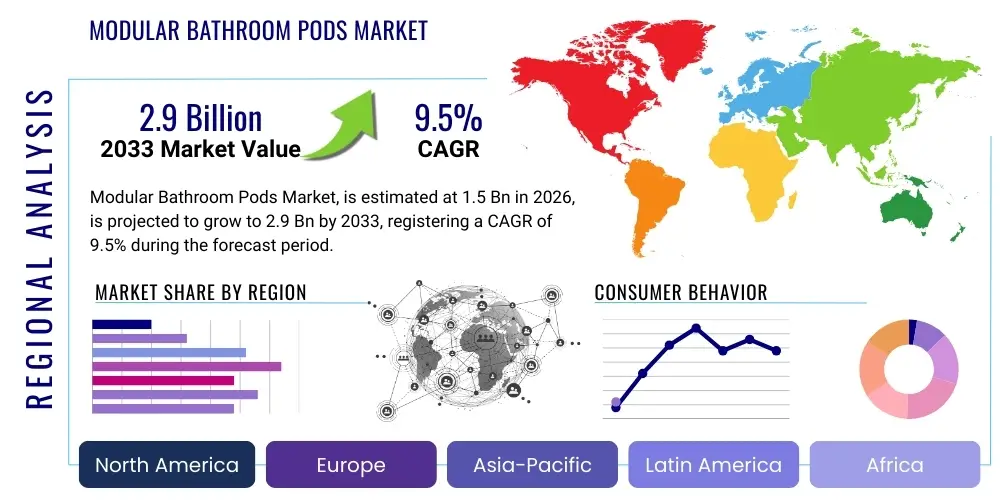

Modular Bathroom Pods Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440891 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Modular Bathroom Pods Market Size

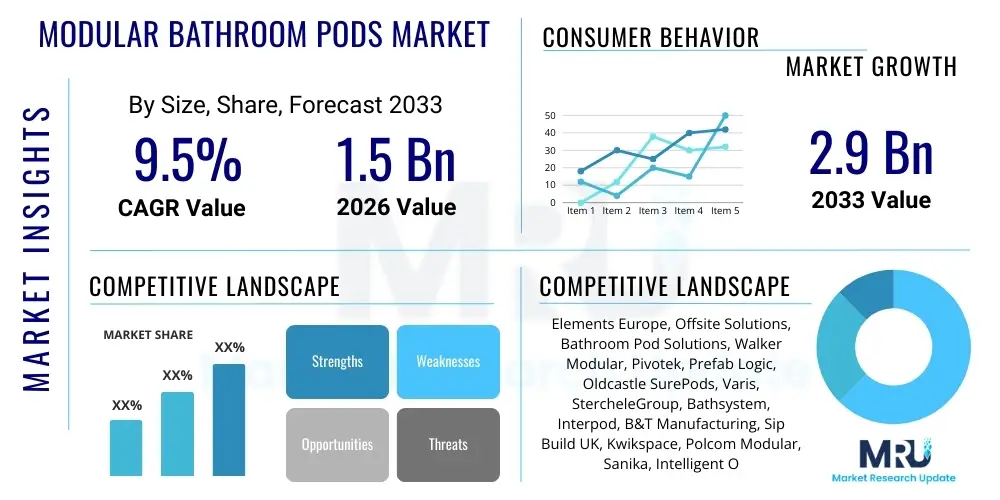

The Modular Bathroom Pods Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.9 Billion by the end of the forecast period in 2033.

Modular Bathroom Pods Market introduction

The Modular Bathroom Pods Market encompasses the design, manufacture, and installation of pre-fabricated, self-contained bathroom units that are produced off-site and installed as plug-and-play modules in construction projects. These units, ranging from high-end luxury specifications to basic functional designs, offer significant advantages in construction efficiency, quality control, and reduction of on-site labor time, making them increasingly popular across diverse sectors globally. The core product involves a fully fitted bathroom delivered as a single unit, complete with plumbing, electrical fittings, fixtures, and finishes, ready for connection to main services. Key applications span residential buildings, student housing, healthcare facilities, hotels, and large infrastructure projects where speed and standardization are critical requirements.

Major applications driving the adoption of modular bathroom pods include high-rise residential developments seeking accelerated construction timelines, and the hospitality sector, which prioritizes standardized, high-quality finishes across multiple rooms with minimal disruption. The benefits inherent to modular construction—such as reduced material waste, predictable costs, improved worker safety, and consistent quality achieved through factory production—are central to the market’s growth trajectory. Furthermore, the ability to concurrently manage off-site manufacturing while on-site preparation takes place significantly reduces overall project duration, addressing persistent industry challenges related to skilled labor shortages and escalating site overheads. This efficiency proposition is particularly appealing in densely populated urban centers with high real estate costs and tight regulatory deadlines.

Driving factors for this market include the global trend toward urbanization and infrastructure modernization, leading to a surge in high-density construction projects. Regulatory pressures for sustainable and energy-efficient building practices further favor modular techniques, as factory environments allow for precise material usage and waste reduction not easily achievable on traditional construction sites. The increasing acceptance of design for manufacturing and assembly (DfMA) methodologies within the architecture, engineering, and construction (AEC) industry is providing a robust foundational platform for market penetration. Additionally, advancements in material science and digital construction tools (such as BIM) are enhancing the customization capabilities and structural integrity of these prefabricated units, broadening their appeal beyond budget housing to encompass premium developments.

Modular Bathroom Pods Market Executive Summary

The Modular Bathroom Pods Market is undergoing rapid expansion, primarily driven by the imperative for faster construction delivery and superior quality control in high-volume projects globally. Business trends indicate a strong shift towards integration, where manufacturers are increasingly offering full design-to-installation services, moving beyond simple production to become comprehensive solution providers. Strategic partnerships between specialized pod manufacturers and large General Contractors (GCs) are defining the competitive landscape, aimed at securing long-term supply contracts for large-scale institutional and residential projects. Furthermore, a discernible trend involves technology integration, utilizing Building Information Modeling (BIM) for precise digital prefabrication and minimizing site rework, thus boosting profitability margins and reinforcing the value proposition of off-site construction methods.

Regionally, Europe and North America currently dominate the market due to established regulatory frameworks supporting modular construction and high labor costs that incentivize off-site manufacturing efficiencies. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by massive urbanization, infrastructure development programs, and a rapidly expanding hospitality sector, especially in countries like China, India, and Southeast Asian nations. Regional trends also reflect variations in material preferences, with North America favoring lightweight steel frame construction for durability and seismic resilience, while parts of Europe show continued reliance on concrete or GRP (Glass Reinforced Plastic) options based on specific fire rating and thermal performance requirements. Local manufacturing hubs are also emerging across developing economies to reduce high logistics costs associated with transporting large, bulky volumetric modules across continents.

Segment trends highlight the dominance of the residential segment (including multi-family housing and student accommodation) due to standardization opportunities and large project scales. In terms of material, the lightweight steel frame segment is experiencing robust growth due to its versatility, structural strength, and compatibility with high-rise structures. The hospitality sector, driven by major hotel chains seeking brand consistency and rapid expansion, remains a critical high-value application segment. Future trends indicate growing demand for highly customized pods in the healthcare sector, which requires specialized features related to hygiene and accessibility, alongside a push toward sustainable and recyclable materials across all end-use segments.

AI Impact Analysis on Modular Bathroom Pods Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Modular Bathroom Pods market predominantly center on optimizing the design and manufacturing workflow, enhancing supply chain predictability, and automating quality control processes. Common themes include how AI can rapidly generate optimal pod layouts based on project constraints (space, budget, technical specifications), manage the complex logistics of coordinating material flow for mass customization, and apply machine learning algorithms to defect detection during the assembly phase. Concerns often revolve around the initial capital investment required for adopting AI-driven manufacturing systems and the potential disruption to established conventional design practices. Expectations are high regarding AI’s ability to further compress construction timelines and minimize material waste, thereby maximizing the inherent cost and sustainability benefits of modular construction.

The deployment of AI is anticipated to revolutionize the front-end design process, moving beyond traditional parametric modeling towards generative design where algorithms explore thousands of viable pod configurations, optimized for structural efficiency, material cost, and manufacturability, within minutes. This capability drastically shortens the design lifecycle, allowing manufacturers to quickly prototype and customize solutions for diverse client requirements—a major competitive advantage in the high-stakes modular construction industry. Furthermore, predictive maintenance models, leveraging AI, can analyze sensor data from manufacturing equipment to forecast failures, ensuring maximum production uptime and reliability in factory settings, which is crucial for meeting demanding project deadlines.

In the supply chain, AI algorithms can process vast amounts of data regarding material lead times, geopolitical risks, and transport logistics to create highly resilient and efficient material procurement schedules. This mitigates delays, a common bottleneck in construction, by providing accurate, real-time forecasts of component availability. For quality assurance, computer vision systems powered by deep learning are being integrated into assembly lines to perform automated, consistent inspections of plumbing, electrical work, and surface finishes, ensuring every pod adheres precisely to specifications before leaving the factory floor, far exceeding the consistency achievable through manual checks.

- AI-driven generative design accelerates optimal pod layout creation, reducing pre-construction lead times.

- Predictive analytics optimizes inventory management and supply chain logistics for just-in-time material delivery.

- Machine learning algorithms enhance quality control through automated visual inspection systems on the assembly line.

- Robotic process automation, guided by AI, improves precision and throughput in repetitive manufacturing tasks.

- AI facilitates mass customization by efficiently managing variations in component specifications across high-volume production runs.

- Predictive maintenance schedules for manufacturing machinery increase factory uptime and operational efficiency.

DRO & Impact Forces Of Modular Bathroom Pods Market

The Modular Bathroom Pods market is significantly influenced by a dynamic interplay of factors categorized under Drivers, Restraints, and Opportunities (DRO). Major drivers include the global push for accelerated construction schedules and the critical shortage of skilled on-site labor, compelling developers to adopt off-site manufacturing solutions. Restraints primarily involve the substantial upfront capital investment required for establishing dedicated manufacturing facilities and the inherent logistical challenges associated with transporting oversized modules to complex urban sites. Opportunities lie primarily in leveraging advanced digital technologies like BIM and AI for enhanced customization and operational efficiency, alongside expanding penetration into emerging markets and specialized sectors like high-end luxury residential and healthcare facilities, providing customized solutions that meet stringent industry standards. These forces collectively shape the market’s growth trajectory and competitive dynamics, favoring companies that can achieve scale and technological superiority.

The core impact forces shaping this market revolve around economic stability, regulatory acceptance, and technological maturity. Economic impact forces are primarily manifest through fluctuating material costs (e.g., steel, timber, composites) and access to financing for large-scale factory investments. Regulatory impact forces include regional variations in building codes, acceptance of off-site manufactured elements, and specific fire and seismic standards that must be met, which can either facilitate or impede market entry. Finally, technological impact forces—driven by advancements in robotic assembly, additive manufacturing (3D printing of fixtures), and sophisticated project management software—are continually reducing production costs and enhancing the quality and design complexity achievable with modular methods, thereby lowering entry barriers for innovative players and increasing the overall attractiveness of the solution.

Further analysis of the market structure reveals that standardization challenges within the global construction industry act as a critical restraint. Unlike automotive manufacturing, construction projects often require unique specifications, making it difficult for pod manufacturers to achieve perfect economies of scale across diverse client portfolios. Furthermore, the perception among some traditional developers that modular construction equates to lower quality or less design flexibility remains a soft barrier, requiring sustained market education and successful high-profile project completions to overcome. Conversely, the sustainability mandate presents a powerful opportunity; modular construction's lower waste footprint and higher energy efficiency potential are becoming essential selling points as developers pursue green building certifications and meet increasingly stringent environmental, social, and governance (ESG) investor requirements.

Segmentation Analysis

The Modular Bathroom Pods market is segmented based on critical attributes including Material Type, Construction Type, End-Use Sector, and Size. This segmentation allows for precise market targeting and reflects the diverse needs of the construction industry globally. Material type differentiation, such as GRP, Steel Frame, and Concrete, dictates the cost, weight, durability, and suitability for different applications, with GRP often favored for lightweight, high-volume projects, and steel/concrete preferred for structural integrity in high-rise and luxury installations. Construction type distinguishes between new builds, which represent the bulk of demand, and renovation/refurbishment projects, a growing segment focusing on quick facility upgrades. The End-Use sector analysis is crucial, highlighting the varying demands from hospitality, residential, healthcare, and commercial applications, each requiring specialized compliance and finish standards, ultimately determining pricing and competitive intensity across the market.

- Material Type

- Glass Reinforced Plastic (GRP) Pods

- Steel Frame Pods

- Concrete Pods

- Hybrid Pods

- Construction Type

- New Construction

- Renovation & Refurbishment

- End-Use Sector

- Residential (Multi-Family, Student Housing)

- Hospitality (Hotels, Resorts)

- Healthcare (Hospitals, Clinics, Aged Care)

- Commercial (Offices, Retail)

- Industrial/Infrastructure

- Size/Weight

- Standard Size Pods

- Custom/Large Pods

Value Chain Analysis For Modular Bathroom Pods Market

The value chain for the Modular Bathroom Pods market is characterized by a high degree of integration between design, manufacturing, and installation phases, distinguishing it significantly from traditional construction supply chains. Upstream activities involve the sourcing of raw materials, including steel, composite materials (GRP resins), sanitary ware, fittings, and internal finishes. Efficiency in this phase is highly dependent on strong relationships with specialized suppliers and bulk purchasing agreements to maintain cost competitiveness. Midstream activities encompass the core intellectual property and manufacturing processes: design refinement using BIM, factory assembly, quality control checks, and transportation logistics planning. The ability of manufacturers to optimize the flow of components through the assembly line using lean manufacturing principles directly impacts profitability and throughput.

Downstream activities center on logistics and final integration at the construction site. This involves specialized heavy lifting and precise placement of the fully fitted pods, followed by connection to the site's main services (plumbing and electrical). The distribution channel relies heavily on direct sales and collaborative partnerships. Most high-volume transactions are direct, involving long-term contracts between the pod manufacturer and the General Contractor (GC) or the developer. Indirect channels may involve specialized distributors or agents in specific geographical areas, particularly in fragmented markets or for smaller-scale projects, though this is less common for large, complex modular solutions.

The dominant distribution strategy is a direct-to-developer/GC model, offering greater control over the complex logistics and installation process, ensuring technical specifications are met precisely. This direct approach allows manufacturers to provide comprehensive post-installation support and warranties. The value proposition is maximized when the manufacturer actively participates in the early design phase (DfMA), aligning the pod specification perfectly with the overall building structure, thereby minimizing potential clashes and maximizing the efficiency gains of the modular system. Technology integration, specifically using cloud-based project management platforms, is vital for seamless communication across the entire chain—from material procurement to final site handover.

Modular Bathroom Pods Market Potential Customers

The primary customer segments for Modular Bathroom Pods are large-scale property developers, institutional investors, and governmental agencies focused on high-volume, repetitive construction projects where schedule predictability and consistent quality are paramount. End-users or buyers typically fall into sectors such as multi-family residential housing, where projects involve hundreds or thousands of standardized units; the hospitality sector, specifically major hotel chains seeking brand consistency across various locations; and public sector institutions like universities requiring quick deployment of student housing or hospitals needing efficient, hygienic patient facilities. The driving force for these customers is the reduction of site disruption, guaranteed adherence to fixed budgets, and the ability to significantly compress the overall project timeline compared to traditional construction methods.

In the hospitality industry, the demand is fueled by the need for rapid facility refurbishment to minimize downtime and revenue loss, making the swift, clean installation of modular pods highly desirable. For the healthcare sector, specialized customers require pods designed to meet stringent infection control standards, accessibility mandates (ADA compliance), and robust durability specifications. Furthermore, the burgeoning build-to-rent (BTR) residential market represents a rapidly expanding customer base, as these institutional investors prioritize low maintenance costs and high-quality finishes delivered efficiently to ensure rapid occupancy rates and long-term asset value retention. Manufacturers often engage with these customers through early contractor involvement (ECI) to tailor solutions perfectly to specific project requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.9 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Elements Europe, Offsite Solutions, Bathroom Pod Solutions, Walker Modular, Pivotek, Prefab Logic, Oldcastle SurePods, Varis, StercheleGroup, Bathsystem, Interpod, B&T Manufacturing, Sip Build UK, Kwikspace, Polcom Modular, Sanika, Intelligent Offsite, Qube Modular, Ten Fold Engineering, ADMA Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Modular Bathroom Pods Market Key Technology Landscape

The manufacturing of modular bathroom pods relies heavily on advanced fabrication techniques and integrated digital platforms to ensure precision and scalability. A key technology is Building Information Modeling (BIM), which is essential for translating architectural designs into factory production plans, enabling detailed clash detection, and ensuring all mechanical, electrical, and plumbing (MEP) components are placed accurately within the constrained volumetric space of the pod. Robotics and automation are increasingly deployed within production facilities for repetitive tasks such as welding, material handling, and the application of finishes like tiling, guaranteeing extremely high levels of consistency and significantly faster cycle times than manual construction. This focus on DfMA principles is central to maintaining the competitive edge of modular solutions.

Furthermore, material science innovations play a crucial role in enhancing product performance. This includes the development of lightweight, high-strength composite materials, particularly advanced Glass Reinforced Plastic (GRP) formulations that offer superior water resistance, durability, and reduced structural load compared to traditional construction. Alongside materials, the implementation of sophisticated enterprise resource planning (ERP) systems is critical for managing the complex interplay of component suppliers, scheduling production batches, and coordinating the logistics of delivery and installation on multiple sites simultaneously. These systems ensure just-in-time delivery of components to the assembly line, minimizing inventory holding costs and maximizing manufacturing throughput.

Digital quality control technologies, such as laser scanning and 3D measurement systems, are utilized at various stages of production to verify dimensional accuracy before the units are sealed and shipped. The integration of Internet of Things (IoT) sensors within the pods during manufacturing, particularly in high-specification projects like healthcare or hotels, allows for remote monitoring of critical systems during transport and early stages of operation. This technological convergence—from digital design tools (BIM) to automated manufacturing (Robotics) and operational monitoring (IoT)—is defining the modern competitive framework, allowing manufacturers to move from standardized bulk production to efficient mass customization.

Regional Highlights

- North America: This region is characterized by high labor costs and a mature construction industry increasingly adopting DfMA methodologies. The U.S. and Canada represent robust markets, primarily driven by large-scale multi-family residential projects and significant institutional investment in student housing. Regulatory acceptance for modular construction is generally high, supported by standardized building codes and a strong focus on fast-track project delivery, especially in high-density urban areas like New York and Vancouver.

- Europe: Europe is a pioneering region for modular construction, benefiting from early adoption and a strong emphasis on sustainability and energy efficiency standards (e.g., Passive House). Countries like the UK, Germany, and the Nordic nations lead the market, driven by social housing initiatives, extensive hospitality renovations, and advanced manufacturing capabilities. GRP and high-quality steel-framed pods are widely utilized, supported by specialized logistics networks and favorable governmental policies promoting off-site construction for efficiency and environmental benefits.

- Asia Pacific (APAC): Expected to be the fastest-growing market globally due to unprecedented rates of urbanization and infrastructure development in economies such as China, India, Japan, and Australia. The demand is heavily fueled by mass residential projects, new hotel construction, and the rapid expansion of healthcare infrastructure. While logistical challenges in diverse geographies exist, the immense scale of construction opportunities and the need for speed make modular pods a highly attractive solution, with local manufacturing clusters rapidly gaining technological capability.

- Latin America: This market is emerging, characterized by variable economic stability and varying levels of construction sophistication. Adoption is focused mainly on commercial projects, infrastructure developments, and select hospitality expansions, particularly in stable economies like Mexico and Brazil. Market growth here relies on technology transfer and cost optimization, proving the long-term economic benefits over traditional, often slower, construction methods.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) nations (UAE, Saudi Arabia) due to large-scale government-backed infrastructure and tourism projects (e.g., NEOM, Expo-related developments). The demand is for high-specification, durable pods capable of withstanding extreme environmental conditions. The primary drivers are ambitious national development visions and strict timelines, encouraging the rapid deployment of prefabricated solutions in remote or highly controlled construction environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Modular Bathroom Pods Market.- Elements Europe

- Offsite Solutions

- Bathroom Pod Solutions

- Walker Modular

- Pivotek

- Prefab Logic

- Oldcastle SurePods

- Varis

- StercheleGroup

- Bathsystem

- Interpod

- B&T Manufacturing

- Sip Build UK

- Kwikspace

- Polcom Modular

- Sanika

- Intelligent Offsite

- Qube Modular

- Ten Fold Engineering

- ADMA Group

- Modular Systems Inc.

- Volumetric Building Companies (VBC)

- Triumph Modular

- Envision Building Systems

- Denvir Construction

- Box Modular

- Capsule Modular

- Modular Solutions Ltd

- Fremantle Constructions

- Skidmore Construction

- TSSC (Technical Supplies & Services Co.)

- Nixon Hire

- ATCO Structures & Logistics

- Horizon North Logistics

- Black Diamond Group

Frequently Asked Questions

Analyze common user questions about the Modular Bathroom Pods market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary cost benefits of using modular bathroom pods?

The primary cost benefits include significant reductions in on-site labor expenses, minimized material waste due to factory efficiency, faster project completion resulting in lower financing costs, and predictable unit costs established prior to site installation, mitigating budget overruns.

Which end-use sector drives the highest demand for modular bathroom pods?

The Residential segment, specifically multi-family housing and student accommodation, typically generates the highest volume demand due to the potential for standardization and the repetitive nature of the units. The Hospitality sector, however, often drives demand for higher-specification, customized pods.

How do modular bathroom pods address quality control issues in construction?

Pods address quality control by shifting construction from variable, exposed site environments to controlled, climate-regulated factory settings. This allows for rigorous, multi-stage quality checks using standardized processes and often automated systems, ensuring superior and consistent finished quality.

What is the typical lifespan and maintenance requirement for a GRP modular pod versus a steel frame pod?

GRP pods typically offer excellent longevity (30+ years) with minimal maintenance due to their seamless, non-porous surfaces resistant to water damage and mold. Steel frame pods, while structurally robust and durable, may require standard maintenance checks for finishes but are favored for their compatibility with high-rise structural requirements.

What role does BIM technology play in the manufacturing of modular bathroom pods?

BIM (Building Information Modeling) is essential for digital prefabrication. It ensures precise coordination between architectural, structural, and MEP systems, minimizing clashes, generating accurate component lists for procurement, and creating the digital blueprint necessary for the factory assembly process.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager