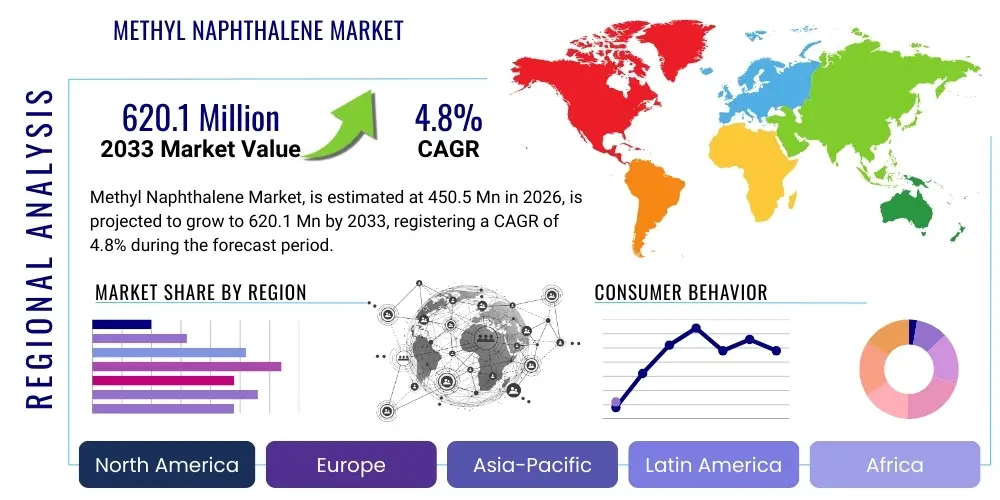

Methyl Naphthalene Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442277 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Methyl Naphthalene Market Size

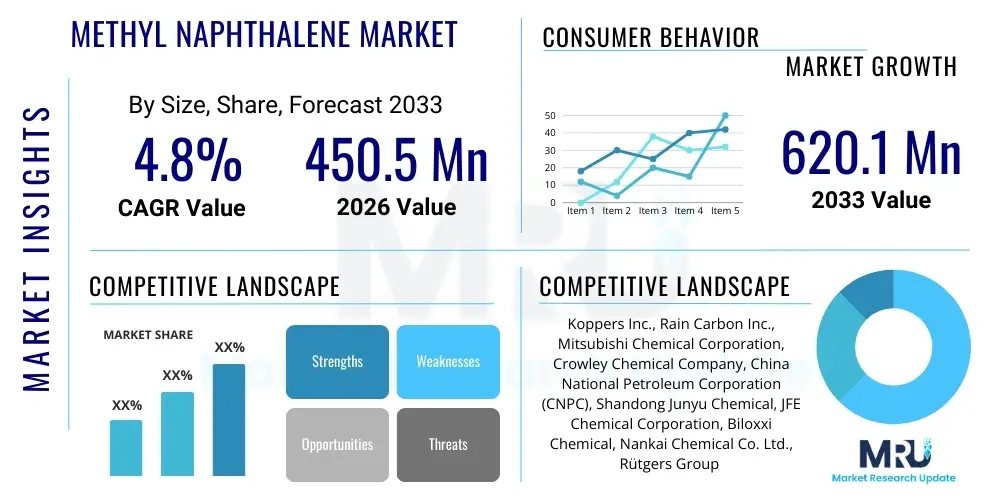

The Methyl Naphthalene Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 620.1 Million by the end of the forecast period in 2033.

Methyl Naphthalene Market introduction

Methyl Naphthalene (MN) refers to a group of organic compounds derived from coal tar distillation, primarily existing as isomers 1-methylnaphthalene and 2-methylnaphthalene. These colorless, oily liquids are characterized by their high boiling points, excellent solvency properties, and thermal stability, making them critical intermediates in various industrial syntheses. The primary function of Methyl Naphthalene lies in its application as a solvent for specialized resins and oils, a raw material for producing high-performance dyes, pigments, and agricultural chemicals, and a key component in the manufacturing of naphthalene-based superplasticizers crucial for the construction industry.

The market expansion is fundamentally driven by the robust growth in global infrastructure development, particularly in emerging economies where demand for high-strength concrete and advanced construction materials is escalating. Methyl Naphthalene derivatives, such as sulfonate condensates, are widely utilized as concrete admixtures (superplasticizers) that significantly improve concrete workability and reduce water content without compromising strength. Furthermore, the compounds serve as vital components in the production of high-grade surfactants and dispersants used extensively across industries like textiles, oil and gas, and agrochemicals, thereby ensuring sustained demand across a diversified application portfolio.

Key benefits of Methyl Naphthalene include its superior thermal oxidative stability, high K-factor (a measure of energy content), and relatively low freezing point, which makes 1-Methylnaphthalene particularly valuable as a standard reference fuel in determining the cetane number of diesel fuels. The driving factors encompass the stringent performance requirements in the construction and specialty chemical sectors, necessitating high-purity intermediates. However, the market faces constraints related to the volatility of raw material sourcing, primarily crude oil and coal tar, alongside increasing regulatory pressure concerning polycyclic aromatic hydrocarbons (PAHs).

Methyl Naphthalene Market Executive Summary

The Methyl Naphthalene market is experiencing moderate but stable growth, fueled predominantly by sustained business trends in the global construction and specialty chemicals sectors. The adoption of advanced concrete technologies, which heavily rely on naphthalene-sulfonate superplasticizers, forms the bedrock of demand, especially as urbanization rates accelerate in Asia Pacific. Business trends indicate a shift toward higher purity grades of Methyl Naphthalene to meet stringent quality requirements in high-end applications like electronics manufacturing and advanced agrochemical formulations, compelling manufacturers to invest in advanced distillation and purification techniques. Consolidation within the coal tar processing industry, which is the primary source of MN, also influences supply chain stability and pricing dynamics globally.

Regionally, Asia Pacific (APAC) stands out as the dominant and fastest-growing market, primarily due to large-scale infrastructure projects in China, India, and Southeast Asian nations. The region not only consumes the largest volume for construction but is also a major production hub, leveraging established coal processing capacities. North America and Europe maintain steady demand, driven by specialized, high-value applications such as jet fuel reference standards and niche solvent markets, though production capacity is relatively constrained compared to APAC. Regulatory trends in developed markets, emphasizing sustainability and the reduction of volatile organic compound (VOC) emissions, are spurring research into bio-based or cleaner synthesis routes for MN derivatives, potentially impacting future regional dynamics.

Segment trends reveal that the Application segment dominated by the Dyes and Pigments and Surfactants category, followed closely by Plasticizers, dictates market volume. Within the Purity Grade segment, high-purity Methyl Naphthalene (98% and above) is gaining traction, commanding premium pricing due to its necessity in sophisticated chemical synthesis and analytical applications. The overall market trajectory is influenced by the cyclical nature of the construction industry and the global price fluctuations of crude oil, which impact raw material costs derived from petroleum fractions, requiring robust hedging strategies among major market participants to maintain operational profitability.

AI Impact Analysis on Methyl Naphthalene Market

User queries regarding AI's influence in the Methyl Naphthalene market center around optimizing complex manufacturing processes, particularly in distillation and purification, predicting feedstock pricing volatility, and enhancing R&D efficiency for novel derivative creation. Concerns frequently arise about how AI-driven demand forecasting can stabilize supply chains inherently prone to crude oil price swings. The key themes summarized from user expectations involve utilizing predictive maintenance models to minimize downtime in coal tar processing plants, employing machine learning algorithms to fine-tune reaction parameters in sulfonated naphthalene production for better yield and purity control, and using AI-powered material informatics to accelerate the discovery of safer, more sustainable alternatives or high-performance additives based on Methyl Naphthalene scaffolds.

- AI-driven optimization of fractional distillation columns, leading to improved purity yield (e.g., 2-Methylnaphthalene separation).

- Predictive modeling for raw material cost forecasting (coal tar, crude oil fractions), mitigating supply chain risk.

- Enhanced quality control systems using computer vision and sensor data analysis during intermediate processing.

- Acceleration of R&D for novel superplasticizer formulations and high-performance solvents through material informatics platforms.

- Implementation of smart inventory management and logistics optimization to reduce storage costs and delivery lead times.

DRO & Impact Forces Of Methyl Naphthalene Market

The Methyl Naphthalene market is shaped by a confluence of driving factors (D), restraints (R), and opportunities (O), collectively acting as impact forces. The primary driver is the accelerating global infrastructure development, particularly the extensive use of naphthalene-based superplasticizers in large civil and commercial construction projects, demanding higher volumes of MN precursors. Concurrently, the increasing demand for specialized solvents in niche chemical processes and the robust growth in the agrochemicals sector, where MN derivatives function as effective emulsifiers and dispersants, further propel market expansion. These positive drivers establish a strong foundation for sustained revenue growth over the forecast period, linking the market directly to global economic health indicators.

However, the market faces significant restraints. Volatility in the price of crude oil and coal tar—the primary feedstocks—creates substantial cost unpredictability for manufacturers. Environmental regulations targeting polycyclic aromatic hydrocarbons (PAHs), including strict disposal and usage limits, particularly in developed regions like Europe, impose operational limitations and necessitate costly compliance measures. Furthermore, the rising adoption of alternative, non-naphthalene-based high-range water reducers (e.g., polycarboxylate ethers or PCEs) in the construction industry presents a competitive challenge, potentially capping the growth rate of traditional MN derivatives in certain applications.

Opportunities for market players include focusing on the development of bio-based Methyl Naphthalene production methods or utilizing cleaner synthesis routes to address environmental concerns and feedstock volatility. Additionally, expansion into high-growth, specialized applications, such as the use of high-purity MN in advanced battery electrolytes or specialized heat transfer fluids, offers premium market potential. The impact forces are currently skewed toward positive drivers due to overwhelming construction activity in APAC, but regulatory headwinds and the competitive threat from superior PCE technology require continuous technological adaptation and strategic diversification by key market participants to maintain competitive advantage and mitigate future risks.

Segmentation Analysis

The Methyl Naphthalene market is meticulously segmented based on purity grade, reflecting the specific end-use requirements, and by application, which details its diverse industrial consumption. Analyzing these segments provides crucial insight into the economic drivers and technological demands shaping the industry. The Purity Grade segmentation is vital because high-purity MN is essential for specialized chemical synthesis and analytical standards, while lower grades suffice for large-volume applications like solvent blending and basic intermediate use. Application segmentation highlights the construction industry's dominance through superplasticizers, closely followed by the requirements of the Dyes, Pigments, and Agrochemicals sectors, reflecting the product's fundamental role as a chemical building block and performance enhancer.

- Purity Grade: 90%, 95%, 98% and above (High Purity)

- Application: Dyes and Pigments, Surfactants, Plasticizers (Superplasticizers), Solvents, Agricultural Chemicals, Specialty Fuel/Reference Standards, Others

Value Chain Analysis For Methyl Naphthalene Market

The value chain for Methyl Naphthalene begins with the upstream sourcing and processing of raw materials, primarily coal tar (a byproduct of coke oven operations in the steel industry) and specific petroleum fractions. Key upstream activities involve the distillation and extraction of crude naphthalene oil, which contains methyl naphthalene isomers. Stability of supply in this phase is heavily dependent on the global metallurgical coke and crude oil markets. Major coal tar distillers hold significant leverage in the upstream segment, controlling the initial supply and pricing of the crude intermediate product, which requires sophisticated chemical processing for purity enhancement.

The midstream phase involves the specialized chemical processing, purification, and separation of the 1- and 2-methylnaphthalene isomers, crucial steps determining the final product grade. This phase requires significant capital investment in highly efficient fractional distillation and crystallization equipment. Market players often integrate upstream sourcing with midstream processing to optimize cost efficiencies and ensure quality control. Distribution channels for Methyl Naphthalene are complex, utilizing both direct and indirect models. Direct distribution is common for high-volume, long-term contracts with major industrial consumers, such as large construction chemical manufacturers or dedicated dye producers, ensuring supply reliability and technical support.

Downstream activities involve the conversion of purified MN into final products, such as naphthalene sulfonate condensates (superplasticizers), various textile dyes, high-performance surfactants, and specialized solvents. The market is significantly impacted by the performance of the construction and textile industries, which represent the largest end-user segments. Indirect distribution relies on regional chemical distributors and specialized traders who manage smaller volumes and cater to niche industrial applications or smaller geographical markets, providing logistical flexibility and localized inventory management, thereby completing the robust supply framework linking primary manufacturers to the diverse global end-user base.

Methyl Naphthalene Market Potential Customers

The potential customer base for Methyl Naphthalene spans several heavy and specialty industries, reflecting its utility as a versatile chemical intermediate and solvent. The construction chemicals sector represents the single largest group of potential customers, particularly manufacturers specializing in concrete admixtures, where Methyl Naphthalene derivatives are essential for producing high-range water reducers (superplasticizers) critical for modern, high-performance concrete mixes used in infrastructure projects and high-rise construction. Demand from this segment is cyclical but consistently high, tying customer procurement strategies directly to global housing starts and government infrastructure spending.

Another major customer segment includes chemical manufacturers focused on Dyes and Pigments. Methyl Naphthalene is a precursor for various azo dyes used in textile coloring and industrial coatings, requiring consistent, high-purity supply. Similarly, agrochemical companies are substantial buyers, utilizing MN derivatives as emulsifiers and dispersants to ensure the uniform distribution and effectiveness of pesticides and herbicides. These customers prioritize product consistency and regulatory compliance, necessitating secure, certified supply chains capable of handling bulk material delivery. The technical nature of these applications often leads to long-term supply agreements and partnerships.

Finally, niche customers include aviation and automotive testing laboratories that utilize high-purity 1-Methylnaphthalene as a critical reference fuel for cetane rating diesel fuels, ensuring standardization across the petroleum industry. Specialty chemical formulators also purchase MN for use as high-boiling, thermally stable solvents in specialized industrial processes, such as polymerization reactions or resin casting. These diverse applications demonstrate the product's criticality across a spectrum of industrial manufacturing, making stability and purity the core purchasing criteria for all potential customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 620.1 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Koppers Inc., Rain Carbon Inc., Mitsubishi Chemical Corporation, Crowley Chemical Company, China National Petroleum Corporation (CNPC), Shandong Junyu Chemical, JFE Chemical Corporation, Biloxxi Chemical, Nankai Chemical Co. Ltd., Rütgers Group (part of Rain Carbon), Eastman Chemical Company, BASF SE, Arkema S.A., Sinopec, ExxonMobil Chemical |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Methyl Naphthalene Market Key Technology Landscape

The technological landscape in the Methyl Naphthalene market is primarily focused on enhancing the efficiency of separation and purification processes, given that MN is derived from complex mixtures like coal tar or petroleum fractions. Advanced fractional distillation technologies, including high-vacuum and extractive distillation, are paramount for achieving the high purity grades (98% and above) demanded by specialty chemical manufacturers and analytical testing bodies. Continuous improvement in column design and energy recovery systems is a core technological trend, aiming to reduce the high operational costs associated with thermal separation processes, thereby enhancing cost competitiveness, particularly for bulk producers in APAC.

Another significant technological area involves the development and refinement of catalytic processes for synthesis and transformation. While most MN is sourced through distillation, there is ongoing research into catalytic alkylation processes that might offer greater control over isomer ratios and purity, especially for specialized derivatives. Furthermore, process intensification techniques, leveraging microreactors and enhanced mixing elements, are being explored to improve the yield and selectivity of sulfonated methyl naphthalene derivatives (superplasticizers), ensuring consistent product quality vital for the high-performance concrete industry. These technological advancements are critical for maintaining market relevance against competing technologies like polycarboxylate ethers.

Crucially, technology is also focused on environmental compliance and sustainability. Innovations in wastewater treatment and waste gas abatement specific to coal tar processing are becoming standard requirements, particularly in regions with stringent environmental oversight. Bio-based synthetic pathways, although still nascent, represent a future technological frontier. This involves exploring methods to derive methyl naphthalenes or similar high-solvency aromatic compounds from sustainable biomass feedstocks, potentially reducing reliance on fossil fuel derivatives and aligning with global decarbonization goals. Successful implementation of bio-based routes would fundamentally reshape the competitive landscape and address feedstock volatility concerns.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market leader, driven by massive public and private infrastructure spending, rapid urbanization, and a high concentration of textile and specialty chemical manufacturing. Countries like China and India are the largest consumers due to extensive use of naphthalene-based superplasticizers in large-scale construction. The region also hosts the largest installed capacity for coal tar distillation globally, ensuring cost-effective local supply.

- North America: This region maintains a stable demand, primarily concentrated in high-value, niche applications such as specialty solvents, jet fuel reference standards (driven by aviation industry requirements), and specific high-end agrochemical formulations. Growth is moderate, focusing on technological superiority and stringent environmental compliance, preferring high-purity grades.

- Europe: Characterized by mature industrial sectors and strict environmental regulations (REACH), the European market focuses on replacement demand and specialized applications. While construction demand remains a driver, the substitution risk from PCE-based admixtures is higher here. Companies prioritize sustainable sourcing and advanced regulatory compliance for market access.

- Latin America (LATAM): Growth in LATAM is tied to ongoing infrastructure modernization projects, particularly in Brazil and Mexico. The region relies heavily on imports of intermediate MN products, making its market susceptible to global pricing and logistics fluctuations. The agricultural sector is a significant end-user for dispersants.

- Middle East and Africa (MEA): Demand is largely dictated by large-scale energy sector projects and construction activities in the GCC states (Saudi Arabia, UAE). The market potential is growing, supported by ambitious urban development plans and increasing need for specialized construction chemicals to withstand harsh climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Methyl Naphthalene Market.- Koppers Inc.

- Rain Carbon Inc.

- Mitsubishi Chemical Corporation

- Crowley Chemical Company

- China National Petroleum Corporation (CNPC)

- Shandong Junyu Chemical

- JFE Chemical Corporation

- Biloxxi Chemical

- Nankai Chemical Co. Ltd.

- Rütgers Group (part of Rain Carbon)

- Eastman Chemical Company

- BASF SE

- Arkema S.A.

- Sinopec

- ExxonMobil Chemical

- Silver Fern Chemical, Inc.

- VWR International, LLC

- TCI Chemicals (India) Pvt. Ltd.

- Alfa Aesar (Thermo Fisher Scientific)

- Merck KGaA

Frequently Asked Questions

Analyze common user questions about the Methyl Naphthalene market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Methyl Naphthalene primarily used for in the industrial sector?

Methyl Naphthalene is principally used as a chemical intermediate in the synthesis of superplasticizers (concrete admixtures), high-performance dyes, pigments, and surfactants. It is also a critical, high-boiling solvent and the 1-methylnaphthalene isomer serves as a reference standard for determining the cetane number of diesel fuel.

Which purity grades of Methyl Naphthalene are most critical for the specialty chemical industry?

The specialty chemical industry, especially for advanced agrochemicals and electronics, requires high-purity Methyl Naphthalene, typically 98% and above. These higher grades minimize impurities that could interfere with complex chemical reactions or compromise final product performance and stability.

How do environmental regulations impact the Methyl Naphthalene Market?

Environmental regulations, particularly those concerning polycyclic aromatic hydrocarbons (PAHs), impose operational constraints and increase compliance costs for producers. These regulations drive demand for cleaner production processes and potentially favor bio-based or alternative substitutes in regions like Europe and North America.

What is the main alternative competition facing naphthalene-based superplasticizers?

The primary technological competition facing naphthalene-based superplasticizers (NSF) comes from polycarboxylate ethers (PCEs). PCEs generally offer superior water reduction efficiency and longer slump retention in concrete, leading to gradual substitution in high-specification construction projects globally.

Which geographical region accounts for the largest consumption of Methyl Naphthalene?

Asia Pacific (APAC) currently accounts for the largest consumption of Methyl Naphthalene, driven by unprecedented growth in infrastructure and construction activities in major economies such as China and India, which utilize high volumes of naphthalene sulfonate concrete admixtures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager