N-Methylmorpholine Oxide Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443205 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

N-Methylmorpholine Oxide Market Size

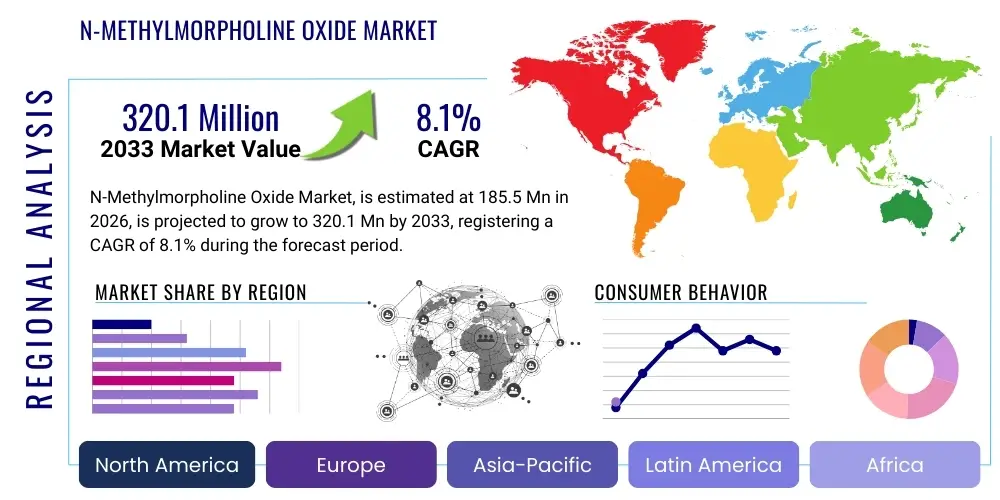

The N-Methylmorpholine Oxide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.1% between 2026 and 2033. The market is estimated at $185.5 Million in 2026 and is projected to reach $320.1 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the escalating global demand for environmentally friendly and sustainable cellulosic fibers, particularly Lyocell, where NMMO serves as the crucial non-toxic solvent. Expanding applications in specialized chemical synthesis and pharmaceutical formulations further contribute to the overall market expansion.

N-Methylmorpholine Oxide Market introduction

N-Methylmorpholine Oxide (NMMO) is a tertiary amine oxide, primarily recognized as an indispensable solvent in the production of Lyocell fibers, often referred to by the trade name Tencel. This compound functions as a direct dissolution agent for cellulose pulp, facilitating the creation of regenerated cellulosic fibers through a highly sustainable, closed-loop process. The unique chemical properties of NMMO, including its ability to dissolve cellulose without derivatization, positioning it as a greener alternative compared to conventional, more toxic solvents like carbon disulfide used in the viscose process. Its increasing adoption aligns with global sustainability mandates and the rising consumer preference for bio-based materials, establishing NMMO as a strategic chemical in the transition towards circular economy practices within the textile and non-woven industries.

The core application driving NMMO market dynamics remains the high-growth Lyocell segment. Lyocell, known for its superior strength, breathability, and luxurious feel, is rapidly replacing traditional synthetic and conventional cellulosic fibers across diverse sectors, including apparel, home textiles, and technical non-wovens. Furthermore, NMMO exhibits utility beyond textiles; it is employed as an oxidizing agent in organic synthesis, notably in reactions involving osmium tetroxide for dihydroxylation. Its versatility ensures demand stability even as textile production processes evolve, cementing its status as a high-value intermediate chemical in the specialty chemicals sector. Market proliferation is also supported by continuous technological advancements aimed at optimizing the NMMO recovery and purification process, enhancing economic viability and reducing environmental footprint.

Major applications encompass the manufacturing of environmentally sound textile products, technical non-woven fabrics for medical and hygiene purposes, and as a specialized reagent in laboratory and industrial chemical processes. Key benefits associated with NMMO usage include its minimal toxicity, high recyclability (typically 99% recovery rate in Lyocell production), and its enabling role in manufacturing premium, high-performance fibers. The primary driving factors are stringent environmental regulations compelling industries to adopt cleaner manufacturing technologies, soaring consumer demand for sustainable fashion, and ongoing capacity expansions by major Lyocell producers globally, especially in the Asia Pacific region where textile manufacturing dominates.

N-Methylmorpholine Oxide Market Executive Summary

The N-Methylmorpholine Oxide market is characterized by robust growth, underpinned by fundamental shifts towards sustainability in the global textile value chain. Business trends indicate significant capital expenditure focused on scaling up Lyocell fiber production facilities, primarily concentrated in China, India, and Southeast Asia, reflecting a strategic response to increasing brand commitment toward eco-friendly sourcing. Innovation in NMMO purification techniques and process optimization, including the development of continuous solvent delivery systems, represents a critical business focus area aimed at improving operational efficiencies and cost competitiveness. The market structure remains moderately consolidated, with a few large chemical manufacturers dominating supply, necessitating resilient supply chain management to mitigate geopolitical and logistics risks inherent in the specialty chemical trade.

Regional trends highlight the Asia Pacific as the undeniable epicenter of demand and consumption, largely owing to its established dominance in textile and apparel manufacturing, coupled with rapid industrialization and growing consumer awareness regarding sustainable products. While North America and Europe demonstrate mature demand driven by high-value technical textiles and stringent regulatory environments favoring green chemistry, APAC's sheer manufacturing volume provides the primary growth impetus. Investment flows suggest a strong commitment in Western markets to developing higher-purity NMMO grades suitable for sensitive applications, such as pharmaceuticals and advanced materials, diversifying the market portfolio beyond traditional textile applications.

Segmentation analysis reveals that the Lyocell grade NMMO segment holds the lion's share, dictated by the monumental growth trajectory of the regenerated cellulose fiber market. The solid form of NMMO, typically NMMO monohydrate, is preferred for ease of handling and stability in fiber production. However, the liquid form is crucial in specific chemical synthesis applications. The purity segment is witnessing differentiation, with ultra-high purity NMMO gaining traction due to demands from pharmaceutical intermediates and high-performance polymer processing, distinguishing it from standard textile-grade NMMO. This segmentation dynamic reflects a dual market path: volume growth driven by fibers, and value growth driven by high-end, niche applications requiring precise chemical specifications and rigorous quality control.

AI Impact Analysis on N-Methylmorpholine Oxide Market

User queries regarding AI's impact on the N-Methylmorpholine Oxide market predominantly center on optimizing the complex, energy-intensive Lyocell production process, ensuring solvent recovery efficiency, and predicting supply chain disruptions. Key themes include the use of machine learning (ML) for real-time process control, predictive maintenance for large-scale solvent regeneration units, and AI-driven quality assurance systems to monitor NMMO purity and concentration within closed-loop systems. Users express expectations that AI will enhance sustainability metrics by minimizing solvent loss, optimizing energy consumption during evaporation and purification, and potentially accelerating research into alternative or improved cellulose dissolution methods, ultimately driving down the production cost of high-quality Lyocell fiber and increasing the competitive edge of NMMO-based processes.

The integration of Artificial Intelligence and Machine Learning algorithms specifically targets the optimization of industrial chemical synthesis, which is particularly relevant for NMMO manufacturing and its utilization in fiber spinning. AI systems are being implemented to analyze vast datasets related to reaction kinetics, temperature control, pressure variations, and the complex fluid dynamics involved in cellulose dissolution and fiber extrusion. This data-driven approach allows manufacturers to maintain optimal operating conditions continuously, reducing batch-to-batch variability and ensuring consistent fiber quality. Furthermore, AI models are essential for managing the solvent recovery loop; by predicting potential fouling or degradation of the solvent, systems can signal preemptive adjustments, dramatically improving the NMMO recovery rate and extending the lifespan of process equipment, thereby enhancing the economic feasibility of the Lyocell process.

In terms of market strategy, AI tools are revolutionizing demand forecasting for NMMO, coupling real-time textile market data with historical consumption patterns to provide highly accurate predictions. This allows NMMO manufacturers to optimize production schedules, manage raw material inventory (N-methylmorpholine and hydrogen peroxide), and streamline logistics. Predictive analytics are also crucial for identifying potential regulatory shifts or supply bottlenecks for key precursors, offering manufacturers a competitive advantage in securing stable supply and pricing. The overarching goal of leveraging AI in this sector is to transform the traditional chemical manufacturing process into a smart, sustainable, and highly efficient operation, ensuring NMMO maintains its leadership position as the preferred solvent for next-generation cellulosic fibers.

- AI-driven optimization of NMMO solvent recovery efficiency (99% target maintenance).

- Machine Learning models for real-time process parameter control in Lyocell spinning lines.

- Predictive maintenance analytics for continuous NMMO purification and distillation equipment.

- Enhanced quality control systems utilizing vision AI for monitoring fiber quality and solvent concentration.

- AI-supported demand forecasting for precursor chemicals (N-methylmorpholine) and finished NMMO product.

- Simulation models for accelerated R&D into advanced, greener NMMO derivatives or co-solvents.

DRO & Impact Forces Of N-Methylmorpholine Oxide Market

The N-Methylmorpholine Oxide market is propelled by significant drivers, primarily the burgeoning global demand for sustainable textiles and the intrinsic advantages of the Lyocell production method. Restraints include the relatively high capital intensity required to establish Lyocell production plants and the sensitivity of NMMO to thermal degradation during the rigorous recovery process, demanding precise engineering solutions. Opportunities lie in diversifying NMMO usage into advanced materials, such as bio-composites and specific pharmaceutical intermediates, alongside continuous innovation to reduce production costs and improve energy efficiency. The interplay of these forces creates a dynamic environment where stringent environmental regulations act as a powerful tailwind for adoption, while economic barriers pose moderate challenges to rapid global expansion.

Key drivers include the global mandate for sustainable manufacturing, exemplified by commitments from major fashion brands to utilize certified sustainable fibers. NMMO facilitates the closed-loop, environmentally responsible production of Lyocell, directly addressing this driver. Additionally, the superior functional attributes of Lyocell fiber—such as excellent moisture management, soft feel, and biodegradability—make it a preferred material over synthetics and traditional rayons, ensuring sustained demand for NMMO. The expanding middle class in emerging economies further fuels the demand for premium, sustainable apparel, accelerating the consumption of NMMO in APAC manufacturing hubs. Technological advancements ensuring high-rate NMMO regeneration significantly lower operational costs over time, reinforcing its economic competitiveness against older processes.

Conversely, significant restraints exist. The initial investment cost for a new Lyocell facility, encompassing specialized reactors and high-efficiency solvent recovery units necessary for handling NMMO, is substantial, creating a barrier to entry for smaller manufacturers. Furthermore, NMMO is chemically sensitive; prolonged exposure to high temperatures or incorrect pH levels can lead to decomposition, potentially compromising fiber quality and recovery yields, which necessitates sophisticated process control and highly trained personnel. The potential opportunity landscape is broad, focusing on green chemistry applications beyond textiles, such as using NMMO as a solvent for specific high-performance biopolymers or as a mild, selective oxidant in complex organic synthesis, capitalizing on its unique solubility profile and moderate reactivity. Impact forces are dominated by regulatory pressures favoring green solvents, coupled with raw material price volatility for precursors like N-methylmorpholine, influencing the final cost structure of Lyocell fibers.

Segmentation Analysis

The N-Methylmorpholine Oxide market is comprehensively segmented based on its physical form, application area, and purity level, reflecting diverse industrial requirements and end-user demands. Analysis by form highlights the dominance of the solid monohydrate form, favored by large-scale fiber producers for its ease of storage and precise measurement, contrasted with the niche but vital liquid solution used in certain specialty chemical reactions. The application segmentation clearly delineates the market into the massive Lyocell fiber manufacturing segment and smaller, high-value specialty chemical and pharmaceutical sectors. Purity levels, ranging from technical grade to high purity, determine the suitability for different end-use applications, with stricter controls applied for materials used in medical textiles or sensitive chemical synthesis, driving price differentiation across the market.

Understanding these segments is crucial for strategic market positioning. The Lyocell segment dictates overall volume and primary price movements, requiring suppliers to focus on scale, cost efficiency, and reliable supply chains. In contrast, the specialty chemical segment, although smaller in volume, demands stringent quality assurance and customization, offering higher margin potential. The continuous growth of the Lyocell fiber market, propelled by global brands’ sustainability goals, ensures that NMMO for solvent purposes will remain the foundational revenue stream. Therefore, investments in capacity expansion are heavily skewed towards meeting the needs of major textile manufacturers, predominantly located in Asian economies. This segmentation dynamic is constantly reviewed based on technological innovations that might broaden NMMO's utility in emerging industrial applications.

Furthermore, segmentation provides insights into regional consumption patterns and regulatory compliance needs. High-purity NMMO often sees greater demand in regions with robust pharmaceutical and advanced material research sectors, such as North America and Europe, which demand certified, low-impurity products. Conversely, technical-grade NMMO is widely accepted in emerging economies prioritizing cost competitiveness for mass-market textile production. The ongoing technological development focuses on creating stabilized NMMO formulations and improving the overall sustainability metrics across all grades, aiming to solidify its position against potential competing solvents in the highly regulated specialty chemicals space. Strategic suppliers must manage a portfolio that balances high-volume, cost-sensitive textile demand with lower-volume, high-specification demand from niche technical industries.

- By Form:

- NMMO Monohydrate (Solid Form)

- NMMO Anhydrous (Liquid Solution)

- By Application:

- Lyocell Fiber Production (Dominant Segment)

- Chemical Synthesis (Oxidation Agent)

- Pharmaceutical Intermediates

- Polymer Processing and Specialty Solvents

- By Purity Grade:

- Technical Grade

- High Purity Grade

- By End-Use Industry:

- Textile and Apparel

- Non-woven and Hygiene Products

- Chemical and Pharmaceutical

Value Chain Analysis For N-Methylmorpholine Oxide Market

The value chain for N-Methylmorpholine Oxide begins with the upstream sourcing of precursor chemicals, primarily N-methylmorpholine (NMM) and hydrogen peroxide. NMM is typically derived from morpholine, which itself is synthesized from diethylene glycol or ethanolamine. The complexity and purity requirements of these raw materials directly impact the final quality and cost of NMMO. Manufacturing involves the oxidation of NMM using hydrogen peroxide, followed by purification and crystallization to achieve the required monohydrate or solution forms. This upstream process requires specialized chemical engineering expertise and strict quality control to manage the exothermic oxidation reaction and prevent degradation, representing a high-value creation stage.

Moving downstream, the distribution channel is critical due to the chemical's sensitivity and the need for specialized logistics. NMMO is supplied directly to major industrial consumers, predominantly large-scale Lyocell fiber manufacturers like Lenzing, Birla Cellulose, and various Chinese producers. Direct sales channels are highly favored to maintain quality control, ensure just-in-time delivery, and facilitate technical support regarding solvent handling and recovery processes. Indirect channels, involving specialized chemical distributors, serve smaller specialty chemical consumers and regional markets where volume demand does not justify direct supplier-to-manufacturer logistics. Effective supply chain integration between NMMO producers and fiber manufacturers is essential, as the solvent is the lifeblood of the Lyocell process.

The final downstream application is dominated by the textile and non-woven industries. End-use products derived from Lyocell fiber, such as high-fashion apparel, medical masks, and technical filters, are then distributed through traditional consumer goods channels. The high recovery rate (upwards of 99%) of NMMO within the Lyocell closed-loop system is a distinctive feature of this value chain, significantly minimizing waste and operational expenditure in the long run. Efficiency in this recovery process is a major competitive factor, driving continuous investment in sophisticated evaporation and distillation equipment. The sustainable narrative generated by the closed-loop NMMO process is ultimately leveraged by fiber producers and apparel brands in their marketing to environmentally conscious consumers, demonstrating the high impact of the upstream chemical on final consumer perception and market value.

N-Methylmorpholine Oxide Market Potential Customers

Potential customers for N-Methylmorpholine Oxide are overwhelmingly centered around global manufacturers of regenerated cellulosic fibers that utilize the Lyocell process. These industrial giants require consistent, high-volume supply of NMMO monohydrate of certified purity to maintain continuous operation of their fiber spinning lines. These customers are highly sensitive to price stability, supply reliability, and technical support regarding solvent maintenance and recycling effectiveness. Their purchasing decisions are driven by production capacity, commitment to sustainable sourcing, and the need to meet stringent quality standards for high-end textile and non-woven applications, making long-term strategic contracts the norm.

Beyond the dominant textile segment, a second significant customer group comprises specialty chemical companies and pharmaceutical manufacturers. In the chemical sector, NMMO is purchased for use as a mild, selective oxidant in complex organic synthesis, particularly in reactions requiring the regeneration of catalysts like osmium tetroxide (e.g., in the Upjohn dihydroxylation). These customers require smaller, bespoke volumes of ultra-high purity NMMO solution, often with specific packaging and handling requirements. In the pharmaceutical industry, NMMO acts as an intermediate in the synthesis of certain active pharmaceutical ingredients (APIs), demanding compliance with Good Manufacturing Practices (GMP) and detailed documentation regarding trace impurities and stability.

The third group includes research institutions and academic laboratories focused on material science, particularly those exploring advanced biopolymers, cellulose derivatives, and bio-composites. NMMO’s unique solvent properties make it an invaluable tool for dissolving natural polymers to create novel materials. While their purchase volumes are negligible compared to textile manufacturers, they drive future innovation and potential new applications for NMMO. Overall, the primary customer base remains the industrial Lyocell producers who act as the volume anchor for the entire NMMO market, influencing pricing, standardization, and global distribution patterns.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185.5 Million |

| Market Forecast in 2033 | $320.1 Million |

| Growth Rate | 8.1% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, BASF SE, N-Methylmorpholine Oxide Co. Ltd., Sigma-Aldrich (Merck), Changzhou Yongsheng Chemical Co., Ltd., Anhui Fengyuan Chemical Co., Ltd., Shandong Xingfu Pharmaceutical & Chemical Co., Ltd., Loba Chemie Pvt. Ltd., Otto Chemie Pvt. Ltd., TCI Chemicals (India) Pvt. Ltd., Hangzhou Keying Chemical Co., Ltd., Shanghai Chem-Gen Industrial Co., Ltd., Hefei TNJ Chemical Industry Co., Ltd., Acros Organics (Thermo Fisher Scientific), AK Scientific Inc., Parchem fine & specialty chemicals, Santa Cruz Biotechnology, Inc., Chemspec Ltd., Alfa Aesar (Thermo Fisher Scientific) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

N-Methylmorpholine Oxide Market Key Technology Landscape

The technological landscape of the N-Methylmorpholine Oxide market is intrinsically linked to advancements in the Lyocell fiber production process, focusing intensely on solvent purity, recovery efficiency, and energy consumption minimization. The core technology centers on the closed-loop spinning system, where high-efficiency evaporation and distillation units are paramount for achieving the required 99% recovery rate of NMMO. Innovations involve developing specialized multi-effect evaporators and thin-film distillation equipment optimized to handle the viscous nature of the NMMO-water solution and minimize thermal degradation, ensuring that the recovered solvent maintains the chemical integrity necessary for repeated cellulose dissolution cycles. Process control technologies, often integrating sensor arrays and advanced automation, are standard to maintain precise temperature and concentration parameters throughout the dissolution and spinning stages, safeguarding both the solvent and the quality of the regenerated fiber.

Furthermore, significant research and development efforts are directed toward improving the synthesis and stabilization of NMMO itself. This includes optimizing the batch or continuous oxidation process using hydrogen peroxide to maximize yield and purity while minimizing unwanted byproducts that can inhibit cellulose dissolution or accelerate NMMO decomposition during recycling. Novel stabilization techniques, such as proprietary additives or mild processing conditions, are being explored to enhance the thermal and chemical stability of the solvent, thereby extending its usable lifespan and further improving the sustainability metrics of the Lyocell process. The shift towards higher throughput machinery in fiber manufacturing demands NMMO formulations that are consistently reliable under high-stress processing conditions, driving innovation in chemical formulation and quality consistency testing.

Another emerging technological area involves the use of NMMO in novel material applications, requiring specific high-purity grades. Technologies here include specialized crystallization and purification techniques, such as continuous chromatography, designed to remove trace metallic impurities and residual unreacted N-methylmorpholine, which are critical for pharmaceutical and advanced electronic applications. The overall technology trajectory is toward making the NMMO value chain greener, more energy-efficient, and increasingly scalable, enabling the Lyocell fiber to compete effectively against conventional fibers on both sustainability and cost fronts. Patents are continuously filed surrounding improved methods for filtering and removing cellulose fines and impurities from the recovered NMMO solution, sustaining the integrity and performance of the closed-loop system.

Regional Highlights

Regional dynamics play a crucial role in shaping the N-Methylmorpholine Oxide market, reflecting varied consumption patterns, regulatory environments, and manufacturing capabilities. The Asia Pacific (APAC) region is the most dominant market globally, characterized by massive textile manufacturing bases in China, India, and Southeast Asian countries. This region not only produces the largest volume of Lyocell fibers but also represents the fastest-growing consumer market for the final apparel products. Capacity expansion of major Lyocell producers is heavily concentrated here, driven by lower operational costs and government initiatives supporting sustainable textile production. The demand for NMMO in APAC is thus overwhelmingly volume-driven and tied directly to the exponential growth of sustainable fashion initiatives.

Europe and North America represent mature markets for NMMO, characterized by high demand for high-value specialty textile applications, such as medical non-wovens, technical fabrics, and premium fashion brands committed to traceable sustainability. Although production volumes are lower compared to APAC, these regions drive the demand for high-purity and specialized grades of NMMO, often used in research, pharmaceutical intermediates, and advanced material development. Stringent environmental regulations in Europe, particularly those mandating cleaner chemical processes (e.g., REACH compliance), strongly favor the closed-loop, environmentally benign nature of the NMMO-based Lyocell process, ensuring continued market stability and premium pricing for high-specification products.

Latin America and the Middle East & Africa (MEA) currently hold smaller market shares but are exhibiting promising growth potential. Latin American countries, particularly Brazil, are developing local textile manufacturing capabilities and increasing consumer awareness regarding sustainable materials. MEA markets, while diverse, are witnessing growing investment in localized chemical production and textile processing, aiming to reduce reliance on imports. Growth in these regions is heavily reliant on foreign direct investment in Lyocell capacity and the local adoption of international sustainability standards, providing emerging opportunities for NMMO suppliers to establish early market positions and capitalize on nascent industrial development.

- Asia Pacific (APAC): Dominant consumer and producer due to major Lyocell manufacturing centers (China, India, Indonesia); high volume demand for textile-grade NMMO; fastest growth rate globally driven by sustainable fashion adoption.

- Europe: Mature market focusing on high-purity NMMO for technical textiles and specialty chemicals; strict environmental regulations favoring closed-loop solvents; key region for advanced R&D applications.

- North America: Significant market for premium Lyocell products and non-woven applications; steady demand for certified sustainable materials; focus on pharmaceutical and specialty chemical synthesis using high-purity grades.

- Latin America (LATAM): Emerging market with increasing domestic textile production capacity; growth driven by regional economic development and rising middle-class consumer demand for quality apparel.

- Middle East & Africa (MEA): Low current consumption but potential for growth through industrial diversification and investments in localized chemical production and textile hubs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the N-Methylmorpholine Oxide Market.- Merck KGaA

- BASF SE

- N-Methylmorpholine Oxide Co. Ltd.

- Sigma-Aldrich (Merck)

- Changzhou Yongsheng Chemical Co., Ltd.

- Anhui Fengyuan Chemical Co., Ltd.

- Shandong Xingfu Pharmaceutical & Chemical Co., Ltd.

- Loba Chemie Pvt. Ltd.

- Otto Chemie Pvt. Ltd.

- TCI Chemicals (India) Pvt. Ltd.

- Hangzhou Keying Chemical Co., Ltd.

- Shanghai Chem-Gen Industrial Co., Ltd.

- Hefei TNJ Chemical Industry Co., Ltd.

- Acros Organics (Thermo Fisher Scientific)

- AK Scientific Inc.

- Parchem fine & specialty chemicals

- Santa Cruz Biotechnology, Inc.

- Chemspec Ltd.

- Alfa Aesar (Thermo Fisher Scientific)

- Tokyo Chemical Industry Co., Ltd. (TCI)

Frequently Asked Questions

Analyze common user questions about the N-Methylmorpholine Oxide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary application of N-Methylmorpholine Oxide (NMMO)?

The primary and most commercially significant application of N-Methylmorpholine Oxide (NMMO) is its use as the critical non-toxic solvent in the patented closed-loop process for manufacturing Lyocell fibers (regenerated cellulose), known for their sustainability and superior performance properties in textiles.

Why is NMMO considered an environmentally friendly solvent?

NMMO is considered environmentally friendly primarily because the Lyocell process uses a closed-loop system where the solvent is recovered and reused at rates typically exceeding 99%. Additionally, NMMO is non-toxic and biodegradable, offering a green alternative to traditional viscose solvents like carbon disulfide.

Which geographical region dominates the NMMO market demand?

The Asia Pacific (APAC) region dominates the NMMO market demand. This dominance is driven by the concentration of large-scale Lyocell fiber manufacturing facilities in countries like China and India, which cater to the massive global textile and apparel industry.

What is the key factor restraining the growth of the NMMO market?

A key factor restraining market growth is the high initial capital expenditure required for setting up new Lyocell production plants. These facilities need specialized, complex machinery for efficient NMMO handling and high-rate solvent recovery, which presents a significant barrier to entry.

How is NMMO used outside of textile production?

Outside of textile production, NMMO is utilized in specialty chemical synthesis as a mild oxidizing agent, particularly in the dihydroxylation of olefins. It is also employed as an intermediate in certain pharmaceutical manufacturing processes and as a solvent in advanced biopolymer research.

What are the different forms of NMMO available in the market?

NMMO is predominantly marketed in two forms: NMMO Monohydrate, a solid crystalline form favored for large-scale Lyocell production due to its stability and ease of handling; and NMMO Anhydrous, a liquid solution used primarily for specific laboratory and specialty chemical applications.

How does NMMO Purity Grade affect its usage and pricing?

NMMO purity grade is crucial. Technical Grade is used for bulk textile production, while High Purity Grade, which requires additional stringent purification, commands a premium price and is essential for sensitive applications such as pharmaceutical synthesis and high-performance polymer processing where trace impurities cannot be tolerated.

What role does AI play in the NMMO and Lyocell value chain?

AI, through machine learning and predictive analytics, is increasingly optimizing the NMMO and Lyocell value chain by enabling real-time process control, enhancing the efficiency of the solvent recovery loop, and predicting equipment maintenance needs, thereby improving operational consistency and sustainability metrics.

Which end-use industries contribute significantly to NMMO consumption?

The end-use industries contributing most significantly to NMMO consumption are the Textile and Apparel industry, followed by the Non-woven and Hygiene Products sector (medical gowns, filters), and the Chemical and Pharmaceutical industries utilizing NMMO as a reagent or intermediate.

What growth rate is projected for the NMMO market between 2026 and 2033?

The NMMO market is projected to expand at a robust Compound Annual Growth Rate (CAGR) of 8.1% during the forecast period (2026–2033), reflecting the persistent shift toward sustainable fiber production globally and increasing Lyocell capacity investments.

How is regulatory pressure influencing the demand for NMMO?

Regulatory pressure, particularly stringent environmental mandates in regions like Europe and North America, strongly influences demand by favoring NMMO. Its utilization in the closed-loop Lyocell process helps manufacturers comply with green chemistry principles, accelerating its adoption over conventional, pollution-intensive solvents.

Who are the main potential customers for high-volume NMMO supply?

The main potential customers for high-volume NMMO supply are global Lyocell fiber manufacturers, including multinational corporations such as Lenzing AG and Birla Cellulose, who require reliable and consistent supply to operate their continuous fiber spinning and solvent recovery lines.

What technological advancements are critical for the NMMO market?

Critical technological advancements include the development of highly efficient multi-effect evaporators and distillation columns optimized for NMMO recovery, along with advanced sensor technology and automation to manage the sensitive dissolution and stabilization processes effectively.

How does raw material pricing impact the cost of NMMO?

The cost structure of NMMO is significantly impacted by the volatile pricing and supply chain stability of its primary precursors, N-methylmorpholine and hydrogen peroxide. Fluctuations in these upstream chemical costs directly translate to variability in the final production cost of NMMO and subsequently, Lyocell fiber.

Is NMMO considered a toxic chemical?

NMMO is generally classified as a non-toxic solvent compared to the highly toxic and volatile solvents traditionally used in other cellulose regeneration processes (like carbon disulfide in viscose production). Its low toxicity profile is a core factor driving its preference in sustainable manufacturing.

What opportunities exist for NMMO beyond the textile industry?

Opportunities exist in its application as a solvent for emerging advanced materials, such as specific bio-composites and high-performance films, utilizing its unique ability to dissolve high molecular weight natural polymers, alongside its established niche in pharmaceutical synthesis.

How important is the solvent recovery rate in Lyocell production?

The solvent recovery rate is economically and environmentally paramount in Lyocell production. Achieving recovery rates of 99% or higher is crucial for minimizing operational costs, reducing environmental impact, and maintaining the competitive viability of NMMO against other processing methods.

Which segments of NMMO purity offer the highest profit margins?

The highest profit margins are typically found within the High Purity Grade NMMO segment, demanded by the pharmaceutical and specialty chemical industries, due to the exacting standards, smaller batch sizes, and the specialized purification required for these highly sensitive applications.

What is the difference between NMMO and N-methylmorpholine?

N-methylmorpholine (NMM) is the precursor chemical, an amine, used to synthesize NMMO. NMMO is N-methylmorpholine Oxide, the final oxidized product which functions as the cellulose solvent; NMM is oxidized using hydrogen peroxide to produce NMMO.

How do competitive fibers affect the NMMO market?

The NMMO market is indirectly influenced by the performance and pricing of competitive fibers, such as polyester, cotton, and modal/viscose. However, Lyocell’s superior sustainability profile and performance attributes continually drive demand for NMMO, positioning it favorably in premium and eco-conscious markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager