Montelukast Intermediate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442634 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Montelukast Intermediate Market Size

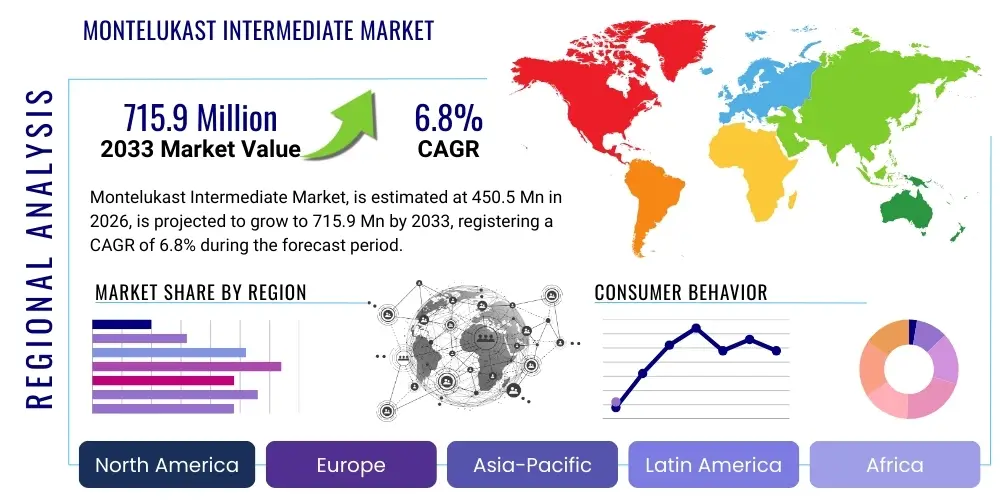

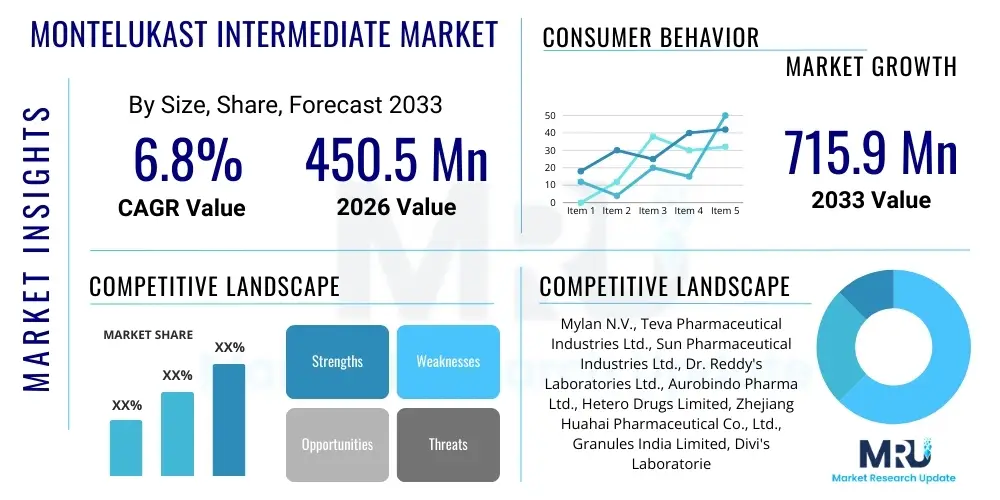

The Montelukast Intermediate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 715.9 Million by the end of the forecast period in 2033.

Montelukast Intermediate Market introduction

The Montelukast Intermediate Market encompasses the specialized chemical compounds required for the synthesis of Montelukast, a globally recognized leukotriene receptor antagonist predominantly used in the treatment of asthma and allergic rhinitis. Montelukast sodium acts by blocking the action of leukotrienes, inflammatory mediators released in the airways that cause bronchoconstriction and mucus secretion. Key intermediates, such as 1-(mercaptomethyl)cyclopropaneacetic acid and various chiral precursors, are critical components whose quality, purity, and efficient production directly influence the final drug efficacy and cost structure. The increasing global prevalence of respiratory disorders, coupled with sustained demand for cost-effective generic versions of Montelukast, establishes a robust foundation for market growth, particularly across emerging economies where air quality challenges necessitate increased therapeutic intervention.

Product Description in this market primarily includes highly purified chemical entities used in the multi-step synthesis route of Montelukast. The major applications are strictly confined to pharmaceutical manufacturing, serving both large-scale generic drug producers and innovator companies seeking streamlined supply chains. Benefits derived from optimized intermediate production include reduced manufacturing cycle times, minimized risk of contamination, and enhanced compliance with stringent regulatory standards imposed by bodies like the FDA and EMA. Driving factors include expanding healthcare expenditure in the Asia Pacific region, the expiration of key Montelukast patents enabling generic proliferation, and continuous advancements in chemical synthesis technologies aimed at improving yield and sustainability, thus creating compelling opportunities for intermediate suppliers specializing in high-quality, scalable production.

Montelukast Intermediate Market Executive Summary

The Montelukast Intermediate Market demonstrates resilient growth driven by sustained clinical demand for asthma management and the robust expansion of the global generic pharmaceuticals sector. Business trends indicate a strong focus on strategic vertical integration by major Active Pharmaceutical Ingredient (API) manufacturers, aiming to secure intermediate supply chains and mitigate volatility in raw material costs. Furthermore, geopolitical shifts and heightened regulatory scrutiny concerning source material traceability are prompting pharmaceutical companies to diversify their supplier base, favoring manufacturers with established quality management systems and clear environmental, social, and governance (ESG) commitments. Efficiency gains through optimized chemical synthesis processes, such as enzymatic catalysis and continuous flow chemistry, are transforming the competitive landscape, rewarding suppliers capable of delivering high-purity intermediates consistently at competitive prices.

Regional Trends highlight the Asia Pacific (APAC) as the primary engine of market expansion, primarily due to the concentration of large-scale generic API production hubs in India and China, coupled with a vast and underserved patient population requiring respiratory medication. North America and Europe, while mature markets, continue to represent significant revenue streams, emphasizing quality assurance and rapid regulatory compliance for intermediate suppliers. Segment trends reveal increasing demand for high-purity intermediates (above 99.5%), necessitated by stricter impurity guidelines set forth by regulatory bodies globally. Furthermore, the market is observing a segmentation shift towards specialized, protected intermediates that offer intellectual property advantages or simplified final-step synthesis, allowing API producers to differentiate their offerings in a highly competitive therapeutic area.

AI Impact Analysis on Montelukast Intermediate Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Montelukast Intermediate Market frequently center on themes of enhanced synthesis efficiency, quality control, and supply chain predictability. Users are specifically concerned with how machine learning algorithms can accelerate the identification of novel, higher-yielding synthetic routes for complex intermediates, thereby reducing research and development timelines and minimizing waste. A secondary, critical user concern revolves around AI's capability to monitor real-time chemical reaction parameters (pressure, temperature, flow rate) during intermediate production, ensuring batch consistency and preemptively identifying potential quality deviations, which is crucial given the pharmaceutical nature of the end product. Expectations are high that AI will optimize raw material sourcing and inventory management, providing predictive models for demand fluctuations based on global respiratory disease outbreaks and patient prescription patterns, ultimately stabilizing the highly sensitive pharmaceutical supply chain.

- AI-driven Retrosynthesis Planning: Utilizing algorithms to design more efficient, environmentally friendly, and cost-effective synthetic routes for complex Montelukast precursors.

- Process Optimization: Implementation of Machine Learning (ML) models to fine-tune reaction conditions (e.g., solvent selection, catalyst concentration) in real-time, maximizing intermediate yield and purity.

- Predictive Quality Control (PQC): AI deployment in manufacturing facilities to analyze spectroscopic data and sensor readings, predicting potential batch failures before they occur and ensuring regulatory compliance.

- Supply Chain Resilience: Use of AI for demand forecasting and risk assessment, optimizing inventory levels of raw materials and intermediates to prevent critical shortages.

- Green Chemistry Enhancement: Employing AI simulations to identify synthesis pathways that minimize the use of hazardous solvents and reduce energy consumption in intermediate production.

DRO & Impact Forces Of Montelukast Intermediate Market

The Montelukast Intermediate Market is currently shaped by a delicate balance of strong demand drivers originating from public health needs and stringent regulatory restraints impacting production complexity and cost. Opportunities predominantly stem from technological advancements in chemical engineering and globalization of healthcare access, while the collective impact forces compel stakeholders to prioritize operational efficiency and regulatory adherence. The core driver remains the escalating global incidence of chronic respiratory conditions such as asthma, particularly in densely populated and industrialized regions, necessitating sustained pharmaceutical intervention. Conversely, significant restraints include the intense price pressure exerted by generic competition, which necessitates continual cost reduction without compromising the critical quality attributes required for API synthesis, alongside increasing environmental regulations concerning chemical waste management.

Key impact forces involve the persistent need for backward integration within the pharmaceutical supply chain to secure high-quality inputs, minimizing reliance on external suppliers for critical raw materials. This trend drives mergers and acquisitions among API manufacturers and intermediate producers, consolidating market power and technological expertise. Opportunities are emerging through the adoption of innovative manufacturing techniques, specifically continuous flow chemistry, which offers superior control, reduced reactor size, and enhanced safety profile compared to traditional batch processing. Furthermore, expansion into underserved markets, particularly in Africa and Latin America, presents significant long-term growth potential for generic Montelukast manufacturers, thereby boosting demand for intermediates. Successful navigation of these dynamic forces requires robust investment in both process innovation and regulatory compliance infrastructure.

Segmentation Analysis

The Montelukast Intermediate Market is segmented across several critical dimensions, enabling stakeholders to analyze demand patterns, competitive dynamics, and technological preferences within the pharmaceutical supply chain. These segmentations are crucial for identifying niche opportunities and understanding the specific requirements imposed by different end-user types and regulatory environments. The primary methods of classification include the type of intermediate (defined by its chemical structure and position in the synthesis route), the application (primarily generic drug manufacturing versus research and development), the purity level (which correlates directly with regulatory clearance), and the manufacturing process employed (batch versus continuous flow). Detailed analysis of these segments reveals distinct growth trajectories, with high-purity and advanced intermediates witnessing accelerated demand due to stricter pharmaceutical guidelines worldwide.

Analysis by intermediate type confirms that intermediates integral to the final steps of synthesis, such as the Montelukast thiol derivative and specific cyclopropaneacetic acid compounds, constitute the largest revenue segments due to their immediate proximity to the final API. Segmentation by application shows that generic API manufacturing dominates the consumption volume globally, driven by patent expirations and increasing market saturation of low-cost versions of the drug. High-volume, standardized intermediates are prioritized here. Conversely, intermediates used in research and development, though smaller in volume, demand extremely high purity and specialized batch sizes, often commanding premium pricing due to the complexity of synthesis and low volume requirements.

Further segmentation based on purity reveals a significant trend towards 99.5% purity and above, reflecting the industry's shift away from acceptable trace impurity levels to maximize patient safety and regulatory acceptance. The segmentation based on the manufacturing process highlights the nascent but rapidly growing adoption of continuous manufacturing technologies. While traditional batch processing currently holds the majority share, continuous flow methodologies are increasingly being explored, particularly by innovative suppliers in developed economies, offering long-term prospects for reduced operational costs and improved environmental footprints, signaling a potential long-term technological shift in intermediate production.

- By Intermediate Type:

- 1-(mercaptomethyl)cyclopropaneacetic acid

- (S)-tert-butyl 2-(3-((3-(2-(7-chloro-2-quinolinyl)ethenyl)phenyl)-3-hydroxypropyl)phenyl)acetate

- Montelukast Thiol Intermediate

- Other Critical Precursors

- By Application:

- Generic Drug Manufacturing

- Branded Drug Manufacturing

- Research & Development (R&D)

- By Purity Level:

- 98% - 99% Purity

- Above 99.5% Purity (High Purity Grade)

- By Manufacturing Process:

- Batch Manufacturing

- Continuous Flow Manufacturing

Value Chain Analysis For Montelukast Intermediate Market

The value chain for the Montelukast Intermediate Market commences with upstream raw material procurement, which involves securing basic commodity chemicals and specialized reagents, primarily sourced from the petrochemical and fine chemical industries. Upstream analysis focuses intensely on the cost volatility and purity of these starting materials, as fluctuations significantly impact the final intermediate cost structure and manufacturing viability. Intermediate manufacturers then engage in complex, multi-step chemical synthesis, where process optimization and quality control are paramount. This stage involves substantial capital investment in specialized reaction vessels, analytical equipment, and skilled chemical engineers. The efficiency of the upstream segment is critical; secure, reliable, and diversified sourcing of initial precursors minimizes production downtime and shields intermediate suppliers from supply shocks, which is a major concern in the globalized pharmaceutical supply chain.

The distribution channel is predominantly direct or highly controlled indirect, given the high-value and regulated nature of the product. Direct distribution is favored by major API manufacturers who contract directly with intermediate suppliers under long-term supply agreements to ensure specification compliance and traceability. Indirect channels involve specialized chemical distributors who handle warehousing, logistics, and quality assurance documentation for smaller pharmaceutical clients or international markets where direct shipment is logistically complex. Downstream analysis focuses on the buyers—the API manufacturers—who transform the intermediates into the final Montelukast API through terminal synthesis steps. Further downstream are the Finished Dosage Form (FDF) manufacturers who formulate the final tablets or granules, ultimately supplying the healthcare system. The entire value chain is characterized by stringent regulatory oversight, dictating the necessity for exhaustive documentation and validation at every transfer point, emphasizing quality over cost minimization.

Montelukast Intermediate Market Potential Customers

Potential customers for Montelukast Intermediates are concentrated within the pharmaceutical industry, specifically encompassing two primary categories: Active Pharmaceutical Ingredient (API) manufacturers and Contract Development and Manufacturing Organizations (CDMOs). API manufacturers, particularly those specializing in generic drug production, represent the largest volume consumers. These companies require large, consistent batches of high-purity intermediates to scale up their production of Montelukast Sodium, targeting global markets where generic penetration is high. Their purchasing decisions are primarily influenced by price competitiveness, supplier reliability, and demonstrated compliance with global regulatory standards, including good manufacturing practices (GMP).

CDMOs also constitute a critical customer segment, offering integrated services from process optimization to large-scale commercial manufacturing for pharmaceutical companies, both branded and generic. These organizations increasingly seek specialized, high-quality intermediates to ensure smooth technology transfer and scalable production for their diverse client portfolio. Furthermore, smaller, niche research and development laboratories, focused on novel drug delivery systems or next-generation formulations of Montelukast, are also customers, albeit requiring smaller, often custom-synthesized batches of intermediates. The trend of outsourcing API and intermediate manufacturing to CDMOs is significantly expanding the customer base beyond traditional in-house API producers, demanding flexibility and rapid adaptation from intermediate suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 715.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mylan N.V., Teva Pharmaceutical Industries Ltd., Sun Pharmaceutical Industries Ltd., Dr. Reddy's Laboratories Ltd., Aurobindo Pharma Ltd., Hetero Drugs Limited, Zhejiang Huahai Pharmaceutical Co., Ltd., Granules India Limited, Divi's Laboratories Ltd., BASF SE, Lonza Group AG, Dishman Carbogen Amcis Ltd., Manus Aktteva Biopharma LLP, Lianyungang Xingang Pharmaceutical Co., Ltd., Nanjing Sanchuan Chemical Co., Ltd., Hubei Dongchao Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Montelukast Intermediate Market Key Technology Landscape

The manufacturing landscape for Montelukast Intermediates is rapidly evolving, driven by the dual needs of achieving ultra-high purity required by modern pharmacopoeias and improving sustainability profiles. Traditional production relies heavily on multi-step batch synthesis, which, while established and scalable, often involves significant solvent usage, waste generation, and complex purification steps. However, the emerging technological focus is centered on Green Chemistry principles. Key technological advancements involve the sophisticated use of chiral synthesis techniques, particularly biocatalysis and asymmetric synthesis, enabling the efficient production of the stereochemically pure intermediates crucial for Montelukast, minimizing undesirable enantiomers that can affect drug safety and efficacy. These methods not only improve yield but also significantly reduce the environmental impact associated with traditional chemical routes, aligning with global pharmaceutical industry sustainability mandates.

A transformative technology gaining traction is Continuous Flow Manufacturing (CFM). Unlike traditional batch reactors, CFM utilizes specialized microreactors or tube reactors, allowing reactions to occur in a continuous stream under highly controlled conditions. This approach offers superior reaction management, instantaneous mixing, and precise temperature control, which are essential for exothermic or complex multi-phase reactions common in Montelukast intermediate synthesis. The benefits include enhanced safety, reduced footprint, and quicker scale-up from pilot to commercial production, leading to lower overall capital expenditure in the long run. Furthermore, advanced analytical techniques, such as Process Analytical Technology (PAT), are being integrated directly into the manufacturing lines. PAT allows for real-time monitoring of critical quality attributes (CQAs) of the intermediates, ensuring that deviations are identified and corrected instantly, significantly improving product consistency and expediting regulatory release processes, thereby driving the adoption of more automated and technologically intensive manufacturing platforms globally.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global intermediate market in terms of production volume and holds the fastest growth potential. Countries like India and China serve as the epicenter for generic API manufacturing, leveraging cost advantages, established chemical infrastructure, and a substantial skilled workforce. The regional demand is further fueled by the massive patient pool requiring affordable respiratory medication and government initiatives supporting domestic pharmaceutical production and exports. Regulatory compliance and quality consistency, however, remain key challenges for local suppliers aiming for export to highly regulated Western markets.

- North America: North America represents a mature, high-value consumer market, prioritizing regulatory compliance and guaranteed quality over absolute cost minimization. Demand for Montelukast intermediates is stable, driven by sustained prescription volumes and stocking requirements by major pharmaceutical companies and CDMOs based in the U.S. and Canada. The region focuses heavily on adopting advanced manufacturing technologies like Continuous Flow, ensuring supply chain resilience and minimizing geopolitical risks associated with overseas sourcing.

- Europe: Similar to North America, the European market emphasizes stringent quality assurance, traceability, and adherence to EU GMP guidelines. European intermediate suppliers often focus on niche, high-purity intermediates or utilize sophisticated green chemistry processes to meet strict environmental regulations. The market growth is stable, underpinned by established healthcare systems and high per capita expenditure on respiratory drugs, making quality certification (e.g., CEP/EDMF filing) a prerequisite for market entry.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions are emerging as significant growth areas, driven by improving healthcare access, growing disposable income, and increasing awareness of chronic respiratory diseases. While domestic production of intermediates remains limited, rising demand for affordable generic Montelukast APIs in these regions translates to increased imports of intermediates, creating long-term opportunities for global suppliers focused on expanding their distribution networks and regulatory documentation support.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Montelukast Intermediate Market.- Mylan N.V. (Viatris)

- Teva Pharmaceutical Industries Ltd.

- Sun Pharmaceutical Industries Ltd.

- Dr. Reddy's Laboratories Ltd.

- Aurobindo Pharma Ltd.

- Hetero Drugs Limited

- Zhejiang Huahai Pharmaceutical Co., Ltd.

- Granules India Limited

- Divi's Laboratories Ltd.

- BASF SE

- Lonza Group AG

- Dishman Carbogen Amcis Ltd.

- Manus Aktteva Biopharma LLP

- Lianyungang Xingang Pharmaceutical Co., Ltd.

- Nanjing Sanchuan Chemical Co., Ltd.

- Hubei Dongchao Chemical Co., Ltd.

- Shandong Xinhua Pharmaceutical Co., Ltd.

- Jubilant Life Sciences Ltd.

- Wockhardt Ltd.

- Cipla Ltd.

Frequently Asked Questions

Analyze common user questions about the Montelukast Intermediate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Montelukast Intermediates?

The primary driver is the increasing global prevalence of chronic respiratory diseases, such as asthma and allergic rhinitis, coupled with the widespread adoption of generic Montelukast formulations following patent expirations, necessitating large volumes of high-purity precursors.

Which geographical region dominates the production of Montelukast Intermediates?

The Asia Pacific (APAC) region, specifically manufacturing hubs in India and China, currently dominates the production volume, driven by established chemical synthesis capabilities, lower operational costs, and significant generic API manufacturing capacity.

How is technology influencing the manufacturing process of these intermediates?

Key technological advancements include the adoption of Continuous Flow Manufacturing (CFM) for enhanced yield and safety, and the use of sophisticated asymmetric and biocatalysis methods to ensure the production of stereochemically pure intermediates compliant with stringent regulatory requirements.

What purity level is currently mandated for high-quality Montelukast Intermediates?

Regulatory and industry trends increasingly mandate a minimum purity level of 99.5% and above for critical Montelukast intermediates to minimize impurities and ensure the safety and efficacy of the final Active Pharmaceutical Ingredient (API).

Who are the main buyers in the Montelukast Intermediate market value chain?

The main buyers are Active Pharmaceutical Ingredient (API) manufacturers, particularly large generic pharmaceutical companies, and Contract Development and Manufacturing Organizations (CDMOs) who synthesize the final drug substance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager