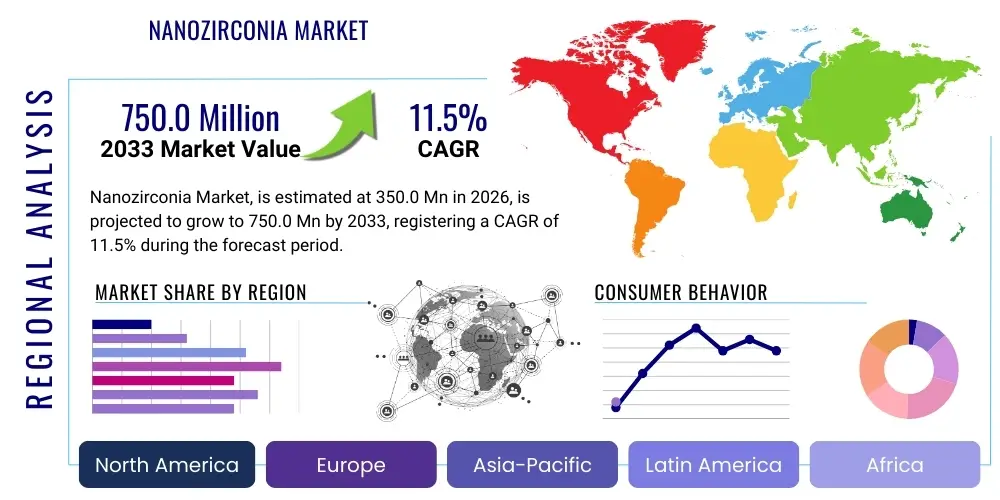

Nanozirconia Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441172 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Nanozirconia Market Size

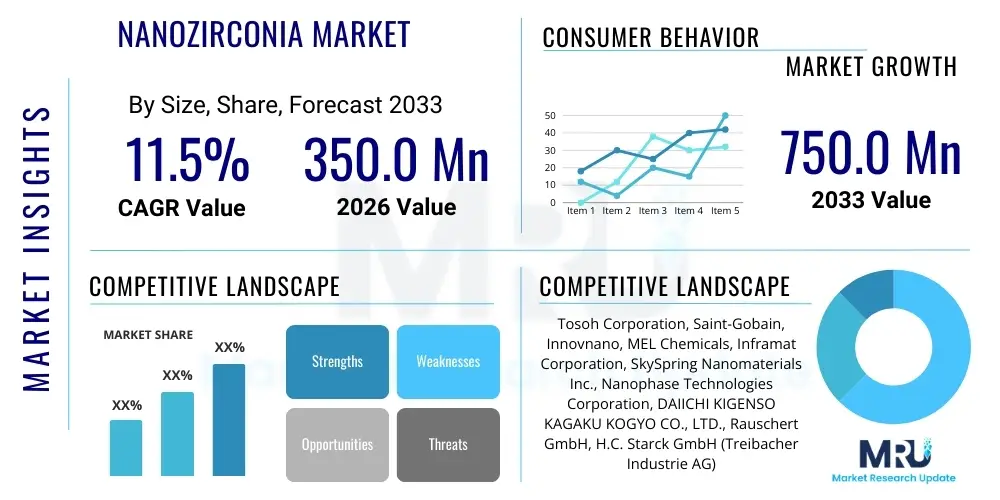

The Nanozirconia Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 350.0 million in 2026 and is projected to reach USD 750.0 million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the material’s superior mechanical, chemical, and thermal properties, making it indispensable across high-performance sectors such as medical prosthetics, advanced ceramics, and electronics manufacturing. The increasing demand for miniaturization in electronic components and the ongoing shift toward durable, biocompatible materials in healthcare are primary accelerators of this growth trajectory.

Nanozirconia Market introduction

The Nanozirconia Market encompasses the production, distribution, and utilization of zirconium dioxide (ZrO₂) particles exhibiting dimensions typically below 100 nanometers. Nanozirconia, often stabilized with yttria (Y-TZP) or magnesia, offers exceptional hardness, fracture toughness, chemical inertness, and high-temperature stability, distinguishing it from conventional micron-sized ceramics. The unique nanoscale structure imparts enhanced sintering capabilities and improved mechanical reliability, particularly vital for load-bearing applications in extreme environments. Its versatility spans from structural applications requiring high strength to functional roles leveraging its ionic conductivity.

Major applications of nanozirconia are concentrated in biomedical engineering, particularly dental and orthopedic implants, where its biocompatibility and aesthetic qualities are paramount. Furthermore, it is extensively used in solid oxide fuel cells (SOFCs) as an electrolyte due to its high oxygen ion conductivity, positioning it as a key material in sustainable energy technology. In the abrasives and polishing industry, nanozirconia serves as a high-efficiency polishing agent, enabling precision finishing required in optics and semiconductors. The product's application portfolio is continually expanding, driven by innovations in material synthesis techniques allowing for precise control over particle morphology and size distribution.

The market expansion is significantly driven by robust governmental funding in advanced materials research and increasing consumer demand for highly aesthetic and durable dental restorations. Benefits include superior wear resistance, reduced component failure rates, and enhanced energy efficiency in solid-state devices. Key driving factors involve the rapid technological advancements in 3D printing of ceramics, which utilizes nanozirconia powder for intricate structures, and the escalating need for efficient catalytic converters in the automotive sector, where nanozirconia acts as a critical oxygen buffer and support material. These drivers collectively ensure sustained market momentum throughout the forecast period.

Nanozirconia Market Executive Summary

The global Nanozirconia Market is characterized by intense innovation in synthesis techniques and a sharp focus on vertical integration across the value chain, particularly among major Asian and European manufacturers. Current business trends indicate a strong move towards tailored solutions, where manufacturers offer customized particle size distributions and surface modifications to meet specific application requirements in electronics and healthcare. Mergers and acquisitions are common strategies for securing intellectual property related to high-purity production processes and expanding geographical reach into high-growth manufacturing hubs, cementing the market’s competitive landscape around quality and functional specialization.

Regionally, Asia Pacific (APAC) currently dominates the market, largely propelled by exponential growth in the electronics, automotive, and emerging biomedical device manufacturing sectors in countries like China, Japan, and South Korea. This dominance is further reinforced by lower operating costs and significant government investment in material science R&D. North America and Europe, while mature, remain critical markets characterized by high penetration in premium biomedical and aerospace applications, emphasizing regulatory compliance and quality assurance. Future growth is anticipated to be highest in APAC due to industrialization, but substantial investment in renewable energy infrastructure (SOFCs) will buoy demand in Western economies.

Segment trends reveal that the biomedical segment, particularly dental ceramics, accounts for a dominant share due to favorable aging demographics and increasing access to advanced restorative procedures globally. Furthermore, the segmentation by type shows that Yttria Stabilized Zirconia (YSZ) leads the market, attributable to its exceptional mechanical strength and widespread use in structural ceramics and electrolytes. The chemical segment, including catalysts and coatings, is projected to register the fastest growth, benefiting from stringent global environmental regulations necessitating high-performance catalytic materials for pollution control and chemical synthesis processes. This rapid segmental diversification underscores the material’s fundamental role as an enabler of advanced technological solutions.

AI Impact Analysis on Nanozirconia Market

Common user questions regarding AI's impact on the Nanozirconia Market primarily revolve around how machine learning can optimize synthesis protocols, predict material performance under varying conditions, and accelerate the discovery of novel zirconia-based composites. Users are keen to understand the efficiency gains in reducing batch variation and ensuring high purity levels, which are traditionally complex challenges in nanopowder production. Concerns also focus on the potential integration of AI in quality control and characterization, specifically the use of computer vision for analyzing microscopic structures and identifying defects in sintered products. Expectations center on AI driving down production costs, enabling faster iteration cycles in R&D, and facilitating personalized materials design for biomedical applications.

AI's influence is transforming the R&D pipeline for nanozirconia, moving from traditional trial-and-error synthesis to data-driven predictive modeling. Machine learning algorithms are increasingly being deployed to analyze complex parameter spaces—including temperature profiles, precursor concentration, and reaction kinetics—to rapidly identify optimal synthesis conditions, such as sol-gel or hydrothermal methods, that yield desired particle size, morphology, and phase purity (e.g., tetragonal phase retention). This computational approach not only saves significant time and resources but also enhances the consistency of the final nanopowder, addressing a major quality hurdle faced by high-tech end-users.

Furthermore, AI is instrumental in accelerating material characterization and application design. Generative AI models are being used to simulate the mechanical behavior and long-term durability of nanozirconia components, such as dental crowns or SOFC electrolytes, before physical prototyping. This predictive capability is crucial for manufacturers targeting demanding sectors like aerospace and medical devices, where material failure carries significant risk. The integration of AI-powered sensor networks within manufacturing plants enables real-time monitoring and autonomous adjustment of processing variables, thereby maximizing yield and minimizing waste, solidifying AI's role as a core driver of efficiency and innovation in the Nanozirconia Market.

- Optimization of synthesis parameters (sol-gel, hydrothermal) using deep learning algorithms.

- Predictive modeling of material properties, accelerating the development of new composites.

- Enhanced quality control and defect detection via AI-driven computer vision systems for particle characterization.

- Simulation of component performance (e.g., fracture toughness, corrosion resistance) in high-stress environments.

- Automation of manufacturing processes, leading to reduced batch variation and improved purity levels.

- Accelerated discovery of novel dopants and stabilizers for enhanced ionic conductivity in fuel cells.

DRO & Impact Forces Of Nanozirconia Market

The Nanozirconia Market is governed by a confluence of strong growth drivers and critical limiting factors, shaping its overall trajectory. Key drivers include the exponential increase in demand from the dental industry for high-aesthetic, metal-free restorations, coupled with global regulatory push for cleaner energy solutions stimulating the use of nanozirconia in SOFCs. However, the market faces significant restraints, primarily the high cost associated with manufacturing high-purity, uniform nanopowders and concerns regarding the long-term environmental and biological safety of nanomaterials, which necessitates adherence to strict, evolving regulatory frameworks. Opportunities emerge from the potential integration of nanozirconia into additive manufacturing technologies and its expanding role in high-efficiency catalysts, providing avenues for market diversification and value creation.

Impact forces dictate the competitive intensity and market attractiveness. Supplier power is moderate; while raw material (zircon sand) is abundant, specialized processing technology required to achieve nano-scale purity gives specialized nanozirconia producers leverage. Buyer power is also moderate to high, particularly in consolidated end-user industries (e.g., large dental labs or SOFC manufacturers) who demand strict specifications and price stability. The threat of substitutes is low in high-end structural ceramics and biomedical applications where nanozirconia’s unique combination of toughness and biocompatibility is difficult to replicate. Conversely, the threat of new entrants is moderate, deterred by the high capital investment required for specialized manufacturing facilities and intellectual property barriers related to stabilization techniques.

The macroeconomic impact forces, such as global investments in renewable energy infrastructure and healthcare modernization, provide strong external impetus for market growth. Technological innovation acts as the most significant positive impact force, continually improving synthesis efficiency and opening up new application spaces, such as transparent dental ceramics or advanced thermal barrier coatings in aerospace engines. The dynamic interplay between the strong demand in medical and energy sectors (Drivers) and the stringent manufacturing complexity and regulatory scrutiny (Restraints) defines the market's moderate-to-high growth velocity, making strategic investments in process innovation critical for sustained success and market penetration.

Segmentation Analysis

The Nanozirconia Market is comprehensively segmented based on Type, Application, and Region to provide granular insights into market dynamics and growth potential across various dimensions. Segmentation by Type differentiates between various stabilized forms, with Yttria Stabilized Zirconia (YSZ) dominating due to its superior mechanical performance and utility as an oxygen sensor and solid electrolyte, while Magnesia Stabilized Zirconia (MSZ) and Ceria Stabilized Zirconia (CSZ) cater to specific needs in thermal insulation and oxygen storage, respectively. This categorization helps manufacturers tailor their product offerings to meet precise performance requirements mandated by different industrial standards.

Segmentation by Application is critical, highlighting the material's widespread adoption across diverse high-value sectors. The primary application areas are Biomedical (including dental and orthopedic implants), Electronics & Electricals (involving capacitors and sensors), Energy (SOFCs and batteries), and Industrial Ceramics (abrasives, structural components). The Biomedical sector is the largest revenue contributor, driven by ongoing research into next-generation biocompatible materials, whereas the Energy sector is projected to exhibit the highest CAGR, spurred by the global transition toward cleaner energy generation and storage solutions, requiring high-efficiency ceramic electrolytes.

Geographical segmentation provides a clear perspective on regional demand patterns and manufacturing concentration. Asia Pacific leads the market primarily due to robust manufacturing capabilities and high-volume demand from electronic and automotive industries. North America and Europe emphasize premium, technologically advanced applications in aerospace and high-end medical devices, supporting steady revenue streams. Understanding these segmented dynamics allows stakeholders to identify optimal investment areas, allocate resources efficiently, and formulate targeted market entry and competitive strategies tailored to regional regulatory and industrial requirements.

- By Type:

- Yttria Stabilized Zirconia (YSZ)

- Magnesia Stabilized Zirconia (MSZ)

- Ceria Stabilized Zirconia (CSZ)

- Others (Calcium Stabilized Zirconia, etc.)

- By Application:

- Biomedical (Dental, Orthopedics)

- Electronics and Electricals

- Energy (Solid Oxide Fuel Cells, Batteries)

- Industrial Ceramics and Abrasives

- Catalysts and Coatings

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Nanozirconia Market

The value chain for the Nanozirconia Market begins with upstream activities focused on the secure sourcing and purification of precursor materials, primarily zircon sand (ZrSiO₄), which is mined and chemically processed into zirconium oxychloride or zirconium salts. The most critical upstream process involves the synthesis of nano-sized particles, utilizing sophisticated techniques such as chemical precipitation, hydrothermal synthesis, or plasma synthesis, which require significant capital expenditure and specialized technical expertise to ensure control over particle size, crystallinity, and phase purity. Efficiency in this stage dictates the overall material cost and performance metrics, thereby giving early-stage manufacturers who possess patented synthesis methods a strong competitive advantage.

The midstream phase involves the stabilization, calcination, and surface modification of the produced nanopowders, often customizing the material for specific industrial applications like ceramics or composites. Nanozirconia manufacturers may sell the powder directly or integrate forward into producing intermediate products like slips, granules, or green bodies. Distribution channels are highly specialized; high-volume segments like industrial abrasives utilize indirect distribution through established chemical distributors, whereas high-specification end-users, such as major dental CAD/CAM milling centers or advanced electronics firms, rely heavily on direct channels to ensure technical support, quality traceability, and supply security. The demand for customization favors direct sales models, particularly in biomedical markets.

Downstream activities center on end-user processing, including sintering, machining, and final component assembly, which transforms the nanozirconia into functional products like dental blocks, ceramic armor plates, or SOFC components. The high investment in advanced sintering equipment and precision machining validates the material’s premium pricing. The value chain is characterized by a high degree of technical interdependence between raw material suppliers, nanopowder producers, and component manufacturers, necessitating strong collaboration to meet the stringent quality standards demanded by high-reliability applications such as medical implants. Effective quality control mechanisms and traceability systems throughout the entire chain are essential for market acceptance and regulatory compliance.

Nanozirconia Market Potential Customers

Potential customers for nanozirconia are predominantly clustered within high-technology and high-reliability industries that necessitate materials with exceptional mechanical, thermal, and dielectric properties. The largest segment of end-users are manufacturers in the biomedical sector, specifically dental laboratories, implant manufacturers, and orthopedic device companies that procure stabilized nanozirconia powder or pre-sintered blocks for fabricating highly durable, biocompatible dental crowns, bridges, and hip joint replacements. These customers prioritize ISO certification, long-term clinical performance data, and consistent batch quality, often operating under stringent regulatory scrutiny, which influences their procurement decisions towards established, reputable suppliers.

Another significant group of potential customers includes companies involved in advanced electronics and energy storage and conversion technologies. This includes solid oxide fuel cell (SOFC) stack manufacturers who rely on yttria-stabilized nanozirconia as the critical electrolyte material for proton or oxygen ion transport, seeking extremely fine-grained, high-density powders to maximize ionic conductivity and device efficiency. Furthermore, manufacturers of multilayer ceramic capacitors (MLCCs) and specialized ceramic sensors utilize nanozirconia for its dielectric properties and thermal stability. These industrial customers focus on scalability, cost-effectiveness, and the material’s ability to withstand high operational temperatures and chemical environments.

Finally, the industrial ceramics and coatings sectors represent substantial, growing customer bases. This encompasses abrasive manufacturers demanding uniform, high-hardness nanozirconia for precision grinding and polishing applications in semiconductor wafers and optics, as well as aerospace and automotive companies requiring high-performance thermal barrier coatings (TBCs) for engine components. These end-users typically purchase material in bulk and prioritize mechanical performance, particle uniformity, and the supplier's capacity to deliver customized specifications, reflecting a market demand driven by performance optimization rather than solely cost minimization, thereby ensuring sustained demand across multiple high-value segments globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.0 Million |

| Market Forecast in 2033 | USD 750.0 Million |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tosoh Corporation, Saint-Gobain, Innovnano, MEL Chemicals, Inframat Corporation, SkySpring Nanomaterials Inc., Nanophase Technologies Corporation, DAIICHI KIGENSO KAGAKU KOGYO CO., LTD., Rauschert GmbH, H.C. Starck GmbH (Treibacher Industrie AG), American Elements, Zircomet Ltd., Nano Products Corporation, US Research Nanomaterials, Inc., Reade International Corp., PlasmaChem GmbH, Advanced Nanopowders, Merck KGaA, S & S Advanced Materials, Nanobond Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nanozirconia Market Key Technology Landscape

The technology landscape of the Nanozirconia Market is defined by continuous advancements in material synthesis methodologies aimed at achieving tighter control over particle size, morphology, surface area, and phase stability, which are all critical determinants of end-product performance. Current dominating production technologies include chemical precipitation, where aqueous solutions of zirconium precursors are reacted to form hydroxides that are subsequently calcined, and hydrothermal synthesis, which uses high temperature and pressure to directly crystallize the nanopowder, offering high crystallinity and narrow size distribution, particularly favored for high-purity biomedical grades. Plasma synthesis (e.g., plasma torches) represents a high-energy alternative capable of producing ultra-fine, spherical powders rapidly, though the scalability and cost efficiency remain challenging for bulk production compared to wet chemical routes.

A major technological focus is the refinement of stabilization techniques, primarily using yttria, to prevent destructive phase transformations (specifically the transition from tetragonal to monoclinic phase) that occur during cooling or under stress, ensuring the material’s signature high fracture toughness. Innovations are centered on developing novel, low-temperature stabilization processes that reduce energy consumption and prevent particle agglomeration. Furthermore, the integration of computational materials science and machine learning (as discussed in the AI section) is rapidly becoming a core technology, allowing researchers to simulate and predict the performance of novel dopant combinations and sintering additives, effectively streamlining the development cycle for advanced nanozirconia grades used in challenging environments like high-temperature SOFCs.

Downstream technology advancements are equally important, particularly in powder processing and component manufacturing. The shift towards ceramic additive manufacturing (3D printing), utilizing nanozirconia slurries or specialized filaments, is revolutionizing the production of complex, patient-specific implants and intricate ceramic components with minimal material waste. Furthermore, sophisticated characterization techniques, including high-resolution transmission electron microscopy (HRTEM), X-ray diffraction (XRD) coupled with Rietveld analysis, and dynamic light scattering (DLS), are essential tools for ensuring quality control and verifying the nanoscale structure and purity before the material moves to final sintering. These technical advancements collectively enhance the material's viability across demanding high-specification applications, maintaining competitive edge within the specialized materials sector.

Regional Highlights

- Asia Pacific (APAC): APAC commands the largest share of the global nanozirconia market due to its robust industrial base and extensive manufacturing ecosystem, particularly in China, Japan, and South Korea. The region benefits from high production volumes in electronics (e.g., ceramic capacitors, sensors) and massive governmental investments in infrastructure and advanced materials research. The rapid growth of dental tourism and the increasing affluence leading to higher adoption rates of premium dental restorative procedures further consolidate APAC's position. Regional focus is on cost-effective mass production and catering to the surging demand from the local automotive industry for catalytic converters and sensor materials.

- North America: North America represents a mature, high-value market driven by rigorous quality standards and heavy R&D expenditure in aerospace, defense, and advanced medical technology. The United States is a key consumer, leading in the adoption of nanozirconia for specialized biomedical implants and high-performance technical ceramics requiring ultra-high reliability and compliance with FDA regulations. Market growth here is less volume-driven and more focused on technological superiority, particularly in leveraging nanozirconia in advanced solid-state battery research and high-temperature material applications.

- Europe: Europe maintains a strong presence, particularly in Germany and Switzerland, which are global leaders in precision engineering, advanced ceramics, and specialized machinery manufacturing. The region is a pioneer in sustainable energy solutions, driving strong demand for nanozirconia in SOFCs (Solid Oxide Fuel Cells) and advanced catalytic systems aligned with strict EU environmental policies. The European market emphasizes circular economy practices and the development of eco-friendly synthesis routes, focusing on high-quality, specialized grades for orthopedic devices and luxury automotive applications.

- Latin America (LATAM) and Middle East & Africa (MEA): These emerging regions show high growth potential, albeit from a smaller base. Growth in LATAM is driven primarily by the expanding healthcare sector and infrastructural development in Brazil and Mexico, leading to increased demand for dental materials. MEA growth is supported by diversification efforts away from oil economies, focusing on technological investment, particularly in localized petrochemical processing (catalysts) and localized production of medical devices, although reliance on imports for high-purity nanopowders remains significant.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nanozirconia Market.- Tosoh Corporation

- Saint-Gobain

- Innovnano

- MEL Chemicals

- Inframat Corporation

- SkySpring Nanomaterials Inc.

- Nanophase Technologies Corporation

- DAIICHI KIGENSO KAGAKU KOGYO CO., LTD.

- Rauschert GmbH

- H.C. Starck GmbH (Treibacher Industrie AG)

- American Elements

- Zircomet Ltd.

- Nano Products Corporation

- US Research Nanomaterials, Inc.

- Reade International Corp.

- PlasmaChem GmbH

- Advanced Nanopowders

- Merck KGaA

- S & S Advanced Materials

- Nanobond Technologies

Frequently Asked Questions

Analyze common user questions about the Nanozirconia market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Nanozirconia primarily used for in the medical field?

Nanozirconia, specifically Yttria Stabilized Zirconia (YSZ), is extensively used in the medical field for high-strength, aesthetic dental restorative materials (crowns, bridges) and orthopedic implants (hip joint components) due to its excellent biocompatibility, exceptional fracture toughness, and superior wear resistance, making it a reliable, metal-free alternative.

Which stabilization agent is most critical for achieving high mechanical performance in nanozirconia?

Yttria is the most critical stabilization agent, commonly used to create Yttria Stabilized Zirconia (YSZ). Yttria stabilizes the tetragonal phase of zirconia at room temperature, which is essential for maximizing transformation toughening, thereby providing the material with its characteristic high fracture resistance and structural integrity necessary for demanding applications.

How do high manufacturing costs impact the adoption of nanozirconia?

High manufacturing costs, primarily driven by the specialized synthesis methods required to ensure ultra-high purity, nanoscale uniformity, and controlled morphology, restrict the material's adoption mainly to high-end, high-reliability applications such as aerospace, medical implants, and premium electronics, limiting its penetration into bulk industrial markets.

What role does nanozirconia play in Solid Oxide Fuel Cells (SOFCs)?

In Solid Oxide Fuel Cells (SOFCs), nanozirconia, particularly YSZ, functions as the critical solid electrolyte. Its high ionic conductivity facilitates the efficient transport of oxygen ions at elevated operating temperatures, making it indispensable for converting chemical energy directly into electrical energy with high efficiency and low environmental impact.

Which geographical region exhibits the fastest growth rate for the Nanozirconia Market?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth rate in the Nanozirconia Market, primarily fueled by massive industrial expansion, rapid technological adoption in consumer electronics manufacturing, increasing investments in healthcare infrastructure, and the scaling up of high-volume industrial ceramic production capabilities across countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager