Marine Fire Damper Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441592 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Marine Fire Damper Machine Market Size

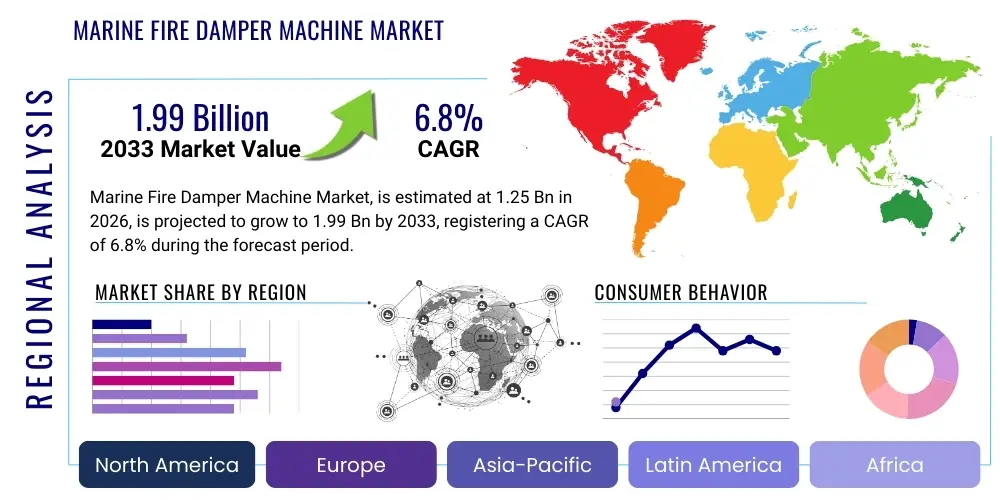

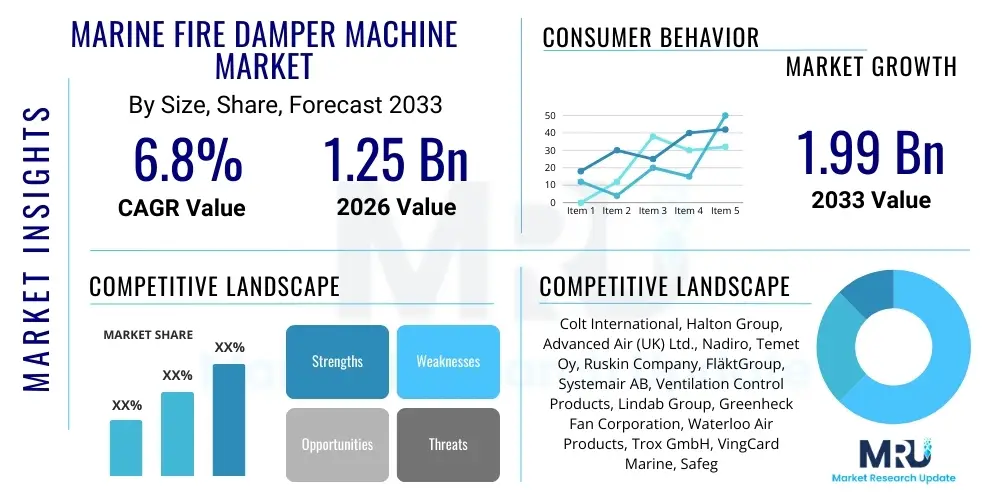

The Marine Fire Damper Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.99 Billion by the end of the forecast period in 2033. This growth trajectory is intrinsically linked to the mandatory implementation of rigorous international maritime safety standards, specifically those governed by the Safety of Life at Sea (SOLAS) convention and subsequent regulatory updates. The consistent need to upgrade existing fleet safety infrastructure, coupled with robust new shipbuilding orders across Asia-Pacific and Europe, serves as a foundational element supporting market expansion over the forecast period. The increasing complexity and size of modern vessels, particularly large cruise ships, liquefied natural gas (LNG) carriers, and offshore platforms, amplify the requirement for highly efficient, classified fire suppression and compartmentalization systems.

Marine Fire Damper Machine Market introduction

The Marine Fire Damper Machine Market encompasses the design, manufacture, and deployment of specialized mechanical devices engineered to prevent the spread of fire and smoke through ventilation ducts, air handling systems, and bulkheads within marine environments. These critical safety components, known as fire dampers, automatically close upon detection of heat or smoke, thereby maintaining the fire integrity of marine compartments as classified by regulatory bodies. The product range includes motorized, pneumatic, and fusible link activated dampers, categorized based on their fire rating (e.g., A-class, B-class, H-class) suitable for various hazardous environments on commercial and naval vessels, offshore drilling rigs, and floating production storage and offloading (FPSO) units. These systems are non-negotiable safety elements, crucial for protecting crew, passengers, and high-value cargo.

Major applications of marine fire damper machines span the entire spectrum of the maritime industry, including merchant shipping (tankers, container ships, bulk carriers), passenger vessels (ferries, cruise ships), and specialized industrial marine infrastructure (offshore wind platforms, research vessels). The primary benefits of utilizing these specialized dampers include compliance with mandatory international safety laws, enhanced structural fire protection, minimized risk of fire spreading between zones, and assured ventilation isolation during emergencies. These benefits directly contribute to reduced operational risk and lower insurance premiums for vessel operators, making the investment in high-quality, certified dampers an essential operational expenditure.

Driving factors for this market are centered around stringent global regulations promulgated by the IMO, the increasing average age of the global merchant fleet requiring substantial modernization and retrofitting of safety systems, and the ongoing technological advancements in materials science that allow for lighter, more resilient, and higher-rated fire dampers. Furthermore, heightened public awareness and corporate responsibility regarding maritime safety following high-profile incidents continuously push for the adoption of best-in-class fire prevention technology. The growth of the global LNG trade, necessitating vessels with inherently higher safety requirements, also provides a significant demand catalyst for H-class and specialized high-integrity dampers.

Marine Fire Damper Machine Market Executive Summary

The Marine Fire Damper Machine Market is characterized by stable, mandatory demand driven predominantly by regulatory frameworks and the cyclical nature of the global shipbuilding industry. Key business trends show a pronounced shift towards intelligent, digitally integrated damper systems that can interface directly with vessel management systems (VMS) and sophisticated fire detection networks, moving away from purely mechanical linkages. Manufacturers are focusing on reducing weight without compromising fire integrity, utilizing advanced alloys and composite materials to meet fuel efficiency demands. Regionally, the Asia Pacific (APAC) market, spearheaded by shipbuilding hubs in China, South Korea, and Japan, remains the dominant region in terms of production volume and initial installation demand, while North America and Europe drive the demand for high-end, retrofit, and highly customized damper solutions for complex offshore and naval projects. Segment trends indicate robust growth in the electrically operated and pneumatically controlled damper segments due to their superior remote control capabilities and integration potential compared to traditional fusible link mechanisms, particularly in critical areas like engine rooms and cargo pump rooms.

The competitive landscape is moderately consolidated, featuring established global HVAC and safety component suppliers alongside specialized marine equipment manufacturers. Strategic alliances, mergers, and acquisitions are common as companies strive to secure long-term supply contracts with major shipyards and classification societies. Sustainability is emerging as a critical trend, influencing the development of dampers using environmentally conscious materials and manufacturing processes, aligning with broader industry goals for decarbonization. Furthermore, predictive maintenance and condition monitoring capabilities, often integrated into new generation damper actuators, are becoming standard requirements for maximizing operational uptime and ensuring continuous safety compliance, thereby driving innovation in sensor and control technology within this specialized niche.

AI Impact Analysis on Marine Fire Damper Machine Market

Common user inquiries concerning the impact of Artificial Intelligence (AI) on the Marine Fire Damper Machine Market primarily revolve around predictive maintenance schedules, optimized system testing routines, and the integration of machine learning algorithms for enhanced anomaly detection within HVAC safety networks. Users seek clarity on how AI can move damper maintenance from fixed, time-based intervals to dynamic, condition-based monitoring, potentially reducing labor costs and minimizing false alarms. A major theme is the potential for AI-driven analytics to process sensor data from actuators, temperature monitors, and smoke detectors across a vessel, allowing the Vessel Management System (VMS) to anticipate potential failures in damper operation before they occur, ensuring compliance readiness and optimizing system performance during critical events. There is also significant interest in using AI for regulatory compliance simulation, allowing operators to model fire scenarios and test the resilience and responsiveness of installed damper configurations virtually before physical inspection.

- AI enables predictive failure analysis for damper actuators and control circuitry, reducing unplanned maintenance downtime.

- Machine learning algorithms optimize the frequency and scope of mandatory fire damper testing based on operational conditions and environmental stress factors.

- AI-driven VMS integration facilitates faster, more accurate remote diagnostics and response coordination during actual fire events.

- Digital twins powered by AI allow for high-fidelity simulation of fire and smoke spread, validating damper placement and performance prior to vessel commissioning.

- Automated compliance reporting generated by AI systems ensures rigorous adherence to classification society requirements (e.g., ABS, DNV GL) with minimal human error.

DRO & Impact Forces Of Marine Fire Damper Machine Market

The dynamics of the Marine Fire Damper Machine Market are shaped by a complex interplay of mandatory regulatory Drivers (D), operational and economic Restraints (R), and emerging technological Opportunities (O), all subjected to significant Impact Forces. Primary drivers include the continuous enforcement and periodic updates of IMO SOLAS regulations, especially concerning passenger vessel safety and highly hazardous cargo containment, which mandate certified fire boundaries. Restraints mainly center on the high initial cost associated with complex, certified A-60 or H-120 rated damper systems and the regulatory barrier to entry, which requires extensive, time-consuming certification processes through global classification societies. Opportunities lie in developing smart damper systems integrated with IoT capabilities, enabling remote diagnostics and predictive maintenance, and leveraging advanced, corrosion-resistant materials to enhance product lifespan in harsh marine environments. The dominant impact force is the highly cyclical nature of the global shipbuilding industry, where new orders directly dictate initial equipment installation volumes, coupled with the geopolitical stability affecting global trade routes and fleet utilization.

Segmentation Analysis

The Marine Fire Damper Machine Market is extensively segmented based on the operational mechanism, the fire integrity rating, the primary material utilized in construction, and the final application within different vessel types. Understanding these segments is crucial for manufacturers to target specific compliance requirements and operational environments. Mechanically, the market divides into fusible link dampers (cost-effective, passive), pneumatic dampers (high-speed response, ideal for hazardous areas), and electric motor-operated dampers (precise control, VMS integration). Segmentation by fire rating is non-negotiable, separating A-class (steel bulkheads, up to 60 minutes integrity), B-class (non-structural divisions), and H-class (hydrocarbon fires, offshore applications) dampers, reflecting the hazard level of the compartment. Furthermore, material segmentation, primarily between galvanized steel and stainless steel (316L for high corrosion areas), dictates longevity and suitability for harsh saltwater exposure. The highly regulated nature of the market ensures that product specifications must rigorously adhere to the requirements of the chosen segment, leading to specialized manufacturing and supply chains.

- By Mechanism:

- Fusible Link Dampers

- Pneumatic Dampers

- Electric Motorized Dampers

- Spring Operated Dampers

- By Fire Integrity Rating:

- A-Class Dampers (e.g., A-0, A-30, A-60)

- B-Class Dampers (e.g., B-0, B-15)

- H-Class Dampers (High Heat Hydrocarbon, e.g., H-60, H-120)

- By Material:

- Galvanized Steel

- Stainless Steel (304, 316L)

- Specialized Alloys

- By Application:

- Commercial Vessels (Tankers, Cargo Ships)

- Passenger Vessels (Cruise Ships, Ferries)

- Naval Vessels

- Offshore Platforms and Specialized Vessels (FPSOs, Rigs)

Value Chain Analysis For Marine Fire Damper Machine Market

The value chain for the Marine Fire Damper Machine Market begins with the upstream procurement of specialized raw materials, predominantly high-grade steel plates (galvanized, stainless 316L) and sophisticated actuation components (electric motors, pneumatic cylinders, control panels). Raw material suppliers must meet exacting quality standards to ensure fire integrity and corrosion resistance. The midstream involves specialized manufacturing, assembly, and rigorous testing processes. Manufacturers must navigate complex international certification requirements administered by classification societies like Lloyd's Register, DNV, and ABS, which represent a significant value-added step, ensuring compliance and market acceptance. This highly specialized manufacturing process also includes the integration of advanced control electronics for smart dampers.

Downstream activities focus on the distribution and installation phase. Distribution channels are typically segmented into direct sales to major global shipyards for new builds, and indirect channels relying on marine equipment distributors and specialized HVAC contractors for retrofit and maintenance markets. Direct channels offer greater control over product integration during vessel construction, while indirect channels are crucial for accessing the global fleet requiring replacement parts and system upgrades. The final stage involves specialized installation, commissioning, and periodic inspection services provided by certified marine engineering firms, ensuring the dampers function correctly within the vessel's overall fire safety matrix.

The interplay between direct and indirect channels is critical. Large, established original equipment manufacturers (OEMs) often maintain direct relationships with Tier 1 shipyards in Asia for high-volume new construction projects. Conversely, the high-margin, fragmented global aftermarket—driven by mandatory 5-year and 10-year surveys requiring damper inspection and repair—is heavily reliant on highly skilled indirect distributors and service providers. Technological advancements, such as digital configuration and remote monitoring capabilities, are increasingly impacting the downstream segment by enabling more efficient maintenance protocols, thereby enhancing the value delivered throughout the product lifecycle.

Marine Fire Damper Machine Market Potential Customers

The primary end-users and buyers of marine fire damper machines are highly specific and regulatory-driven entities operating within the global maritime and offshore sectors. Key customers include large, internationally recognized shipbuilding yards (such as Hyundai Heavy Industries, Samsung Heavy Industries, Fincantieri, and CSSC) that incorporate these certified components during the new construction phase of all vessel types. These shipyards represent the largest volume buyers, driven by design specifications and classification requirements. Additionally, vessel owners and operators, ranging from major container lines and cruise ship operators to national navies, represent significant buyers in the aftermarket for replacement, repair, and system upgrades during mandatory dry-docking periods.

Furthermore, specialized segments such as the offshore oil and gas industry—including operators of drilling rigs, jack-up platforms, and FPSO vessels—constitute a high-value customer base requiring specialized, high-integrity (H-class) dampers suitable for extreme hydrocarbon fire scenarios. The growing offshore renewable energy sector, particularly wind farm maintenance and support vessels, is also emerging as a dedicated customer segment prioritizing long-term durability and minimal maintenance requirements. Due to the critical safety function of these components, procurement decisions are highly influenced by compliance certificates from recognized classification societies and proven operational track records, rather than solely by price competition.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.99 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Colt International, Halton Group, Advanced Air (UK) Ltd., Nadiro, Temet Oy, Ruskin Company, FläktGroup, Systemair AB, Ventilation Control Products, Lindab Group, Greenheck Fan Corporation, Waterloo Air Products, Trox GmbH, VingCard Marine, Safegard Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Marine Fire Damper Machine Market Key Technology Landscape

The technological landscape of the Marine Fire Damper Machine Market is rapidly evolving, driven by the need for enhanced reliability, lighter construction, and seamless digital integration. Historically dominated by passive, fusible link mechanisms, the industry is transitioning towards sophisticated electromechanical and pneumatic actuation systems. Key advancements include the miniaturization of electric actuators, allowing for precise control and significantly reduced response times compared to mechanical systems. These motorized dampers are crucial for modern vessels, enabling centralized monitoring and control from the ship's bridge or designated safety control centers, adhering to the principles of safe return to port (SRtP) regulations for large passenger vessels. Furthermore, the integration of advanced sensors—monitoring temperature, smoke density, and actuator position—is now standard, providing real-time operational status data.

Material innovation is another crucial technological area. Manufacturers are increasingly utilizing higher grades of stainless steel, such as marine-grade 316L, and sometimes specialized nickel alloys, to combat the extreme corrosive environment prevalent in ventilation systems exposed to saltwater air, particularly for dampers installed close to the hull or in exhaust zones. This focus on corrosion resistance directly extends the operational lifespan and minimizes maintenance requirements, offering a significant Total Cost of Ownership (TCO) advantage. Furthermore, the development of lighter, certified composite materials is being explored to reduce overall vessel weight, contributing to fuel efficiency, although steel remains the dominant material due to its proven fire integrity under extreme thermal load.

The most transformative technology involves the convergence of Internet of Things (IoT) principles and sophisticated Vessel Management Systems (VMS). New generation smart dampers are designed with proprietary communication protocols (e.g., Modbus or specific network interfaces) allowing them to transmit diagnostic data continuously, supporting condition-based monitoring programs. This technological leap supports AEO by optimizing maintenance cycles and dramatically improving regulatory compliance tracking. The implementation of smart diagnostic features, such as self-testing capabilities and remote resetting, drastically reduces the need for manual, time-consuming inspections, making the safety management process more efficient and reliable across the entire fleet operation.

Regional Highlights

The Marine Fire Damper Machine Market exhibits distinct regional dynamics heavily influenced by shipbuilding capacity, fleet size, and prevailing regulatory environments. The Asia Pacific (APAC) region stands as the undisputed largest market, driven by high production volumes in the world's leading shipbuilding nations: China, South Korea, and Japan. These countries possess the industrial capacity to construct the majority of new global tonnage, resulting in immense initial equipment demand for fire dampers. Furthermore, rapid infrastructural development in emerging APAC economies and substantial naval modernization programs contribute to sustained regional growth. The competition in this region is fierce, focusing on balancing cost-efficiency with mandatory certifications.

Europe represents a crucial market characterized by stringent adherence to safety standards and a strong focus on high-value, specialized vessel construction, particularly in cruise ships, ferries, and complex research vessels. European demand is often centered on sophisticated, highly customized damper systems, including pneumatic and electric types, with emphasis on noise reduction and seamless integration into luxury vessel HVAC systems. The regional demand is bolstered by significant retrofitting activity aimed at updating the older European fleet to meet the latest safety requirements imposed by EU directives and classification societies. This region is also home to several key technology developers and high-end component manufacturers.

North America, while not a major shipbuilding hub for commercial tonnage, drives substantial demand in the naval and specialized offshore segments, including the burgeoning offshore wind sector and the high-value oil and gas infrastructure. Regulations here are often intertwined with homeland security requirements, demanding top-tier, certified components. The Middle East and Africa (MEA) and Latin America regions are primarily driven by demand related to the oil and gas export industry, requiring robust H-class damper installations for FPSOs and associated marine transport, making their demand cycles closely linked to global energy prices and infrastructure investment.

- Asia Pacific (APAC): Dominates the new-build market due to mass shipbuilding capabilities; high demand for certified, cost-competitive A-class and B-class dampers for container and bulk carrier fleets (China, South Korea).

- Europe: Focuses on the high-end retrofit market and specialized vessel construction (cruise ships, LNG carriers); strong regulatory push for advanced electric and integrated safety systems (Germany, Norway, Finland).

- North America: Significant buyer for naval applications and specialized offshore infrastructure (e.g., platforms, wind farm vessels); emphasizes compliance with US Coast Guard and specialized safety standards.

- Middle East & Africa (MEA): Demand is cyclical, heavily tied to upstream offshore energy investments; requires robust, high-integrity H-class dampers for hazardous environments.

- Latin America: Emerging market driven by fleet modernization, primarily focused on coastal trade and resource extraction vessels, requiring standardized, reliable safety components.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Marine Fire Damper Machine Market.- Halton Group

- Trox GmbH

- Systemair AB

- Colt International

- Advanced Air (UK) Ltd.

- Ruskin Company

- FläktGroup

- Nadiro

- Temet Oy

- Ventilation Control Products

- Lindab Group

- Greenheck Fan Corporation

- Waterloo Air Products

- VingCard Marine

- Safegard Systems

- Shandong Jiejing Environmental Protection Technology Co., Ltd.

- Tomma Marine

- Heinen & Hopman

- Dampa A/S

- Al-Futtaim Engineering

Frequently Asked Questions

Analyze common user questions about the Marine Fire Damper Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary regulatory standards governing the installation of marine fire dampers?

The installation and certification of marine fire dampers are primarily governed by the International Maritime Organization (IMO) Safety of Life at Sea (SOLAS) Convention, along with the requirements of recognized classification societies such as DNV, Lloyd’s Register, and ABS, which ensure compliance with specific A, B, and H class fire integrity ratings.

How do electric motorized dampers differ functionally from traditional fusible link dampers in marine applications?

Electric motorized dampers offer centralized control, remote operation, and seamless integration with the Vessel Management System (VMS) for immediate, automated response, unlike traditional fusible link dampers which operate passively and locally based solely on high-temperature detection.

Which vessel types generate the highest demand for specialized H-class fire dampers?

H-class fire dampers, designed to withstand intense hydrocarbon fires, are required predominantly by high-hazard vessels, including LNG/LPG carriers, crude oil tankers, offshore platforms, and Floating Production Storage and Offloading (FPSO) units, where the risk of catastrophic fire is elevated.

What material considerations are most critical for fire damper durability in marine environments?

Corrosion resistance is paramount; hence, stainless steel (especially marine-grade 316L) is preferred over galvanized steel for dampers exposed to aggressive saltwater and moist air, ensuring long-term functional integrity and compliance with safety regulations.

Is predictive maintenance utilizing IoT technology a growing trend in the marine damper market?

Yes, the market is rapidly adopting IoT and sensor technology to enable predictive maintenance, allowing operators to transition from scheduled, manual testing to condition-based monitoring, optimizing operational efficiency, and enhancing reliable safety performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager