Marine Split Air Conditioning System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442548 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Marine Split Air Conditioning System Market Size

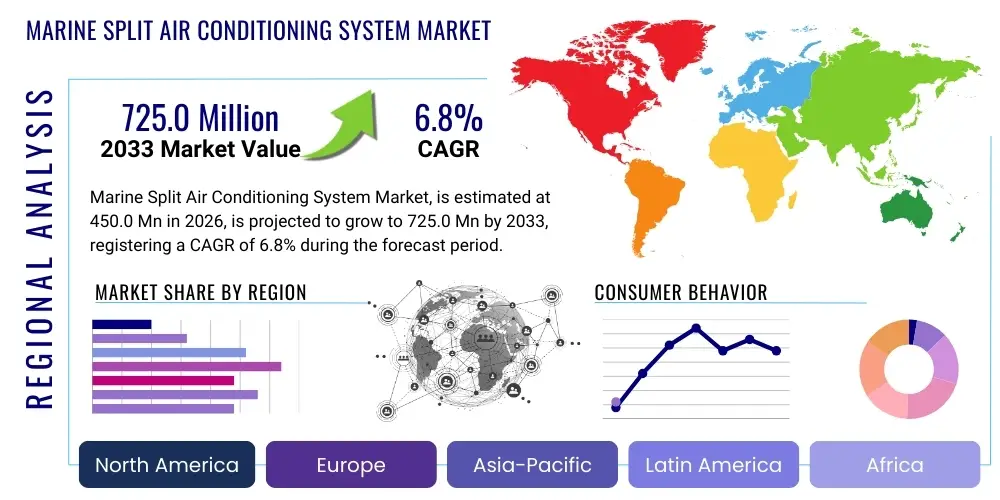

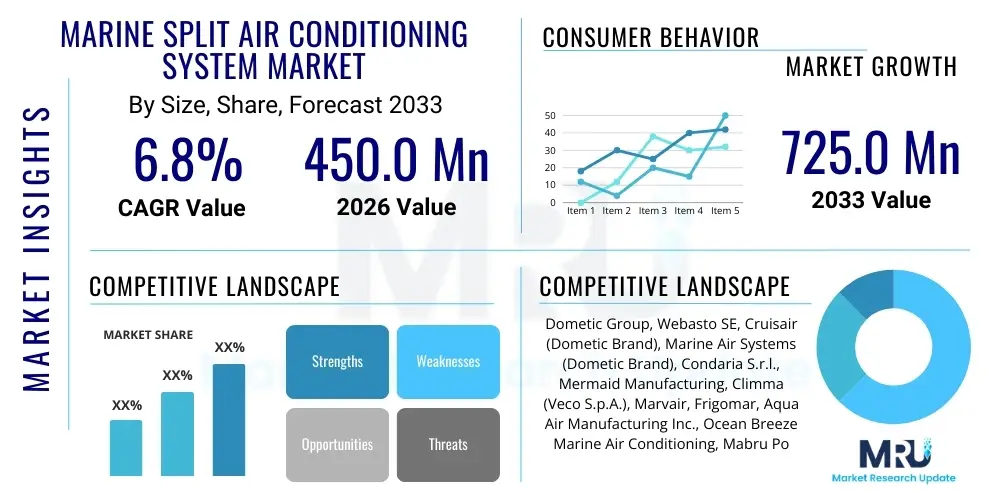

The Marine Split Air Conditioning System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.0 million in 2026 and is projected to reach USD 725.0 million by the end of the forecast period in 2033.

Marine Split Air Conditioning System Market introduction

The Marine Split Air Conditioning System Market encompasses highly specialized HVAC solutions designed specifically for maritime environments, including yachts, commercial vessels, naval ships, and offshore platforms. These systems are essential for maintaining comfortable and safe internal temperatures, dehumidifying air, and ensuring optimal operational conditions for sensitive electronics and machinery. Unlike conventional HVAC units, marine split systems are engineered to withstand severe operating conditions, such as high salinity, corrosive environments, continuous vibration, and extreme temperature fluctuations, requiring robust construction, specialized coatings, and marine-grade components. They consist of two main units: the condensing unit (typically installed in a machinery space or outside) and the air handling unit (evaporator, installed within the living or working spaces), connected by refrigerant lines and electrical cabling. This split design allows for flexible installation, minimizes noise in occupied areas, and provides customized cooling solutions tailored to the unique architectural constraints of various vessels. The efficacy of these systems is crucial not only for passenger comfort but also for adherence to crew welfare standards mandated by international maritime organizations.

The core product in this market is the efficient and durable split AC unit, often utilizing inverter technology for variable capacity control, leading to reduced energy consumption and quieter operation. Key applications span luxury leisure vessels, which demand silent operation and aesthetic integration, to large commercial vessels (tankers, cargo ships) where reliability and ease of maintenance are paramount. The benefit of utilizing marine-specific split AC units lies in their compliance with classification society rules (such as Lloyd’s Register or DNV), superior corrosion resistance, and optimized thermal performance under high humidity loads characteristic of the open sea. Furthermore, modern systems integrate sophisticated control interfaces, often networked, allowing for centralized monitoring and diagnostic capabilities, enhancing overall vessel management efficiency. The system's robustness ensures longevity, minimizing downtime for critical operations at sea, which is a major value proposition for commercial fleet operators.

Major driving factors fueling market expansion include the sustained growth in global shipbuilding, particularly in the luxury yacht and cruise line sectors, where passenger expectations for climate control are continuously rising. Simultaneously, stringent international regulations regarding crew accommodation standards and the ongoing push for energy efficiency and reduced emissions necessitate the adoption of newer, high-efficiency AC systems. The replacement cycle of older, less efficient R-22-based systems (due to refrigerant phase-outs) also acts as a significant market driver, pushing owners to invest in modern, compliant units utilizing HFCs or HFOs. Increased maritime transport volumes globally, coupled with greater naval defense spending on modern vessel fleets equipped with advanced electronic cooling requirements, further accelerate the demand for reliable and technically advanced marine split air conditioning solutions. These technological advancements ensure that marine environments remain habitable and conducive to complex operations regardless of ambient conditions.

Marine Split Air Conditioning System Market Executive Summary

The Marine Split Air Conditioning System Market is characterized by robust commercial trends focusing on energy efficiency, digitalization, and regulatory compliance. Business trends indicate a strong shift towards high-SEER (Seasonal Energy Efficiency Ratio) inverter-driven systems that significantly reduce fuel consumption, aligning with industry mandates for decarbonization. Manufacturers are increasingly prioritizing modular designs for easier installation and maintenance, along with integrated IoT sensors for real-time performance monitoring and predictive failure analysis. Furthermore, there is a pronounced move toward sustainable refrigeration solutions, driven by global efforts to phase out high Global Warming Potential (GWP) refrigerants, necessitating costly yet essential system redesigns. The market sees intense competition based not only on price but primarily on system reliability, service network availability, and compliance with stringent environmental and safety standards imposed by various maritime authorities.

Regional trends highlight the Asia Pacific (APAC) region as the primary growth engine, fueled by dominant shipbuilding activities in China, South Korea, and Japan, which serve as global manufacturing hubs for commercial vessels and tankers. Europe maintains a strong presence, particularly in the high-end luxury yacht segment, driving innovation in compact, silent, and highly customized air conditioning solutions. North America demonstrates consistent demand, driven primarily by naval procurement and recreational boating activities, emphasizing systems that meet strict environmental regulations pertaining to water discharge and noise pollution. The Middle East and Africa (MEA) region show increasing potential due to expanding offshore energy exploration and naval fleet modernization programs, demanding rugged, high-capacity cooling systems capable of operating efficiently in extremely high ambient temperatures and dusty conditions.

Segment trends reveal that the 'Capacity' segment is favoring medium to high capacity units (above 12,000 BTU/hr) due to the trend of building larger, more complex vessels requiring distributed cooling across numerous zones. By 'Application,' the commercial marine segment (including cargo, tanker, and passenger ships) holds the largest market share, prioritizing durability and operational cost savings. However, the recreational and leisure segment is witnessing the highest growth rate, propelled by the luxury yacht market’s exponential expansion and demand for multi-zone, silent, aesthetic HVAC integration. In terms of technology, variable refrigerant flow (VRF) and inverter-based systems are rapidly supplanting traditional fixed-speed units, providing superior control, energy savings, and adaptation to fluctuating cooling loads across different parts of the vessel simultaneously.

AI Impact Analysis on Marine Split Air Conditioning System Market

Common user questions regarding AI’s impact on the Marine Split Air Conditioning System Market primarily revolve around how machine learning can optimize energy consumption in dynamic maritime conditions, whether predictive maintenance driven by AI can extend equipment lifespan and prevent critical failures at sea, and the feasibility of integrating autonomous climate control with existing vessel management systems. Users are keenly interested in algorithms that can interpret vast datasets (engine load, ambient temperature, humidity, passenger occupancy, solar exposure) to dynamically adjust refrigerant flow and compressor speed, thereby minimizing energy draw without compromising crew or cargo safety. Concerns often center on the security of networked AI-controlled systems and the necessity for robust, specialized training data reflective of the harsh, varied marine operating environment, distinct from terrestrial HVAC applications. The overarching expectation is that AI will move marine AC systems from reactive operation to proactive, hyper-efficient energy management tools.

- AI-Driven Predictive Maintenance: Utilizing sensor data and machine learning algorithms to anticipate component wear, refrigerant leaks, or compressor failures before they occur, optimizing maintenance scheduling and minimizing unplanned downtime.

- Energy Consumption Optimization: Implementing neural networks to analyze real-time environmental and operational parameters, automatically adjusting system setpoints and capacity modulation to achieve maximum efficiency and reduce fuel consumption significantly.

- Autonomous Climate Control: Developing self-adjusting systems that learn occupant preferences and vessel heat load dynamics, managing climate zones independently without constant manual input, improving crew comfort and reducing operational complexity.

- Fault Detection and Diagnostics (FDD): Employing AI for immediate, precise identification of system anomalies, drastically reducing the time required for diagnosis and repair of complex multi-zone split AC networks.

- Refrigerant Management Efficiency: Using AI models to track refrigerant charge levels and identify subtle leakage patterns early, ensuring regulatory compliance (F-Gas, Montreal Protocol) and maintaining system performance integrity under variable sea conditions.

- Design Optimization and Simulation: Leveraging AI tools during the vessel design phase to simulate heat transfer and air distribution characteristics within complex hull structures, ensuring optimal placement and sizing of split system components.

DRO & Impact Forces Of Marine Split Air Conditioning System Market

The Marine Split Air Conditioning System Market is primarily driven by rigorous regulatory requirements for crew welfare and the continuous pursuit of operational cost reduction through energy efficiency, directly correlating with fuel savings. Restraints include the high initial capital investment required for specialized, corrosion-resistant marine equipment and the technical complexities associated with retrofitting existing fleets, which often involves challenging installation in confined spaces and integration with legacy power systems. Significant opportunities emerge from the increasing demand for luxury and expedition yachts, which require customized, high-specification cooling solutions, alongside the modernization of global naval fleets which demand robust, shock-resistant HVAC. The major impact forces acting on the market are the accelerating pace of environmental legislation concerning refrigerants and emissions (driving technological shifts) and the volatile global shipping and shipbuilding cycles which directly influence new system procurement volumes, necessitating market adaptability in manufacturing output and inventory management.

Key drivers include global shipbuilding growth, especially in specialized vessel types like LNG carriers and large container ships, where cooling requirements for both cargo (reefer containers) and crew are critical. Furthermore, the imperative for reducing the environmental footprint of vessels pushes adoption of advanced technologies such as variable frequency drives (VFDs) and high-efficiency heat exchangers. The mandatory requirement for vessels to adhere to ISO standards and classification society rules (ensuring reliability and safety at sea) also serves as a perpetual demand driver, as non-compliant or aging systems must be replaced promptly. Regulatory pressures, particularly the European Union's Ship Recycling Regulation and global efforts to curb HFC usage, stimulate investment in research and development for new, low-GWP refrigerant systems, fundamentally reshaping the product offering across the entire market spectrum.

Conversely, the high maintenance costs associated with marine systems, exacerbated by the corrosive nature of saltwater environments and the difficulty in accessing specialist technicians in remote ports, pose a substantial restraint. The market also faces technical restraints related to the power limitations on smaller vessels and the need for compact yet powerful cooling solutions that do not infringe upon valuable space. Opportunities are maximized through diversification into new market niches, such as hybrid and electric vessels which require highly specialized battery cooling and power management integration alongside climate control. The development of remote monitoring capabilities and standardized, easily replaceable component modules represents a significant opportunity to mitigate maintenance restraints, improve serviceability, and strengthen customer loyalty across diverse geographical operational areas.

Segmentation Analysis

The Marine Split Air Conditioning System market is meticulously segmented based on key functional and application parameters to address the diverse needs of the maritime industry. These segments include categorization by System Type (e.g., direct expansion, chilled water, VRF), Capacity (measured in BTU/hr), Component (compressors, condensers, air handlers), Vessel Application (commercial, recreational, naval), and Distribution Channel (OEM, Aftermarket). This structured segmentation allows manufacturers to tailor product specifications—such as materials used for corrosion resistance, noise suppression levels, and power consumption profiles—to specific end-user requirements, ensuring optimized performance whether the unit is installed on a luxury superyacht demanding near-silent operation or a harsh-duty offshore supply vessel prioritizing rugged durability and minimal maintenance.

- By System Type:

- Direct Expansion (DX) Systems

- Chilled Water Systems (often larger capacity)

- Variable Refrigerant Flow (VRF) Systems

- Inverter-Based Systems

- By Capacity (BTU/hr):

- Below 12,000 BTU/hr (Small Boats/Cabin)

- 12,000 BTU/hr to 36,000 BTU/hr (Mid-sized Yachts/Fishing Vessels)

- Above 36,000 BTU/hr (Commercial Vessels/Large Yachts)

- By Application:

- Commercial Marine (Cargo, Tankers, Passenger Ships)

- Recreational Marine (Yachts, Cruisers, Sailboats)

- Naval and Defense Vessels

- Offshore Platforms (Rigs and Support Vessels)

- By Component:

- Compressors (Rotary, Scroll, Reciprocating)

- Condensers (Cupro-Nickel, Titanium tube)

- Evaporators/Air Handlers

- Control Systems and Thermostats

- By Distribution Channel:

- Original Equipment Manufacturers (OEM)

- Aftermarket and Replacement

Value Chain Analysis For Marine Split Air Conditioning System Market

The value chain for marine split AC systems begins with upstream activities involving the sourcing of highly specialized raw materials and core components, such as corrosion-resistant metals (cupro-nickel for condensers, stainless steel casings), advanced refrigerants (R-410A, R-32), and high-efficiency compressors and electrical motors. Due to the critical operating environment, component suppliers must adhere to stringent material specifications and quality certifications dictated by maritime standards. The manufacturing process involves specialized assembly and rigorous hydrostatic and performance testing to ensure reliability under extreme vibration and thermal loads. Key upstream relationships are characterized by long-term contracts with specialized metallurgy firms and advanced electronics suppliers who provide marine-grade PCBs and control interfaces, differentiating the marine AC value chain from its terrestrial counterpart due to mandatory compliance with Classification Society standards.

The midstream segment involves the core manufacturers who design, assemble, and certify the complete split system units. Certification by bodies like ABS, DNV-GL, or Lloyd’s Register is a critical value-add checkpoint, validating the system's compliance with safety and environmental mandates. Distribution channels are highly structured and typically bifurcated. The direct channel focuses on Original Equipment Manufacturers (OEMs), where AC systems are integrated into new vessel builds, requiring close collaboration with shipyards and naval architects during the design phase. The indirect channel relies heavily on specialized marine equipment distributors, authorized dealers, and marine service centers, which handle aftermarket sales, spare parts, and system retrofits for existing fleets globally, often providing localized technical support and installation expertise.

Downstream activities are dominated by installation, commissioning, maintenance, and repair services. The complexity of marine refrigeration systems necessitates highly trained technicians, making aftermarket service and spare parts revenue a significant part of the total market value. Potential customers, including shipyard managers, fleet owners, and yacht brokers, prioritize long-term Total Cost of Ownership (TCO) over initial acquisition price, driving demand for systems with high Mean Time Between Failures (MTBF). The effectiveness of the service network and the availability of global stock for crucial components directly impact the operational continuity of vessels, thus influencing purchasing decisions at the downstream end of the value chain. This focus on long-term support creates robust interdependence between manufacturers and authorized service providers.

Marine Split Air Conditioning System Market Potential Customers

Potential customers for Marine Split Air Conditioning Systems are diverse, ranging from large multinational commercial shipping companies and national navies to individual high-net-worth individuals who own recreational vessels. The primary end-users fall into three broad categories: commercial fleet operators (including cargo, tanker, bulk carrier, and container ships), who purchase high-capacity, robust, and easily maintainable systems; yacht owners and builders, who demand aesthetically discreet, ultra-quiet, multi-zone climate control integrated with luxury interiors; and governmental/naval entities, requiring specialized, shock-resistant, and electromagnetically shielded systems for defense applications. Procurement decisions are typically centralized within fleet management or new construction procurement departments, heavily influenced by regulatory compliance, system durability, and global serviceability. Reliability in transit and energy efficiency are key decision criteria across all customer segments.

For the commercial sector, the buyer is generally the procurement department of the shipping company or the shipyard acting on behalf of the owner. Their focus is maximizing operational uptime and minimizing running costs; therefore, they prioritize systems with low power draw, common spare parts availability, and long warranties, often opting for medium to high capacity chilled water or VRF systems due to the size of the application. In the recreational market, the customer is often the yacht builder or naval architecture firm during the construction phase, or the yacht management company for retrofits, demanding sophisticated digital controls and customized zoning tailored to unique cabin layouts and specific luxury specifications, often favoring highly efficient inverter-based split DX systems for personalized comfort in confined areas.

Naval and government end-users represent a highly specialized, capital-intensive segment. These buyers, typically defense ministries or coast guard agencies, require systems that meet rigorous military standards for shock loading, vibration resistance, electromagnetic compatibility (EMC), and non-magnetic operation. The purchasing process is characterized by long tender cycles and strict compliance requirements, often leading to custom-engineered solutions rather than off-the-shelf products. Additionally, offshore energy companies operating drilling platforms and support vessels represent another critical customer base, demanding explosion-proof (ATEX compliant) or specially certified heavy-duty split systems capable of sustained operation in harsh, often remote, and high-risk environments, where reliability is non-negotiable for crew safety.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.0 million |

| Market Forecast in 2033 | USD 725.0 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dometic Group, Webasto SE, Cruisair (Dometic Brand), Marine Air Systems (Dometic Brand), Condaria S.r.l., Mermaid Manufacturing, Climma (Veco S.p.A.), Marvair, Frigomar, Aqua Air Manufacturing Inc., Ocean Breeze Marine Air Conditioning, Mabru Power Systems, S&P Marine, Johnson Controls International PLC, Carrier Global Corporation, Parker Hannifin Corp, Daikin Industries Ltd., Midea Group Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Marine Split Air Conditioning System Market Key Technology Landscape

The Marine Split Air Conditioning System market is undergoing rapid technological evolution driven primarily by demands for higher energy efficiency, quieter operation, and enhanced digitalization for remote management. A pivotal technological trend is the widespread adoption of DC inverter technology, which allows compressors to run at variable speeds rather than fixed cycles (on/off). This variable speed capability precisely matches the cooling output to the actual thermal load, drastically reducing peak power consumption, lowering noise levels, and improving overall system reliability compared to traditional fixed-speed units. Furthermore, the migration toward alternative refrigerants with lower Global Warming Potential (GWP), such as R-32, is a major focus, necessitating redesigns of compressors and heat exchangers to handle different thermodynamic properties while adhering to international environmental compliance mandates like the Kigali Amendment and related European F-Gas regulations.

Another crucial element of the technology landscape involves advanced material science utilized in heat exchange components. To combat the severe corrosion caused by saltwater exposure, manufacturers are increasingly using specialized alloys like cupro-nickel, titanium, and highly resistant polymer coatings in condensers and associated piping. This investment in durable materials significantly extends the system lifespan and reduces the lifecycle cost for vessel owners, a crucial metric in commercial operations. Sophistication in control systems is also paramount; modern marine split AC systems incorporate microprocessors and IoT connectivity, enabling vessel operators to monitor performance parameters, diagnose faults remotely, and integrate the climate control system seamlessly with the vessel's centralized power management and monitoring system (SCADA or PMS), optimizing power distribution across all onboard consumers.

The integration of Variable Refrigerant Flow (VRF) technology, initially popular in large commercial buildings, is increasingly being scaled and hardened for marine applications, particularly on large yachts and passenger ships. VRF systems allow a single outdoor condensing unit to be connected to multiple indoor air handlers, each individually controllable, providing precise climate control in numerous distinct zones while offering superior energy efficiency and redundancy. Furthermore, noise and vibration mitigation technology, utilizing specialized anti-vibration mounts and acoustic insulation materials, is continually advancing, meeting the stringent silence requirements of the luxury and cruise sectors. These technological enhancements are essential for maintaining competitiveness and meeting the escalating expectations of safety, comfort, and environmental responsibility within the global maritime industry.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant region in the Marine Split Air Conditioning System market, primarily due to its status as the global epicenter for shipbuilding. Countries like China, South Korea, and Japan lead in the construction of large commercial vessels, including tankers, bulk carriers, and container ships, driving massive OEM demand for robust, certified split AC systems. Furthermore, rising disposable incomes in emerging Asian markets are fueling a significant expansion in the recreational boating and superyacht industries, particularly in coastal centers like Singapore and Australia. Regional growth is strongly tied to infrastructure projects and naval modernization programs in nations like India and Vietnam, ensuring sustained, high-volume procurement of marine HVAC equipment.

- Europe: Europe is characterized by a strong focus on high-quality, customized, and technologically advanced systems, particularly serving the luxury yacht, mega-yacht, and high-end cruise ship markets centered around Italy, Germany, and the Netherlands. European manufacturers are often pioneers in adopting environmentally friendly refrigerants (driven by F-Gas regulations) and developing ultra-silent inverter technology. Demand is also robust in the replacement market, driven by the aging European fleet requiring upgrades to meet contemporary efficiency and environmental standards. The presence of stringent Classification Societies and specialized marine equipment suppliers reinforces Europe's role as a benchmark for premium marine HVAC technology.

- North America: The North American market is driven primarily by the extensive recreational boating sector, particularly along the coasts of Florida, California, and the Great Lakes, alongside significant governmental spending on the modernization of the US Navy and Coast Guard fleets. Demand centers on durable, easy-to-install split systems for smaller to mid-sized boats, emphasizing modular design and local serviceability. Regulatory compliance, specifically related to energy efficiency standards and the handling of refrigerants, exerts a strong influence on product development, promoting the adoption of advanced, high-efficiency cooling technology across the civilian marine fleet.

- Middle East and Africa (MEA): This region is experiencing considerable growth, largely concentrated in the Gulf Cooperation Council (GCC) countries. The demand is unique due to extremely high ambient temperatures and humidity levels, requiring high-capacity, heavy-duty cooling solutions often paired with robust dehumidification capabilities. Investment in offshore oil and gas exploration necessitates specialized AC systems for rigs and support vessels. Additionally, the increasing development of coastal tourism infrastructure and luxury marinas is stimulating demand for high-end split AC systems for new luxury yachts and chartered vessels operating in the Red Sea and Arabian Gulf.

- Latin America (LATAM): The LATAM market, while smaller in scale, shows steady growth driven by coastal fishing fleets, inland waterway transport (rivers and canals), and limited naval fleet renewal projects, particularly in Brazil and Mexico. Economic volatility can sometimes restrain large-scale investment, but the fundamental need for reliable crew cooling and cargo preservation ensures a persistent baseline demand for reliable, accessible, and mid-range capacity split air conditioning units that offer low acquisition costs and acceptable operational longevity in tropical climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Marine Split Air Conditioning System Market.- Dometic Group

- Webasto SE

- Cruisair (Dometic Brand)

- Marine Air Systems (Dometic Brand)

- Condaria S.r.l.

- Mermaid Manufacturing

- Climma (Veco S.p.A.)

- Marvair

- Frigomar

- Aqua Air Manufacturing Inc.

- Ocean Breeze Marine Air Conditioning

- Mabru Power Systems

- S&P Marine

- Johnson Controls International PLC

- Carrier Global Corporation

- Parker Hannifin Corp

- Daikin Industries Ltd.

- Midea Group Co. Ltd.

- Mitsubishi Electric Corporation

- Tecnautic Srl

Frequently Asked Questions

Analyze common user questions about the Marine Split Air Conditioning System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes a marine split AC system from a standard residential unit?

Marine split AC systems are engineered with superior corrosion resistance, utilizing marine-grade materials (like cupro-nickel heat exchangers) and robust components to withstand salt spray, continuous vibration, and extreme humidity, ensuring compliance with strict international classification society standards for safety and reliability at sea.

Which refrigerants are being adopted in new marine split AC systems to comply with environmental regulations?

New marine systems are increasingly utilizing low Global Warming Potential (GWP) refrigerants, primarily R-410A in the transition phase, with growing movement towards R-32 and specialized HFO blends. This shift is driven by global phase-out schedules for high-GWP HFCs and specific regional regulations like the EU F-Gas Regulation and the Kigali Amendment.

How does inverter technology benefit marine split AC system efficiency?

Inverter technology allows the compressor to modulate its speed continuously based on cooling demand, preventing the power surges associated with traditional on/off fixed-speed units. This results in significantly lower energy consumption, reduced noise levels, and precise temperature maintenance, leading directly to lower operational fuel costs for the vessel owner.

What are the primary challenges facing the aftermarket segment of the marine split AC market?

The primary challenges include the complexity of retrofitting new systems into existing vessel infrastructure, which often involves confined spaces and legacy power integration, and the high cost and logistical difficulty of supplying specialized spare parts and skilled technicians globally, especially in remote port locations.

In which application segment is the highest growth anticipated for marine split AC systems?

The highest growth rate is anticipated in the Recreational Marine segment, specifically within the luxury yacht and superyacht categories. This segment demands sophisticated, quiet, multi-zone climate control systems due to increasing vessel size and rising passenger expectations for customized, high-comfort onboard environments, driving premium system sales.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager