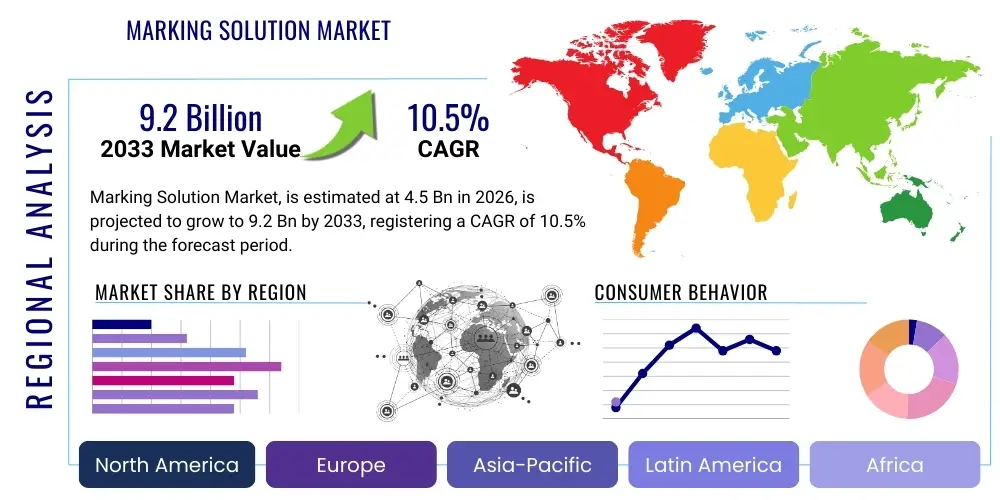

Marking Solution Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443029 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Marking Solution Market Size

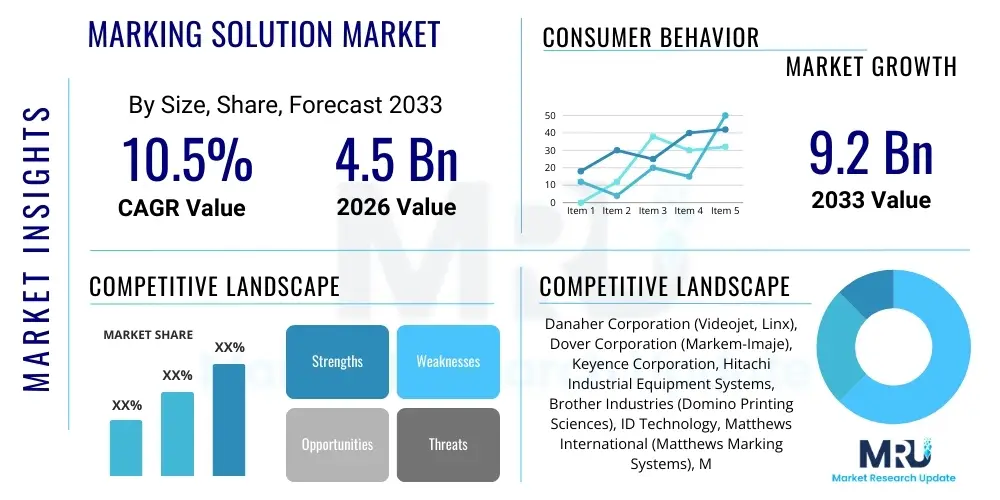

The Marking Solution Market is projected to grow at a Compound Annual Growth Rate (CAGR) of [10.5%] between 2026 and 2033. The market is estimated at [USD 4.5 Billion] in 2026 and is projected to reach [USD 9.2 Billion] by the end of the forecast period in 2033. This substantial growth is driven primarily by the escalating demand for product traceability and anti-counterfeiting measures across regulated industries globally. Furthermore, the integration of advanced technologies such as laser marking and high-resolution inkjet printing into automated production lines is accelerating market expansion. The shift towards digitized manufacturing and adherence to stringent international standards, particularly in the automotive and aerospace sectors, mandates robust, permanent, and machine-readable identification, ensuring the consistent upward trajectory of market valuation throughout the forecast period. The increasing complexity of global supply chains necessitates sophisticated marking solutions capable of enduring harsh environmental conditions.

Marking Solution Market introduction

The Marking Solution Market encompasses a diverse range of technologies and equipment designed for imprinting, etching, or labeling permanent or semi-permanent identification marks onto products, components, or packaging materials. These solutions are crucial for achieving fundamental operational goals, including supply chain transparency, quality control, brand protection, and regulatory compliance. Key product categories within this sector involve laser marking systems (fiber, CO2, UV), industrial inkjet printers (Continuous Inkjet - CIJ, Drop-on-Demand - DOD), dot peen/pinstamp systems, thermal transfer overprinting (TTO), and advanced labeling technologies. The selection of a specific marking solution is contingent upon factors such as the substrate material (metal, plastic, glass, paper), the required mark permanence, line speed, and the overall integration complexity within the manufacturing environment. Modern marking solutions are increasingly networked, integrating seamlessly with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) to facilitate real-time data capture and traceability across the product lifecycle.

Major applications of marking solutions span virtually every industrial sector. In the automotive industry, they are essential for VIN (Vehicle Identification Number) etching and component tracking for safety recalls. The aerospace sector relies on precise laser marking for critical, high-stress parts to ensure material integrity and lifetime traceability. In the pharmaceutical and medical device sectors, marking solutions are mandatory for serialization and Unique Device Identification (UDI) compliance, combating counterfeiting and enhancing patient safety. Additionally, the electronics industry utilizes highly precise marking for small components, enabling efficient inventory management and quality assurance. The benefits derived from implementing effective marking solutions are multifaceted, extending beyond mere identification to include optimized inventory flow, reduced instances of product tampering, and significantly improved regulatory adherence, thus contributing substantially to operational excellence.

Driving factors underpinning the market expansion are numerous and interconnected. Foremost among these is the rigorous global regulatory landscape, particularly mandates like the EU’s Falsified Medicines Directive (FMD) and the U.S. FDA’s UDI regulations, which compel manufacturers to adopt high-fidelity serialization techniques. Furthermore, the global proliferation of Industry 4.0 and smart factory initiatives drives the adoption of automated marking systems that can communicate data instantaneously. The sustained growth of the e-commerce sector places greater emphasis on verifiable packaging and secure tracking, pushing the demand for high-speed, flexible inkjet and thermal marking solutions. The continuous technological evolution, specifically in solid-state laser technology offering faster speeds and reduced maintenance, serves as a pivotal enabler for market growth, encouraging manufacturers to upgrade legacy systems to more efficient, compliant alternatives. These driving forces collectively ensure robust market momentum throughout the forecast period.

Marking Solution Market Executive Summary

The Marking Solution Market is characterized by vigorous innovation focused on digitalization, speed, and precision, reflecting broader industrial automation trends. Business trends highlight a pronounced shift towards integrated systems that combine marking hardware with sophisticated traceability software platforms, allowing for centralized data management and compliance reporting. Key players are increasingly focusing on developing modular solutions that offer ease of integration and scalability across diverse manufacturing environments, particularly appealing to SMEs undergoing digital transformation. Furthermore, sustainability is becoming a key business differentiator, with manufacturers developing solvent-free or minimal-waste marking technologies, such as UV laser marking or water-based inkjet inks, to meet evolving environmental standards and corporate responsibility goals. This drive toward integrated, sustainable, and highly accurate marking systems forms the core competitive landscape and investment focus for the market leaders over the next decade.

Regional trends indicate that Asia Pacific (APAC) is poised for the most rapid growth, fueled by massive investments in manufacturing infrastructure, particularly in China, India, and Southeast Asian nations where industrial output is scaling rapidly across electronics, automotive components, and consumer goods. North America and Europe, while representing mature markets, maintain high revenue shares due to the early adoption of highly specialized and high-cost marking solutions required by stringent aerospace, defense, and pharmaceutical regulations. These regions are characterized by demand for system upgrades, leveraging advanced software for data analytics and predictive maintenance integrated into existing marking infrastructure. The Middle East and Africa (MEA) and Latin America are emerging markets exhibiting accelerating adoption rates driven by infrastructure development and increasing regulatory enforcement, particularly concerning food and beverage safety and traceability standards, representing significant untapped potential for localized service providers.

Segment trends reveal that the laser marking technology segment continues to dominate in terms of value, owing to its superior permanence, precision, and low operational cost over time, making it the preferred choice for high-value components. However, the software and services segment is projected to exhibit the highest CAGR, reflecting the growing complexity of data management associated with serialization and traceability protocols; businesses are increasingly investing in cloud-based platforms for centralized control and archiving. End-user analysis shows that the automotive and pharmaceutical sectors remain primary revenue generators, driven by stringent safety and compliance requirements, whereas the packaging sector is rapidly increasing its contribution, demanding high-speed, flexible coding solutions for mass customization and enhanced consumer engagement efforts. The convergence of marking hardware reliability with sophisticated traceability software defines the contemporary dynamics across all segmentations.

AI Impact Analysis on Marking Solution Market

Common user questions regarding AI’s impact on the Marking Solution Market typically revolve around whether AI can automate quality inspection, predict equipment failure, and optimize marking parameters for various materials. Users are highly interested in the feasibility of utilizing machine vision, powered by deep learning algorithms, to instantly verify the quality and readability of codes (e.g., Data Matrix, QR codes) under high-speed manufacturing conditions, replacing traditional manual or rule-based inspection systems. There is also significant curiosity about how AI-driven analytics can integrate marking data with broader production metrics to identify root causes of defects or supply chain bottlenecks. The core themes center on achieving zero-defect marking through intelligent control, enhancing overall equipment effectiveness (OEE) via predictive maintenance scheduling for high-throughput marking machines, and leveraging generative algorithms for personalized and secure anti-counterfeiting marking patterns.

AI is transforming marking solutions from simple output devices into intelligent components within the smart factory ecosystem. Its primary influence is evident in the integration of advanced computer vision systems capable of performing real-time quality assurance checks. Deep learning models are trained on vast datasets of acceptable and defective marks, allowing them to rapidly identify subtle flaws, poor contrast, or incorrect placement, achieving inspection speeds and accuracy far exceeding human capability or legacy vision systems. This capability is paramount in sectors like electronics and pharmaceuticals, where micro-marks and high compliance standards are non-negotiable. Furthermore, AI algorithms are being deployed to dynamically adjust laser power, focus, and etching speeds based on variations in material composition or ambient temperature, ensuring consistent mark quality regardless of input fluctuations. This adaptive control mechanism minimizes waste and maximizes throughput efficiency.

Beyond quality control, the application of AI extends robustly into predictive maintenance for marking equipment. High-speed inkjet printheads or critical laser components are subject to wear and tear, and downtime is expensive. AI monitors operational parameters—such as vibration, temperature, ink pressure, or laser current—to predict potential failures accurately before they occur, triggering maintenance alerts proactively. This transition from scheduled maintenance to condition-based monitoring dramatically reduces unexpected outages and optimizes the lifespan of costly equipment. Finally, in the realm of security and anti-counterfeiting, AI is utilized to generate unique, complex, and verifiable serialization codes or hidden digital watermarks that are difficult for counterfeiters to replicate, providing an enhanced layer of brand protection. The cumulative effect of AI integration is a substantial enhancement in reliability, efficiency, and security across the marking solution landscape.

- Implementation of AI-powered Computer Vision for real-time 100% mark quality verification and defect detection.

- Integration of Predictive Maintenance (PdM) algorithms to forecast component failures in laser sources and printheads, maximizing uptime.

- Dynamic adjustment of marking parameters (e.g., laser power, CIJ droplet charge) based on material feedback and environmental variables for consistent quality.

- Enhanced security through AI-generated, complex, and unique serialization patterns for superior anti-counterfeiting measures.

- Optimization of overall equipment effectiveness (OEE) through intelligent scheduling and resource allocation for marking operations.

DRO & Impact Forces Of Marking Solution Market

The market dynamics of Marking Solutions are powerfully shaped by a balance of compelling drivers and persistent restraints, coupled with significant growth opportunities, all contributing to influential impact forces. Drivers primarily include the global push for regulatory compliance, especially serialization and traceability mandates in sensitive industries (e.g., Pharma, Medical Devices), the pervasive integration of Industry 4.0 principles emphasizing automated data capture and connectivity, and the escalating global threat of product counterfeiting necessitating advanced security marking. These factors create sustained, non-negotiable demand for high-performance marking equipment. Conversely, restraints such as the substantial upfront capital investment required for high-end laser systems, the technical complexity involved in integrating diverse marking technologies into existing legacy IT infrastructure, and the continuous need for skilled personnel to operate and maintain sophisticated equipment pose challenges to rapid mass adoption, particularly for smaller enterprises. The overall impact forces are strongly positive, pushing the market towards more integrated, software-centric, and automated solutions.

Opportunities for market growth are significant and center on technological evolution and untapped regional demand. The rising need for micro-marking in miniaturized electronics and complex medical implants opens avenues for highly precise UV and femtosecond laser technologies. Furthermore, the development of sustainable, food-safe, and environmentally benign marking consumables (inks, solvents) presents a major growth opportunity, aligning with corporate sustainability goals. The expansion into emerging economies, where domestic manufacturing is scaling rapidly, and where regulatory frameworks are maturing, offers substantial potential for basic and mid-range marking systems. The market is also seeing opportunities in offering Marking-as-a-Service (MaaS) models, which reduce capital expenditure barriers and allow manufacturers to access cutting-edge technology through subscription or usage-based pricing structures, thereby democratizing access to advanced solutions and mitigating the restraint of high initial costs. This strategic approach helps overcome adoption hesitancy.

The convergence of these forces dictates market trajectory. The most significant impact force is the mandatory compliance requirement which ensures a baseline level of investment regardless of economic conditions. The pursuit of operational efficiency, a secondary but powerful force, drives the adoption of faster and more reliable systems (like fiber lasers replacing older technologies), justifying the higher initial expenditure through lower total cost of ownership (TCO) and improved OEE. The overall environment favors solution providers who offer comprehensive packages encompassing robust hardware, intelligent software for data management, and specialized service contracts. The competitive advantage increasingly lies not just in the speed of the mark, but in the seamless, verifiable, and secure integration of the marked data into the global digital supply chain infrastructure. The market is thus actively prioritizing solutions that offer superior connectivity and data security above mere marking speed.

Segmentation Analysis

The Marking Solution Market is systematically segmented based on Technology, Offering, End-Use Industry, and Geography, providing a multi-dimensional view of market dynamics and opportunity areas. Technological segmentation differentiates between contact and non-contact methods, recognizing that industrial requirements—such as speed, substrate, and permanence—drive solution choice. The Offering segmentation highlights the strategic importance of software and service revenue streams over purely hardware sales, indicating a shift towards holistic solution provisioning. End-use segmentation validates the critical reliance of highly regulated industries, such as pharmaceuticals and aerospace, on specialized marking compliance, contrasting with the high-volume needs of general manufacturing and packaging sectors. These segmentations are crucial for mapping competitive strategies and identifying areas for specialized product development and geographical expansion efforts, ensuring that strategic planning is aligned with specific industrial demands and technological evolution within each category.

- By Technology:

- Laser Marking (Fiber Laser, CO2 Laser, UV Laser, Green Laser)

- Inkjet Marking (Continuous Inkjet - CIJ, Drop-on-Demand - DOD, Thermal Inkjet - TIJ)

- Dot Peen/Pinstamp Marking

- Thermal Transfer Overprinting (TTO)

- Chemical Etching and Stenciling

- By Offering:

- Hardware (Marking Systems, Consumables, Accessories)

- Software (Serialization Software, Traceability Platforms, Data Management Solutions)

- Services (Integration, Maintenance, Training, Consultation)

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Electronics and Semiconductors

- Pharmaceutical and Medical Devices

- Food and Beverage

- Packaging and Logistics

- General Industrial Manufacturing

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Marking Solution Market

The value chain for the Marking Solution Market is characterized by highly specialized stages, beginning with sophisticated upstream component manufacturing and culminating in complex system integration and exhaustive post-sales services. Upstream analysis focuses on core component suppliers, including specialized laser source manufacturers (e.g., fiber, CO2, UV sources), high-precision optics providers (lenses, mirrors, galvanometers), and industrial ink and solvent producers. The performance, reliability, and cost of the final marking system are critically dependent on the quality and innovation provided by these suppliers. Intellectual property and deep technological expertise in physics and chemistry are major competitive advantages at this stage. Major marking system integrators maintain strong relationships with a select group of reliable upstream component providers to ensure supply chain resilience and maintain competitive pricing, often involving long-term strategic agreements to secure priority access to cutting-edge technologies and materials, which is crucial given the high customization requirements in specific marking applications.

Midstream activities involve the design, assembly, software development, and testing of the complete marking solution systems. This stage is where value is added through engineering integration, ensuring hardware-software compatibility, user interface development, and meeting specific industry compliance standards (e.g., GAMP, FDA requirements). System assemblers often customize core technology platforms, optimizing them for high-speed industrial environments, resistance to dust and chemicals, and seamless integration with conveyor belts or robotic arms. The value addition here lies in providing a robust, reliable, and compliant final product. Downstream activities focus heavily on distribution, installation, commissioning, and long-term service and support. Direct and indirect channels are utilized; direct sales teams often handle complex, high-value projects in aerospace or pharmaceuticals requiring extensive consultation, while indirect channels (distributors, resellers, and value-added integrators) efficiently cover wider geographical regions and lower-complexity industrial applications like general packaging or entry-level marking tasks.

The distribution network is crucial for market penetration and timely service delivery. Direct channels ensure high customer engagement and specialized application support, maintaining tight control over the customer experience and managing complex software licensing and integration projects. Indirect channels provide local presence, inventory management, and rapid response to localized maintenance needs, which is particularly vital for consumables replenishment in inkjet systems. The overall efficiency of the value chain is increasingly judged by the responsiveness of the service component. Offering high-quality, localized technical support and predictive maintenance services is now a core differentiator, moving beyond the initial equipment sale to establishing long-term revenue streams through software updates, consumables supply, and service contracts, enhancing the total customer lifecycle value. Effective supply chain management is also critical in mitigating geopolitical risks affecting component availability and stabilizing pricing pressures in a highly competitive global market environment.

Marking Solution Market Potential Customers

Potential customers for Marking Solutions represent a vast and diverse industrial landscape, united by the fundamental necessity for product identification, traceability, and brand security. The primary end-users are large-scale manufacturers operating in highly regulated environments, particularly the global pharmaceutical and medical device manufacturers who require robust serialization capabilities mandated by global regulatory bodies such as the FDA and EMA. These customers demand validated systems, high uptime, and precise, indelible marks capable of surviving sterilization processes. The second major group comprises global automotive and aerospace original equipment manufacturers (OEMs) and their Tier 1 suppliers, who utilize marking solutions for critical component tracking, failure analysis, and lifetime durability records, often requiring deep etching or high-contrast laser marks on specialized metal alloys. These critical application customers prioritize system reliability and longevity above all else, often employing proprietary marking standards.

A rapidly expanding customer segment includes high-volume consumer packaged goods (CPG) companies and food and beverage producers. While their marking needs are less focused on permanence than those of aerospace firms, they require extremely high-speed, flexible, and often food-grade coding solutions for best-before dates, batch codes, and promotional information on diverse substrates (plastic, glass, carton). This segment drives demand for high-speed CIJ and TIJ printers that can keep pace with fast production lines and frequent product changeovers, requiring systems that minimize downtime during ink changes and maintenance. Furthermore, the logistics and e-commerce fulfillment sectors are increasingly becoming major consumers, requiring reliable, cost-effective print-and-apply labelers and high-resolution inkjet systems for marking shipping containers and parcels with dynamic information, enhancing logistical efficiency and reducing mis-shipments throughout the complex network of modern distribution centers.

In the electronics and semiconductor sectors, customers require ultra-precise marking capabilities for miniaturized components, leveraging advanced UV and green lasers to mark delicate silicon or polymer materials without causing thermal damage. This group places a high premium on minimal component stress and micro-level accuracy. Lastly, general industrial fabricators, encompassing tool and die makers, electrical component manufacturers, and metal processing shops, represent a continuous baseline demand for versatile and durable marking solutions, such as dot peen and fiber lasers, for basic part numbering, branding, and inventory control applications. These various customer profiles dictate the specific technological requirements and integration complexities that providers in the Marking Solution Market must address, leading to a highly specialized and application-driven sales environment, necessitating tailored consultation and long-term support for diverse operational requirements across different manufacturing philosophies globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | [USD 4.5 Billion] |

| Market Forecast in 2033 | [USD 9.2 Billion] |

| Growth Rate | [10.5% CAGR] |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Danaher Corporation (Videojet, Linx), Dover Corporation (Markem-Imaje), Keyence Corporation, Hitachi Industrial Equipment Systems, Brother Industries (Domino Printing Sciences), ID Technology, Matthews International (Matthews Marking Systems), Macsa ID, SICK AG, Coherent Corp., Gravotech Group, Han’s Laser Technology Industry Group, TRUMPF GmbH + Co. KG, FOBA Laser Marking + Engraving, Telesis Technologies Inc., MECCO, Zetes, Koenig & Bauer Coding GmbH, Control Print Limited, REA JET. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Marking Solution Market Key Technology Landscape

The Marking Solution Market is characterized by a rapid evolution in foundational technologies, driven by the demand for higher speed, greater precision, and lower environmental impact. Laser marking technology, particularly fiber lasers, dominates the high-performance segment due to its minimal maintenance, operational longevity, and ability to create permanent, high-contrast marks on metals and plastics without the need for consumables. UV laser technology is gaining traction for heat-sensitive materials (like certain plastics and medical packaging) as it performs "cold marking," preventing material degradation. Meanwhile, inkjet technologies remain crucial for variable data printing on packaging and soft materials, with Thermal Inkjet (TIJ) systems seeing increased adoption over Continuous Inkjet (CIJ) in certain applications due to their cleaner operation and maintenance simplicity, although CIJ still holds sway in high-speed, 24/7 industrial environments requiring specialized inks, such as marking on curved surfaces or through condensation. The technological focus is moving towards hybrid systems that combine the speed and data handling of advanced software with robust hardware components.

A central trend defining the current technology landscape is the integration of traceability software platforms that operate independently of the marking hardware. These platforms handle complex serialization schemes, manage regulatory reporting requirements, and archive marking data in secure, cloud-based environments. Solutions are shifting from proprietary communication protocols to standardized interfaces (such as OPC UA) to facilitate true Industry 4.0 integration, allowing real-time data exchange with MES and ERP systems. This transition positions software as the primary value driver, optimizing the use of marking data for broader operational intelligence. Furthermore, the development of specialized, highly compliant inks and consumables—such as migration-safe inks for food contact materials and biocompatible inks for medical devices—continues to be a critical area of chemical innovation, ensuring safety and compliance across diverse application mandates.

Future technological developments are focusing intensely on enhanced machine vision systems, which utilize high-resolution cameras and advanced processing to verify mark quality instantly, moving toward "closed-loop" marking systems where vision feedback automatically adjusts the marking parameters in real-time, drastically reducing human intervention and waste. Research into direct-write technologies, including advanced 3D printing and precise chemical vapor deposition for marking, is emerging, although currently niche. The overall technology trajectory is one of miniaturization—making marking heads smaller and easier to integrate into compact or highly roboticized production lines—and increased connectivity, where every marking event is not just a physical action but a secure, verifiable data point uploaded instantly to the cloud, enhancing global supply chain resilience and data integrity across all sectors relying on reliable product identification systems.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by rapid industrialization, massive investments in automotive and electronics manufacturing (especially in China, South Korea, and Southeast Asia), and evolving government regulations concerning food safety and pharmaceutical serialization. The region is characterized by high-volume, cost-sensitive manufacturing, leading to strong demand for high-speed, cost-effective inkjet solutions, although investment in high-end laser technology is increasing rapidly due to quality requirements in export-oriented manufacturing segments like precision machinery and high-tech components. The demand is further amplified by significant domestic consumption growth, necessitating robust localized traceability infrastructure.

- North America: North America holds a substantial market share, primarily fueled by stringent regulations in the medical device and aerospace sectors (e.g., UDI requirements, military standards). The market here is technologically mature, showing strong demand for advanced, fully automated laser marking systems and sophisticated serialization software platforms that integrate with existing complex enterprise systems. High labor costs also drive intense automation, favoring solutions that offer reliability, predictive maintenance capabilities, and minimal human interaction, contributing to a high average selling price (ASP) for marking equipment and associated service contracts.

- Europe: Europe represents a mature market with high regulatory compliance standards (e.g., EU FMD). Growth is steady, driven largely by system modernization, the penetration of Industry 4.0 within established manufacturing bases (Germany, Italy, France), and a strong emphasis on sustainable marking solutions. There is a notable preference for advanced laser marking technologies and solvent-free inkjet alternatives, aligning with strict EU environmental directives. The automotive sector, facing transformation, is a key driver for component traceability and quality assurance marking in the transition to electric vehicles (EVs).

- Latin America (LATAM): LATAM is an emerging market showing accelerating growth, particularly in Brazil and Mexico, fueled by expanding domestic manufacturing capacity and increasing enforcement of food and beverage traceability regulations. The market here is generally price-sensitive, initially favoring CIJ and low-to-mid-range laser systems, but investment in advanced solutions is growing as global manufacturers expand operations into the region, necessitating adherence to international quality and compliance benchmarks. Infrastructure development and supply chain modernization are key growth accelerators.

- Middle East and Africa (MEA): MEA is experiencing gradual growth, largely concentrated in industrialized hubs like the UAE and Saudi Arabia, driven by diversification efforts away from oil dependence towards manufacturing, logistics, and pharmaceutical production. Investments in port infrastructure and logistics hubs are boosting demand for robust coding and marking solutions for packaging and inventory management, focusing primarily on basic coding requirements and counterfeit protection measures across consumer goods and imported pharmaceuticals.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Marking Solution Market.- Danaher Corporation (Videojet, Linx)

- Dover Corporation (Markem-Imaje)

- Keyence Corporation

- Hitachi Industrial Equipment Systems

- Brother Industries (Domino Printing Sciences)

- ID Technology

- Matthews International (Matthews Marking Systems)

- Macsa ID

- SICK AG

- Coherent Corp.

- Gravotech Group

- Han’s Laser Technology Industry Group

- TRUMPF GmbH + Co. KG

- FOBA Laser Marking + Engraving

- Telesis Technologies Inc.

- MECCO

- Zetes

- Koenig & Bauer Coding GmbH

- Control Print Limited

- REA JET

Frequently Asked Questions

Analyze common user questions about the Marking Solution market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Marking Solution Market?

The primary driver is the global enforcement of stringent regulatory mandates, specifically related to product serialization and traceability, such as the U.S. FDA’s UDI system and the EU’s Falsified Medicines Directive, which require manufacturers across key sectors like pharmaceuticals and medical devices to adopt reliable, permanent marking solutions to ensure end-to-end supply chain integrity and combat counterfeiting effectively.

Which marking technology offers the highest level of permanence and lowest long-term operational cost?

Laser marking technology, particularly fiber lasers, offers the highest degree of mark permanence and the lowest Total Cost of Ownership (TCO) over its operational lifespan. While the initial capital expenditure is higher than inkjet or TTO, laser systems require minimal consumables and very little maintenance, making them highly economical for applications demanding indelible, high-resolution marks on durable materials like metals and high-grade plastics.

How is Industry 4.0 influencing the adoption of new marking solutions?

Industry 4.0 drives the demand for networked, smart marking solutions that facilitate real-time data capture and integration. Modern systems are equipped with communication protocols (e.g., OPC UA) to connect seamlessly with MES and ERP systems, enabling automated quality checks, remote monitoring, and comprehensive data traceability for every marked item, thus enhancing operational intelligence and supporting autonomous manufacturing environments efficiently.

What key challenges face manufacturers when implementing advanced marking systems?

The main challenges involve the high upfront investment cost for sophisticated equipment, complex system integration into existing legacy production lines without disrupting operations, and the critical requirement for highly skilled technical personnel to maintain, calibrate, and troubleshoot the advanced software and hardware components, particularly in high-precision laser and serialization setups, requiring continuous training investment.

Which market segment is expected to show the fastest growth rate through 2033?

The Software and Services segment is anticipated to exhibit the fastest Compound Annual Growth Rate (CAGR). This acceleration is due to the rising complexity of regulatory compliance and data management associated with serialization and traceability. Manufacturers are increasingly relying on advanced, cloud-based software platforms for secure data archiving, reporting, and predictive maintenance services, shifting expenditure from pure hardware purchases to integrated solution subscriptions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager