Micronized Pea Flour Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441018 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Micronized Pea Flour Market Size

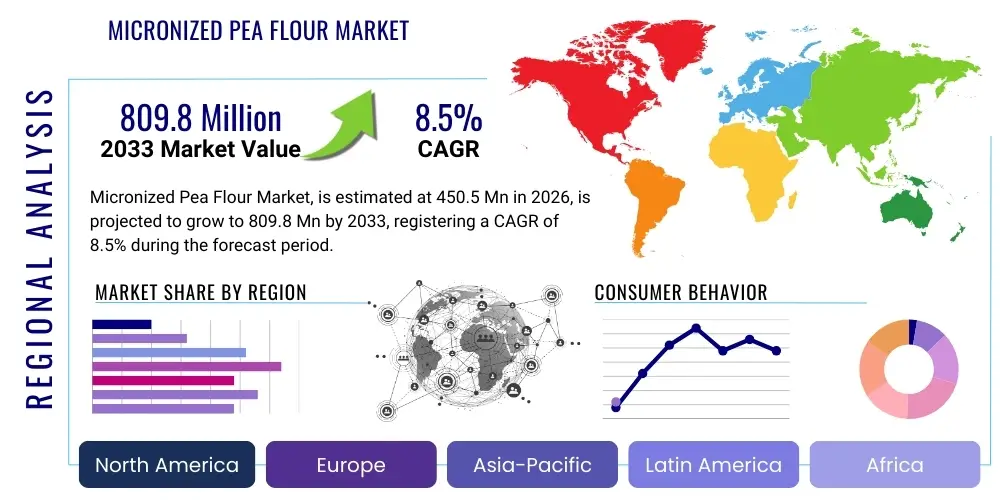

The Micronized Pea Flour Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 809.8 Million by the end of the forecast period in 2033.

Micronized Pea Flour Market introduction

Micronized pea flour represents a highly refined derivative of yellow peas, produced through advanced milling and particle size reduction technologies. This specialized ingredient capitalizes on the rising global demand for sustainable, high-protein, and allergen-friendly food components. The micronization process significantly reduces the particle size of traditional pea flour, enhancing its functional properties such as water binding capacity, emulsification, and solubility, which are critical for seamless integration into complex food matrices. This ultra-fine particle structure minimizes grittiness and improves the textural profile of end products, making it a preferred choice over standard pea flour in premium formulations.

The primary applications of micronized pea flour span across the dynamic segments of plant-based meats, gluten-free baked goods, nutritional supplements, and functional beverages. Its neutral flavor profile, when compared to other plant proteins, allows for greater versatility in formulation, especially in applications where flavor masking is challenging. Furthermore, micronized pea flour is valued for its excellent nutritional composition, providing a rich source of essential amino acids and dietary fiber, contributing significantly to consumer health and wellness trends. The intrinsic benefits, including non-GMO status, natural origin, and sustainability credentials, strongly position it as a key driver in the clean-label movement within the global food industry.

Key driving factors accelerating market adoption include the exponential growth in flexitarian and vegan populations seeking protein alternatives, coupled with increasing regulatory support for sustainable agricultural practices. Consumer awareness regarding the environmental impact of traditional protein sources is shifting purchasing habits towards plant-derived ingredients. Moreover, continuous innovation in micronization technology, which allows for consistent quality and functional tailoring of the flour, enables food manufacturers to develop next-generation products that meet stringent consumer demands for taste, texture, and nutritional value. This synergy of consumer demand, technological advancement, and nutritional benefits establishes micronized pea flour as a fundamental building block in modern food systems.

Micronized Pea Flour Market Executive Summary

The Micronized Pea Flour Market is characterized by robust expansion, primarily fueled by the paradigm shift in global dietary patterns towards plant-centric nutrition and the escalating prevalence of gluten intolerance. Business trends indicate significant capital investment in capacity expansion by key players, focusing particularly on regions like North America and Europe, which possess mature infrastructure for plant-based food production and high consumer acceptance rates. Strategic alliances between pea processors and major multinational food and beverage corporations are becoming commonplace, aimed at securing consistent supply chains and driving innovation in co-formulation. Furthermore, the emphasis on vertical integration—from raw material sourcing to final micronization—is a prevailing trend adopted by market leaders to ensure quality control and optimize operational costs, crucial for maintaining competitive pricing in a rapidly evolving market landscape.

Regionally, North America maintains the dominant market share, driven by a highly established vegan consumer base and aggressive product development in the alternative meat sector. Europe follows closely, benefiting from stringent clean-label legislation and strong governmental promotion of sustainable proteins under initiatives like the European Green Deal. Asia Pacific (APAC) is projected to record the highest growth rate, primarily attributed to increasing disposable incomes, westernization of diets, and rising demand for fortified and functional foods in populous nations like China and India. The regional expansion strategies are heavily focused on tailoring product specifications, such as heat stability and water absorption, to local culinary requirements, thereby ensuring broader market penetration.

Segment trends highlight the dominance of the food and beverage sector, specifically within extruded snacks, bakery applications, and dairy alternatives, due to the functional advantages offered by micronized particles. The application in sports nutrition and clinical nutrition is also witnessing accelerated uptake, leveraging the high protein digestibility and hypoallergenic nature of pea flour. By source, yellow pea remains the primary raw material, but research into green pea varieties for specialized coloration and nutritional profiles is gaining momentum. These segment trajectories underscore a market moving beyond simple protein replacement to becoming a sophisticated functional ingredient vital for clean-label, high-performance food products across the global value chain.

AI Impact Analysis on Micronized Pea Flour Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Micronized Pea Flour Market typically revolve around optimizing supply chain resilience, predicting volatile commodity pricing, and accelerating novel product formulation tailored to regional consumer preferences. Consumers and industry stakeholders are keen to understand how AI-driven predictive analytics can mitigate risks associated with crop yields and seasonal variability of yellow peas, ensuring stable input costs for manufacturers. There is also significant interest in AI's role in fine-tuning the micronization process itself—specifically, using machine learning algorithms to optimize milling parameters (e.g., speed, temperature) to achieve precise particle size distribution and enhanced functionality (such as improved emulsification or reduced anti-nutritional factors) with minimal energy expenditure. Furthermore, inquiries focus on leveraging AI to analyze massive datasets related to consumer sensory perception, enabling rapid iteration and customization of micronized pea flour blends for plant-based products, thereby reducing time-to-market for successful new food formulations.

- AI-driven precision agriculture optimizes pea crop yields and quality, improving raw material consistency.

- Predictive analytics forecasts volatile commodity pricing, enabling proactive procurement strategies and cost stabilization.

- Machine learning algorithms optimize micronization equipment settings for tailored particle size distribution and superior functionality.

- AI enhances quality control through real-time image analysis of flour samples, ensuring uniform texture and purity.

- Generative AI accelerates new product development by simulating formulation outcomes and identifying optimal ingredient ratios for taste and texture improvement.

- Advanced algorithms analyze consumer sensory data and flavor preference maps, guiding targeted R&D efforts for regional market penetration.

- Supply chain optimization using AI minimizes logistics costs and enhances traceability from farm to processor, bolstering sustainability claims.

DRO & Impact Forces Of Micronized Pea Flour Market

The market for micronized pea flour is significantly shaped by a confluence of accelerating drivers (D) related to health and sustainability, critical restraints (R) tied to processing and sensory attributes, and substantial opportunities (O) arising from technological breakthroughs and emerging market demands. The primary driving forces include the burgeoning global trend of protein diversification, where consumers actively seek alternatives to soy and dairy due to allergen concerns or ethical reasons. Simultaneously, the imperative for clean-label ingredients, minimizing artificial additives and prioritizing natural sourcing, strongly favors micronized pea flour. However, the market faces constraints such as the inherent challenges of flavor masking, as pea protein can possess slight earthy or beany notes that require sophisticated processing solutions, alongside price volatility and supply chain dependence on agricultural output. The overall market dynamics are impacted by strong competitive rivalry and the critical need for continuous investment in processing efficiency to maintain cost-effectiveness and product differentiation.

The core Drivers stem from demographic shifts and public health mandates. The rise in cardiovascular diseases and obesity, coupled with the increasing focus on preventive nutrition, elevates the demand for high-fiber, low-glycemic, and protein-rich ingredients. Furthermore, the proven environmental superiority of pea cultivation compared to livestock farming resonates strongly with environmentally conscious consumers and corporate sustainability goals. These drivers create a compelling necessity for food manufacturers to integrate sustainable protein sources, solidifying the market position of micronized pea flour as an essential ingredient for future-proof food production. Government initiatives promoting pulse cultivation and reducing environmental footprints further amplify these driving forces, turning consumer preference into mainstream industry practice.

Opportunities for market growth are expansive, particularly in developing novel applications beyond core segments. This includes customized flour blends for specialized therapeutic diets, such as those targeting sarcopenia or managing diabetes, and leveraging the flour's unique binding and textural properties in 3D food printing technology. Geographically, untapped potential in Southeast Asia and parts of Latin America, where plant-based diets are culturally accepted but industrial processing is nascent, offers significant market entry points. The ability to overcome current restraints through advanced enzymatic hydrolysis or microencapsulation techniques to eliminate off-flavors represents a major opportunity for companies aiming for market leadership, allowing them to capture the high-end functional food segment.

- Drivers: Exponential growth in plant-based food consumption; High nutritional profile (protein, fiber); Clean label ingredient status; Non-GMO and non-allergen advantages over soy/wheat; Regulatory promotion of sustainable protein sources.

- Restraints: Raw material price fluctuation based on agricultural yield; Technical challenges in flavor masking and achieving ultra-smooth texture; High initial investment cost for advanced micronization equipment; Competition from other pulse flours (e.g., lentil, chickpea).

- Opportunities: Expansion into novel fortified food applications (e.g., baby food, elderly nutrition); Development of optimized functional blends for specific industrial applications (e.g., high-shear mixing); Market penetration in emerging APAC and MEA regions; Utilization of advanced enzymatic treatment for improved digestibility and functionality.

- Impact Forces: Strong regulatory oversight on food safety and labeling; Disruptive innovation in processing technologies (e.g., ultra-fine milling, air classification); Intense competitive rivalry among established ingredient suppliers; Shifting consumer perception towards taste and texture parity with animal-based products.

Segmentation Analysis

The Micronized Pea Flour market is comprehensively segmented based on its source material, primary application areas, distribution channels, and geographical reach. Segmentation by source is critical, differentiating between yellow pea and green pea, where yellow pea dominates due to its widespread availability and slightly more neutral color profile, making it highly suitable for general food manufacturing. Application-based segmentation reveals the market's reliance on the Food & Beverage industry, which is further subdivided into plant-based meat substitutes, bakery and confectionery, snacks and cereals, and beverages, reflecting the ingredient’s multifunctional role in product structuring and nutritional enhancement. Understanding these segments provides manufacturers with targeted strategies for product development and market positioning, aligning functional attributes with specific industrial needs and consumer demands.

The structure of distribution channels, ranging from direct B2B sales to ingredient distributors and finally to end-product manufacturers, defines the operational efficiency and logistical challenges within the market. Direct sales are often preferred for large-volume contracts requiring highly customized specifications, such as tailored particle sizes for precision bakery applications. Conversely, the market is regionally segmented across key mature markets like North America and Europe, which lead in innovation and consumption volume, and high-growth potential regions such as Asia Pacific, where localized sourcing and culturally appropriate formulations are paramount for success. This granular segmentation approach aids in uncovering niche market opportunities, such as the increasing demand for organic and non-GMO certified micronized pea flour within specific geographical pockets.

- By Source:

- Yellow Pea

- Green Pea

- By Application:

- Plant-Based Meat Substitutes

- Bakery and Confectionery

- Nutritional Supplements (Sports & Clinical)

- Snacks and Cereals

- Beverages and Dairy Alternatives

- By Distribution Channel:

- Direct Sales (B2B)

- Distributors/Ingredient Suppliers

- Online Channels

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain)

- Asia Pacific (China, India, Japan, Australia)

- Latin America (Brazil, Argentina)

- Middle East and Africa (South Africa, GCC Countries)

Value Chain Analysis For Micronized Pea Flour Market

The value chain for micronized pea flour is complex and highly specialized, beginning with agricultural production (upstream analysis) and extending through sophisticated processing (midstream) to final application and consumer consumption (downstream analysis). Upstream activities involve the cultivation and harvesting of high-quality yellow or green peas, demanding stringent control over agricultural practices to ensure non-GMO compliance and minimal pesticide residue, which are crucial for clean-label market acceptance. Key factors at this stage include seed selection, sustainable farming techniques, and efficient large-scale storage to manage seasonal availability. The success of the initial stage significantly determines the functional quality and yield efficiency during the subsequent processing phases.

The midstream processing stage is where significant value addition occurs. This involves cleaning, dehulling, and then the critical processes of milling and micronization, often utilizing advanced air classification and jet milling technologies to achieve particle sizes in the low micron range (typically less than 100 micrometers). Further refinement processes, such as protein concentration (if required) and flavor optimization techniques (enzymatic treatments or controlled drying), dictate the final functional attributes of the flour. Direct and indirect distribution channels play a vital role here; manufacturers often employ direct B2B sales to large food processors who require specific technical support and customized products, while utilizing specialized ingredient distributors (indirect channels) to reach smaller and medium-sized enterprises across diverse geographical locations.

Downstream analysis focuses on the integration of micronized pea flour into final consumer products. Major buyers include manufacturers in the plant-based meat sector who utilize the flour for binding and texturization, bakery companies leveraging its gluten-free structure, and nutraceutical firms valuing its high protein content. The effectiveness of the distribution channel relies heavily on specialized logistics capable of handling bulk food ingredients, ensuring quality maintenance, and complying with international food safety standards. The efficiency of this value chain, from sustainable sourcing to final product formulation, is paramount for securing consistent quality and competitive cost structures necessary for sustained market growth and consumer trust.

Micronized Pea Flour Market Potential Customers

The potential customer base for micronized pea flour is broad and rapidly expanding, primarily categorized into three core industries: Food & Beverage, Nutraceuticals, and Specialized Animal Feed. Within the Food & Beverage sector, key customers are those driving the plant-based revolution—specifically, manufacturers of meat analogs (e.g., burgers, sausages, crumbles) who require highly functional binding agents and protein extenders that offer superior texture and water retention compared to standard flours. Additionally, gluten-free bakery producers are substantial buyers, utilizing micronized pea flour to improve dough structure and crumb texture in products traditionally reliant on wheat gluten, while simultaneously boosting protein content for enhanced nutritional profiles.

The Nutraceuticals and Dietary Supplements segment represents a high-growth customer area. Companies specializing in sports nutrition, weight management, and clinical dietary supplements seek micronized pea flour for its high protein digestibility score (PDCAAS), hypoallergenic status, and suitability for incorporating into protein powders, meal replacement drinks, and energy bars. The ultra-fine particle size is particularly advantageous here as it ensures minimal sedimentation and a smooth mouthfeel in liquid applications, addressing a major sensory hurdle often associated with plant protein supplements. This segment values purity, non-GMO verification, and clinical efficacy data.

Furthermore, specialized segments within the animal feed industry, particularly premium pet food and aquaculture feed manufacturers, are emerging as significant potential customers. They use micronized pea flour as a high-quality, sustainable protein source to replace traditional ingredients like fishmeal or soy in specialty feed formulations. These end-users prioritize the ingredient's consistent quality, high nutrient density, and non-allergenic properties to meet the growing consumer demand for premium, scientifically formulated pet nutrition. The diversity of these end-user segments underscores the ingredient's versatility and its fundamental role in addressing various nutritional and functional requirements across multiple industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 809.8 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Roquette Frères, Ingredion Incorporated, Puris, Emsland Group, Axiom Foods, Fenchem, Batory Foods, AGT Food and Ingredients, Shandong Jianyuan Foods Co. Ltd., Yantai Shuangtai Food Co. Ltd., The Scoular Company, Vestkorn Milling, Farbest Brands, Parabel USA Inc., BiPro Global, NutriPea Ltd., Merit Functional Foods, GEMEF Industries, A&B Ingredients, Bulk Nutrients. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Micronized Pea Flour Market Key Technology Landscape

The technological landscape underpinning the production of high-quality micronized pea flour is highly sophisticated and centers on achieving precise particle size reduction and enhanced functional properties. The core technology utilized is advanced dry-milling and particle classification, often involving air jet mills or mechanical attrition mills. These systems are specifically engineered to process the dry pea material into an ultra-fine powder (typically under 50 microns) without generating excessive heat that could denature the protein or impair its functional characteristics. Precision in micronization is paramount because particle size directly correlates with sensory attributes, such as grittiness, and functional metrics, including water solubility and oil holding capacity, which are vital for application success in beverages and emulsion systems.

Beyond the physical reduction of particle size, the technology landscape includes innovative methods aimed at flavor modification and anti-nutritional factor reduction. Techniques such as enzyme-assisted processing or controlled thermal treatment are being integrated post-milling to mitigate the inherent 'beany' or earthy off-flavors associated with raw pea derivatives. Furthermore, specialized separation technologies, notably air classification, are employed to separate the micronized flour particles based on density and aerodynamic behavior, allowing manufacturers to create customized fractions—some richer in protein, others in starch—to meet diverse industrial requirements. These processes require precise sensors and monitoring systems to ensure consistency across large batches, driving the integration of AI and machine learning for predictive quality control.

The emerging technological focus is on developing sustainable and energy-efficient processing methodologies. High-pressure processing (HPP) and novel enzymatic hydrolysis techniques are being explored not only to improve flavor and digestibility but also to enhance the bioavailability of key micronutrients present in the pea. Manufacturers are investing heavily in technologies that allow for particle surface modification—such as microencapsulation—to further protect functional components, improve shelf stability, and ensure seamless dispersion in complex food systems. The ultimate goal of this technological evolution is to transform raw pea material into a truly versatile, tasteless, and highly functional ingredient that seamlessly replaces conventional non-plant-based options in mainstream food formulations.

Regional Highlights

The global Micronized Pea Flour Market exhibits distinct geographical consumption and production patterns, with North America and Europe dominating consumption volume, while the Asia Pacific region emerges as the fastest-growing market. North America, specifically the United States and Canada, holds the leading position due to its established infrastructure for plant-based food manufacturing, strong consumer acceptance of meat alternatives, and the presence of major food tech startups focusing heavily on plant protein innovation. Regulatory environments in these regions strongly support the labeling and marketing of clean-label and non-GMO ingredients, providing a fertile ground for market expansion. The high per capita expenditure on fortified foods and dietary supplements further solidifies North America’s market leadership.

Europe represents the second largest market, driven by consumer concerns over sustainability, animal welfare, and a high incidence of gluten and lactose intolerance. Countries such as Germany, the UK, and the Netherlands are pivotal, characterized by strong governmental support for transitioning to a circular bio-economy and promoting domestic pulse cultivation. European manufacturers often prioritize highly functional, organically certified micronized pea flour to meet stringent quality and provenance requirements. The European market is characterized by fierce competition and a strong emphasis on continuous functional improvement, particularly in reducing anti-nutritional factors and improving solubility for dairy alternative applications.

Asia Pacific (APAC) is projected to showcase superior growth during the forecast period. While traditional diets in many APAC countries are already plant-heavy, the increasing westernization of food consumption, rising middle-class disposable income, and growing awareness of protein inadequacy are boosting demand for processed, high-protein ingredients like micronized pea flour. China and India are the primary growth engines, driven by massive domestic food manufacturing industries seeking cost-effective, sustainable, and functional alternatives to traditional soy-based proteins. However, market success in APAC requires adaptation to local regulatory frameworks and catering to regional palate preferences, necessitating tailored product formulations and local sourcing strategies.

- North America: Market leader; High consumption in plant-based meats and sports nutrition; Driven by extensive R&D and established vegan consumer base.

- Europe: Strong second position; Focus on clean label, sustainability, and organic certification; Strict regulatory standards influencing product quality.

- Asia Pacific (APAC): Fastest-growing region; Expansion driven by urbanization, rising health awareness, and demand for fortified foods in China and India.

- Latin America (LATAM): Emerging market; Growth tied to increasing industrial food processing capabilities and economic stability in Brazil and Mexico.

- Middle East & Africa (MEA): Niche market; Uptake concentrated in specialized functional foods and fortified products, leveraging import capabilities in GCC countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Micronized Pea Flour Market.- Roquette Frères

- Ingredion Incorporated

- Puris

- Emsland Group

- Axiom Foods

- Fenchem

- Batory Foods

- AGT Food and Ingredients

- Shandong Jianyuan Foods Co. Ltd.

- Yantai Shuangtai Food Co. Ltd.

- The Scoular Company

- Vestkorn Milling

- Farbest Brands

- Parabel USA Inc.

- BiPro Global

- NutriPea Ltd.

- Merit Functional Foods

- GEMEF Industries

- A&B Ingredients

- Bulk Nutrients

Frequently Asked Questions

Analyze common user questions about the Micronized Pea Flour market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is micronized pea flour and how does it differ from standard pea flour?

Micronized pea flour is produced using advanced milling techniques to achieve an ultra-fine particle size, typically less than 100 microns. This fine consistency significantly improves functional properties, such as water solubility, emulsification, and reduces grittiness, making it superior for use in smooth beverages and high-end texture applications compared to standard, coarser pea flour.

What are the primary health benefits associated with consuming micronized pea flour?

It is a highly nutritious, complete vegetable protein source, rich in essential amino acids and dietary fiber. It is naturally non-GMO, gluten-free, and hypoallergenic, supporting muscle building, satiety, and digestive health, making it ideal for individuals with common food sensitivities.

In which food applications is micronized pea flour most effectively utilized?

Micronized pea flour is critically important in the production of plant-based meat substitutes, where it acts as a binder and protein fortifier. Its smooth texture also makes it essential for gluten-free baked goods, nutritional bars, and protein-fortified beverages requiring minimal sedimentation.

How is the taste profile of micronized pea flour managed in final food products?

Through advanced processing, including specialized milling and enzymatic treatments, manufacturers actively work to minimize the inherent earthy or 'beany' notes. This flavor neutrality is key for its successful integration into sensitive food matrices like dairy alternatives and sports nutrition products without requiring significant flavor masking.

Which geographical region exhibits the highest growth potential for this market?

The Asia Pacific (APAC) region is projected to demonstrate the fastest growth rate, driven by escalating consumer demand for high-protein, functional foods, increasing disposable incomes, and the rapid industrialization of the food processing sector in major economies such as China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager