Nanofibrillated Cellulose Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443508 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Nanofibrillated Cellulose Market Size

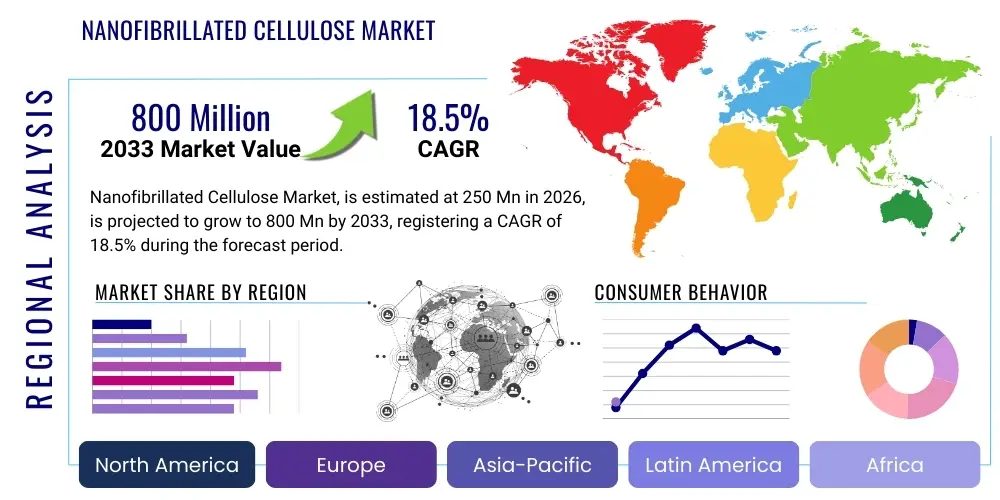

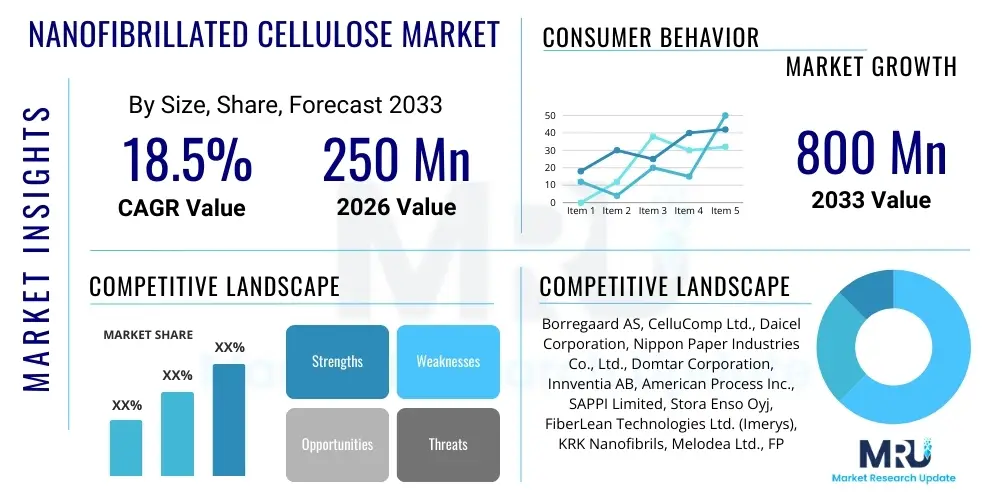

The Nanofibrillated Cellulose Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2026 and 2033. The market is estimated at $250 million in 2026 and is projected to reach $800 million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for sustainable, high-performance materials across diverse industrial sectors, notably packaging, construction, and biomedical applications. The unique mechanical properties, high surface area, and exceptional barrier characteristics of nanofibrillated cellulose position it as a critical enabling technology for next-generation material development, especially in replacing petroleum-based plastics and traditional reinforcing agents.

Nanofibrillated Cellulose Market introduction

The Nanofibrillated Cellulose (NFC) Market encompasses the commercialization and application of cellulose fibers refined to the nanoscale, typically characterized by diameters ranging from 5 to 50 nanometers and lengths extending several micrometers. NFC, often derived from wood pulp or other cellulosic biomass through intensive mechanical processing, represents a paradigm shift in material science, offering exceptional attributes such as high specific strength, low density, high aspect ratio, and tunable rheological properties. The primary applications span across advanced composites for automotive and aerospace sectors, high-barrier packaging films replacing conventional plastics, specialized paper and board enhancement for improved strength and smoothness, and complex biomedical scaffolds for tissue engineering and drug delivery systems. The inherent biodegradability and renewability of NFC are major compelling benefits, positioning it as a pivotal material in the transition toward a circular bioeconomy, reducing reliance on fossil resources and addressing global concerns regarding plastic pollution.

The driving factors propelling this market expansion are multifaceted, including stringent regulatory frameworks promoting sustainable sourcing and green manufacturing practices, significant investment in R&D focusing on scalable production techniques (such as high-pressure homogenization, microfluidization, and cryocrushing), and increasing consumer preference for eco-friendly products. Furthermore, the ability of NFC to function effectively as a rheology modifier, thickener, stabilizer, and reinforcing filler in water-based systems without requiring extensive chemical modification broadens its applicability considerably across paints, coatings, adhesives, and personal care products. The enhanced performance offered by incorporating NFC—such as improved stiffness, thermal stability, and superior gas barrier properties—makes it highly attractive to manufacturers seeking competitive advantages in specialized high-value markets.

Nanofibrillated Cellulose Market Executive Summary

The global Nanofibrillated Cellulose Market is undergoing robust commercial maturation, characterized by strategic partnerships between pulp producers and material science innovators focusing on streamlining production costs and increasing throughput efficiency. Current business trends indicate a shift from pilot-scale production to industrial-scale facilities, particularly in Scandinavia, North America, and parts of Asia, aiming to meet the expanding volume requirements from the packaging and composite industries. The market's competitive landscape is defined by intellectual property consolidation and diversification of raw material sources, moving beyond conventional bleached wood pulp to utilize agricultural residues, bacterial cellulose, and various waste streams, thereby improving cost-effectiveness and supply chain resilience. This technological push is crucial for NFC to move from niche applications into high-volume commodity markets.

Regional trends highlight that Europe maintains a leading position, heavily supported by the European Union’s commitment to sustainability goals and the strong presence of established forest product companies actively integrating NFC into their material portfolios for barrier coatings and sustainable paper products. Asia Pacific is emerging as the fastest-growing region due to rapid industrialization, increasing governmental support for sustainable materials in economies like China, Japan, and India, and the burgeoning demand from the construction and packaging sectors. Segment trends reveal that the composites and packaging segments dominate the market share, driven by the need for lightweighting in transportation and the push for biodegradable food packaging solutions. The biomedical segment, while smaller in volume, exhibits the highest growth rate due to continuous advancements in hydrogel technology, wound dressings, and advanced medical device coatings leveraging the biocompatibility of NFC.

AI Impact Analysis on Nanofibrillated Cellulose Market

Users frequently inquire about how Artificial Intelligence (AI) can optimize the complex, energy-intensive production of Nanofibrillated Cellulose, specifically targeting questions regarding real-time process control, material quality consistency, and new material formulation. Key concerns revolve around the high initial capital investment required for AI implementation versus the potential energy savings and yield improvements, and how machine learning (ML) models can accurately predict NFC performance characteristics (e.g., rheology, mechanical strength) based on diverse input biomass sources. The core expectations center on AI’s ability to minimize batch-to-batch variability, accelerate the discovery of novel chemical modifications or blending techniques, and ultimately, drive down the cost of NFC, facilitating its mainstream adoption across major industrial applications such as high-volume packaging and construction materials, where material consistency and price competitiveness are paramount.

The integration of AI and machine learning techniques into the NFC supply chain offers substantial opportunities for transformative efficiency gains, moving beyond simple process monitoring to predictive modeling and autonomous optimization. AI algorithms can analyze vast datasets generated during mechanical and chemical treatments (such as homogenization pressure, temperature, consistency, and chemical pre-treatment conditions) to precisely map optimal operational parameters that maximize nanofibril yield and desired aspect ratio while minimizing specific energy consumption. This capability ensures that the final product quality remains highly consistent, addressing a major commercialization hurdle related to scalability and reliability in materials derived from natural, inherently variable biomass. Furthermore, AI-driven simulation platforms are increasingly employed to rapidly screen and predict the functional properties of NFC composites and hydrogels, significantly reducing the traditionally long and expensive cycle of physical material synthesis and characterization, thereby accelerating product development and market entry for specialized NFC variants.

- AI optimizes energy consumption in mechanical fibrillation processes by dynamically adjusting machine parameters based on real-time sensor data.

- Machine Learning (ML) models predict the mechanical and rheological properties of NFC products based on variations in raw biomass source and pre-treatment conditions, ensuring quality consistency.

- AI accelerates the discovery of novel NFC modification chemistries, simulating binding affinities and polymerization efficacy for advanced functional materials.

- Predictive maintenance schedules for high-pressure homogenization equipment are enhanced by AI, reducing unexpected downtime and operational costs.

- Generative AI tools assist researchers in formulating optimized composite blends, rapidly identifying suitable matrices and dispersion methods for NFC reinforcement.

DRO & Impact Forces Of Nanofibrillated Cellulose Market

The Nanofibrillated Cellulose Market is profoundly shaped by a powerful confluence of driving forces, significant restraining challenges, and untapped commercial opportunities, which together define its trajectory and impact. Key drivers include global regulatory shifts favoring biodegradable and bio-based materials, technological advancements leading to energy-efficient production techniques, and robust demand from industries like packaging and automotive seeking lightweight and high-strength reinforcement. However, the market faces significant headwinds, primarily the high energy intensity and consequently high cost associated with the fibrillation process, coupled with the difficulty in ensuring consistent product dispersion and quality during high-volume manufacturing, which acts as a restraint on mass adoption. The substantial opportunity lies in developing cost-effective, continuous production methods, expanding into large-scale civil engineering applications, and pioneering use in next-generation electronic displays and sensors, where NFC’s optical transparency and high surface area are highly advantageous.

The primary impact force remains the sustained global push toward environmental sustainability. This pressure forces industries to actively seek replacements for traditional fossil fuel-derived materials, making renewable resources like NFC exceptionally attractive. Conversely, the market is severely impacted by the current limitations in achieving true price parity with conventional materials such as glass fiber or synthetic polymers, especially in commodity markets. If R&D efforts successfully mitigate the high energy input required for deconstruction—potentially through enzyme-assisted or chemical pre-treatments—the subsequent reduction in manufacturing cost will dramatically amplify the positive impact forces, enabling rapid market penetration. Strategic governmental funding and public-private research consortia focused on scaling technology transfer also exert a strong, positive impact force, transforming fundamental science into economically viable industrial processes.

Segmentation Analysis

The Nanofibrillated Cellulose market is comprehensively segmented based on its source material, application, and end-use industry, reflecting the diverse pathways through which NFC is produced and utilized. Segmentation by source material is crucial as it determines cost structure and environmental footprint, differentiating between wood pulp (softwood and hardwood), non-wood plant sources (e.g., cotton, agricultural residues), and bacterial cellulose. The application segmentation reveals the material's versatility, covering high-performance reinforcing composites, barrier films, hydrogels, and additives in paints and cement. Analyzing these segments provides strategic insights into areas of highest revenue generation and fastest growth potential, enabling manufacturers to tailor production capabilities and optimize market entry strategies based on specific technical requirements of the consuming industries, such as the need for high clarity in optical applications or superior moisture resistance in packaging.

The end-use industry analysis highlights the primary sectors driving demand, including packaging, automotive, construction, and biomedical fields. The packaging industry dominates due to the urgent need for recyclable and biodegradable barrier coatings for food and beverage containers. The automotive sector utilizes NFC for lightweighting structural and non-structural components, contributing to fuel efficiency. The construction industry integrates NFC into cement and concrete formulations to enhance mechanical strength and reduce cracking, while the biomedical sector leverages its excellent biocompatibility for advanced drug delivery systems and tissue scaffolds. Understanding these granular segments is vital for predicting technological shifts, such as the increased adoption of bio-based fibers in 3D printing applications, further solidifying NFC's position as a key enabling nanomaterial for sustainable engineering solutions across multiple economic fronts.

- By Source Type:

- Wood Pulp (Softwood, Hardwood)

- Non-Wood Plant Sources (e.g., Cotton, Agricultural Waste, Hemp)

- Bacterial Cellulose

- Recycled Fiber

- By Application:

- Composites and Nanocomposites

- Barrier Films (Oxygen, Water Vapor)

- Paper and Board Additives

- Hydrogels and Aerogels

- Rheology Modifiers and Thickeners

- Paints, Coatings, and Adhesives

- By End-Use Industry:

- Packaging (Food, Beverages, Consumer Goods)

- Automotive and Aerospace

- Construction and Building Materials (Concrete, Cement)

- Biomedical and Pharmaceutical (Scaffolds, Wound Dressings)

- Electronics and Sensor Technology

- Textiles and Non-Wovens

Value Chain Analysis For Nanofibrillated Cellulose Market

The value chain for the Nanofibrillated Cellulose market is complex, initiating with the upstream analysis involving the sourcing and pre-treatment of cellulosic biomass. This stage is dominated by large forestry companies and agricultural processors who supply high-quality wood pulp or agricultural residues, focusing on efficient delignification and pre-conditioning (chemical or enzymatic treatment) to make the cellulose fibers amenable to subsequent mechanical processing. Raw material consistency and sustainability certifications (like FSC or PEFC) are crucial at this stage. The core value addition occurs in the middle segment, involving specialized manufacturers who utilize high-energy processes—such as high-pressure homogenization, microfluidization, or grinding—to transform macro-sized fibers into nanoscale fibril suspensions. The capital expenditure and energy costs incurred here are the primary determinants of the final product price, and innovations in process engineering are continuously targeting cost reduction and yield maximization.

Downstream analysis focuses on the formulation and integration of NFC into final products. This segment involves compounders, material converters, and specialized chemical manufacturers who incorporate NFC as a reinforcing agent, rheology modifier, or barrier coating additive. Product differentiation often hinges on achieving optimal dispersion of the fibrils within various matrices (polymeric, cementitious, or aqueous). Distribution channels are highly fragmented, reflecting the diverse end-uses. For high-volume applications like packaging additives, distribution is often indirect, relying on large chemical distributors and regional agents capable of handling bulk liquid or dried NFC material. Conversely, for specialized, low-volume applications, such as advanced biomedical hydrogels or optical electronics, the distribution often occurs directly between the NFC manufacturer and the highly technical end-user, often involving specialized technical support and customized formulation development. This dual-channel approach ensures market penetration across both industrial and niche sectors.

Nanofibrillated Cellulose Market Potential Customers

The potential customers for Nanofibrillated Cellulose span a broad spectrum of industrial manufacturers driven by the need for superior functional performance combined with sustainable sourcing. Primary end-users or buyers include major global packaging corporations, such as those involved in food and beverage containment, who seek highly effective oxygen and water vapor barrier coatings that are fully biodegradable and compostable. Large automotive and aerospace manufacturers constitute another critical customer segment, utilizing NFC to develop lightweight polymer composites that meet stringent safety and performance standards while reducing overall vehicle weight and carbon footprint. These customers prioritize high mechanical strength, dimensional stability, and consistent supply reliability.

Furthermore, the construction chemicals industry represents a growing clientele, where NFC is integrated into cement, concrete, and dry-mix mortars to improve hydration kinetics, reduce permeability, and enhance overall structural integrity, offering a greener alternative to synthetic additives. In the biomedical sector, research institutions and specialized pharmaceutical companies are major buyers, procuring high-purity, often sterilized NFC grades for advanced applications like injectable hydrogels, surgical meshes, and sophisticated wound care products. These highly technical buyers require materials with exceptional biocompatibility, defined surface chemistry, and detailed documentation regarding particle size distribution and purity, driving demand for specialized, high-cost NFC products with rigorous quality control protocols.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $250 Million |

| Market Forecast in 2033 | $800 Million |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered |

|

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nanofibrillated Cellulose Market Key Technology Landscape

The Nanofibrillated Cellulose market is defined by several sophisticated production and modification technologies crucial for achieving nanoscale dimensions and desired functional attributes. The mechanical fibrillation approach remains dominant, relying on high-shear processing methods such as high-pressure homogenization, microfluidization, and grinding. Homogenization, a highly effective but energy-intensive method, forces cellulose slurries through narrow nozzles at extremely high pressures, causing intense shear forces that liberate nanofibrils. Advancements in this area focus heavily on designing more robust and efficient machinery, utilizing ceramic components, and optimizing flow dynamics to reduce energy consumption per kilogram of NFC produced. Complementing these mechanical treatments are various pre-treatment technologies, including enzymatic hydrolysis and temporary chemical modification (e.g., TEMPO-mediated oxidation or carboxymethylation), which significantly reduce the energy barrier for mechanical separation, thereby lowering overall operational costs and making large-scale production more economically feasible.

Beyond core fibrillation, the technological landscape includes significant innovations in drying and functionalization methods essential for market usability. Converting the highly viscous NFC hydrogels (typically 1-5% solids content) into a dry, easily dispersible powder without irreversible agglomeration is a major challenge. Technologies such as supercritical drying, spray drying assisted by surface modifiers, and freeze-drying are employed, each offering different trade-offs between cost and final redispersibility. Furthermore, surface functionalization via graft polymerization or chemical grafting enables the tailoring of NFC surface energy to improve compatibility with non-polar polymer matrices (such as polypropylene or polyethylene) for composite applications, thereby unlocking utilization in broader industrial sectors. The shift toward continuous, integrated processing lines, often incorporating in-line quality monitoring and feedback control systems, represents the current frontier of manufacturing technology, crucial for delivering commercial quantities of highly consistent NFC products to global markets.

Regional Highlights

The Nanofibrillated Cellulose market exhibits pronounced regional disparities in growth dynamics and application focus, heavily influenced by local resource availability, regulatory environments, and industrial structure.

- Europe: Leading the global market, Europe benefits from strong governmental mandates supporting bio-based materials (e.g., the EU’s Circular Economy Action Plan) and a robust forest industry base, particularly in Nordic countries (Finland, Sweden, Norway). The region excels in developing high-performance barrier coatings for packaging and incorporating NFC into specialty paper and board products. Extensive collaboration between research institutions and industry players drives continuous innovation in cost-effective production techniques.

- North America: Characterized by significant R&D investment and a focus on high-value applications, particularly in lightweight automotive composites and advanced materials for defense and aerospace. The U.S. and Canada possess vast timber resources, facilitating a stable raw material supply. Efforts are concentrated on scaling up industrial production, often leveraging government grants and partnerships between national labs and private companies to overcome technological hurdles related to high-volume manufacturing consistency.

- Asia Pacific (APAC): Positioned as the fastest-growing region, APAC is driven by rapid industrial expansion, increasing consumer awareness regarding sustainable packaging, and competitive manufacturing costs in countries like China and India. The application focus is broad, including construction materials (enhancing concrete performance) and general packaging. Japan and South Korea are key technology centers, focusing particularly on NFC applications in electronics (flexible displays) and high-end filtration media.

- Latin America (LATAM): Growth is primarily centered on utilizing regionally abundant agricultural waste (e.g., sugarcane bagasse) as low-cost source material. Brazil and Chile are emerging players, focusing on basic NFC grades for local construction and paper additive markets, although commercial maturity lags behind North America and Europe.

- Middle East and Africa (MEA): Currently a nascent market, primarily relying on imports for specialized NFC applications. Future growth is anticipated to be linked to large-scale infrastructure projects and investment in local bio-refining capabilities, particularly within the Gulf Cooperation Council (GCC) nations seeking diversification from oil economies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nanofibrillated Cellulose Market.- Borregaard AS

- CelluComp Ltd.

- Daicel Corporation

- Nippon Paper Industries Co., Ltd.

- Domtar Corporation

- Stora Enso Oyj

- SAPPI Limited

- FiberLean Technologies Ltd. (Imerys)

- KRK Nanofibrils

- Melodea Ltd.

- FPInnovations

- UPM-Kymmene Oyj

- American Process Inc.

- Innventia AB

- Ashland Global Holdings Inc.

- Novozymes A/S

- Kemira Oyj

- Aalto University (Research focus)

- Alberta Innovates (Research/Pilot focus)

- Zelfo Technology GmbH

Frequently Asked Questions

Analyze common user questions about the Nanofibrillated Cellulose market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary challenges hindering the mass adoption of Nanofibrillated Cellulose?

The primary challenges include the high energy consumption during mechanical fibrillation, leading to high production costs compared to traditional materials, and technical difficulties related to achieving uniform dispersion of NFC within non-aqueous matrices for composite manufacturing.

In which end-use industry is Nanofibrillated Cellulose expected to witness the highest growth rate?

The biomedical and pharmaceutical industry is expected to demonstrate the highest Compound Annual Growth Rate (CAGR) due to expanding research in advanced drug delivery systems, tissue engineering scaffolds, and biocompatible wound dressings that leverage NFC's unique structural and surface properties.

How is Nanofibrillated Cellulose typically manufactured?

NFC is primarily manufactured through top-down mechanical processes, such as high-pressure homogenization or microfluidization, often following a chemical or enzymatic pre-treatment (like TEMPO oxidation) designed to reduce the high energy input required to separate the cellulose microfibers into nanoscale fibrils.

What is the main environmental benefit of using NFC in packaging materials?

The main environmental benefit is NFC's role as a renewable, biodegradable, and sustainable high-barrier coating that can replace non-recyclable plastic layers (like EVOH or aluminum foil) used in food and beverage packaging, significantly improving the end-of-life options for the packaging material.

Which geographical region currently holds the largest market share for NFC?

Europe currently holds the largest market share for Nanofibrillated Cellulose, largely driven by stringent regulatory frameworks promoting bio-based economies, robust investment in scaling forest-based innovations, and a strong existing industrial base focused on sustainable paper and packaging solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager