Modified Asphalt Emulsion Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441132 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Modified Asphalt Emulsion Market Size

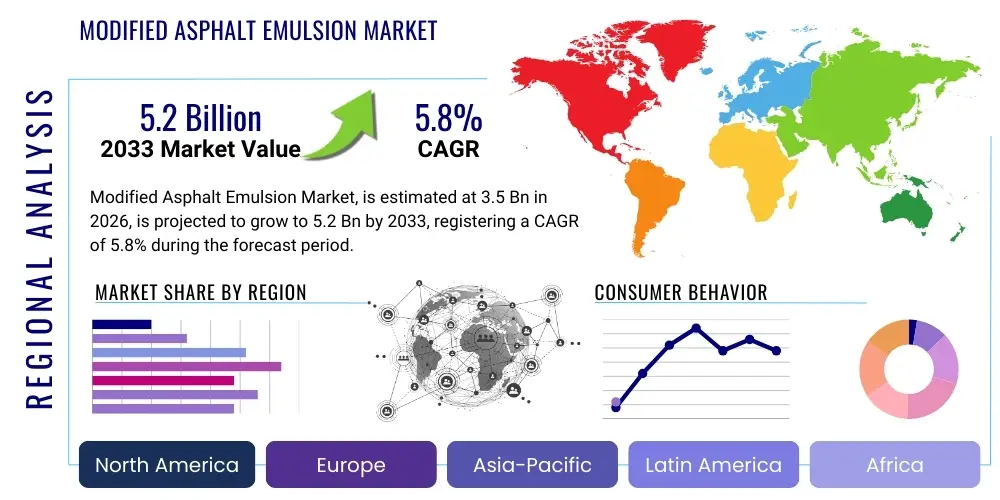

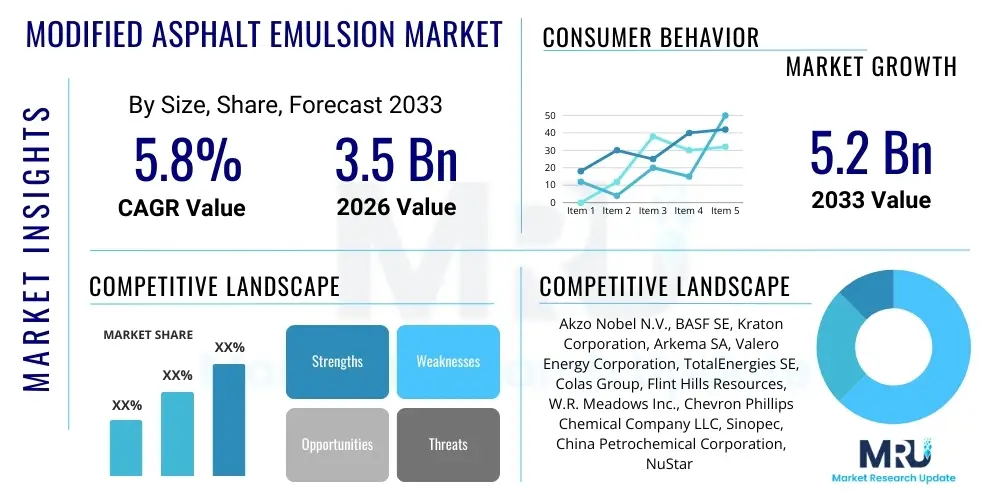

The Modified Asphalt Emulsion Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $3.5 Billion in 2026 and is projected to reach $5.2 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by increasing global infrastructure investments, particularly in developing economies prioritizing road network maintenance and expansion, coupled with the rising adoption of high-performance paving materials that offer superior longevity and resilience compared to traditional asphalt products. The inherent benefits of modified asphalt emulsions, such as enhanced flexibility, improved resistance to temperature variations, and reduced environmental impact during application, solidify their position as essential materials in modern civil engineering projects, thereby sustaining robust market demand throughout the projected timeline.

Modified Asphalt Emulsion Market introduction

The Modified Asphalt Emulsion Market encompasses specialized bituminous binders where standard asphalt is dispersed in water, often stabilized with emulsifying agents, and crucially, enhanced through the incorporation of various modifying additives such as polymers (like SBS, SBR, EVA), crumb rubber, or reactive additives. These modifiers fundamentally alter the rheological and mechanical properties of the resulting binder, granting superior performance characteristics like increased elastic recovery, higher softening points, and improved resistance to fatigue cracking and rutting under heavy traffic loads and extreme climatic conditions. The primary product description centers on highly stable, low-viscosity liquids that are applied cold or warm, eliminating the need for high-temperature mixing, which enhances safety and reduces energy consumption during pavement construction and maintenance activities.

Major applications for modified asphalt emulsions span critical infrastructure sectors, dominated by paving applications such including tack coats, chip seals, slurry seals, micro-surfacing, and cold mix asphalt. Beyond road construction, these materials are increasingly utilized in roofing membranes for superior waterproofing and UV resistance, as well as in protective coatings and industrial sealing applications requiring enhanced durability and chemical resistance. The benefits derived from their use are significant, encompassing extended pavement service life, reduced life-cycle costs for infrastructure owners, improved worker safety due to lower application temperatures, and a reduced carbon footprint compared to traditional hot mix asphalt technologies, making them highly attractive to governmental agencies and private contractors seeking sustainable and high-quality solutions.

Driving factors propelling this market include stringent regulatory requirements mandating the use of durable and environmentally friendly road materials, coupled with massive global investments in transportation infrastructure renewal and expansion projects, especially in rapidly urbanizing regions across Asia Pacific and Latin America. Technological advancements in emulsion chemistry and modifier integration, which continually improve product performance and storage stability, further catalyze market growth. The increasing awareness among infrastructure planners regarding the economic benefits of preventative maintenance utilizing high-performance modified emulsions, rather than costly full rehabilitation, also acts as a powerful demand accelerator.

Modified Asphalt Emulsion Market Executive Summary

The Modified Asphalt Emulsion Market is experiencing dynamic growth, driven primarily by favorable business trends emphasizing sustainable construction practices and long-term infrastructure investment. Key business trends include the consolidation of specialized chemical and construction material suppliers, intensive R&D efforts focused on bio-based emulsifiers and high-performance polymer modification techniques, and a shift towards performance-based specifications in public procurement contracts. Manufacturers are increasingly focusing on developing tailored solutions for specific climatic challenges, such as high-stress applications in regions experiencing extreme heat or severe freeze-thaw cycles, leading to product diversification and premium pricing for advanced formulations. The transition towards cold-in-place recycling techniques, heavily reliant on modified emulsions, is a major trend influencing manufacturing output and distribution strategies globally.

Regionally, the market exhibits varied maturity levels. Asia Pacific currently leads the market share, fueled by large-scale government infrastructure initiatives in countries like China, India, and Southeast Asian nations aimed at rapidly expanding highway networks and urban roads. North America and Europe, while being mature markets, show steady growth driven by the need for maintenance, repair, and rehabilitation (MR&R) of aging infrastructure, coupled with rigorous environmental mandates promoting cleaner application methods. Emerging markets in Latin America and the Middle East & Africa are characterized by high potential growth due to increasing urbanization, substantial investments in resource transportation infrastructure, and the early adoption of polymer-modified emulsions to handle extreme temperature conditions prevalent in these geographies.

Segment trends indicate that Polymer Modified Emulsions, particularly those utilizing Styrene-Butadiene-Styrene (SBS) and Styrene-Butadiene Rubber (SBR), dominate the market due to their superior elasticity and fatigue resistance, essential for high-stress pavement surfaces. However, Crumb Rubber Modified Emulsions are gaining traction, supported by circular economy initiatives aimed at utilizing waste tires in road construction, offering a cost-effective and environmentally beneficial modifier. Application segmentation highlights Micro-surfacing and Chip Seal as the fastest-growing sectors, attributed to their effectiveness and cost-efficiency as preventative maintenance treatments, extending the lifespan of existing pavements significantly, thereby reducing overall capital expenditure requirements for road authorities.

AI Impact Analysis on Modified Asphalt Emulsion Market

User queries regarding AI's influence on the Modified Asphalt Emulsion Market primarily revolve around themes of predictive maintenance scheduling, optimization of emulsion formulation for specific performance criteria, and the enhancement of quality control during manufacturing and application processes. Users frequently ask if AI can predict pavement degradation rates accurately enough to time preventative maintenance using emulsions optimally, minimizing waste and maximizing efficiency. Furthermore, there is significant user interest in how machine learning algorithms can analyze vast datasets of raw material properties (bitumen source, modifier type, emulsifier concentration) and correlate them with real-world pavement performance metrics (rutting, cracking index) to autonomously suggest the most effective and stable emulsion designs for diverse environmental settings. The overarching expectation is that AI will move the industry from reactive or scheduled maintenance to highly optimized, predictive, and customized material application.

This analysis reveals that key user concerns center on the reliability of AI models in predicting the long-term chemical stability of complex modified emulsions under storage conditions and the initial capital investment required for implementing AI-driven quality assurance systems, such as advanced sensor technologies and real-time data processing units at manufacturing plants. Users anticipate that AI will facilitate the move toward "smart roads" where material properties are dynamically adjusted based on real-time traffic and weather data, ensuring pavements can withstand evolving stresses. The summaries indicate that AI's influence is seen less in direct material modification chemistry and more in the digital optimization of the entire value chain, from raw material sourcing and formulation through to precise, data-driven application and performance monitoring.

- AI-driven predictive maintenance scheduling for optimal timing of chip seals and micro-surfacing applications.

- Optimization of asphalt emulsion formulation using machine learning to correlate raw material ratios with end-product stability and performance metrics.

- Enhanced real-time quality control (QC) during manufacturing through sensor data analysis, ensuring consistent modifier dispersion and particle size distribution.

- Automated analysis of road network conditions (using drones and satellite imagery) to recommend the most suitable modified emulsion type for specific pavement segments.

- Improved supply chain efficiency and inventory management by predicting demand fluctuations for specific modified emulsion types based on infrastructure project pipelines.

- Simulation and digital twinning of pavement performance under various climate and load scenarios, validating emulsion efficacy before field trials.

DRO & Impact Forces Of Modified Asphalt Emulsion Market

The Modified Asphalt Emulsion Market is primarily driven by global governmental emphasis on sustainable, durable infrastructure and the subsequent rise in preventative pavement maintenance activities utilizing cost-effective emulsion treatments. However, the market faces significant restraints stemming from the relatively short shelf life and storage instability of certain high-polymer content emulsions, coupled with dependency on fluctuating crude oil prices, which directly impact the cost of the base bitumen. Opportunities abound in the development of novel, high-stability bio-based emulsifiers and the expansion of market penetration in emerging economies focusing on rapid infrastructure build-out. The market is impacted by influential forces including stringent environmental regulations pushing for lower volatile organic compound (VOC) emissions, high technological barriers related to ensuring consistent modifier dispersion and particle stability, and the competitive pressure from traditional hot mix asphalt alternatives, although the latter is gradually diminishing due to superior life-cycle cost analysis favoring modified emulsions.

The primary Drivers include increasing awareness of life-cycle cost savings provided by modified emulsions compared to conventional maintenance, leading to their preference in long-term public works planning, alongside significant global population growth and urbanization demanding expanded and resilient transportation networks. Restraints are marked by the critical dependence on ambient weather conditions during application, as emulsions require specific temperature ranges for effective curing and setting, limiting their use during colder seasons, and the high performance requirements imposed by end-users necessitating complex, precise formulation, which can sometimes result in production bottlenecks and inconsistencies if quality control is inadequate. The market's high sensitivity to the fluctuating costs of raw materials, particularly petroleum-derived bitumen and synthetic polymers, also acts as a perennial constraint on profit margins for manufacturers.

Opportunities are strongly linked to innovation in sustainable chemistry, specifically the commercialization of warm-mix asphalt emulsions that extend the application window into cooler temperatures and the utilization of recycled materials like crumb rubber or reclaimed asphalt pavement (RAP) integrated into emulsion formulations. Furthermore, geographic expansion into underserved rural areas globally presents a substantial growth trajectory. Impact forces influencing the market dynamics include macro-economic stability influencing governmental infrastructure spending, technological advancements in testing and characterization methods for modified binders ensuring product quality compliance, and shifts in regulatory mandates concerning pavement noise reduction and water runoff management, which favor specialized emulsion surface treatments.

Segmentation Analysis

The Modified Asphalt Emulsion Market is comprehensively segmented based on the type of modifier utilized, the core application area, the material charge type, and the required end-use characteristics. This segmentation allows manufacturers to tailor product offerings precisely to specific project requirements, addressing variations in traffic volume, climatic conditions, and existing pavement structure. Polymer modification dominates the high-performance segment, while application segmentation clearly delineates the massive requirement for pavement preservation treatments versus specialized roofing and waterproofing needs. Understanding these segments is critical for strategic planning, resource allocation, and targeted marketing efforts within the global infrastructure maintenance industry.

- By Type of Modifier:

- Polymer Modified (SBS, SBR, EVA, others)

- Crumb Rubber Modified (CRM)

- Chemical Modified

- Fiber Modified

- By Application:

- Paving (Tack Coats, Chip Seals, Slurry Seals, Micro-surfacing, Fog Seals)

- Roofing

- Waterproofing

- Protective Coatings

- By Material Charge Type:

- Anionic Emulsions

- Cationic Emulsions

- Non-ionic Emulsions

- By End-Use Sector:

- Road Construction & Maintenance

- Building & Construction

- Industrial

Value Chain Analysis For Modified Asphalt Emulsion Market

The value chain for the Modified Asphalt Emulsion Market begins intensely upstream with the sourcing of critical raw materials, primarily crude oil refining to produce base bitumen, and specialized chemical manufacturing to produce emulsifying agents and performance-enhancing modifiers (like SBS polymers). The stability and cost of these upstream inputs significantly dictate the final product cost and market competitiveness. The complexity lies in ensuring a stable supply of consistent quality base asphalt, which directly influences the success of the subsequent emulsification and modification processes. Manufacturers invest heavily in proprietary blending technologies to ensure homogeneous dispersion and long-term storage stability of the complex modified binders, positioning production as a critical, high-value-add stage.

Downstream analysis focuses on the distribution and application phases. Modified asphalt emulsions are typically distributed through a mix of direct sales channels to large governmental highway agencies and indirect distribution via specialized regional distributors and construction material suppliers who maintain local storage and application expertise. Due to the high weight and time-sensitive nature (limited shelf-life), logistics and local storage tank capacity are crucial elements of the downstream segment. The final application stage involves specialized road construction contractors who use sophisticated machinery for precision application (e.g., synchronized chip spreaders for chip seals or micro-surfacing machines). Quality control at the application site is paramount, as improper curing or weather conditions can severely undermine the product's performance, necessitating strong technical support from the manufacturer.

The distribution channel is characterized by a balance between direct and indirect sales. Direct channels are preferred for high-volume public tenders and large-scale infrastructure projects where manufacturers provide technical consultation and supply directly to the primary contractor or governmental body. Indirect channels, utilizing specialized chemical distributors and construction material wholesalers, are more prevalent for smaller maintenance projects, roofing applications, and regions requiring rapid, localized supply. The success of the distribution network hinges on timely delivery and technical expertise provided at the local level to guide proper storage and application techniques, ensuring the high performance characteristics of the modified emulsion are realized by the end-user.

Modified Asphalt Emulsion Market Potential Customers

The primary customers and end-users of modified asphalt emulsions are vast governmental and private entities responsible for maintaining and developing civil infrastructure. Foremost among these are public works departments, state departments of transportation (DOTs), and municipal governments globally, which represent the largest volume buyers for road construction and preventative maintenance applications (e.g., micro-surfacing, chip sealing of highways and local roads). Private road operators and concessionaires, who manage toll roads and large logistical centers, also constitute a significant customer base, valuing the extended service life and reduced maintenance frequency offered by modified products. Beyond road infrastructure, key buyers include commercial roofing contractors specializing in low-slope roofing systems, seeking high-performance, durable, and cold-applied waterproofing solutions, and large industrial clients requiring protective coatings for storage tanks, pipelines, and specialized pavement areas.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $3.5 Billion |

| Market Forecast in 2033 | $5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Akzo Nobel N.V., BASF SE, Kraton Corporation, Arkema SA, Valero Energy Corporation, TotalEnergies SE, Colas Group, Flint Hills Resources, W.R. Meadows Inc., Chevron Phillips Chemical Company LLC, Sinopec, China Petrochemical Corporation, NuStar Energy L.P., Shell plc, Exxon Mobil Corporation, Nynas AB, Paramount Global, Dow Inc., Ingevity Corporation, Marathon Petroleum Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Modified Asphalt Emulsion Market Key Technology Landscape

The technological landscape of the Modified Asphalt Emulsion market is characterized by continuous refinement aimed at improving emulsion stability, enhancing performance characteristics, and reducing environmental impact. A key technology revolves around High-Shear Mixing and Colloid Mill Technology, which is essential for ensuring the uniform dispersion of the base asphalt particles and the modifying agents (especially high-viscosity polymers like SBS) within the aqueous phase. Advanced colloid mills operating at extremely high shear rates are critical to achieving the required particle size distribution (typically 1-10 micrometers) necessary for stable, high-performance emulsions that resist separation during storage and transport. Failure in this stage leads to premature breaking or phase separation, negating the benefits of the modification, hence continuous innovation in mill design and operation parameters, often guided by real-time sensor feedback, remains central to manufacturing excellence.

Another pivotal technological area is Polymer Modification Chemistry and Cross-Linking Agents. The trend has shifted toward creating highly reactive, customized polymers and incorporating sophisticated cross-linking chemistries directly within the emulsion formulation. This allows the polymer network to develop fully during the emulsion curing process on the road, maximizing elasticity and temperature susceptibility resistance. Furthermore, the development of specialized emulsifying agents is crucial. Modern technology focuses on environmentally benign, low-VOC emulsifiers that provide exceptional compatibility with various bitumen sources and modifying polymers, while also accelerating the breaking and setting time of the emulsion on the pavement surface, thus minimizing road closure times and maximizing application efficiency. Bio-based and lignin-derived emulsifiers represent a burgeoning technological opportunity driven by sustainability mandates.

Finally, the growing adoption of Warm Mix Asphalt Emulsion (WMAE) Technology represents a significant shift. Unlike traditional cold emulsions, WMAE systems allow the base bitumen to be modified and emulsified at slightly elevated temperatures (but still significantly below hot mix temperatures), improving workability and extending the application window. These technologies often involve specialized chemical additives that temporarily reduce the viscosity of the emulsion, allowing it to be mixed with aggregates at lower temperatures, leading to substantial reductions in energy consumption, fuming, and greenhouse gas emissions associated with paving operations. The integration of advanced testing methodologies, such as Multiple Stress Creep Recovery (MSCR) testing, is also critical for accurately characterizing the modified binder performance under high-stress conditions, driving the specification and subsequent technological development of superior modified emulsions.

Regional Highlights

The global Modified Asphalt Emulsion Market exhibits distinct dynamics across key regions, influenced by infrastructure maturity, climatic conditions, and regulatory frameworks.

- Asia Pacific (APAC): Dominates the market, propelled by aggressive governmental spending on new highway construction and urban infrastructure development, particularly in China, India, and Southeast Asia. The rapid urbanization rates demand extensive road networks, leading to high consumption volumes. The region is seeing significant adoption of micro-surfacing and chip seals as cost-effective preservation techniques.

- North America: Characterized by a high demand for high-performance, polymer-modified emulsions used primarily in the maintenance, rehabilitation, and preventative preservation of extensive, aging interstate highway systems. Strict performance specifications and a strong regulatory push for sustainable, cold-applied materials are key drivers in the United States and Canada, with crumb rubber modification being notably strong due to waste tire utilization programs.

- Europe: Focuses heavily on sustainability and innovation, driving demand for low-VOC, warm-mix, and bio-based modified emulsions. Market growth is stable, centered on maintaining and upgrading existing high-quality road networks. Germany, France, and the UK are key markets emphasizing longevity and minimized environmental impact in their paving specifications.

- Latin America: Exhibits strong potential growth due to increasing infrastructure investment, particularly in Brazil and Mexico. The market is highly sensitive to economic cycles but shows a growing trend towards adopting polymer modification to address varied climatic zones and improve the durability of new road constructions subjected to heavy loads.

- Middle East and Africa (MEA): Poised for rapid expansion, especially in the Gulf Cooperation Council (GCC) countries, driven by massive construction projects and the need for materials capable of withstanding extreme high temperatures and intense UV radiation. Polymer modification, especially SBS, is highly valued for its ability to resist rutting and softening under severe heat, making performance the overriding procurement factor.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Modified Asphalt Emulsion Market.- Akzo Nobel N.V.

- BASF SE

- Kraton Corporation

- Arkema SA

- Valero Energy Corporation

- TotalEnergies SE

- Colas Group

- Flint Hills Resources

- W.R. Meadows Inc.

- Chevron Phillips Chemical Company LLC

- Sinopec

- China Petrochemical Corporation

- NuStar Energy L.P.

- Shell plc

- Exxon Mobil Corporation

- Nynas AB

- Paramount Global

- Dow Inc.

- Ingevity Corporation

- Marathon Petroleum Corporation

Frequently Asked Questions

Analyze common user questions about the Modified Asphalt Emulsion market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Modified Asphalt Emulsion and how does it differ from standard asphalt?

Modified Asphalt Emulsion (MAE) is a mixture of asphalt binder, water, and an emulsifying agent, enhanced by performance-improving additives such as polymers (e.g., SBS, SBR) or crumb rubber. Unlike standard hot asphalt, MAE is applied at lower temperatures (cold or warm), significantly improving worker safety, reducing energy consumption, and providing enhanced flexibility, resistance to cracking, and overall pavement durability due to the added modifiers.

Which type of modifier dominates the market and why is it preferred for high-stress pavements?

Polymer modifiers, particularly Styrene-Butadiene-Styrene (SBS), dominate the high-performance segment. SBS modification imparts superior elasticity and elastic recovery to the asphalt binder, meaning the pavement can deform under traffic load or temperature changes and return to its original shape, effectively resisting fatigue cracking and rutting common in high-stress, high-volume traffic corridors.

What are the primary applications where modified asphalt emulsions provide the greatest return on investment?

The greatest return on investment (ROI) is achieved in preventative maintenance treatments such as micro-surfacing and chip seals. These applications use modified emulsions to seal existing pavement against water intrusion and restore surface friction, thereby significantly extending the service life of the road for a fraction of the cost required for full pavement rehabilitation or overlay projects.

What are the main constraints facing the adoption of modified asphalt emulsions in construction projects?

Key constraints include the volatility of base bitumen and polymer raw material costs, which impact pricing stability, and the critical issue of storage stability. High-performance modified emulsions often have a limited shelf life and can separate or 'break' if stored improperly or for too long, necessitating tight supply chain management and specialized storage facilities.

How is sustainability impacting the future development of the Modified Asphalt Emulsion market?

Sustainability is a major driver, leading to increased research and commercialization of bio-based emulsifiers, utilization of recycled materials like crumb rubber, and the development of warm-mix emulsion technologies. These innovations reduce reliance on petroleum-derived chemicals, consume waste materials, and lower the energy demands and carbon footprint associated with road construction and maintenance activities globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager