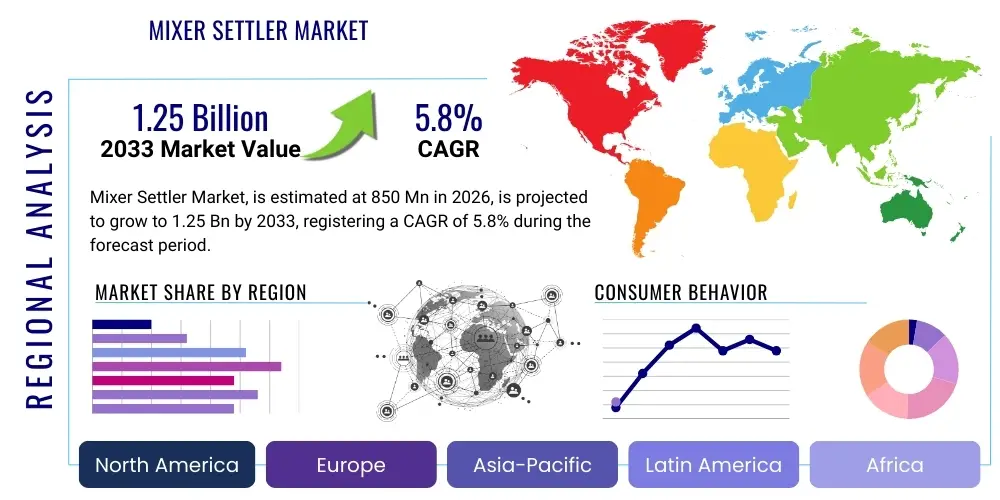

Mixer Settler Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443105 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Mixer Settler Market Size

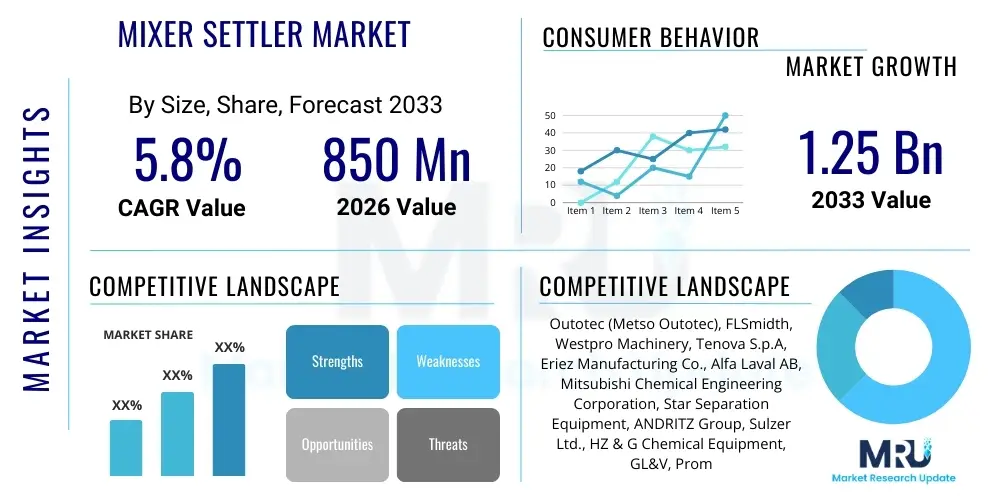

The Mixer Settler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1.25 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by increasing global demand for base metals, coupled with significant investments in sophisticated hydrometallurgical processing techniques across emerging economies. The inherent reliability and operational robustness of mixer settler units, particularly in large-scale solvent extraction operations, solidify their crucial role in mineral processing and chemical synthesis, ensuring sustained market trajectory over the next decade.

Mixer Settler Market introduction

The Mixer Settler Market encompasses equipment vital for liquid-liquid extraction processes, functioning as a continuous counter-current device utilized primarily for separating components based on differential solubility between two immiscible phases. These units are characterized by a mixing chamber (mixer), where intense agitation ensures intimate contact and mass transfer between the heavy and light phases, followed by a settling chamber (settler), where gravitational forces allow the phases to disengage based on density differences. This separation efficiency is paramount in high-value industrial applications, underpinning the extraction of critical elements and purification of complex chemical streams. The technological maturity and established operational reliability of mixer settlers make them the preferred choice for large-scale, high-throughput solvent extraction plants globally, particularly in environments requiring stringent quality control and high purity levels.

Major applications for mixer settlers span across the hydrometallurgical industry for copper, cobalt, uranium, and rare earth element extraction; the nuclear sector for spent fuel reprocessing; and the chemical industry for phosphoric acid purification and fine chemical synthesis. The core benefit of employing mixer settlers lies in their high stage efficiency, adaptability to various flow rates, and ease of scaling and operation, contributing significantly to improved yield and reduced operational complexity compared to alternative separation technologies. Driving factors for market growth include the rising global necessity for refined battery materials, increased capital expenditure in mining projects due to escalating metal prices, and stringent environmental regulations favoring closed-loop and efficient extraction methodologies that minimize waste generation. The ongoing push for digitalization in process control further enhances the attractiveness of these units by enabling optimized chemical dosing and rapid phase separation management.

Mixer Settler Market Executive Summary

The Mixer Settler Market is poised for stable expansion, characterized by a fundamental shift toward higher efficiency designs and modular deployment across core industrial sectors, including mining, nuclear, and specialty chemicals. Business trends indicate a strong emphasis on automation and the integration of advanced process control (APC) systems to optimize solvent extraction parameters, directly addressing the industry need for reduced footprint and quicker phase disengagement times, thereby lowering overall capital expenditure (CAPEX) per unit of production. Furthermore, major market players are focusing heavily on developing corrosion-resistant materials and incorporating smart sensor technologies to monitor interphase levels and detect emulsion formation early, translating into enhanced operational uptime and reduced maintenance overheads. This drive for operational excellence is setting new standards for equipment longevity and throughput capacity, particularly in demanding acidic environments typical of copper and nickel extraction.

Regionally, Asia Pacific is maintaining its dominance and emerging as the fastest-growing market, primarily due to large-scale infrastructure investments, burgeoning demand for electric vehicle (EV) batteries driving cobalt and lithium extraction projects, and significant governmental focus on establishing robust domestic processing capabilities for critical raw materials. Segment trends highlight the 'Large Capacity' segment as the most lucrative, reflecting the global trend toward economies of scale in hydrometallurgical processing, where high flow rates and continuous operation are critical for profitability. Moreover, the modular mixer settler systems segment is gaining traction, offering flexible deployment options and rapid scalability, especially relevant for pilot plants and smaller, specialized chemical operations. The focus on environmentally conscious reagents and solvent recovery technologies is also shaping product innovation, ensuring compliance with global sustainability mandates and mitigating potential environmental risks associated with high-volume liquid handling.

AI Impact Analysis on Mixer Settler Market

User queries regarding the impact of Artificial Intelligence (AI) on the Mixer Settler Market predominantly revolve around optimizing phase separation efficiency, predicting and mitigating operational bottlenecks such as crud formation, and integrating predictive maintenance schedules. Key concerns include the feasibility of retrofitting existing conventional units with AI-driven monitoring systems, the return on investment (ROI) for advanced process control (APC) implementation, and the accuracy of machine learning models in handling highly variable input ore grades and fluctuating solvent compositions. Users expect AI to transcend basic automation, providing real-time, self-correcting capabilities to minimize solvent loss, optimize energy consumption associated with mixing, and achieve higher purity extraction yields consistently. This collective inquiry underscores a market readiness to adopt sophisticated computational tools to overcome the long-standing challenges of maintaining stable and efficient liquid-liquid interphases in complex chemical processing environments.

- AI enables real-time monitoring and dynamic adjustment of mixer impeller speed and weir settings, optimizing phase disengagement kinetics.

- Predictive maintenance algorithms, leveraging sensor data (temperature, pressure, vibration), forecast equipment failure and reduce unplanned downtime in extraction plants.

- Machine Learning (ML) models analyze complex solvent composition data to optimize reagent consumption, significantly reducing operational costs and environmental impact.

- AI-driven image processing and sensor fusion detect early stages of crud formation (stable emulsions), allowing operators to apply immediate corrective action.

- Implementation of AI-powered digital twins simulates various extraction scenarios, facilitating rapid optimization and efficient scale-up of new processes or solvents.

- Enhanced process stability and yield forecasting through deep learning techniques, improving overall plant efficiency and output consistency.

DRO & Impact Forces Of Mixer Settler Market

The market trajectory for mixer settlers is fundamentally driven by the escalating demand for critical minerals—specifically copper, nickel, cobalt, and lithium—essential components for the global transition to renewable energy and electric mobility, demanding high-throughput, high-purity extraction capabilities. Restraints primarily involve the substantial upfront capital investment required for constructing large-scale solvent extraction plants and the technical complexity associated with managing diverse, volatile chemical reagents and ensuring effective phase stability across varying process conditions. Opportunities are abundant in the reprocessing of electronic waste (e-waste) and the utilization of unconventional or lower-grade ore bodies, both requiring advanced hydrometallurgical techniques where mixer settlers excel. These dynamics exert a powerful collective impact, compelling manufacturers to innovate toward more modular, corrosion-resistant, and operationally intelligent systems that offer higher efficiency and lower lifetime costs, thereby navigating economic pressures and environmental mandates simultaneously.

Key drivers include rapid industrialization in Southeast Asia and Africa, stimulating new mining projects and associated processing facilities, alongside technological advancements in solvent chemistry that necessitate robust separation equipment capable of handling higher specific gravity differentials and viscosities. However, the regulatory environment poses a significant restraint; complex and protracted permitting processes for chemical and nuclear facilities can substantially delay project timelines and increase development costs, limiting the speed of market adoption in certain geographies. Opportunities are also evident in the pharmaceutical and food processing sectors, utilizing smaller-scale, highly hygienic mixer settlers for specialized purification tasks, expanding the market scope beyond traditional metallurgy. The overall impact forces demonstrate a strong positive correlation with global commodity market trends and governmental green initiatives, pushing the market toward sustainable and efficient liquid-liquid extraction solutions while continuous material science innovation addresses the durability constraints imposed by aggressive chemical environments, ultimately stabilizing long-term growth prospects.

Segmentation Analysis

The Mixer Settler Market segmentation provides a granular view of diverse product applications and technological preferences across various end-user industries, facilitating targeted marketing and product development strategies. The market is primarily segmented based on the capacity of the unit (Small, Medium, Large), the mechanism type (Pump-Mix and Gravity Flow), the construction material (Stainless Steel, FRP/Plastics, Specialty Alloys), and the primary End-User Industry (Mining & Metallurgy, Nuclear, Chemical Processing, and Others). Analyzing these segments reveals varying growth rates and adoption patterns; for instance, the demand for large capacity units is dictated by major base metal extraction projects, while specialty alloys and FRP materials see heightened demand in corrosive chemical and nuclear environments, respectively, showcasing the technical diversity inherent in this market.

- By Capacity:

- Small Capacity (Pilot scale, research)

- Medium Capacity (Specialty chemicals, niche processing)

- Large Capacity (High-throughput metallurgy, industrial scale)

- By Type/Mechanism:

- Pump-Mix Mixer Settlers (High shear, integrated mixing)

- Gravity Flow Mixer Settlers (Conventional separation)

- Pulsed Column Systems (Related alternative technology)

- By Material of Construction:

- Stainless Steel

- Fiber Reinforced Plastic (FRP) & Plastics (e.g., HDPE, PTFE lined)

- Specialty Alloys (e.g., Titanium, Hastelloy)

- By Application/End-User:

- Mining & Metallurgy (Copper, Nickel, Rare Earth Elements, Uranium)

- Nuclear Industry (Fuel reprocessing, waste management)

- Chemical Processing (Phosphoric acid purification, fine chemical synthesis)

- Pharmaceuticals & Food Processing

Value Chain Analysis For Mixer Settler Market

The value chain for the Mixer Settler Market begins with upstream activities, encompassing the sourcing of raw materials, primarily high-grade metals (stainless steel, titanium) and advanced polymers (FRP, specialized plastics) used for construction, where material cost fluctuations significantly impact final product pricing. This stage also includes the procurement of critical components such as impellers, motors, pumps, and control instrumentation, often sourced from specialized mechanical and automation suppliers. Manufacturing and fabrication involve sophisticated engineering design, focusing on computational fluid dynamics (CFD) modeling to ensure optimal mixing intensity and phase separation characteristics, necessitating highly skilled labor and specialized fabrication techniques tailored to large, customized chemical process equipment. Effective supplier management and quality control over raw material specifications are paramount to ensuring the structural integrity and corrosion resistance required for aggressive industrial use, thereby defining the foundation of product quality and reliability across the entire value chain.

Downstream analysis focuses heavily on the distribution channel, which typically involves a mix of direct sales channels for major, customized plant projects and indirect distribution via specialized engineering, procurement, and construction (EPC) firms or regional distributors for standardized units or replacement parts. Direct sales are crucial for large-scale mining and nuclear projects, where extensive consultation, site-specific customization, and rigorous commissioning services are non-negotiable components of the offering. EPC firms often act as intermediaries, integrating mixer settlers into larger process plants, adding significant value through project management and system integration expertise. The final stage involves extensive post-sales services, including installation support, operator training, maintenance contracts, and the supply of spare parts. The competitive advantage often resides in the level of technical support and the rapidity of response to operational challenges, particularly given the critical role these units play in continuous, high-value industrial processes where minimal downtime is acceptable. This integrated approach ensures that the sophisticated equipment performs optimally throughout its operational lifecycle.

Mixer Settler Market Potential Customers

Potential customers for mixer settlers are predominantly large-scale industrial entities engaged in highly technical liquid-liquid separation processes where high purity and consistent throughput are essential performance indicators. The primary buyers include multinational mining corporations focused on the extraction and refining of base metals like copper, nickel, and uranium, who utilize massive mixer settler banks as the core unit in their solvent extraction facilities to purify pregnant leach solutions. Additionally, governmental and private nuclear fuel reprocessing facilities represent a vital customer segment, requiring specialized, often shielded, mixer settlers constructed from highly corrosion-resistant materials to manage radioactive waste streams and recover valuable isotopes. The intense demand for infrastructure and renewable energy components ensures sustained purchasing power from these capital-intensive industries.

Beyond the core hydrometallurgy sector, significant purchasing activity originates from large chemical manufacturing groups, particularly those involved in producing phosphoric acid, fertilizers, and complex organic chemicals, where the equipment is used for impurity removal and concentration steps. Furthermore, the specialized chemical and pharmaceutical industries, while requiring smaller batch sizes, seek highly sanitary and precise mixer settlers for solvent extraction in the synthesis of active pharmaceutical ingredients (APIs) and fine chemicals, prioritizing material compatibility and ease of cleaning over sheer volume. The decision to purchase is heavily influenced by total cost of ownership (TCO), demonstrated reliability, proven stage efficiency, and the manufacturer's ability to provide customized engineering solutions tailored to unique chemical process demands and regulatory compliance, ensuring a rigorous procurement cycle focused on long-term performance guarantees.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1.25 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Outotec (Metso Outotec), FLSmidth, Westpro Machinery, Tenova S.p.A, Eriez Manufacturing Co., Alfa Laval AB, Mitsubishi Chemical Engineering Corporation, Star Separation Equipment, ANDRITZ Group, Sulzer Ltd., HZ & G Chemical Equipment, GL&V, Prominent Fluid Controls, McLanahan Corporation, KHD Humboldt Wedag GmbH, Technip Energies, Koch-Glitsch, PETROFLUID, Veolia Water Technologies, Dechema. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mixer Settler Market Key Technology Landscape

The key technological landscape of the Mixer Settler Market is characterized by continuous optimization focused on enhancing mass transfer efficiency, reducing solvent inventory, and improving phase separation kinetics to minimize hydraulic constraints and maximize throughput. Modern mixer settler designs leverage advanced computational fluid dynamics (CFD) modeling and finite element analysis (FEA) during the design phase to optimize impeller geometry, baffle placement, and flow patterns within the mixer compartment, ensuring maximized interfacial area generation with minimal energy input, thereby preventing localized short-circuiting and promoting higher stage efficiency. The adoption of specialized static mixer elements and proprietary baffling designs in the settling zone is crucial for accelerating droplet coalescence and ensuring rapid, clean disengagement of the organic and aqueous phases, a process increasingly monitored by high-resolution optical and ultrasonic sensors.

Furthermore, a major technological thrust involves the integration of advanced automation and control systems, specifically targeting the stabilization of the liquid-liquid interface (interphase) within the settler. Technologies such as adjustable weir systems, sophisticated interphase level controllers, and real-time density and conductivity measurements are crucial for dynamic process regulation, especially when dealing with varying feed compositions common in mining operations. The material science frontier is also highly active, with increasing use of advanced polymers and dual-laminate construction, such as FRP lined with PTFE or PVDF, to offer superior resistance to highly corrosive reagents (e.g., concentrated acids) and minimize metal contamination, which is paramount in high-purity chemical and nuclear applications. The ongoing focus on modular, containerized units represents a significant innovation, facilitating faster deployment, easier expansion, and reduced construction time for remote or temporary processing sites, thereby expanding the accessibility and flexibility of solvent extraction technology.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, driven by unparalleled growth in industrial activities, particularly in China, India, and Southeast Asian nations. The region hosts massive hydrometallurgical processing centers for rare earth elements, copper, and nickel, catering to the booming electric vehicle battery manufacturing sector and robust infrastructure development. Significant government investments in establishing critical raw material supply chains further catalyze the deployment of large-capacity, high-throughput mixer settler units. This necessitates continual technological upgrades and expansion of existing solvent extraction facilities.

- North America: The market in North America is mature but stable, characterized by strict environmental regulations and high operational standards, driving demand for technologically advanced and highly automated mixer settlers that prioritize energy efficiency and solvent recovery. The revival of domestic mineral processing for critical minerals, alongside established nuclear waste management operations, ensures consistent investment, particularly in customized, corrosion-resistant equipment. Focus is strong on predictive maintenance systems and integration of smart manufacturing principles to optimize existing large-scale plants across the US and Canada.

- Europe: European market growth is stable, primarily focused on high-value chemical processing, pharmaceutical applications, and sophisticated nuclear fuel reprocessing projects, rather than high-volume base metal mining. European companies emphasize modular systems, stringent quality control, and units constructed from specialty alloys to handle complex or hazardous chemicals. Sustainability mandates and circular economy initiatives heavily influence procurement decisions, favoring energy-efficient and highly reliable extraction technologies that support resource recovery from secondary sources, such as industrial waste streams and urban mining initiatives.

- Latin America (LATAM): LATAM represents a major growth hub, highly dependent on the mining sector, especially for copper in Chile and Peru, and lithium in the Lithium Triangle (Chile, Argentina, Bolivia). This region sees substantial demand for large-scale, rugged mixer settler banks capable of handling aggressive leachates and high flow rates. Market performance is intrinsically linked to global commodity prices and foreign direct investment into major mining expansion projects. The necessity to process increasingly complex or low-grade ores further fuels the need for efficient solvent extraction technology to maintain economic viability.

- Middle East and Africa (MEA): The MEA market, while smaller, is growing rapidly, propelled by new mining ventures in Africa (especially cobalt, gold, and uranium) and significant investments in chemical and phosphoric acid production in the Middle East. Challenges related to harsh operating environments, water scarcity, and logistics complexity drive demand for robust, easily maintainable, and often containerized or modular mixer settler systems suitable for remote installations. The focus is on establishing foundational processing infrastructure to move up the value chain from raw material export to refined metal production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mixer Settler Market.- Metso Outotec

- FLSmidth

- Westpro Machinery

- Tenova S.p.A

- Eriez Manufacturing Co.

- Alfa Laval AB

- Mitsubishi Chemical Engineering Corporation

- Star Separation Equipment

- ANDRITZ Group

- Sulzer Ltd.

- HZ & G Chemical Equipment

- GL&V (General Kinematics)

- Prominent Fluid Controls

- McLanahan Corporation

- KHD Humboldt Wedag GmbH

- Technip Energies

- Koch-Glitsch

- PETROFLUID

- Veolia Water Technologies

- Dechema

Frequently Asked Questions

Analyze common user questions about the Mixer Settler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a mixer settler in industrial processes, and where is it most commonly used?

The primary function of a mixer settler is liquid-liquid extraction (solvent extraction), which involves the selective separation of components from a feed solution (aqueous phase) into an organic solvent phase. It is most commonly used in large-scale hydrometallurgy for extracting and purifying metals like copper, nickel, and uranium, and extensively in the nuclear industry for fuel reprocessing and chemical synthesis.

How does the adoption of modular mixer settler units influence project timelines and capital expenditure (CAPEX)?

Modular mixer settler units significantly reduce project timelines by enabling parallel construction and minimizing on-site fabrication time, as modules are factory-assembled and tested. This modularization typically leads to lower installation costs, reduced overall CAPEX risk, and greater flexibility for plant expansion or relocation, making them highly attractive for greenfield projects and remote mining sites.

What are the key technical challenges facing mixer settler operations, and how can they be mitigated?

Key technical challenges include maintaining stable phase separation (interphase control), minimizing solvent loss due to entrainment, and preventing the formation of stable emulsions (crud). Mitigation strategies involve the implementation of advanced process control systems (APC), optimization of impeller speed based on real-time data, and regular monitoring of reagent quality and interphase level using sophisticated ultrasonic or optical sensors.

Which materials of construction are favored in highly corrosive solvent extraction applications, and why are they preferred?

In highly corrosive solvent extraction applications, materials such as Fiber Reinforced Plastic (FRP), particularly those lined with fluoropolymers like PTFE or PVDF, and specialty metallic alloys (e.g., Titanium or Hastelloy) are favored. These materials offer superior chemical inertness and corrosion resistance against strong acids and aggressive reagents typical in metallurgical and nuclear processing, ensuring extended equipment lifespan and minimizing metal contamination of the final product.

What role does automation play in optimizing the efficiency and throughput of modern mixer settler circuits?

Automation plays a critical role by utilizing sensors and programmable logic controllers (PLCs) to continuously monitor and adjust operational parameters such as flow rates, pH, temperature, and interphase levels. This real-time optimization minimizes manual intervention, ensures stable operation, maximizes stage efficiency, and allows for rapid response to process disturbances, leading directly to higher throughput and reduced operating expenditure (OPEX) in the solvent extraction circuit.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager