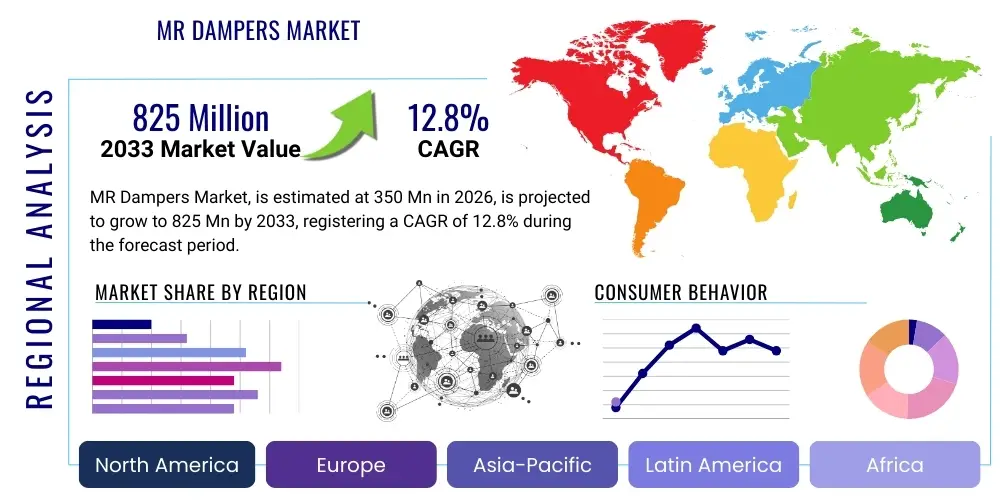

MR Dampers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442414 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

MR Dampers Market Size

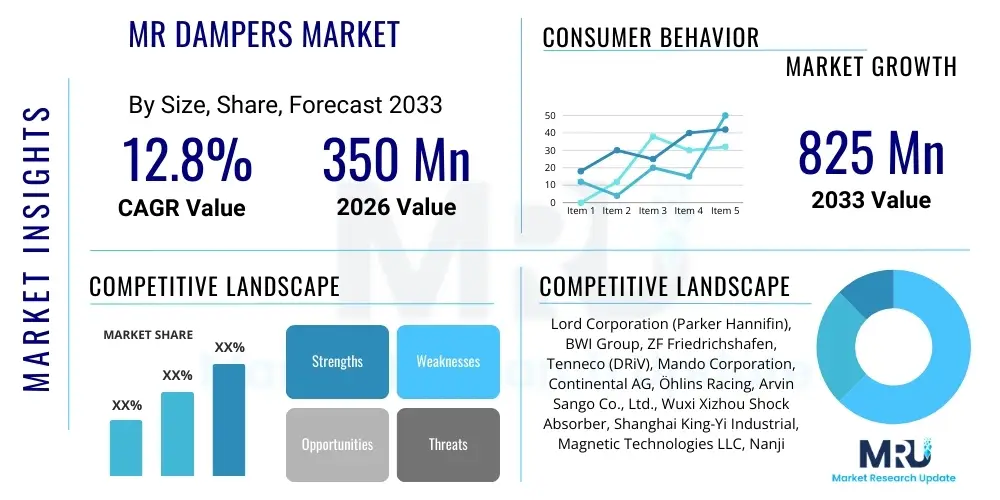

The MR Dampers Market, critical for advanced semi-active suspension and vibration control systems, is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.8% between 2026 and 2033. This robust expansion is fueled by increasing demand for enhanced safety, comfort, and stability across high-performance automotive and specialized industrial applications. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 825 Million by the end of the forecast period in 2033, demonstrating a significant shift towards smart, adaptive damping technologies.

MR Dampers Market introduction

Magnetorheological (MR) dampers are sophisticated semi-active devices utilizing magnetorheological fluid, a smart material whose viscosity can be rapidly and reversibly controlled by an applied magnetic field. This allows the damping characteristics to be modulated in real-time, offering unparalleled flexibility in vibration control. Unlike traditional passive dampers that offer fixed resistance, MR dampers provide variable resistance, making them essential components in next-generation suspension systems across the automotive, aerospace, and civil engineering sectors where precision control of motion is paramount.

The primary product characteristic of MR dampers is their fast response time, typically measured in milliseconds, enabling instant adaptation to changing road conditions or structural movements. Major applications include high-end automotive suspension systems to enhance handling and passenger comfort, seismic vibration mitigation in bridges and buildings, and specialized industrial machinery requiring precise isolation from external vibrations. The core benefit derived from utilizing MR dampers is the significant improvement in system performance, often resulting in optimized energy absorption and reduced wear on associated mechanical components, thereby extending overall product lifespan and reliability.

Key driving factors accelerating the adoption of MR dampers include the continuous push by automotive original equipment manufacturers (OEMs) towards integrating semi-active and active safety features into mid-range and luxury vehicles, coupled with stringent regulatory standards related to vehicle dynamic stability and structural resilience in earthquake-prone regions. Furthermore, technological advancements in magnetorheological fluid composition, focusing on improved stability and temperature tolerance, are making these systems more viable for a broader range of demanding operational environments, ensuring consistent high performance under varying load conditions.

MR Dampers Market Executive Summary

The global MR Dampers market is experiencing transformative growth, driven primarily by evolving automotive business trends centered on electric vehicle (EV) development and autonomous driving technologies. EVs, with their heavier battery packs and unique weight distribution challenges, significantly benefit from the dynamic load adjustment capabilities offered by MR dampers, which optimize ride quality and energy recuperation potential. The business landscape is characterized by intense competition among Tier 1 automotive suppliers who are investing heavily in miniaturization and integration capabilities to seamlessly embed MR systems within existing vehicle architecture, enhancing their commercial appeal across global automotive platforms.

Regionally, the market is currently dominated by North America and Europe due to the high concentration of luxury vehicle manufacturers and robust civil infrastructure spending on seismic protection systems. However, the Asia Pacific (APAC) region is projected to register the highest growth rate during the forecast period. This rapid expansion in APAC is fueled by expanding domestic automotive production, increasing consumer disposable income leading to higher demand for premium vehicle features, and significant governmental investment in smart infrastructure projects in countries like China and Japan, where earthquake resistance is a critical engineering requirement. Latin America and the Middle East and Africa (MEA) are emerging as high-potential markets, particularly for civil infrastructure applications.

Segment trends indicate a strong preference for double-coil MR damper configurations due to their enhanced controllability and higher damping force capacity, making them suitable for heavy-duty applications. In terms of end-use segmentation, the OEM segment holds the largest market share, driven by large volume contracts in the automotive sector, yet the aftermarket segment is seeing sustained, high-value growth related to system maintenance, performance upgrades, and specialized industrial retrofitting. Continued innovation in sensor fusion and control algorithm development remains a critical trend influencing product differentiation and market leadership.

AI Impact Analysis on MR Dampers Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the MR Dampers Market predominantly revolve around themes of real-time predictive control, optimization of semi-active systems in autonomous vehicles (AVs), and enhanced system diagnostics. Common questions address how machine learning (ML) algorithms can predict road surface changes before physical impact, how AI can harmonize MR damper performance with other vehicle control systems (like stability control and steering assist), and whether AI integration will significantly reduce maintenance costs through superior failure prediction. The consensus is that AI is transitioning MR dampers from merely 'semi-active' devices to truly 'smart' systems capable of learning and adapting to specific driver behavior and dynamic environmental changes, thereby maximizing vehicle safety and performance envelopes.

- AI-driven Predictive Damping Control: Utilizing ML to analyze sensor data (Lidar, camera, accelerometers) to predict road anomalies milliseconds in advance, allowing the damper viscosity to be optimally adjusted pre-emptively.

- Enhanced System Calibration: AI algorithms facilitate automated, dynamic calibration of MR damper settings specific to vehicle load, driving style, and environmental conditions, eliminating the need for static, factory-set parameters.

- Integration with Autonomous Driving Platforms: AI ensures seamless coordination between suspension control and AV navigation systems, guaranteeing optimal vehicle stability and passenger comfort necessary for Level 4 and Level 5 autonomy.

- Failure Prediction and Diagnostics: Machine learning models analyze operational telemetry to detect subtle deviations from normal performance, predicting potential damper fluid degradation or coil failure before complete system malfunction, thus enabling proactive maintenance.

- Optimized Energy Management: AI systems can adjust damping forces not only for comfort but also to maximize kinetic energy recovery potential, contributing to improved energy efficiency in electric and hybrid vehicles.

DRO & Impact Forces Of MR Dampers Market

The MR Dampers market dynamics are defined by a strong set of drivers coupled with significant cost and complexity restraints, which together shape high-growth opportunities. The principal driver is the globally increasing emphasis on passenger safety and driving comfort, especially within the premium and luxury vehicle segments where MR damper systems are often standard or high-demand options. Concurrently, the necessity for robust structural control in infrastructure, particularly in high seismic activity zones, provides a sustained demand base outside of the automotive sector. The driving forces are inherently tied to technological advancements that continually improve the reliability and response time of magnetorheological fluids and the associated control electronics.

However, the market faces notable restraints, primarily related to the high initial cost of MR damping systems compared to conventional passive shock absorbers, which limits their penetration into the mass-market vehicle segments. Furthermore, the specialized nature of the magnetorheological fluid requires precise manufacturing and sealing processes to prevent contamination or leakage, presenting technical hurdles that can escalate production costs. The systems also require sophisticated electronic control units (ECUs) and multiple sensors, adding complexity to the vehicle architecture and requiring specialized technician knowledge for maintenance and repair, acting as a frictional force against broader adoption.

Despite these challenges, substantial opportunities exist for market expansion. The largest opportunity lies in the rapid electrification of the global vehicle fleet, as electric vehicles intrinsically require highly adaptable suspension solutions to manage significant battery weight and optimize range. Furthermore, the burgeoning demand for specialized industrial applications, such as high-speed robotics and military vehicles requiring highly precise vibration isolation, presents lucrative niche markets. Successfully leveraging these opportunities requires manufacturers to focus on cost reduction through mass production and developing robust, modular MR damping kits suitable for retrofit applications across various industries, thereby lowering the barrier to entry for smaller-scale industrial adopters.

Segmentation Analysis

The MR Dampers market is meticulously segmented across key dimensions including damper configuration, end-use application, and geographical presence, allowing for targeted product development and market penetration strategies. This segmentation highlights the diverse operational requirements across different industries, from high-frequency, low-amplitude control needed in prosthetics to high-force, sustained damping required in civil infrastructure. Understanding these segments is crucial for stakeholders aiming to capitalize on specific industry trends, such as the automotive sector's drive towards lighter, more responsive suspension systems, or the increasing requirements for robust seismic dampening solutions globally.

- By Type:

- Single Coil MR Dampers

- Double Coil MR Dampers

- Rotational MR Dampers

- Linear MR Dampers

- By Application:

- Automotive (Passenger Vehicles, Commercial Vehicles, High-Performance Sports Cars)

- Civil Infrastructure (Bridges, High-Rise Buildings, Tunnels)

- Aerospace and Defense (Landing Gear, Cockpit Control Systems)

- Industrial Machinery (Robotics, Precision Manufacturing Equipment)

- Prosthetics and Medical Devices

- By End-Use:

- Original Equipment Manufacturer (OEM)

- Aftermarket and Retrofit

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For MR Dampers Market

The value chain for the MR Dampers market begins with upstream activities focused on the specialized material science required for magnetorheological fluid and advanced coil component manufacturing. Upstream success is highly dependent on securing stable supplies of key raw materials, particularly ferrous particles (typically micron-sized iron powder) and high-performance carrier oils, requiring strong relationships with specialized chemical and metal powder suppliers. The quality of the magnetorheological fluid directly dictates the performance characteristics—such as temperature stability, sedimentation rate, and maximum yield stress—of the final MR damper product, making R&D and quality control at this initial stage absolutely critical for competitive differentiation.

Mid-stream activities involve the highly precise engineering and assembly of the MR damper units, including the housing, pistons, internal coils, and seals. This phase is dominated by Tier 1 suppliers who possess the necessary expertise in semi-active suspension design and integration with electronic control systems. Direct sales are common in the OEM segment, where automotive manufacturers enter into long-term supply agreements with these Tier 1 providers (e.g., ZF, BWI Group). The distribution channel is predominantly an indirect channel, relying on these large suppliers for integration into final products before distribution to global assembly lines. For the smaller aftermarket and niche industrial segments, specialized distributors and industrial parts dealers play a vital role in reaching end-users requiring retrofitting or customized solutions.

Downstream analysis focuses heavily on the integration and service phases. For automotive applications, this involves collaboration between the damper manufacturer and the vehicle OEM during the design phase to optimize the system for specific vehicle dynamics and software requirements. The aftermarket distribution channels, though smaller in volume, are crucial for long-term revenue, relying on certified service centers and authorized dealers for system replacement and fluid maintenance. The overall health of the downstream market relies heavily on robust service networks and the continuous training of technicians to handle the electronic sophistication and specialized fluid requirements of MR damper technology.

MR Dampers Market Potential Customers

The primary customers for MR Dampers are large-scale Original Equipment Manufacturers (OEMs) across sectors where precision vibration control translates directly into safety, performance, or structural integrity. Automotive OEMs constitute the largest buyer segment, specifically manufacturers of luxury sedans, sports cars, and high-end electric vehicles (EVs), who prioritize superior ride quality and dynamic stability. These customers require high-volume, highly customized units that integrate seamlessly with complex vehicle control architecture and meet stringent long-term durability standards, leading to highly structured procurement processes based on technical specifications and long-term supply capacity.

A secondary, yet rapidly expanding, customer base exists within the civil infrastructure sector, including governmental bodies, specialized engineering firms, and construction companies that undertake large-scale projects like long-span bridges and high-rise structures in seismic zones. These end-users utilize MR dampers for seismic mitigation and structural damping, demanding extremely robust systems designed for decades of service with minimal maintenance. Furthermore, the specialized industrial and medical technology sectors, including manufacturers of high-precision robotics, military/defense vehicles, and advanced prosthetic limbs, form a crucial niche customer segment, seeking MR technology for precise, lightweight, and responsive haptic control and vibration isolation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 825 Million |

| Growth Rate | CAGR 12.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lord Corporation (Parker Hannifin), BWI Group, ZF Friedrichshafen, Tenneco (DRiV), Mando Corporation, Continental AG, Öhlins Racing, Arvin Sango Co., Ltd., Wuxi Xizhou Shock Absorber, Shanghai King-Yi Industrial, Magnetic Technologies LLC, Nanjing Kaimai Mechanical and Electrical, Jiangsu Xinrui Shock Absorber Co., Ltd., Beijing West Industries (BWI), KYB Corporation, ThyssenKrupp AG, Delphi Technologies, Hitachi Astemo, Showa Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

MR Dampers Market Key Technology Landscape

The core technology underpinning the MR Dampers market lies in the specialized formulation of the magnetorheological fluid itself. These fluids are suspensions of micro-sized magnetic particles (typically iron) within a non-magnetic carrier fluid. Advancements in this area focus on reducing particle sedimentation, improving thermal stability across wide operating temperature ranges, and maximizing the adjustable yield stress—the critical parameter defining the maximum damping force. Ongoing research is driving the development of fluids that require lower magnetic field strengths to achieve maximum viscosity modulation, thereby reducing the necessary electrical power consumption and facilitating integration into power-sensitive systems like electric vehicles.

Another crucial technological element is the sophisticated sensor array and the associated Electronic Control Unit (ECU). Modern MR damper systems rely on high-frequency feedback from various sensors, including accelerometers, displacement sensors (LVDTs), and sometimes inertial measurement units (IMUs), all integrated into the vehicle chassis. The ECU utilizes advanced proprietary algorithms to analyze these inputs, predict required damping forces, and modulate the current supplied to the electromagnetic coils in milliseconds. The continuous technological push involves transitioning from purely reactive control algorithms to model-predictive and AI-enhanced control strategies, significantly improving the responsiveness and optimization capabilities of the suspension system.

Furthermore, manufacturing technology plays a critical role in the damper's reliability. Achieving robust sealing mechanisms is paramount to prevent leakage or contamination of the MR fluid, which can severely degrade performance. Key players are investing in advanced composite materials and magnetic shielding techniques to minimize hysteresis effects and ensure consistent performance over the lifespan of the vehicle or structure. Miniaturization of the electromagnetic coils and improvements in power density are also vital trends, allowing MR dampers to be packaged more efficiently within compact modern vehicle architectures without compromising damping force output.

Regional Highlights

- North America: Holds a significant market share, driven by strong penetration in the high-performance and luxury automotive segments, particularly due to the presence of key OEM manufacturing facilities and high consumer willingness to adopt advanced vehicle technology. Additionally, significant investments in structural control solutions for critical infrastructure in seismically active areas contribute substantially to regional demand.

- Europe: Characterized by early adoption of sophisticated automotive suspension technologies, particularly in Germany and Italy, fueled by stringent safety standards and a robust luxury vehicle manufacturing base. Europe is a hub for MR fluid R&D and advanced system integration, maintaining a leadership position in design innovation and quality standards for semi-active systems.

- Asia Pacific (APAC): Forecasted to be the fastest-growing market, primarily due to the rapid expansion of the middle class, increased disposable income driving demand for premium vehicles in countries like China and India, and critical infrastructure developments. High seismic risk in nations like Japan and Indonesia also mandates the use of advanced structural damping solutions, accelerating adoption in the civil engineering segment.

- Latin America (LATAM): Emerging market potential focused primarily on infrastructural projects requiring seismic protection and gradual adoption within high-end imported vehicles. Market growth is constrained by high import duties and slower technological adoption compared to developed regions, but shows significant long-term potential.

- Middle East and Africa (MEA): Growth driven by luxury vehicle imports and substantial governmental spending on megaprojects and smart city infrastructure. Demand is currently concentrated in the Gulf Cooperation Council (GCC) countries, focusing on premium transportation and specialized military vehicle applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the MR Dampers Market.- Lord Corporation (Parker Hannifin)

- BWI Group

- ZF Friedrichshafen

- Tenneco (DRiV)

- Mando Corporation

- Continental AG

- Öhlins Racing

- Arvin Sango Co., Ltd.

- Wuxi Xizhou Shock Absorber

- Shanghai King-Yi Industrial

- Magnetic Technologies LLC

- Nanjing Kaimai Mechanical and Electrical

- Jiangsu Xinrui Shock Absorber Co., Ltd.

- Beijing West Industries (BWI)

- KYB Corporation

- ThyssenKrupp AG

- Delphi Technologies

- Hitachi Astemo

- Showa Corporation

Frequently Asked Questions

Analyze common user questions about the MR Dampers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of MR Dampers over traditional hydraulic shock absorbers?

The primary technical advantage is the real-time, instantaneous variability of the damping coefficient. MR Dampers can modulate their resistance within milliseconds by altering the magnetic field, allowing for superior control over ride comfort and vehicle dynamics, which passive hydraulic systems cannot achieve.

How significantly does the high cost of MR Dampers restrain market growth?

The high initial manufacturing cost, mainly due to specialized magnetorheological fluid and complex electronic controls, remains the chief restraint. This cost barrier limits widespread adoption to the premium, luxury, and high-performance vehicle segments, slowing penetration into mass-market vehicles.

Are MR Dampers primarily used only in the automotive industry, or are other applications significant?

While the automotive sector is the largest application segment, MR Dampers are increasingly vital in non-automotive fields. Significant applications include seismic mitigation in civil infrastructure, precision vibration isolation in industrial robotics, and advanced semi-active systems in specialized defense and prosthetic devices.

How is AI impacting the future performance and reliability of MR Damping systems?

AI is transforming MR systems by enabling predictive control, allowing the damper to anticipate road conditions and adjust parameters pre-emptively using machine learning algorithms based on camera and sensor data, rather than merely reacting to existing motion, thereby maximizing effectiveness and system lifespan.

Which geographical region is expected to demonstrate the highest growth rate for the MR Dampers Market?

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to expanding automotive manufacturing, significant infrastructure investments, and increasing consumer demand for premium and technologically advanced vehicle features in key economies like China, India, and Japan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager