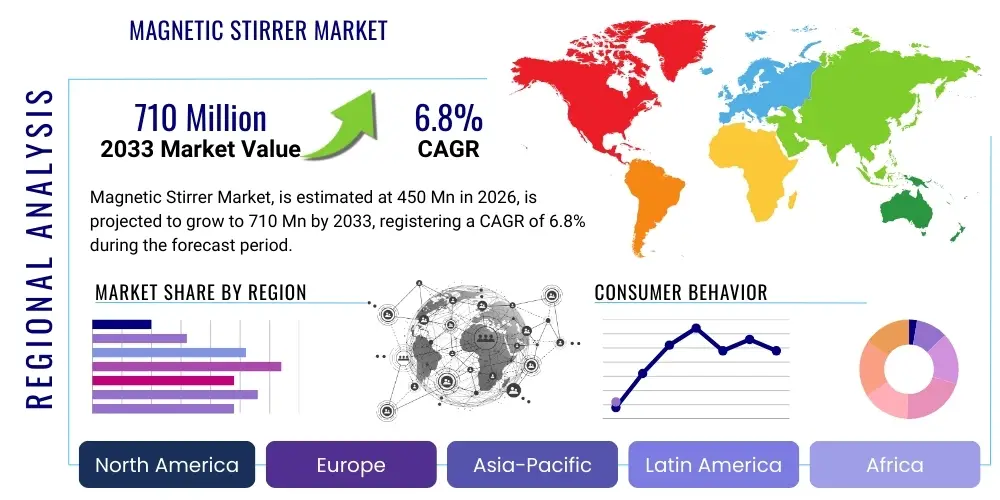

Magnetic Stirrer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443459 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Magnetic Stirrer Market Size

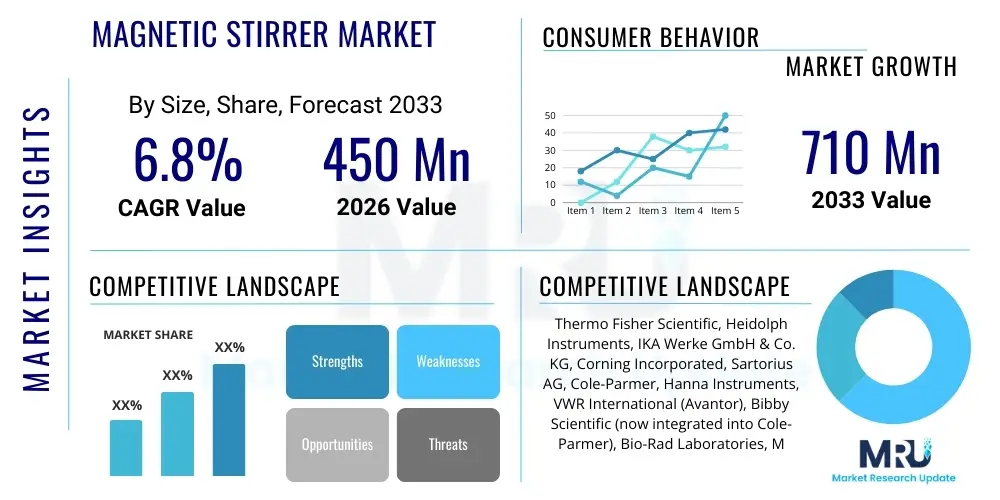

The Magnetic Stirrer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033.

Magnetic Stirrer Market introduction

The Magnetic Stirrer Market encompasses the global sales and distribution of laboratory devices that employ a rotating magnetic field to cause a stir bar (or flea) submerged in a liquid to spin rapidly, thereby mixing the substance. These devices are foundational tools in chemistry, biology, medicine, and industrial laboratories, essential for creating homogenous mixtures, dissolving solutes, or facilitating chemical reactions under controlled conditions. The fundamental importance of precise sample preparation and consistent reaction monitoring in modern scientific endeavors solidifies the magnetic stirrer's critical role across diverse research and quality control environments, driving consistent demand growth.

Magnetic stirrers, ranging from simple analog units to sophisticated digital models integrated with heating plates and temperature feedback control, offer significant advantages over mechanical stirrers, particularly when dealing with closed vessels or hazardous materials, as there is no need for external moving parts or seals. Major applications span pharmaceutical research for drug formulation, academic institutions for educational experiments and advanced material synthesis, and the chemical industry for rigorous quality assurance and process development. The core benefit derived from utilizing these instruments is the achievement of highly reproducible and contamination-free stirring, which is paramount for sensitive analytical procedures and demanding synthesis protocols.

Driving factors propelling market expansion include the burgeoning global investment in life sciences research, especially in emerging economies, coupled with stringent regulatory requirements concerning laboratory accuracy and traceability. Furthermore, the continuous trend toward laboratory automation and the integration of smart, Internet of Things (IoT)-enabled laboratory equipment necessitates the deployment of high-precision digital magnetic stirrers capable of interfacing with automated systems. The growing prevalence of chronic diseases also fuels pharmaceutical and biotech R&D activities, directly increasing the procurement rates of essential laboratory infrastructure like advanced stirring technology, ensuring sustained market impetus throughout the forecast horizon.

Magnetic Stirrer Market Executive Summary

The Magnetic Stirrer Market is characterized by robust growth, driven primarily by technological advancements in digitalization and the escalating need for high-throughput screening in drug discovery and personalized medicine. Current business trends indicate a strong move towards integrated solutions, where magnetic stirrers are bundled with heating plates, auto-titrators, and data logging capabilities, offering researchers precise control and compliance documentation. Key vendors are focusing on developing chemically resistant, ceramic-top stirrers and multi-position units to maximize laboratory efficiency and accommodate complex experimental setups, thereby fostering market competitiveness and innovation in product features and durability.

Regionally, North America and Europe maintain dominance due to high R&D expenditures, well-established pharmaceutical industries, and significant governmental funding allocated to academic research. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by rapidly expanding biotech sectors in China and India, increased establishment of global manufacturing facilities, and growing investments in clinical diagnostics infrastructure. Regional trends also highlight localized manufacturing initiatives aimed at reducing supply chain vulnerabilities and offering more cost-effective solutions tailored to regional budgetary constraints in developing nations, slightly shifting the global manufacturing landscape.

Segmentation trends reveal that the Digital Magnetic Stirrers segment is gaining significant market share over traditional analog counterparts, owing to their superior temperature accuracy, programmable protocols, and ease of integration into sophisticated laboratory workflows. Among end-users, the Pharmaceutical and Biotechnology segment remains the most dominant consumer, reflecting the essential nature of these devices in drug development and quality control (QC). Meanwhile, the High-Capacity Stirrers segment is witnessing increased adoption in industrial chemistry and environmental analysis where large-volume mixing tasks are routine, underscoring diversification in product application based on volume and required shear force.

AI Impact Analysis on Magnetic Stirrer Market

Users frequently inquire whether Artificial Intelligence (AI) will fundamentally alter the operational requirement or design of magnetic stirrers, focusing on topics such as predictive maintenance, optimization of stirring protocols, and integration into fully autonomous laboratories. The consensus expectation revolves around AI enhancing efficiency and reproducibility rather than replacing the physical stirring mechanism itself. Key concerns address how AI can analyze complex reaction data in real- time, adjusting stirring speeds or temperatures autonomously to ensure optimal reaction kinetics, especially in high-throughput experimentation (HTE) environments. This integration signals a shift toward smart laboratory equipment that minimizes human error and accelerates research cycles.

- AI integration enables predictive maintenance, forecasting potential component failures in the stirring mechanism or heating elements, thus reducing downtime.

- Machine learning algorithms can analyze previous experimental runs to suggest optimized stirring speeds, durations, and temperature profiles for specific chemical reactions or viscosities.

- AI facilitates enhanced process control by interpreting real-time sensor data (viscosity, temperature, pH) from the stirred solution and autonomously adjusting the stirrer’s parameters to maintain stringent quality standards.

- Autonomous robotic labs rely on AI to sequence and execute complex multi-step protocols, utilizing magnetic stirrers as controlled nodes within a fully automated synthesis or screening workflow.

- Data logging and analysis are automated, allowing AI to immediately identify anomalies in stirring behavior or reaction progress, ensuring higher data integrity and compliance.

DRO & Impact Forces Of Magnetic Stirrer Market

The Magnetic Stirrer Market is primarily driven by expanding global R&D investments, particularly in emerging markets, coupled with mandatory compliance requirements for reproducible experimental data. Restraints primarily involve high initial procurement costs for advanced digital and multi-position units, and the increasing market saturation in developed regions for standard analog models. Opportunities lie in the penetration of underdeveloped markets, development of specialized stirrers for highly viscous or temperature-sensitive applications, and capitalizing on the trend toward miniaturization and automation. The market's stability is significantly influenced by the sustained funding cycles within the academic and pharmaceutical sectors, establishing these instruments as non-negotiable tools in any functioning laboratory environment.

Market growth drivers include the continuous escalation of pharmaceutical and biotechnology research budgets aimed at addressing complex health issues, requiring constant updates and expansion of laboratory infrastructure. Furthermore, technological advancements leading to the development of highly precise digital stirrers with integrated data management features are significantly appealing to compliance-heavy industries. The shift towards green chemistry and sustainable practices also encourages the use of controlled reaction conditions facilitated by modern magnetic stirrers, reducing waste and enhancing safety protocols, thereby ensuring market buoyancy and continued capital investment by end-users seeking operational efficiency.

Key restraints include the intense competition from alternative mixing technologies, such as mechanical overhead stirrers for large-volume, high-viscosity applications, and ultrasonic homogenizers for specific cell lysis or dispersion tasks. Additionally, challenges related to the consistent maintenance of the magnetic coupling—especially at high speeds or high viscosity—can limit adoption in certain industrial settings. The underlying impact forces, including regulatory mandates for laboratory quality systems (e.g., GLP/GMP), economic fluctuations affecting R&D budget allocation, and the rate of scientific innovation demanding new operational requirements, collectively shape the competitive dynamics and growth trajectory of the magnetic stirrer sector globally.

Segmentation Analysis

The Magnetic Stirrer Market is segmented based on Type, Platform, and End-User, reflecting the diverse application requirements across scientific disciplines. This segmentation is crucial for understanding specific product demand and optimizing targeted marketing strategies, particularly as end-users increasingly seek highly specialized equipment tailored to nuanced research needs, such as ultra-low profile stirrers for confined spaces or high-torque stirrers for complex polymer solutions. The platform division between analog and digital units highlights the fundamental shift toward precise, programmable control, which is the primary driver of digital adoption in compliance-driven laboratories.

In terms of product classification, the distinction between standard and high-capacity models caters to the disparity between small-scale academic research and large-scale industrial or process development activities, influencing pricing and material robustness requirements. Furthermore, the End-User segmentation reveals that the market is heavily reliant on investment cycles within the Life Sciences sector, contrasting with the more stable, routine procurement patterns observed in the academic and food & beverage segments. Analyzing these segments provides stakeholders with actionable insights into where capital expenditure is most concentrated and identifies niche opportunities for innovation in specialty stirring applications, such as temperature-sensitive cell culture media preparation or anaerobic chemistry.

- By Type

- Standard Magnetic Stirrers

- High-Capacity Magnetic Stirrers

- Multi-Position Magnetic Stirrers

- Hot Plate Magnetic Stirrers

- By Platform

- Analog Stirrers

- Digital Stirrers

- By End-User

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Chemical Industry

- Food and Beverage Industry

- Environmental Testing Laboratories

Value Chain Analysis For Magnetic Stirrer Market

The value chain for the Magnetic Stirrer Market begins with upstream activities focused on the sourcing of critical raw materials, predominantly high-grade magnets (neodymium or samarium-cobalt), specialized motor components, and durable housing materials such as chemically inert stainless steel, ceramics, or high-performance polymers. Manufacturing involves complex assembly processes, precision engineering of the magnetic plate to ensure uniform rotation speed, and the integration of microprocessors and temperature sensors in digital models. Key upstream risks include volatility in rare earth magnet pricing and ensuring the availability of high-quality electronic components necessary for reliable digital control and data feedback systems.

The midstream activities center on distribution channels. This phase is dominated by large, global laboratory equipment distributors (like VWR, Avantor, and Fisher Scientific), who leverage extensive logistics networks and established client relationships to move products from manufacturers to end-users. Direct sales by specialized manufacturers also constitute a significant portion, particularly for high-end, customized instruments used in specialized R&D settings. Efficient inventory management and the ability to offer calibration and maintenance services are critical value-adds at this stage, significantly impacting customer satisfaction and market access for manufacturers.

Downstream analysis focuses on the end-users—researchers, QA/QC personnel, and educators—who rely on the instruments for daily operations. Direct channels facilitate faster feedback loops on product performance, enabling manufacturers to rapidly iterate on design improvements. Indirect channels, through large distributors, offer broad geographic reach and consolidated purchasing options for institutions. The aftermarket services, including calibration, repair, and consumable supply (stir bars), form a crucial revenue stream and influence long-term customer loyalty, making robust service support an essential component of the overall value proposition in this technical market segment.

Magnetic Stirrer Market Potential Customers

Potential customers for magnetic stirrers are ubiquitous across the scientific and industrial landscape, fundamentally comprising organizations that require highly accurate, repeatable, and contamination-free mixing processes. The primary consumer group is the global Pharmaceutical and Biotechnology sector, where magnetic stirrers are indispensable for formulation development, media preparation, cell culture maintenance, and analytical sample processing under strict regulatory guidelines (GMP/GLP). The constant demand for new drug discovery and biological testing ensures continuous capital expenditure from this segment, making it the most lucrative and high-volume customer base for premium, technologically advanced stirring solutions.

Academic and governmental research institutions represent another crucial customer segment. These entities utilize magnetic stirrers for fundamental scientific exploration, chemical synthesis, and educational purposes. While often budget-conscious, their procurement is stable and driven by long-term research grants and institutional upgrades. They primarily seek durable, versatile units—both analog and digital—to support a wide array of experimental complexity, ranging from basic undergraduate labs to highly specialized advanced material research centers. The need for multi-position and robust hot plate stirrers is particularly high in these environments to maximize laboratory space and teaching efficiency.

Furthermore, various industrial sectors, including the chemical processing industry, environmental monitoring laboratories, and food & beverage quality control, serve as significant end-users. Chemical manufacturers use high-capacity stirrers for pilot plant studies and small-batch processing. Environmental labs rely on them for sample preparation before heavy metal or contaminant analysis, ensuring homogenization of complex matrices. Food and beverage companies require precise mixing for standardization and quality assurance of ingredients and finished products. These industrial buyers prioritize reliability, chemical resistance, and ease of validation for their specific manufacturing or testing protocols, often preferring specialized models designed for harsh operating environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Heidolph Instruments, IKA Werke GmbH & Co. KG, Corning Incorporated, Sartorius AG, Cole-Parmer, Hanna Instruments, VWR International (Avantor), Bibby Scientific (now integrated into Cole-Parmer), Bio-Rad Laboratories, Metrohm AG, Benchmark Scientific, Troemner (Mettler Toledo), Phoenix Instrument, Glass-Col. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetic Stirrer Market Key Technology Landscape

The technological landscape of the Magnetic Stirrer Market is evolving rapidly, moving beyond basic magnetic induction to incorporate sophisticated control and safety features. A key technological trend is the adoption of advanced sensor feedback systems, particularly Pt1000 temperature sensors, which provide highly accurate monitoring and regulation of solution temperature, crucial for temperature-sensitive reactions like PCR preparation or cell culture media maintenance. This precision thermal management minimizes experimental variability and enhances the reproducibility of results, directly addressing regulatory demands for quality assurance. Furthermore, modern stirrers utilize advanced brushless DC motors, ensuring quieter operation, extended lifespan, and the ability to maintain consistent torque even under varying load conditions or high viscosity, which is a common challenge with older induction motor designs.

Digitalization represents the most profound shift, with manufacturers integrating microprocessors that allow for programmable stirring profiles, ramp functions, and automated data logging compliant with GLP/GMP standards. Many high-end models now feature connectivity options such as USB or Ethernet ports, enabling integration with Laboratory Information Management Systems (LIMS) or automated laboratory platforms. This connectivity facilitates remote control, real-time monitoring of experimental parameters, and seamless documentation, aligning the instruments with the broader trend of Lab 4.0. Furthermore, advancements in plate material technology, specifically the use of highly durable and chemically resistant ceramic tops, improve safety and allow for use with a wider range of aggressive chemicals without degradation.

Innovation is also evident in specialized design features tailored for niche applications. For instance, multi-position stirrers leverage synchronized magnetic fields to provide homogeneous stirring across multiple vessels simultaneously, greatly enhancing throughput in screening applications. Another specialized area involves the development of submersible and remote-controlled stirrers designed for use in harsh environments, glove boxes, or bioreactors where traditional benchtop models are impractical. The increasing sophistication of the internal magnetic drive mechanisms, including stronger magnets and optimized field geometry, allows for more powerful stirring capabilities, enabling the effective mixing of larger volumes and higher viscosity fluids that traditionally required mechanical overhead stirrers, thereby expanding the potential application scope of magnetic stirring technology.

Regional Highlights

- North America: North America remains the foundational market for advanced laboratory equipment, including magnetic stirrers. The United States, in particular, drives market demand due to massive R&D spending by leading pharmaceutical giants, robust government funding for university research, and the presence of world-class biotechnology clusters. The region exhibits high adoption rates for premium, digital, and automated stirring solutions required for compliance with stringent FDA regulations and for integration into high-throughput screening workflows. The sustained expansion of personalized medicine and genomics research guarantees continued investment in high-precision laboratory tools.

- Europe: Europe represents a mature but technologically dynamic market, fueled by strong public sector research initiatives (e.g., Horizon Europe programs) and the presence of globally influential chemical and medical device manufacturing hubs, especially in Germany, Switzerland, and the UK. The focus is increasingly on energy-efficient and highly reliable equipment with comprehensive traceability features. Regulatory environments, such as REACH compliance in the chemical sector, necessitate sophisticated stirring equipment capable of operating under highly controlled and documented conditions, favoring the sales of digitally controlled hot plate stirrers with verifiable performance logs.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven primarily by the rapid infrastructural development in key economies like China, India, South Korea, and Japan. Increased foreign direct investment in establishing pharmaceutical manufacturing and research centers is creating immense demand for laboratory equipment. While price sensitivity exists, there is a clear upward trend in the adoption of advanced digital stirrers in major urban research clusters, moving away from reliance solely on low-cost, basic analog models. Governments are prioritizing investment in biotechnology, positioning the region as a future powerhouse in drug discovery and clinical diagnostics, thus ensuring high procurement rates.

- Latin America (LATAM): The LATAM market, while smaller, is exhibiting steady growth, especially in countries like Brazil and Mexico. Market penetration is often linked to the establishment of multinational pharmaceutical subsidiaries and improvements in national health infrastructure. Growth is constrained by fluctuating economic conditions and dependence on imported equipment, but opportunities exist in academic upgrades and essential public health laboratory modernization projects. Demand primarily centers on robust, easy-to-maintain standard stirrers suitable for general laboratory operations and routine quality control processes.

- Middle East and Africa (MEA): The MEA region is developing, with growth concentrated in the Gulf Cooperation Council (GCC) nations (Saudi Arabia, UAE) due to strategic investments aimed at diversifying economies away from oil and into knowledge-based industries, specifically healthcare and biotechnology research parks. Africa shows emerging demand, often driven by international aid and public health initiatives focused on infectious disease research. The market here demands reliable, often battery-operated or highly durable stirrers suitable for environments with potentially unstable power grids, emphasizing ruggedness and ease of calibration in challenging field conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Stirrer Market.- Thermo Fisher Scientific

- Heidolph Instruments GmbH & Co. KG

- IKA Werke GmbH & Co. KG

- Corning Incorporated

- Sartorius AG

- Cole-Parmer

- Hanna Instruments

- VWR International (Avantor)

- Bibby Scientific (now integrated into Cole-Parmer)

- Bio-Rad Laboratories

- Metrohm AG

- Benchmark Scientific

- Troemner (Mettler Toledo)

- Phoenix Instrument

- Glass-Col

- Eppendorf AG

- VELP Scientifica

- Wiggens GmbH

- AccuSci

- Lab Companion

Frequently Asked Questions

Analyze common user questions about the Magnetic Stirrer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of digital magnetic stirrers over analog models?

Digital magnetic stirrers offer superior precision, reproducibility, and control compared to analog units. They feature programmable stirring profiles, exact temperature setting via sensor feedback (e.g., Pt1000), and integrated digital displays, making them essential for regulated environments requiring precise parameter documentation and minimal experimental variance.

Which factors should be considered when selecting a magnetic stirrer for a pharmaceutical application?

For pharmaceutical applications, key selection factors include temperature control accuracy and stability, the ability to validate protocols (digital models with data logging), compliance with GLP/GMP standards, chemical resistance of the plate surface (ceramic tops preferred), and high-torque capabilities to handle viscous drug formulations reliably and consistently.

How do multi-position magnetic stirrers enhance laboratory throughput?

Multi-position magnetic stirrers significantly enhance throughput by allowing synchronous, homogeneous stirring of multiple samples (often 4 to 15) across a single plate utilizing synchronized magnetic fields. This capability is critical for high-throughput screening, parallel synthesis, and large-scale quality control testing, optimizing laboratory efficiency and reducing required bench space.

What impact does the material of the stirring plate have on performance and safety?

The plate material, typically ceramic or aluminum, profoundly affects performance and safety. Ceramic plates offer superior chemical resistance, are easy to clean, and provide uniform heating, making them ideal for corrosive chemicals or high-temperature heating applications. Aluminum plates heat faster but are less chemically inert, often used when rapid temperature changes are needed.

Is the integration of IoT technology common in modern magnetic stirrers?

Yes, integration of IoT technology is becoming increasingly common in high-end magnetic stirrers. IoT capabilities enable remote monitoring, real-time data transmission to LIMS, automatic parameter adjustment, and centralized control of multiple devices. This connectivity is vital for realizing fully automated and compliant Lab 4.0 environments, improving data integrity and operational flexibility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager