Multifunction Calibrators Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441614 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Multifunction Calibrators Market Size

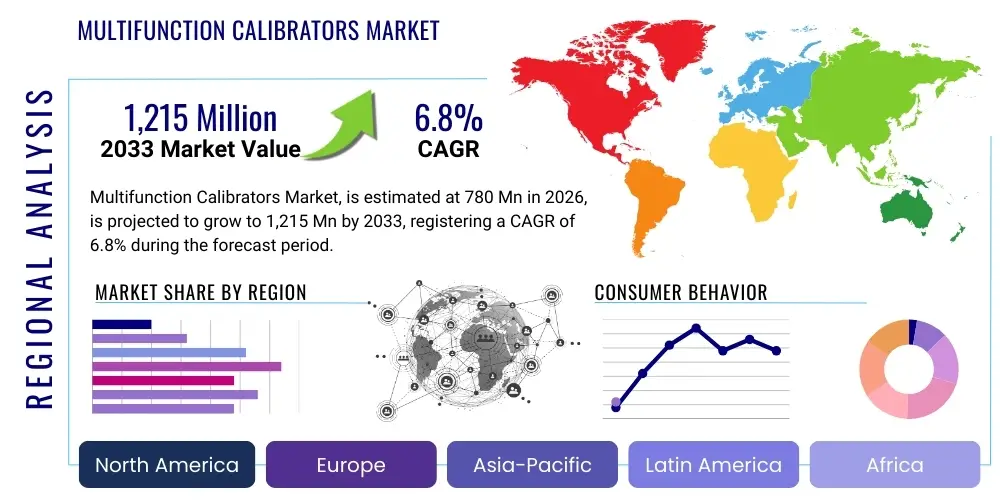

The Multifunction Calibrators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 780 million in 2026 and is projected to reach USD 1,215 million by the end of the forecast period in 2033.

Multifunction Calibrators Market introduction

The Multifunction Calibrators Market encompasses the manufacturing, distribution, and utilization of precision instruments designed to calibrate, test, and verify multiple types of parameters simultaneously, such as voltage, current, resistance, temperature (thermocouple and RTD), pressure, and frequency. These devices are crucial for maintaining measurement integrity and ensuring compliance with stringent quality standards across diverse industrial environments. Multifunction calibrators streamline the calibration process, reduce downtime, minimize the need for carrying multiple single-function devices, and significantly enhance operational efficiency and accuracy in field and laboratory settings. The core product description involves highly accurate, portable, and often software-integrated devices capable of simulating and measuring various electrical and physical signals. The compact nature and wide range of capabilities make them indispensable tools in modern maintenance and quality assurance programs, particularly those governed by ISO 9001 standards and industry-specific regulatory bodies.

Major applications of these calibrators span critical sectors including manufacturing, pharmaceuticals, aerospace, power generation, oil & gas, and process industries where precise control and monitoring of instrumentation are non-negotiable for safety and product quality. In manufacturing, they ensure the accuracy of sensors controlling automated production lines, while in the pharmaceutical sector, they validate environmental controls and process parameters critical for drug consistency and compliance. The inherent benefits derived from adopting multifunction calibrators include substantial cost savings by reducing inventory of specialized tools, increased technician productivity through faster calibration cycles, and minimized measurement uncertainty. Furthermore, the modern generation of these instruments offers advanced connectivity features, enabling automated data logging and seamless integration with Computerized Maintenance Management Systems (CMMS) and calibration management software, moving towards a truly digitized calibration workflow. This integration is vital for predictive maintenance strategies and comprehensive audit trail creation, a significant driver for market growth.

The market is primarily driven by the escalating demand for high-precision measurements in complex industrial processes, coupled with rigorous global regulatory requirements concerning quality control and environmental monitoring. The increasing adoption of Industrial Internet of Things (IIoT) technologies and smart factory initiatives mandates the continuous verification of connected sensors, thereby boosting the need for advanced, field-ready calibrators. Furthermore, the rapid growth in emerging economies and the subsequent expansion of infrastructure projects (especially in power and process industries) necessitates robust calibration infrastructure. Technological advancements, such such as improved battery life, intuitive user interfaces, higher measurement ranges, and enhanced thermal stability, are further accelerating the replacement cycles of older, less efficient single-function units, ensuring sustained market momentum throughout the forecast period. The shift towards automated, documented calibration procedures is a fundamental growth propeller.

Multifunction Calibrators Market Executive Summary

The Multifunction Calibrators Market exhibits robust business trends characterized by a strong emphasis on automation, portability, and enhanced digital integration. Key manufacturers are focusing on developing hybrid instruments that combine high-accuracy source and measure capabilities with advanced diagnostic features, catering to the complexity of modern industrial instrumentation. The pervasive trend towards preventative and predictive maintenance models is necessitating calibrators that can quickly diagnose issues and provide comprehensive, traceable documentation, fueling the demand for models with integrated memory and wireless communication (e.g., Bluetooth/Wi-Fi). Competitive intensity is high, with players competing not just on price and features, but increasingly on software ecosystems and customer support services related to calibration management, which represents a crucial value-added component in the B2B landscape. Investment in R&D remains focused on increasing battery longevity and improving electromagnetic compatibility (EMC) in harsh industrial environments.

Regional trends indicate that North America and Europe maintain leading market shares, driven by stringent industrial regulations, early adoption of advanced manufacturing technologies, and well-established quality assurance standards in sectors like aerospace and pharmaceuticals. However, the Asia Pacific (APAC) region is projected to register the fastest growth, largely due to massive industrialization, government investments in infrastructure development (especially smart grid and petrochemical facilities), and the burgeoning electronics manufacturing base. Countries like China, India, and South Korea are becoming pivotal consumers as their local industries prioritize quality management and transition from manual to automated calibration practices. In terms of segments, the process calibration segment (temperature and pressure) is dominant, reflecting the sheer volume of analog and smart sensors utilized in process control systems, while the increasing complexity of smart field devices is driving rapid growth in calibrators capable of handling digital communication protocols such such as HART, Foundation Fieldbus, and Profibus.

Segment trends highlight a strong shift from benchtop units, traditionally confined to laboratories, toward highly ruggedized, portable multifunction calibrators favored for field use and remote maintenance tasks. The portability segment benefits directly from the expansion of remote operations in the oil & gas and utilities sectors. Furthermore, the demand for high-accuracy standard laboratory equipment remains steady, driven by national metrology institutes and certified primary calibration laboratories. Within component technology, the integration of advanced microprocessors allowing for instantaneous calculation of measurement uncertainty and automated calibration routines is transforming product offerings. This focus on automation and user experience ensures that even less-experienced technicians can perform complex calibration tasks reliably, democratizing high-quality measurement practices across the industrial spectrum.

AI Impact Analysis on Multifunction Calibrators Market

Analysis of common user questions regarding the impact of Artificial Intelligence (AI) on the Multifunction Calibrators Market reveals significant interest centered around automation, predictive maintenance integration, and data traceability. Users frequently inquire about whether AI can automate the decision-making process during calibration, how AI algorithms can predict instrument drift (thereby optimizing calibration frequency), and the role of machine learning in improving the intrinsic accuracy and stability of the calibrators themselves. Key concerns often revolve around the security and integrity of cloud-based calibration data processed by AI systems, and the potential need for advanced technical skills to manage these sophisticated instruments. Overall, the market expects AI to transition calibration from a scheduled, periodic necessity into a continuous, condition-based activity, ensuring maximum uptime and optimized resource allocation by moving away from calendar-based maintenance schedules toward predictive calibration cycles.

AI's primary influence is manifesting through advanced data analytics applied to calibration history. By analyzing patterns of drift, environmental variables, and usage statistics collected by IIoT-enabled calibrators, AI algorithms can accurately predict when a specific sensor or instrument is likely to fail or drift out of tolerance. This capability allows end-users to shift to predictive calibration strategies, reducing unnecessary calibration costs and preventing catastrophic failures. Furthermore, AI is being integrated into calibration management software to automate report generation, ensure regulatory compliance checks are performed instantaneously, and optimize calibration procedures based on real-time feedback from the measurement environment. This level of intelligent automation significantly elevates the value proposition of modern multifunction calibrators.

However, the implementation of AI also presents challenges related to data standardization and system interoperability. For AI to effectively analyze global calibration data, manufacturers and end-users must agree on common data formats and protocols. The future of multifunction calibrators lies in their capacity to act as intelligent data acquisition hubs, feeding high-fidelity, contextualized measurement data directly to centralized AI platforms. These platforms will then feedback optimized calibration schedules and adjustment parameters directly to the calibrator, completing a closed-loop system of measurement integrity management. This systemic integration underscores the long-term, transformative impact of AI on calibration efficiency and reliability across all process industries.

- AI-driven Predictive Calibration: Optimizing calibration intervals based on drift history and usage patterns, minimizing unnecessary downtime.

- Automated Data Verification: Using machine learning models to instantly verify the validity and quality of calibration results, reducing human error.

- Enhanced Fault Diagnostics: AI algorithms interpreting complex measurement data to pinpoint root causes of instrument malfunction more rapidly than traditional methods.

- Improved Calibration Management Software: Integration of AI for automated regulatory compliance reporting and audit trail generation.

- Cognitive Calibration Procedures: Customizing calibration sequences in real-time based on the specific instrument under test and ambient conditions.

- Security and Traceability: Applying blockchain and AI to ensure the tamper-proof nature and absolute traceability of calibration records.

DRO & Impact Forces Of Multifunction Calibrators Market

The Multifunction Calibrators Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), all contributing to its overall Impact Forces. Major Drivers include the stringent global emphasis on quality assurance standards (such as ISO 9001, GLP/GMP requirements), mandating traceable and high-accuracy measurements across various sectors, especially pharmaceuticals, food & beverage, and aerospace. The rapid expansion of complex industrial infrastructure, driven by high global investment in power generation, oil & gas exploration, and chemical processing, necessitates reliable and continuous monitoring of process variables, bolstering the demand for accurate calibration tools. Furthermore, the inherent efficiency and cost benefits of replacing multiple single-function devices with a single, highly capable multifunction unit serve as a powerful economic driver, particularly for field service companies seeking to reduce tool inventories and logistical overheads. The increasing penetration of smart sensors and IIoT devices requires advanced calibrators capable of handling digital communication protocols (HART, FF), accelerating technological adoption.

However, the market faces significant Restraints that temper growth. The primary constraint is the high initial capital investment required for purchasing advanced, high-accuracy multifunction calibrators, particularly for Small and Medium Enterprises (SMEs) in developing regions. Furthermore, the inherent complexity of utilizing these advanced instruments, often requiring specialized technical training and certified personnel, poses a bottleneck, especially in areas with limited access to qualified calibration technicians. The long calibration cycles required for the calibrators themselves (primary standards) and the logistical challenges associated with maintaining the certified traceability chain present continuous operational restraints. Economic volatility and cyclical downturns in capital-intensive sectors like petrochemicals can also lead to delayed or reduced investment in new calibration equipment, negatively impacting short-term market growth. Lastly, the continued, albeit decreasing, use of older, less accurate single-function devices due to budget constraints acts as a barrier to rapid market penetration.

Opportunities for market expansion are primarily centered on technological innovation and geographical expansion. The development of cloud-connected calibrators and subscription-based calibration software services offers new revenue streams and enhances customer lock-in through integrated ecosystems. The untapped potential in emerging economies, particularly across Southeast Asia, Latin America, and Africa, represents a substantial opportunity as industrial infrastructure matures and regulatory compliance becomes mandatory. The push towards green energy and electric vehicle manufacturing introduces entirely new sets of high-precision measurement requirements (e.g., battery testing and power electronics calibration), offering specialized market niches. Impact Forces—the consolidated effect of these DRO factors—lean positively towards growth, driven by non-negotiable regulatory compliance and the increasing returns on investment derived from predictive maintenance facilitated by accurate calibration data. The long-term trajectory is defined by digitalization and the shift towards fully automated, remote-enabled calibration systems.

Segmentation Analysis

The Multifunction Calibrators Market is strategically segmented based on factors such as type, application, and end-user, providing a granular view of market dynamics and adoption patterns across various industrial landscapes. Segmentation by Type typically differentiates between benchtop (laboratory) calibrators, which offer the highest stability and accuracy, and portable (field) calibrators, which emphasize ruggedness, battery life, and ease of use in diverse operational environments. Application segmentation categorizes the market based on the type of signal or parameter being calibrated, primarily focusing on electrical, pressure, and temperature calibration capabilities, often targeting process control systems. Analyzing these segments is essential for manufacturers to tailor their product development strategies and for stakeholders to understand specific areas of high investment and technological focus within the calibration ecosystem.

The Portable Calibrators segment generally commands a higher market share due to the widespread need for in-situ, field verification and troubleshooting across maintenance, repair, and overhaul (MRO) activities in vast industrial facilities such as refineries, power plants, and utilities. These devices are increasingly sophisticated, integrating features such as advanced human-machine interfaces (HMI), multi-lingual support, and explosion-proof ratings (ATEX/IECEx) for hazardous areas. The Benchtop segment, while smaller in volume, remains crucial for secondary calibration standards and high-end metrology laboratories where maximum accuracy and traceability to national standards are paramount. End-user segmentation reveals that heavy process industries (Oil & Gas, Chemicals) and manufacturing (Automotive, Aerospace) are the largest consumers, driven by safety protocols and the high cost associated with measurement errors.

A key trend within segmentation is the growing demand for devices specialized for digital communication protocols. As industries migrate from purely analog instrumentation to smart field devices, multifunction calibrators must not only source and measure physical parameters but also communicate bi-directionally using protocols like HART, Foundation Fieldbus, and PROFIBUS. This evolution is creating a high-growth sub-segment focused on advanced communication-enabled calibrators, often priced at a premium due to the required complexity and integrated software suites. Future segmentation growth is anticipated in specialized calibrators for high-frequency measurements, crucial for telecommunications and advanced electronics manufacturing, further diversifying the market landscape beyond traditional process control.

- By Type:

- Portable Multifunction Calibrators

- Benchtop Multifunction Calibrators

- By Capability/Application:

- Electrical Calibrators (Voltage, Current, Resistance)

- Temperature Calibrators (RTD, Thermocouple)

- Pressure Calibrators (Gage, Absolute, Differential)

- Frequency and Pulse Calibrators

- Process Signal Calibrators (HART/Fieldbus communication)

- By End-User Industry:

- Oil & Gas and Petrochemicals

- Power Generation and Utilities

- Aerospace and Defense

- Pharmaceuticals and Biotechnology

- Food & Beverage Manufacturing

- Automotive and Manufacturing

- Calibration Service Laboratories

- By Sales Channel:

- Direct Sales

- Distributors/Value-Added Resellers (VARs)

Value Chain Analysis For Multifunction Calibrators Market

The Value Chain for the Multifunction Calibrators Market begins with sophisticated upstream activities involving the sourcing and refinement of highly specialized components, particularly high-precision analog-to-digital converters (ADCs), stable reference standards (e.g., highly linear resistors), and advanced microprocessor units capable of complex signal processing and compensation. Raw material providers focus on materials offering exceptional thermal stability and low noise characteristics essential for maintaining instrument accuracy. R&D and design are critical upstream stages, requiring significant investment in metrology expertise to ensure traceability to international standards (e.g., NIST, NPL) and to develop robust, proprietary compensation algorithms that minimize measurement uncertainty across wide operating ranges. Key success factors at this stage involve partnerships with high-reliability semiconductor manufacturers and mastery of complex signal conditioning techniques, forming the technological foundation of the calibrator.

The manufacturing and assembly phase follows, characterized by rigorous quality control and highly controlled, often cleanroom, assembly processes to prevent contamination and mechanical stress that could degrade accuracy. Following assembly, the calibration phase itself—the core transformation process—is executed, where the instrument is meticulously adjusted and compared against primary or secondary laboratory standards to ensure guaranteed specifications. Downstream activities involve distribution, which is bifurcated into direct sales channels for large industrial clients requiring personalized technical support and complex system integration, and indirect channels relying on a global network of specialized distributors and Value-Added Resellers (VARs). These VARs often provide local language support, pre-sales consultation, and, critically, post-sales technical training and repair services, acting as essential liaisons between the manufacturer and the localized end-user base.

The final element of the value chain is the post-sales service ecosystem, which includes mandatory periodic recalibration and certification services, repair, and software updates. This service layer represents a substantial, recurring revenue stream for manufacturers and certified service centers. The choice of distribution channel (direct vs. indirect) depends heavily on the geographic location and the technical complexity of the required solution. Direct sales dominate in markets with high technical maturity and large procurement contracts (e.g., U.S. defense contractors), while indirect distribution is preferred in geographically dispersed markets or those requiring extensive local integration and support. The effectiveness of the overall value chain is determined by maintaining strict traceability and consistency from the component level through to the final, certified measurement provided to the end-user, guaranteeing the instrument's long-term metrological performance.

Multifunction Calibrators Market Potential Customers

The Multifunction Calibrators Market targets a wide spectrum of potential customers who are fundamentally reliant on precise measurement integrity for operational safety, quality control, and regulatory compliance. The primary buyers are professional calibration laboratories, both commercial providers and in-house laboratory departments within large enterprises, who utilize these devices as secondary standards or working standards for validating other field instruments. This segment requires high-stability, benchtop models with extensive data logging capabilities and guaranteed accreditation traceability. Beyond specialized labs, the largest volume buyers reside in the process control sectors, including instrument and electrical (I&E) technicians and reliability engineers employed by petrochemical refineries, power generation facilities (thermal, nuclear, and renewables), and chemical processing plants. These end-users prioritize rugged, portable calibrators capable of simulating and measuring temperature, pressure, and electrical signals quickly and accurately in demanding field environments.

A rapidly growing customer segment is the pharmaceuticals and biotechnology industry, where Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP) regulations mandate impeccable calibration records for all monitoring equipment used in environmental control, fermentation, and sterilization processes. In this sector, multifunction calibrators are indispensable tools for validating thermocouples, RTDs, and pressure transmitters used in bioreactors and cleanrooms. Similarly, the aerospace and defense sector represents a high-value customer base, demanding extremely high accuracy and rigorous documentation for instruments used in aircraft maintenance, navigational system testing, and material quality assurance. These clients often require specialized calibrators that comply with specific military or aviation standards, leading to customized product offerings.

Furthermore, maintenance, repair, and overhaul (MRO) service providers form a critical customer group. These external contractors rely on multifunction calibrators to service and validate instrumentation across diverse client sites, necessitating versatile, reliable, and easily transportable equipment. Educational and research institutions also constitute a stable customer base, using these instruments for teaching metrology principles and conducting sensor research. Fundamentally, any organization that must adhere to a standardized quality management system (such as ISO 9001) and relies on analog or digital sensors for operational control—ranging from automotive manufacturing assembly lines to municipal water treatment facilities—is a potential buyer of multifunction calibrators, underlining the broad and indispensable nature of this technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 780 Million |

| Market Forecast in 2033 | USD 1,215 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fluke Corporation, Ametek Inc., Yokogawa Electric Corporation, Additel Corporation, Beamex Oy Ab, Druck (Baker Hughes), Martel Electronics, WIKA Group, Siemens AG, GE Measurement & Control, KIMO Instruments, Transcat, PCE Instruments, Gagemaker, Isotech. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Multifunction Calibrators Market Key Technology Landscape

The technology landscape of the Multifunction Calibrators Market is defined by a relentless pursuit of higher accuracy, enhanced portability, and superior digital connectivity. Central to this evolution is the integration of advanced analog front-end circuitry coupled with highly stable internal reference standards, ensuring minimal drift over time and temperature variations. Modern calibrators heavily rely on sophisticated Digital Signal Processing (DSP) techniques to filter noise and compensate for environmental effects, dramatically improving measurement stability and repeatability. Manufacturers are investing significantly in miniaturizing high-performance components, allowing portable units to achieve near-benchtop accuracy, thereby erasing the traditional performance gap between field and laboratory instruments. This push for precision in a portable form factor is a core technological driver, enabling faster, more reliable fieldwork.

Connectivity features represent another critical area of technological advancement. The shift from manual data logging to automated, secure digital documentation is facilitated by integrated wireless technologies (e.g., Bluetooth Low Energy, Wi-Fi). This allows seamless communication with centralized calibration management software (CMS), enabling automatic upload of calibration results and rapid generation of traceable calibration certificates, thereby significantly reducing administrative burden and eliminating manual transcription errors. Furthermore, the integration of digital protocol capabilities (HART communicator, Foundation Fieldbus support) within the multifunction calibrator body is essential, allowing technicians to configure, diagnose, and calibrate smart field devices without needing separate proprietary communicators, streamlining the entire maintenance workflow for modern plants.

Looking forward, the integration of Artificial Intelligence and machine learning algorithms is emerging as a disruptive technology. These algorithms are employed to analyze the long-term historical drift data stored within the calibrator or CMS, allowing the instrument to provide proactive advice on optimal calibration intervals or suggest immediate diagnostic actions. Furthermore, technologies focusing on intrinsic safety (IS) compliance, such as designing ruggedized units certified for use in hazardous (explosive) atmospheres (ATEX/IECEx certifications), continue to be crucial for segments like Oil & Gas. The ongoing reduction in power consumption, extending battery life to support multi-day field operations, coupled with intuitive, touchscreen interfaces designed for harsh industrial environments, collectively define the cutting edge of the Multifunction Calibrator technology landscape.

Regional Highlights

North America maintains a dominant position in the Multifunction Calibrators Market, driven by strict regulatory adherence mandated by bodies such as the FDA (for pharmaceuticals) and environmental agencies, coupled with a highly mature industrial base, particularly in aerospace, defense, and power generation. The U.S. remains the largest consumer, characterized by early adoption of new technology, high labor costs favoring automation, and a strong presence of key market vendors and large contract calibration laboratories. The continuous investment in modernizing existing infrastructure, particularly the shift towards smart grids and advanced manufacturing facilities (Industry 4.0), ensures a sustained high demand for high-precision, connected calibration tools. Market growth in this region is primarily propelled by technological replacement cycles and the increasing implementation of enterprise-level calibration management systems.

Europe represents another key region, marked by stringent European Union regulations (e.g., ATEX, CE marking, REACH) and a strong historical emphasis on metrology standards, particularly in Germany and the UK. The automotive and chemical industries are significant drivers, focusing heavily on quality control and process validation. While growth rates might be moderate compared to Asia Pacific, the demand is stable and high-value, concentrating on advanced, certified, and digitally integrated calibrators. The Asia Pacific (APAC) region is forecasted to exhibit the highest CAGR during the forecast period. This rapid acceleration is fueled by massive industrialization, rapid infrastructure expansion (especially in utilities and petrochemicals in China and India), and the relocation of global electronics manufacturing hubs. As local manufacturers in APAC increasingly compete on the global stage, the necessity for internationally recognized quality standards and certified calibration practices drives robust market penetration and volume growth, often favoring cost-effective yet reliable portable models.

Latin America, and the Middle East & Africa (MEA) regions, while currently smaller, present significant long-term growth opportunities. The MEA market is largely dependent on the cyclical nature of the oil and gas industry, where large-scale extraction and processing projects require extensive field instrumentation and subsequent calibration. Demand is concentrated around explosion-proof (IS) certified calibrators necessary for refinery and pipeline operations. Latin America’s market is characterized by increasing foreign direct investment in manufacturing and mining, pushing local industries toward greater regulatory compliance. However, these regions often face challenges related to logistics, technical training availability, and reliance on indirect distribution channels, influencing purchasing decisions towards robust, user-friendly equipment with localized support infrastructure.

- North America: Market leader due to strict regulatory environment (FDA, FAA) and high adoption rate of IIoT-enabled calibration solutions in aerospace and pharmaceuticals.

- Europe: Stable, high-value market driven by strong metrology standards (traceability) and sophisticated manufacturing sectors (automotive, chemical).

- Asia Pacific (APAC): Highest growth region, fueled by massive infrastructure development, rapid industrialization, and expansion of electronics manufacturing in China, India, and South Korea.

- Middle East & Africa (MEA): Growth strongly tied to the upstream and downstream oil & gas sector, demanding explosion-proof and ruggedized field calibrators.

- Latin America: Emerging market with increasing adoption spurred by foreign investment in mining, manufacturing, and energy sectors, requiring greater compliance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Multifunction Calibrators Market.- Fluke Corporation (Danaher Corporation)

- Ametek Inc.

- Yokogawa Electric Corporation

- Additel Corporation

- Beamex Oy Ab

- Druck (Baker Hughes)

- Martel Electronics

- WIKA Group

- Siemens AG

- GE Measurement & Control

- KIMO Instruments

- Transcat

- PCE Instruments

- Gagemaker

- Isotech

- Chauvin Arnoux

- Extech Instruments

- OMEGA Engineering

- Time Electronics

- Alpha Technics

Frequently Asked Questions

Analyze common user questions about the Multifunction Calibrators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using a multifunction calibrator over single-function devices?

The primary advantage is significant operational efficiency, achieved by consolidating the capabilities of multiple single-function testers (voltage, pressure, temperature, etc.) into a single, portable, and often software-integrated unit. This reduces tool inventory, minimizes setup time in the field, and simplifies documentation and compliance, leading directly to lower MRO costs and faster calibration cycles.

How is the adoption of IIoT influencing the design and functionality of modern calibrators?

IIoT mandates that calibrators be capable of seamless digital communication (e.g., wireless connectivity, HART protocol support) to automate data capture and integrate results directly into centralized Computerized Maintenance Management Systems (CMMS). This transition supports predictive maintenance strategies by providing real-time, traceable calibration data, moving away from manual, paper-based workflows.

Which end-user industries represent the highest growth potential for multifunction calibrators?

The highest growth potential is concentrated in high-compliance sectors such as Pharmaceuticals, due to stringent GMP requirements, and the Power Generation sector, specifically renewables and smart grid infrastructure, where complex process variables require continuous, high-accuracy verification. Geographically, rapid industrialization in the Asia Pacific region drives volume growth.

What are the key differences between portable and benchtop multifunction calibrators?

Benchtop calibrators offer superior accuracy, stability, and lower uncertainty, typically serving as secondary reference standards in laboratories. Portable calibrators prioritize ruggedness, extended battery life, and field mobility, often including hazardous area certifications (ATEX) necessary for in-situ MRO tasks, balancing high accuracy with practical field requirements.

How is AI expected to transform calibration management and instrument drift prediction?

AI is set to transform calibration by enabling predictive maintenance. By applying machine learning algorithms to historical calibration data, AI can accurately forecast when an instrument is likely to drift out of tolerance, allowing end-users to schedule condition-based, optimized calibration intervals rather than adhering to rigid, potentially inefficient, calendar-based schedules.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager