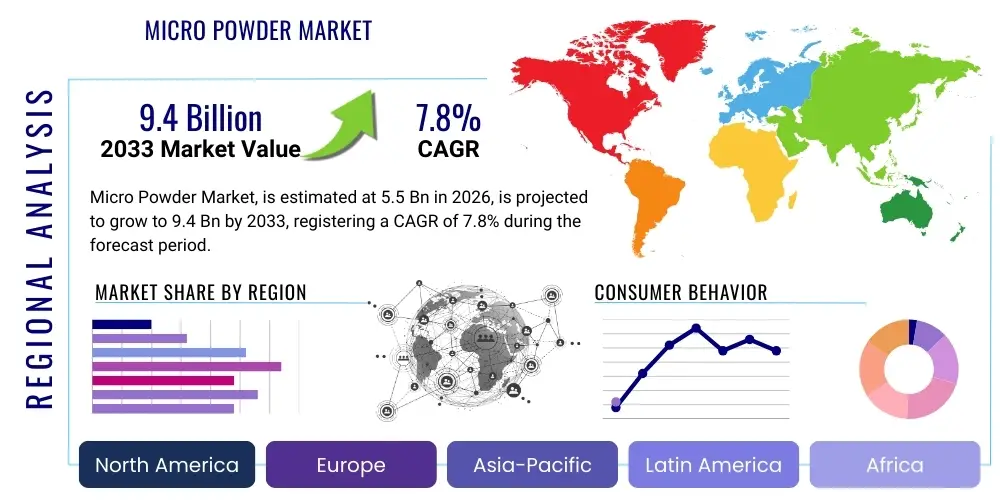

Micro Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443584 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Micro Powder Market Size

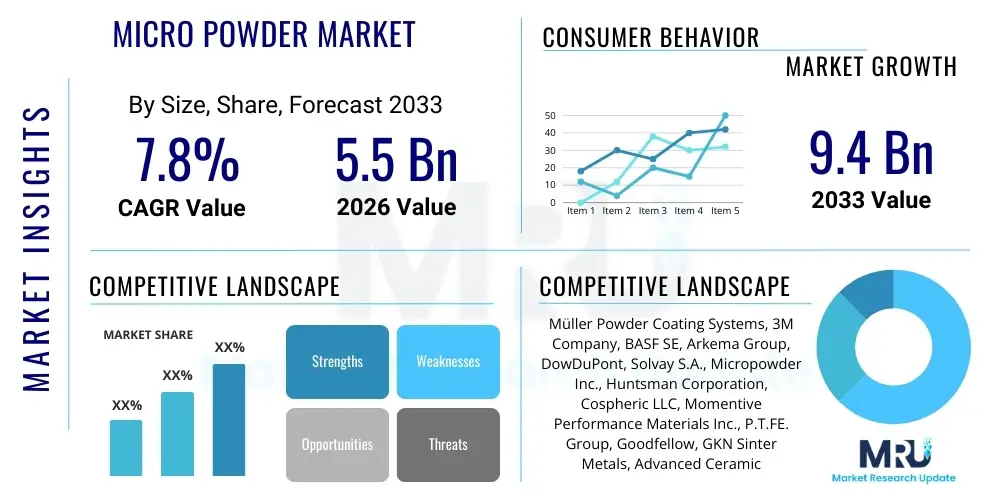

The Micro Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 5.5 Billion in 2026 and is projected to reach USD 9.4 Billion by the end of the forecast period in 2033. This substantial growth trajectory is primarily fueled by the increasing demand for high-performance materials across specialized industrial applications, particularly in advanced manufacturing and additive processes where fine particle size and uniform distribution are crucial for optimal product performance and integrity. The shift toward miniaturization in electronics and the necessity for enhanced durability and specific functional properties in automotive coatings further accelerate market expansion globally.

Micro Powder Market introduction

The Micro Powder Market encompasses finely ground materials with particle sizes typically ranging from 1 to 100 micrometers, spanning various material classes including polymers, ceramics, metals, and composites. These materials offer unique properties such as high surface area-to-volume ratio, enhanced reactivity, and superior structural integration capabilities, making them indispensable components in advanced industrial processes. Major applications include high-end protective coatings, specialized inks for electronics, powder metallurgy, additive manufacturing (3D printing), and pharmaceuticals, where precision delivery and material purity are paramount. The inherent benefits derived from micro powders—such as improved formulation stability, superior finish quality in paints, and enhanced strength in sintered parts—drive their adoption across sectors requiring stringent material specifications. Key driving factors include rapid technological advancements in micronization techniques, escalating demand from the burgeoning 3D printing industry which relies heavily on high-quality metal and polymer micro powders, and rigorous regulatory requirements pushing for lighter, more efficient components in transportation and energy sectors.

Micro Powder Market Executive Summary

The Micro Powder Market demonstrates robust growth, underpinned by fundamental shifts in manufacturing paradigms, particularly the move towards customization and performance enhancement. Business trends indicate a significant consolidation among specialized micronization service providers and raw material suppliers, aimed at ensuring stringent quality control and scaling production to meet global demand from sophisticated industries. Regional trends highlight Asia Pacific (APAC) as the epicenter of growth, driven by massive investments in electronics manufacturing and automotive production hubs in China, Japan, and South Korea, coupled with strong governmental support for R&D in advanced materials. North America and Europe, while mature, show steady growth fueled by demand for high-value micro powders in aerospace and medical device manufacturing. Segment trends point toward the polymeric micro powders segment experiencing the fastest growth rate, attributable to their versatility in coatings, cosmetics, and selective laser sintering (SLS) 3D printing. Simultaneously, the application of ceramic micro powders in thermal barrier coatings and advanced electronics substrates continues to secure its significant market share, reflecting the sustained need for materials capable of operating under extreme conditions.

AI Impact Analysis on Micro Powder Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is beginning to revolutionize the Micro Powder Market, addressing common user questions related to quality consistency, process efficiency, and predictive maintenance. Users frequently inquire about how AI can ensure narrow particle size distribution (PSD) repeatability, optimize energy consumption during comminution (grinding), and accelerate the discovery of novel micro powder compositions suitable for challenging applications like high-temperature alloys or biocompatible implants. The core themes revolve around leveraging AI for autonomous quality control, moving beyond traditional, slower laboratory analysis to real-time, in-line monitoring using vision systems and spectral data analyzed by ML algorithms. This promises to significantly reduce batch rejection rates, a major concern for manufacturers of high-purity micro powders, while simultaneously enabling faster iteration cycles in materials science R&D, thereby shortening the time-to-market for specialized powders.

Concerns often center on the initial investment costs associated with integrating complex AI infrastructure into existing manufacturing facilities and the need for highly specialized personnel to manage and interpret the generated data. However, expectations remain high, particularly concerning AI's ability to create digital twins of micronization processes. These digital representations allow operators to simulate the effects of changing process parameters—such as milling speed, temperature, and feed rate—on the final powder characteristics (morphology, surface energy, PSD), achieving 'right-first-time' manufacturing targets. This predictive capability is expected to significantly enhance operational expenditure efficiency and material utilization, especially critical for expensive metal and ceramic micro powders used in aerospace and medical applications. The ability of generative AI models to propose new material combinations for specific functional requirements, such as improved flowability in additive manufacturing, represents a transformative element for future market competitiveness.

- AI optimizes particle size distribution (PSD) control, ensuring batch consistency.

- Machine Learning algorithms enable predictive maintenance of grinding equipment, minimizing downtime.

- AI-driven image analysis provides real-time, autonomous quality inspection and defect detection.

- Generative AI accelerates the design and formulation of novel micro powder composites.

- Predictive modeling enhances yield optimization and reduces energy consumption in micronization processes.

DRO & Impact Forces Of Micro Powder Market

The Micro Powder Market dynamics are shaped by a complex interplay of powerful growth drivers, persistent operational restraints, and compelling future opportunities, which collectively constitute the critical impact forces steering industry development. Key drivers include the accelerated adoption of Additive Manufacturing (AM), which mandates extremely high-quality, spherical micro powders for processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM). Furthermore, the global push toward lightweight materials in the aerospace and automotive sectors, aimed at improving fuel efficiency and reducing emissions, necessitates micro powder coatings and advanced composite fillers. Restraints primarily involve the high capital expenditure required for advanced micronization equipment capable of achieving ultra-fine particle sizes with tight tolerances, coupled with the inherent complexities in handling highly reactive or combustible fine particulate matter, which elevates safety and operational costs. Regulatory scrutiny regarding dust control and worker exposure further complicates operations.

Opportunities for market players are substantial, particularly in emerging applications such as 5G electronics, where conductive polymer and metal micro powders are essential for flexible circuitry and heat dissipation solutions. The medical device sector offers significant growth potential, driven by demand for biocompatible ceramic and polymeric micro powders used in drug delivery systems, surgical coatings, and bio-scaffolds. Strategic focus on developing sustainable and bio-derived micro powders, addressing environmental concerns and supporting circular economy initiatives, presents a fertile ground for innovation and market differentiation. The impact forces indicate a market shifting toward specialization; the ability to produce highly customized micro powders with engineered surface chemistries, tailored for specific client performance criteria (e.g., flowability, dispersibility, thermal conductivity), will be the ultimate determinant of market leadership.

In essence, while technological complexity and regulatory burdens act as significant limiting factors, the transformative potential of micro powders in next-generation manufacturing techniques—especially in energy storage (batteries), advanced electronics, and personalized medicine—provides sufficient impetus to maintain a strong growth trajectory throughout the forecast period. Companies prioritizing innovation in particle manipulation and process efficiency will capture the highest value segments, mitigating the cost pressures associated with raw material sourcing and specialized processing.

Segmentation Analysis

The Micro Powder Market is intricately segmented based on material type, application, and end-use industry, reflecting the diverse functional requirements these specialized materials fulfill across the industrial landscape. Analysis of these segments is crucial for understanding specific growth pockets and technological preferences. Material type segmentation reveals the dominance of metal micro powders in high-strength applications like aerospace components and tool manufacturing, while polymer micro powders exhibit robust growth due to their use in advanced coatings, consumer goods, and 3D printing. Application segmentation highlights the critical role of micro powders in coatings, which require superior abrasion resistance and finish quality, and in additive manufacturing, where particle morphology directly dictates the quality and integrity of the final printed part. Furthermore, end-use industry analysis underscores the profound influence of the automotive and electronics sectors, which consume vast quantities of micro powders for components, circuits, and protective surfaces.

Detailed examination of the market reveals that advancements in micronization technology are enabling new sub-segments, such as functionalized micro powders, which are surface-treated to enhance specific properties like electrical conductivity, hydrophobicity, or catalytic activity. These functional materials are increasingly demanded by the advanced packaging and medical sectors. The diverse segmentation structure underscores the highly specialized nature of the micro powder business, where success often depends not just on volume production but on the ability to meet extremely rigorous, niche material specifications required by high-tech manufacturers. This necessity for specialization drives higher margins in segments focused on premium materials like ceramic oxides and precious metal micro powders.

- By Material Type:

- Polymer Micro Powders (e.g., Polyethylene, PTFE, Nylon, Acrylics)

- Metal Micro Powders (e.g., Aluminum, Copper, Titanium, Nickel Alloys, Stainless Steel)

- Ceramic Micro Powders (e.g., Alumina, Zirconia, Silicon Carbide)

- Composite Micro Powders

- By Application:

- Coatings and Paints

- Additive Manufacturing (3D Printing)

- Electronics and Electrical Components

- Lubricants and Greases

- Composites and Fillers

- Abrasives and Polishing Media

- Pharmaceuticals and Cosmetics

- By End-Use Industry:

- Automotive and Transportation

- Aerospace and Defense

- Electronics and Semiconductors

- Medical and Healthcare

- Construction and Infrastructure

- Consumer Goods

Value Chain Analysis For Micro Powder Market

The value chain for the Micro Powder Market is complex and highly specialized, beginning with the upstream sourcing of high-purity raw materials. This initial stage involves mining and refining operations for metals and ceramics, and chemical synthesis for polymers. Suppliers at this stage must ensure exceptional purity, as contaminants significantly compromise the performance of the final micro powder product, particularly in sensitive applications like electronics and medical devices. The core value addition occurs in the processing and manufacturing stage, involving sophisticated micronization techniques such as jet milling, ball milling, and spray drying, which require high levels of technical expertise and significant capital investment to achieve precise particle size distribution and morphology. Quality control is paramount here, utilizing advanced analytical tools for particle characterization.

The middle segment of the value chain involves formulation and modification. Processed micro powders are often surface-treated, functionalized, or mixed into specialized formulations, such as masterbatches or liquid suspensions, to enhance compatibility with specific end-use processes (e.g., improving flowability for 3D printing or dispersibility in solvent-based coatings). Distribution channels are bifurcated into direct sales for large, custom orders, primarily serving aerospace and large-scale additive manufacturers, and indirect sales through specialized chemical and material distributors who cater to smaller or geographically diverse end-users, such as regional coatings manufacturers or cosmetic formulators. The effectiveness of the supply chain relies heavily on logistics capable of handling fine powders safely and maintaining product integrity during transit.

The downstream analysis focuses on the integration of micro powders into final manufacturing processes. End-users—ranging from automotive OEMs applying specialized scratch-resistant coatings to medical device companies fabricating intricate surgical tools—demand technical support and reliability. This downstream activity drives innovation upstream, as end-user performance requirements, such as lightweighting in transportation or thermal management in electronics, dictate the particle specifications required from manufacturers. Profit margins tend to be highest for companies that successfully master the micronization of rare or specialized materials and those offering comprehensive technical consulting alongside their products, thereby controlling both the production and application knowledge within the value chain.

Micro Powder Market Potential Customers

The primary customers for micro powders span highly technical and performance-driven industries where material characteristics at the microscopic level are critical to product function and longevity. End-users in the Automotive and Transportation sector utilize micro powders extensively for high-performance friction materials, specialized engine components, and sophisticated exterior coatings that require enhanced UV resistance and scratch protection. The Aerospace and Defense industry represents a high-value customer base, demanding ultra-high-purity metal alloys and ceramic micro powders for critical structural parts, turbine coatings, and advanced thermal management systems, where failure is unacceptable and material integrity must be guaranteed under extreme conditions. Furthermore, the Electronics and Semiconductor industry consumes conductive and dielectric polymer and metal micro powders for printed circuit board manufacturing, advanced packaging materials, and thermal interface materials, driven by the continuous push toward miniaturization and high-speed signal processing.

Another significant customer segment is the Medical and Healthcare industry, which sources biocompatible micro powders for applications ranging from orthopedic implants (using titanium and ceramic powders) to advanced drug delivery systems (using polymeric micro particles). These buyers require strict adherence to regulatory standards (such as FDA and EMA guidelines) regarding toxicity, purity, and particle size consistency. The widespread adoption of Additive Manufacturing across multiple industries, including rapid prototyping services and direct manufacturing, positions AM bureaus and specialized manufacturing plants as exponentially growing customers, demanding tailored flow properties and high sphericity in their metallic and polymeric inputs. Essentially, any sector where product performance relies on precise material formulation, controlled surface properties, or high-definition manufacturing processes constitutes a key potential customer base for the Micro Powder Market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.5 Billion |

| Market Forecast in 2033 | USD 9.4 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Müller Powder Coating Systems, 3M Company, BASF SE, Arkema Group, DowDuPont, Solvay S.A., Micropowder Inc., Huntsman Corporation, Cospheric LLC, Momentive Performance Materials Inc., P.T.FE. Group, Goodfellow, GKN Sinter Metals, Advanced Ceramics Manufacturing, Höganäs AB, Sandvik AB, Kennametal Inc., Praxair Surface Technologies, Saint-Gobain, Kojundo Chemical Laboratory Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Micro Powder Market Key Technology Landscape

The technological landscape of the Micro Powder Market is dominated by advanced size reduction and particle engineering techniques, ensuring the production of materials with controlled morphology, narrow size distribution, and high purity. Crucial upstream technologies include specialized mechanical grinding methods, such as jet milling and air classifier milling, which utilize high-velocity gas streams to comminute materials, achieving particle sizes in the low micrometer range with minimal heat generation, which is essential for temperature-sensitive polymers. Another fundamental technique is spray drying, predominantly used for producing spherical ceramic and composite micro powders from liquid precursors, critical for achieving the high flowability required in Additive Manufacturing (AM) processes like Selective Laser Sintering (SLS) and metal Binder Jetting.

Downstream technological innovations focus heavily on particle surface modification and analysis. Surface treatment technologies, including plasma treatment and chemical vapor deposition (CVD), are increasingly employed to functionalize the surface of micro powders, enhancing properties like dispersion stability in liquid matrices or improving interfacial bonding with polymer resins. This functionalization capability is vital for creating high-performance composites and specialized coatings. Concurrently, advanced analytical instrumentation, such as Dynamic Light Scattering (DLS), automated image analysis systems, and high-resolution scanning electron microscopy (SEM), forms the backbone of quality control, allowing manufacturers to rapidly and accurately characterize particle size distribution, shape factors, and agglomeration tendencies, thereby guaranteeing consistency across large production batches. Investment in continuous processing technology, moving away from traditional batch processing, is also a key trend aimed at improving operational efficiency and scalability.

Furthermore, cryogenic grinding techniques have become indispensable for processing soft or elastic materials, such as certain polymers and rubbers, which are challenging to mill at ambient temperatures. By chilling the material to below its glass transition temperature using liquid nitrogen, the material becomes brittle, allowing for effective size reduction without degradation or agglomeration. The increasing digitalization of manufacturing, leveraging IoT sensors integrated into milling equipment, allows for real-time data collection on energy usage, vibration, and temperature, enabling manufacturers to employ the aforementioned AI/ML systems for predictive process optimization, ensuring that the micro powder characteristics meet the exacting standards of next-generation applications in semiconductors and precision engineering.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing and largest regional market, primarily driven by massive governmental and private sector investments in electronics manufacturing, electric vehicles (EVs), and expansive infrastructure development in countries like China, India, and South Korea. China’s dominance in electronics production and its surging aerospace industry necessitate huge volumes of specialized polymer and metal micro powders for components and coatings. The region benefits from lower manufacturing costs and a robust supply chain ecosystem, encouraging multinational corporations to establish production facilities here. Demand is particularly high for ceramic micro powders used in advanced multilayer ceramic capacitors (MLCCs) and for high-temperature polymer micro powders essential in consumer electronics casings and semiconductor fabrication.

- North America: North America holds a significant market share, characterized by its mature, high-value end-use sectors, notably Aerospace & Defense and Medical Devices. The US market is highly sophisticated, focusing on innovation in high-purity, custom-engineered micro powders for complex applications such as titanium and nickel-alloy powders for critical aircraft parts fabricated via metal Additive Manufacturing. Stringent regulatory environments in healthcare propel demand for traceable, biocompatible ceramic and polymeric micro powders. The region is a major hub for R&D in advanced materials, driving the development of specialized, low-volume, high-margin products.

- Europe: Europe is characterized by strong regulatory compliance and a focus on sustainable manufacturing, driving demand for environmentally friendly micro powders. Germany, with its strong automotive and precision engineering sectors, leads the regional consumption of metal and polymer micro powders for coatings, powder metallurgy, and engineering plastics. The market here is highly competitive, emphasizing quality, long-term performance, and adherence to REACH regulations. Growth is steady, fueled by investments in renewable energy infrastructure, which requires high-performance composite fillers and coatings to protect vital components.

- Latin America (LATAM): The LATAM market is nascent but exhibits growth potential, particularly in Brazil and Mexico, linked to expanding automotive assembly operations and infrastructure projects. The demand is currently focused on standard industrial micro powders for paints, coatings, and basic fillers, often relying on imports from Asian and North American manufacturers. As local industrialization matures, demand for specialized powders for domestic 3D printing services and advanced construction materials is expected to increase significantly, positioning it as an emerging opportunity area.

- Middle East and Africa (MEA): The MEA region is driven by large-scale construction activities and significant investment in the oil and gas sector, particularly in the GCC countries. Micro powders are utilized in high-performance anticorrosive coatings and specialized drilling fluids. The adoption of advanced micro powder technologies in this region is accelerating as part of economic diversification strategies away from reliance on hydrocarbons, particularly the push into localized manufacturing and advanced medical infrastructure development, though current market volumes remain lower than in mature regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Micro Powder Market.- Müller Powder Coating Systems

- 3M Company

- BASF SE

- Arkema Group

- DowDuPont

- Solvay S.A.

- Micropowder Inc.

- Huntsman Corporation

- Cospheric LLC

- Momentive Performance Materials Inc.

- P.T.FE. Group

- Goodfellow

- GKN Sinter Metals

- Advanced Ceramics Manufacturing

- Höganäs AB

- Sandvik AB

- Kennametal Inc.

- Praxair Surface Technologies

- Saint-Gobain

- Kojundo Chemical Laboratory Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Micro Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key drivers for the Micro Powder Market's growth?

The primary drivers are the exponential growth of the Additive Manufacturing (3D Printing) sector, the increasing need for lightweight and high-performance materials in automotive and aerospace industries, and the continuous demand for enhanced functionalities in advanced electronic devices and protective coatings.

Which material segment currently holds the largest market share in Micro Powders?

Metal micro powders, particularly those based on nickel alloys, titanium, and specialized stainless steels, typically hold a dominant share, driven by high-value applications in aerospace structural components and high-strength powder metallurgy processes.

How does particle size distribution (PSD) influence the performance of micro powders?

PSD is critical; a narrow and consistent PSD ensures uniform flowability for 3D printing, consistent film thickness in coatings, and predictable reactivity in chemical processes. Irregular PSD can lead to defects, lower mechanical strength, and poor finish quality in the final product.

What is the impact of environmental regulations on micro powder manufacturers?

Environmental regulations, particularly those concerning dust control and material safety (e.g., REACH), necessitate significant investments in specialized handling, ventilation systems, and dust suppression technologies, pushing manufacturers toward developing safer, bio-based, and non-toxic powder compositions.

Where is the highest growth expected for micro powder applications geographically?

Asia Pacific (APAC) is projected to experience the highest growth rate, fueled by rapid industrialization, massive electronics manufacturing output, and significant governmental investment in infrastructure and next-generation automotive industries across China, South Korea, and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- PTFE Micro Powder Market Size Report By Type (Monomer Polymerization, Resin Degradation), By Application (Industrial Plastics, Inks, Painting, Lubricants & Grease, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Micro Powder Abrasives Market Statistics 2025 Analysis By Application (Automotive, Machinery, Metal Fabrication, Electronics, Other), By Type (BFA, WFA, Pink, Solgel, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Micro Powder Market Statistics 2025 Analysis By Application (Paints& Coatings, Plastics, Inks), By Type (PE, PP), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager