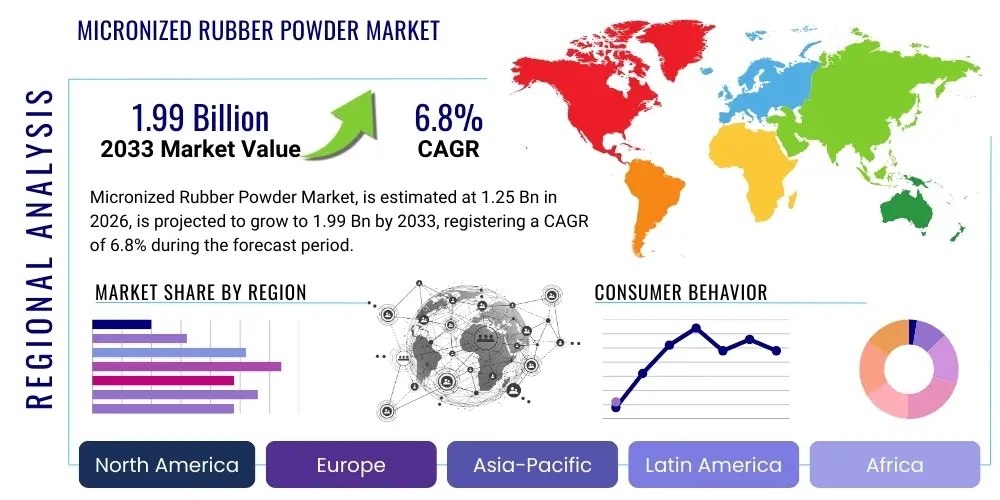

Micronized Rubber Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440833 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Micronized Rubber Powder Market Size

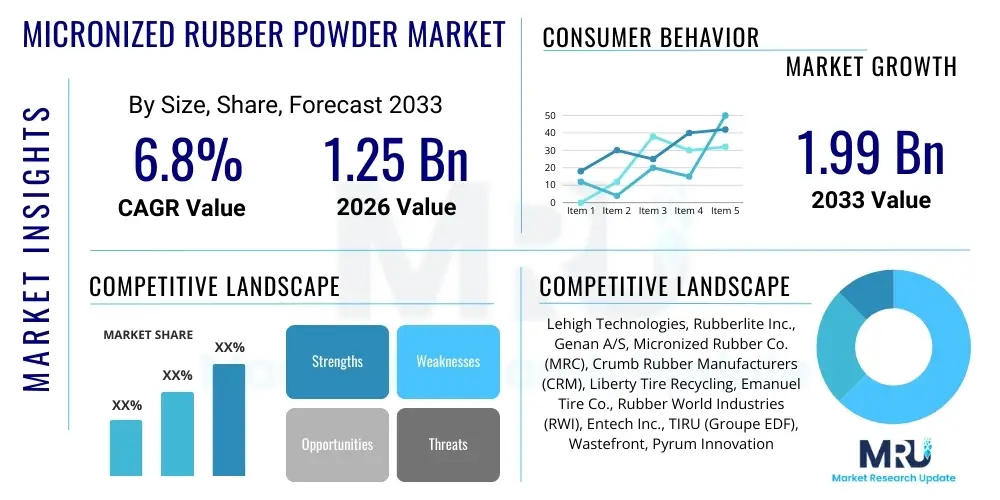

The Micronized Rubber Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.99 Billion by the end of the forecast period in 2033.

Micronized Rubber Powder Market introduction

The Micronized Rubber Powder (MRP) market is an evolving segment within the broader rubber industry, primarily driven by increasing environmental concerns and the growing demand for sustainable materials. MRP refers to finely ground rubber particles, typically derived from recycled tires or other industrial rubber waste, processed to a specific mesh size for various industrial applications. This innovative material serves as a cost-effective and environmentally friendly alternative to virgin polymers, finding extensive use in improving the properties of new rubber compounds, plastics, asphalt, and construction materials. Its application helps to enhance tear strength, abrasion resistance, and overall durability of end products while simultaneously reducing raw material costs and minimizing waste disposal.

The product, Micronized Rubber Powder, is characterized by its small particle size, which allows for homogenous dispersion within various matrices. This fineness is achieved through advanced processing techniques such as cryogenic grinding or ambient mechanical grinding, ensuring consistent quality and performance. The primary source material for MRP is End-of-Life Tires (ELTs), which are repurposed through a multi-stage process involving shredding, granulation, and micronization. This not only diverts massive quantities of waste from landfills but also transforms a problematic waste stream into a valuable resource, aligning with circular economy principles and bolstering resource efficiency across multiple industrial sectors.

Major applications for MRP span a diverse range of industries including automotive, construction, footwear, and consumer goods. In the automotive sector, MRP is incorporated into new tire formulations, sealing systems, and anti-vibration components to enhance performance and reduce manufacturing costs. Within construction, it improves the elasticity, durability, and sound dampening properties of asphalt, roofing materials, and flooring. Benefits extend beyond cost reduction and environmental stewardship, encompassing improved product performance, reduced energy consumption in manufacturing processes due to lower mixing temperatures, and greater material compatibility. These multifarious advantages are significant drivers propelling market expansion and encouraging broader adoption across various industrial landscapes.

Micronized Rubber Powder Market Executive Summary

The Micronized Rubber Powder (MRP) market is experiencing robust growth, propelled by a confluence of business trends emphasizing sustainability, cost-efficiency, and performance enhancement. Businesses are increasingly seeking alternatives to virgin rubber and plastic materials to meet stringent environmental regulations and corporate social responsibility goals. This has led to a surge in demand for recycled content, with MRP emerging as a key solution. Furthermore, the economic advantage of using MRP, which typically offers a lower price point than primary raw materials, is highly attractive to manufacturers looking to optimize their production costs without compromising on product quality. Innovations in processing technologies, such as advanced cryogenic grinding and surface treatment methods, are also contributing to the market's expansion by improving the quality and versatility of MRP, making it suitable for a wider array of high-performance applications and thus driving significant business investments.

Regionally, the market exhibits varied dynamics, with robust growth observed in established industrial economies alongside burgeoning demand in emerging markets. North America and Europe are leading the adoption of MRP, primarily due to their mature recycling infrastructures, stringent environmental policies, and a strong emphasis on sustainable manufacturing practices. These regions benefit from advanced research and development activities focused on expanding MRP applications and improving processing efficiencies. Conversely, the Asia Pacific region, particularly countries like China and India, is emerging as a significant growth hub, driven by rapid industrialization, increasing automotive production, and a growing awareness of environmental sustainability. The sheer volume of waste tires generated in these highly populated areas also provides a substantial feedstock source, further fueling regional market expansion and investment opportunities.

Segmentation trends within the MRP market highlight key areas of focus and innovation. By type, cryogenically ground MRP is gaining traction due to its finer particle size and superior surface characteristics, offering enhanced performance in demanding applications compared to ambient ground rubber. Application-wise, the automotive sector remains the largest consumer, primarily for tire manufacturing and other rubber components, but construction and industrial product sectors are demonstrating accelerated growth as the benefits of MRP in asphalt modification, roofing membranes, and anti-vibration pads become more widely recognized. The trend towards higher mesh sizes, indicating finer powders, also signifies a move towards more sophisticated applications requiring precise material properties. This granular analysis of market segments underscores the diverse opportunities and specific pathways for future growth within the Micronized Rubber Powder industry, guiding strategic development and product diversification efforts.

AI Impact Analysis on Micronized Rubber Powder Market

The integration of Artificial Intelligence (AI) and machine learning technologies is poised to significantly transform the Micronized Rubber Powder (MRP) market by optimizing production processes, enhancing product quality, and improving supply chain efficiencies. Common user questions related to AI's impact often revolve around how it can ensure consistency in particle size distribution, improve feedstock segregation, predict market demand for recycled rubber, and automate quality control. Users are keen to understand how AI can lead to more efficient energy consumption during grinding, optimize equipment maintenance schedules, and facilitate the development of novel MRP applications by analyzing complex material interaction data. There is also considerable interest in AI's role in enabling smart logistics for waste tire collection and distribution, ultimately contributing to a more robust, predictable, and sustainable MRP value chain.

- AI can significantly optimize the cryogenic and ambient grinding processes by analyzing real-time sensor data from machinery, adjusting parameters such as temperature, feed rate, and motor speed to achieve consistent particle size distribution and desired mesh characteristics, thereby improving product quality and reducing energy consumption.

- Predictive analytics powered by AI can forecast market demand for various grades of MRP across different industries, allowing manufacturers to optimize production schedules, manage inventory more effectively, and reduce waste associated with overproduction or shortages.

- AI-driven quality control systems, utilizing computer vision and advanced analytics, can rapidly inspect and classify incoming waste tire feedstock, identifying contaminants and ensuring optimal material input for micronization, which is crucial for producing high-quality and consistent MRP.

- Machine learning algorithms can analyze vast datasets related to material properties and performance in various applications, accelerating research and development efforts to create new formulations and discover novel uses for MRP, thus expanding its market potential and value.

- AI can enhance supply chain logistics for waste tire collection and MRP distribution by optimizing routes, managing fleet maintenance, and predicting potential disruptions, leading to more efficient operations, reduced transportation costs, and a more reliable supply of raw materials and finished products.

- Furthermore, AI tools can facilitate better understanding of customer needs and preferences by analyzing feedback and market trends, enabling MRP producers to tailor products and services more effectively, thereby enhancing customer satisfaction and fostering stronger market relationships.

DRO & Impact Forces Of Micronized Rubber Powder Market

The Micronized Rubber Powder (MRP) market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively shape its trajectory and impact forces. A primary driver is the accelerating global emphasis on environmental sustainability and circular economy principles, prompting industries to seek eco-friendly alternatives to virgin materials. Strict regulations on waste tire disposal in many countries compel recycling initiatives, making MRP a viable and valuable output from this waste stream. The cost-effectiveness of MRP compared to virgin rubber polymers also acts as a significant driver, allowing manufacturers to reduce raw material expenses while often improving specific performance attributes of their final products. Furthermore, the inherent benefits of MRP, such as enhanced sound absorption, improved wear resistance, and increased elasticity when incorporated into various matrices, continually broaden its appeal across diverse application sectors like automotive, construction, and footwear, creating sustained demand.

Despite these strong drivers, the MRP market faces several restraints. One major challenge is the inconsistency in the quality and composition of waste tire feedstock, which can lead to variability in the properties of the resulting MRP, making it difficult for manufacturers to guarantee uniform product performance. The high capital investment required for advanced micronization technologies, particularly cryogenic grinding equipment, also poses a barrier to entry for new players, limiting market competition and expansion. Furthermore, a lack of widespread awareness and understanding among potential end-users regarding the full capabilities and benefits of MRP can hinder its adoption, as some industries remain hesitant to substitute traditional materials without extensive validation. Competition from other recycled materials or cheaper virgin alternatives in certain applications also presents a continuous challenge, necessitating ongoing innovation and value demonstration from MRP producers.

However, significant opportunities exist that could propel the MRP market to new heights. Technological advancements in grinding and surface modification techniques are continuously improving MRP quality, allowing for finer particle sizes and better dispersion, which opens doors to higher-performance and more sensitive applications. The emergence of new application areas, such as advanced composites, 3D printing materials, and specialized coatings, presents untapped market potential. Increased research and development activities focused on developing innovative processing methods and exploring novel uses for MRP are expected to unlock further growth avenues. Moreover, government incentives and supportive policies aimed at promoting recycling and sustainable material usage are creating a more favorable regulatory environment, encouraging greater investment in the MRP sector and fostering a more circular and resilient economy. These opportunities, coupled with escalating environmental consciousness, are expected to mitigate restraints and accelerate market growth in the foreseeable future.

Segmentation Analysis

The Micronized Rubber Powder (MRP) market is extensively segmented to reflect the diverse nature of its production methods, physical characteristics, and end-use applications. This segmentation provides a granular view of market dynamics, revealing key trends and growth opportunities within specific categories. Understanding these segments is crucial for stakeholders to tailor product offerings, develop targeted marketing strategies, and make informed investment decisions across the value chain. The primary segmentation criteria typically include the type of grinding process employed, the specific mesh size of the powder, the source of the rubber material, and the various end-use industries that integrate MRP into their products, each offering unique performance attributes and market demands.

- By Type:

- Cryogenic Grinding: This method involves freezing rubber at extremely low temperatures (using liquid nitrogen) to make it brittle, then grinding it into fine particles. It typically produces finer, more consistent MRP with a cleaner surface, suitable for high-performance applications.

- Ambient Grinding: This process occurs at room temperature, using mechanical shredders and grinders. It is generally more cost-effective but produces slightly coarser particles with a higher surface area irregularity.

- By Mesh Size:

- 30-80 Mesh: Coarser grades, often used in less demanding applications such as asphalt modification, sports surfaces, and general construction materials.

- 80-120 Mesh: Medium grades, suitable for applications where better dispersion and surface interaction are required, such as in certain rubber compounds and plastic blends.

- >120 Mesh (Fine & Ultrafine): Finer grades, including powders up to 300 mesh or even smaller, produced primarily by cryogenic methods. These are critical for high-performance elastomers, sealants, coatings, and specialized plastic applications where minimal particle size interference is paramount.

- By Application:

- Tire Manufacturing: The largest segment, where MRP is used to replace virgin rubber in new tire compounds, reducing raw material costs and enhancing certain performance characteristics like wet grip and rolling resistance.

- Automotive Parts (Non-Tire): Includes various rubber components like belts, hoses, seals, gaskets, anti-vibration mounts, and interior parts where MRP can improve durability and reduce weight.

- Construction and Infrastructure: Utilized in asphalt modification to improve road longevity and crack resistance, in roofing membranes, waterproofing, and specialized concrete mixes to enhance elasticity and durability.

- Footwear: Incorporated into shoe soles, heels, and other components to improve grip, cushioning, and wear resistance, especially in athletic and work footwear.

- Plastics and Polymers: Blended with various plastics (e.g., PP, PE, PVC) to improve impact strength, flexibility, and reduce material costs in applications ranging from automotive components to consumer goods.

- Industrial Products: Diverse applications including conveyor belts, rubber mats, insulation, soundproofing materials, and industrial coatings.

- Sport Surfaces and Playgrounds: Used as infill for artificial turf, impact-absorbing layers in playgrounds, and running tracks, providing safety and durability.

- Adhesives, Sealants & Coatings: Enhances the physical properties and cost-effectiveness of various adhesive formulations and protective coatings.

- By Source:

- End-of-Life Tires (ELTs): Predominantly sourced from discarded vehicle tires, representing the largest and most readily available feedstock.

- Industrial Rubber Waste: Includes scraps and off-cuts from rubber manufacturing processes, offering a cleaner and more consistent material stream.

Value Chain Analysis For Micronized Rubber Powder Market

The value chain for the Micronized Rubber Powder (MRP) market is a complex network involving several stages, beginning from the collection of waste rubber materials and extending through various processing steps to distribution channels that reach diverse end-use industries. The upstream segment of the value chain primarily involves the collection and initial processing of feedstock, predominantly End-of-Life Tires (ELTs). This stage is critical and resource-intensive, requiring robust collection networks, tire dealerships, and specialized waste management companies responsible for gathering, sorting, and delivering tires to recycling facilities. Equipment manufacturers providing shredders, granulators, and separation technologies also play a crucial role upstream, as the efficiency and quality of the initial rubber crumb significantly impact the final MRP product.

Moving downstream, the core of the value chain lies with the MRP manufacturers themselves. These companies invest heavily in sophisticated micronization technologies, such as cryogenic grinding or advanced ambient mechanical processes, to convert rubber crumbs into fine, consistent powder. This stage involves significant R&D to optimize particle size, surface area, and purity, which are critical for various applications. Quality control and testing are paramount here to ensure the MRP meets stringent industry specifications. Following manufacturing, the product moves into distribution. Distribution channels are varied and include direct sales to large industrial consumers, partnerships with chemical distributors, and specialized material suppliers who cater to niche markets. Direct channels allow for closer client relationships and custom product development, while indirect channels provide broader market reach and logistical efficiency, particularly for smaller volumes or geographically dispersed customers.

The final stage of the value chain encompasses the end-users and their application of MRP. Major downstream industries include automotive, construction, footwear, and plastics manufacturing. These industries integrate MRP into their product formulations to achieve benefits such as cost reduction, improved performance (e.g., enhanced elasticity, abrasion resistance, sound dampening), and compliance with sustainability mandates. The interaction between MRP manufacturers and end-users is often collaborative, involving technical support and application development to ensure optimal integration and performance. The success of the MRP market is heavily reliant on the efficiency and collaboration across all these stages, from effective waste collection and advanced processing to robust distribution and successful integration into end-products, demonstrating a clear commitment to resource circularity and value creation.

Micronized Rubber Powder Market Potential Customers

The potential customer base for Micronized Rubber Powder (MRP) is highly diverse, spanning numerous industries that utilize rubber, plastics, and various composite materials in their manufacturing processes. Fundamentally, any industry seeking to reduce material costs, enhance specific performance characteristics of their products, or improve their environmental footprint by incorporating recycled content represents a viable potential customer. Manufacturers in the automotive sector, including tire producers and component suppliers, constitute a significant segment, as they constantly strive for lighter, more durable, and cost-effective materials. Similarly, companies involved in infrastructure development and construction, particularly those producing asphalt, roofing materials, and specialized concretes, are key buyers due to MRP's ability to enhance material longevity and flexibility.

Beyond these major segments, the footwear industry represents a substantial market for MRP, where it is integrated into soles, heels, and other components to improve grip, cushioning, and wear resistance, especially for athletic and work-related footwear. Manufacturers of industrial products, such as conveyor belts, rubber mats, seals, and gaskets, also benefit from MRP's properties, utilizing it to enhance durability and reduce production costs. The plastics and polymer compounding industry is another growing customer segment, as MRP can be blended with various thermoplastics and thermosets to improve impact strength, flexibility, and overall cost-effectiveness of final plastic parts, finding applications in everything from automotive interiors to consumer durable goods and packaging.

Emerging opportunities for MRP also lie with manufacturers producing specialized coatings, adhesives, and sealants, where fine rubber particles can improve elasticity, adhesion, and sound-damping properties. The sports and recreation industry, particularly companies involved in artificial turf manufacturing, playground surfacing, and running tracks, also represent important end-users who value MRP for its shock-absorbing qualities and durability. Furthermore, ongoing research into advanced materials and composites continuously uncovers new potential applications and customer segments, expanding the horizon for MRP adoption. Companies committed to green manufacturing practices and those facing stringent environmental regulations are increasingly prioritizing the use of recycled materials like MRP, positioning themselves as prime candidates for future growth in this dynamic market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.99 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lehigh Technologies, Rubberlite Inc., Genan A/S, Micronized Rubber Co. (MRC), Crumb Rubber Manufacturers (CRM), Liberty Tire Recycling, Emanuel Tire Co., Rubber World Industries (RWI), Entech Inc., TIRU (Groupe EDF), Wastefront, Pyrum Innovations AG, Delta-Energy Group, Green Rubber Global (GRG), Dynasol Elastomers. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Micronized Rubber Powder Market Key Technology Landscape

The technology landscape for the Micronized Rubber Powder (MRP) market is characterized by a blend of established and emerging processes aimed at transforming waste rubber into high-value fine powders. The most prevalent technologies fall into two main categories: ambient grinding and cryogenic grinding. Ambient grinding involves mechanical shredding and grinding at room temperature, using equipment like granulators, crack mills, and pulverizers. While cost-effective, this method can generate heat that degrades rubber properties and typically produces coarser particles with irregular shapes. Innovations in ambient grinding focus on optimizing blade design, increasing energy efficiency, and improving particle classification systems to achieve finer mesh sizes with less thermal degradation, enhancing overall product consistency and broadening application suitability.

Cryogenic grinding represents a more advanced technological approach, where rubber is embrittled by cooling it to extremely low temperatures using liquid nitrogen before mechanical pulverization. This process allows for the production of significantly finer, more uniform particles with a smoother surface texture and minimal thermal degradation, making the MRP suitable for high-performance applications where consistency and pristine material properties are critical. Recent advancements in cryogenic technology aim to reduce energy consumption and operational costs associated with nitrogen usage, through more efficient heat exchange systems and integrated processing units. Furthermore, hybrid systems that combine elements of both ambient and cryogenic methods are emerging, seeking to balance cost-efficiency with superior particle quality, offering a flexible solution for producers to meet diverse market demands.

Beyond the primary grinding technologies, a crucial aspect of the key technology landscape involves downstream processing and quality control. This includes advanced particle size analysis equipment (e.g., laser diffraction, dynamic light scattering) to ensure precise classification and quality assurance of the micronized powder. Surface modification technologies, such as chemical treatments or plasma treatment, are also gaining traction. These treatments enhance the compatibility and adhesion of MRP with various polymer matrices, improving dispersion and overall performance in final products. Additionally, automation and sensor-based systems are increasingly being integrated into production lines to monitor process parameters in real-time, enabling adaptive control and ensuring consistent product quality, thereby pushing the boundaries of what MRP can achieve in terms of application and performance.

Regional Highlights

- North America: This region is characterized by stringent environmental regulations encouraging tire recycling and a mature automotive industry driving demand for sustainable materials. The United States and Canada lead in adopting MRP, supported by robust recycling infrastructure and technological advancements in processing.

- Europe: European countries, particularly Germany, France, and the UK, exhibit strong commitments to circular economy principles and advanced waste management policies. High environmental awareness and a significant presence of automotive and construction sectors contribute to sustained MRP market growth, further boosted by EU directives on waste management and recycling targets.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, burgeoning automotive production, and increasing awareness of environmental issues in countries like China, India, and Japan. The vast generation of End-of-Life Tires (ELTs) provides abundant feedstock, while government initiatives promoting green technologies stimulate market expansion and investment opportunities.

- Latin America: This region is experiencing nascent but growing demand for MRP, driven by improving economic conditions, expanding construction activities, and a gradual shift towards sustainable practices. Brazil and Mexico are key markets, benefiting from increasing local manufacturing and a rising focus on tire recycling programs.

- Middle East and Africa (MEA): The MEA market is still in its early stages but holds significant potential due to ongoing infrastructure development projects and increasing efforts towards waste management and diversification of economies away from oil. Countries like UAE, Saudi Arabia, and South Africa are investing in recycling technologies and sustainable materials, creating new opportunities for MRP adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Micronized Rubber Powder Market.- Lehigh Technologies

- Rubberlite Inc.

- Genan A/S

- Micronized Rubber Co. (MRC)

- Crumb Rubber Manufacturers (CRM)

- Liberty Tire Recycling

- Emanuel Tire Co.

- Rubber World Industries (RWI)

- Entech Inc.

- TIRU (Groupe EDF)

- Wastefront

- Pyrum Innovations AG

- Delta-Energy Group

- Green Rubber Global (GRG)

- Dynasol Elastomers

- Rubberecycle Inc.

- Reclaim Rubber & Recycling (RRR)

- Tyre Recycling Solutions (TRS)

- ETR Group

- CRM Crumb Rubber Sdn. Bhd.

Frequently Asked Questions

What is Micronized Rubber Powder (MRP) and how is it produced?

Micronized Rubber Powder (MRP) is a fine, ground rubber material derived primarily from recycled End-of-Life Tires (ELTs) or industrial rubber waste. Its production involves a multi-stage process that typically begins with shredding and granulating the rubber into coarser crumbs. These crumbs are then further reduced in size through advanced grinding techniques. The two main methods are ambient grinding, which uses mechanical shear at room temperature, and cryogenic grinding, which involves freezing the rubber with liquid nitrogen to make it brittle before pulverization. Cryogenic grinding generally yields finer particles with more consistent properties and a smoother surface. The resulting powder is sieved and classified by mesh size to meet specific industrial requirements, making it suitable for a wide range of applications where it can replace or augment virgin rubber and plastic materials.

What are the primary benefits of using Micronized Rubber Powder in manufacturing?

The utilization of Micronized Rubber Powder (MRP) offers a multifaceted array of benefits across various manufacturing sectors. Environmentally, it significantly contributes to the circular economy by repurposing waste tires, reducing landfill burden, and conserving natural resources that would otherwise be used to produce virgin materials. Economically, MRP serves as a cost-effective alternative to expensive virgin polymers, allowing manufacturers to reduce raw material costs and improve profit margins. Performance-wise, when incorporated into new formulations, MRP can enhance specific properties of end products, such as improving tear strength, increasing abrasion resistance, enhancing elasticity, providing better sound and vibration dampening, and improving anti-slip characteristics. Furthermore, it can sometimes reduce the energy consumption during the mixing and processing stages due to lower friction and heat generation, offering both environmental and operational advantages for manufacturers committed to sustainable and efficient production.

Which industries are the main consumers of Micronized Rubber Powder?

Micronized Rubber Powder (MRP) finds extensive application across a diverse range of industries due to its versatile properties and economic advantages. The automotive sector stands as a primary consumer, particularly in new tire manufacturing where MRP is incorporated to reduce virgin rubber content while maintaining or improving performance characteristics like rolling resistance and grip. Beyond tires, it is used in various automotive components such as belts, hoses, seals, and anti-vibration systems. The construction and infrastructure industry is another significant market, utilizing MRP in asphalt modification to enhance road longevity and crack resistance, as well as in roofing membranes and specialized concrete mixes. The footwear industry incorporates MRP into shoe soles and heels for improved grip, cushioning, and wear resistance. Additionally, the plastics and polymer compounding industry, industrial products manufacturing (e.g., conveyor belts, mats), and the sports surfaces sector (e.g., artificial turf infill) are substantial consumers, leveraging MRP for cost reduction, performance enhancement, and sustainability goals.

What are the key factors driving the growth of the MRP market?

Several pivotal factors are driving the substantial growth of the Micronized Rubber Powder (MRP) market. Foremost among these is the escalating global emphasis on environmental sustainability and the principles of the circular economy, which pressure industries to adopt recycled and eco-friendly materials to reduce their ecological footprint. This is further reinforced by increasingly stringent government regulations worldwide concerning waste tire disposal, mandating recycling and promoting the use of recycled content in manufacturing. The economic incentive of MRP is another major driver; its cost-effectiveness compared to virgin rubber polymers makes it an attractive raw material for manufacturers seeking to optimize production expenses without compromising product quality. Furthermore, continuous technological advancements in grinding and surface modification processes are improving MRP quality and opening up new, high-performance applications, thereby continually expanding its market reach and value proposition. These combined forces create a compelling environment for sustained market expansion.

What challenges does the Micronized Rubber Powder market face?

Despite its significant growth potential, the Micronized Rubber Powder (MRP) market encounters several notable challenges that influence its broader adoption and expansion. A primary hurdle is the inherent variability in the quality and composition of waste tire feedstock. This inconsistency can lead to fluctuations in the physical and chemical properties of the resulting MRP, making it difficult for end-users to guarantee uniform product performance, which is a critical concern in precision manufacturing. The high capital expenditure required for setting up and operating advanced micronization facilities, especially those employing cryogenic grinding technology, presents a substantial barrier to entry for new market players. Furthermore, there remains a degree of limited awareness and understanding among certain potential end-use industries regarding the full capabilities and validated benefits of MRP, leading to hesitancy in substituting traditional materials. Lastly, the market faces ongoing competition from other recycled materials and, in some applications, from cheaper virgin alternatives, necessitating continuous innovation and clear demonstration of MRP's superior value proposition to overcome these competitive pressures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager