Sealing Glass Market Key Technology Landscape

The technology landscape of the Low Temperature Sealing Glass Market is dominated by the continual refinement of glass frit compositions and advanced processing techniques designed to achieve reliable hermeticity at reduced thermal budgets. A primary technological focus involves moving away from hazardous lead-containing formulations toward complex, multicomponent systems based on Bismuth, Vanadium, and Phosphate oxides. Bismuth-based glasses (e.g., Bi2O3-ZnO-B2O3 systems) are preferred for applications requiring sealing below 450°C, benefiting from excellent flow characteristics and low melting points, crucial for OLED display encapsulation where organic layers are highly sensitive to heat. Innovation is concentrated on engineering specific particle size distributions and morphology of the glass powder, as these factors critically influence the resulting porosity, sintering kinetics, and the ultimate mechanical robustness of the sealed joint, requiring sophisticated milling and particle classification technologies.

A secondary, equally critical technological advancement lies in the development and utilization of advanced deposition techniques and bonding processes. Traditional methods like screen printing are being refined for greater precision and thinner layer deposition, essential for high-density semiconductor packaging. Furthermore, laser-assisted sealing techniques and localized heating methods are gaining traction, allowing for selective sealing with minimal overall thermal exposure to the device, improving throughput and reducing the risk of component damage. For energy applications, specifically SOFCs, the technological emphasis shifts towards glass-ceramic composites, where crystalline phases are intentionally precipitated within the amorphous glass matrix during sealing. This controlled crystallization process significantly enhances the long-term stability, chemical resistance to hostile fuel environments, and provides a much closer CTE match to complex ceramic components, thus ensuring seal integrity throughout severe thermal cycling over the device's operational lifetime, representing a key technological differentiator for high-reliability systems.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market region, primarily driven by massive manufacturing capacities in consumer electronics, especially OLED display panel production in China, South Korea, and Japan. The region benefits from substantial government investments in semiconductor fabrication and assembly (e.g., in Taiwan and mainland China), creating unparalleled demand for low-temperature wafer-level packaging seals. Rapid industrialization and the establishment of sophisticated electronics supply chains solidify APAC’s position as the leading consumer and exporter of sealed components.

- North America: This region holds a significant market share characterized by high-value, specialized applications, including aerospace sensors, defense electronics, and advanced medical devices. North American demand is defined by stringent performance requirements and reliability standards, fostering innovation in ultra-reliable, hermetic glass-ceramic formulations and driving adoption in emerging areas like high-temperature sensors for electric vehicle battery management systems and specialized military communication equipment.

- Europe: Europe represents a mature market, strongly influenced by the adoption of Solid Oxide Fuel Cells (SOFC) technology, particularly in Germany and Scandinavian countries, supported by robust policies favoring decentralized energy solutions. The region also maintains a strong presence in high-end automotive electronics and industrial sensor manufacturing, where compliance with strict environmental regulations (RoHS, REACH) has accelerated the transition to high-performance, lead-free sealing solutions, often necessitating customized glass frit development.

- Latin America, Middle East, and Africa (LAMEA): This emerging region exhibits growth potential, primarily centered on increasing foreign investment in local electronics assembly and maintenance, and nascent solar PV manufacturing initiatives. While currently a smaller market share holder, infrastructure development, particularly in telecommunications and localized energy generation projects, is expected to drive steady demand for standardized low temperature sealing glasses for encapsulation and sensor applications in the medium to long term.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Temperature Sealing Glass Market.- Schott AG

- Corning Inc.

- Heraeus Holding

- Nippon Electric Glass Co., Ltd.

- 3M Company

- AGC Inc.

- Sumitomo Chemical Co., Ltd.

- Beijing Huarui Glass Co., Ltd.

- Fusion Ceramics Inc.

- Advanced Glass Industries

- Ohara Corporation

- Potters Industries LLC

- Shenzhen Sunwin Glass Co., Ltd.

- Ferrotec Corporation

- Shanghai Haorui Optical Materials Co., Ltd.

- Sichuan Xingfa Glass Co., Ltd.

- Hebei Huide Glass Co., Ltd.

- Shin-Etsu Chemical Co., Ltd.

- Materion Corporation

- Ametek Inc.

Frequently Asked Questions

Analyze common user questions about the Low Temperature Sealing Glass market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Low Temperature Sealing Glass and why is it essential for modern electronics?

Low Temperature Sealing Glass is a specialized glass frit that melts and forms a hermetic, airtight seal typically below 550°C. It is essential because it enables the robust encapsulation of heat-sensitive components, such as OLED displays and delicate semiconductor devices, providing critical protection against moisture and contaminants without causing thermal damage.

Which chemical compositions dominate the Low Temperature Sealing Glass Market?

The market is primarily dominated by Bismuth-based glass formulations (known for ultra-low sealing temperatures and good wetting) and Vanadium-based glass compositions (often used in Solid Oxide Fuel Cells due to superior chemical stability and tailored Coefficient of Thermal Expansion matching).

How do stringent environmental regulations impact the formulation of these sealing glasses?

Environmental regulations, particularly the RoHS directive, necessitate a shift away from traditional lead-containing glass frits. This drives innovation toward developing high-performance, lead-free alternatives, predominantly leveraging Bismuth Oxide, which requires advanced material science to maintain functional performance parity.

What are the fastest-growing application segments utilizing low temperature sealing technology?

The two fastest-growing application segments are the encapsulation of Organic Light-Emitting Diodes (OLEDs) due to increasing demand for high-resolution displays, and the sealing of components within Solid Oxide Fuel Cells (SOFCs) driven by global clean energy initiatives and the need for reliable, long-term seals in energy systems.

What is the role of the Coefficient of Thermal Expansion (CTE) in the successful use of sealing glass?

The CTE is critical; the sealing glass's expansion characteristics must closely match those of the substrate materials (e.g., ceramic or silicon) being joined. Mismatched CTE creates internal stresses upon cooling, which can lead to catastrophic seal failure or cracking, particularly under operational thermal cycling conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager