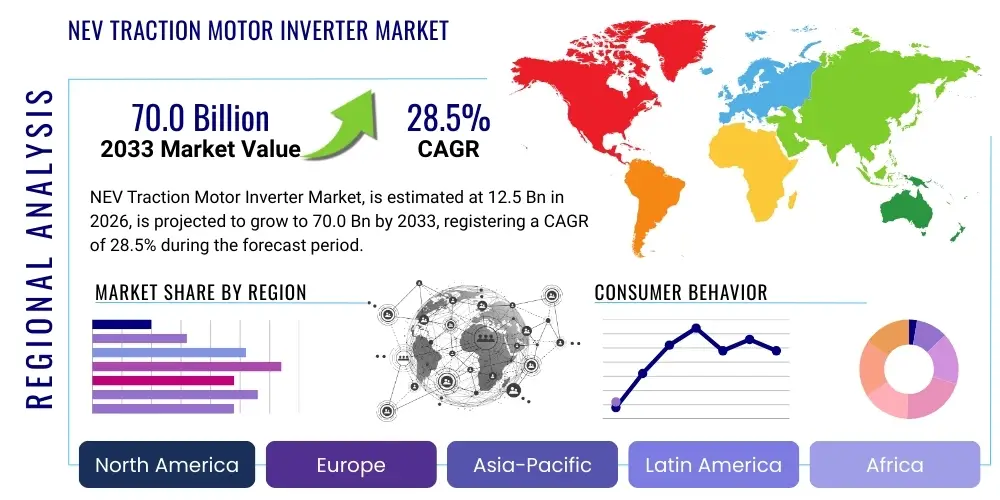

NEV Traction Motor Inverter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440835 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

NEV Traction Motor Inverter Market Size

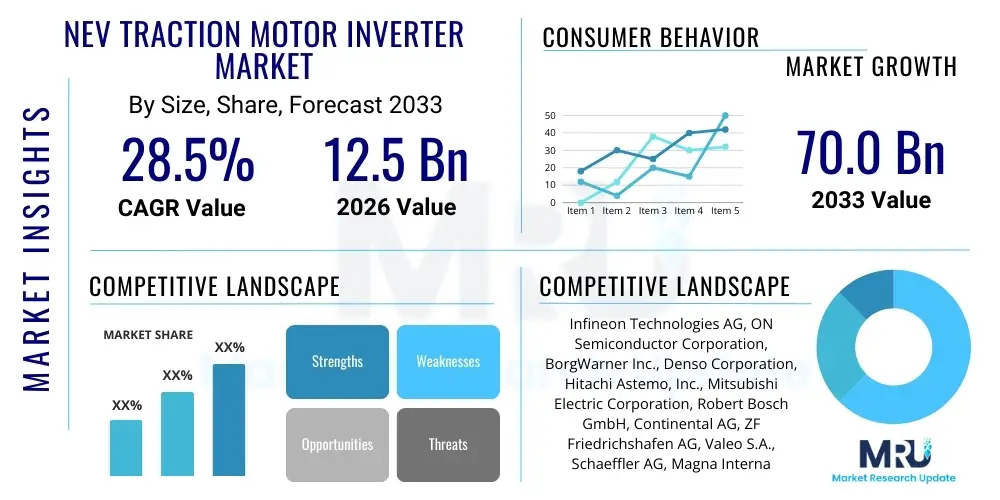

The NEV Traction Motor Inverter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 28.5% between 2026 and 2033. The market is estimated at USD 12.5 billion in 2026 and is projected to reach USD 70.0 billion by the end of the forecast period in 2033.

NEV Traction Motor Inverter Market introduction

The NEV Traction Motor Inverter Market encompasses the global industry dedicated to the development, manufacturing, and distribution of power electronic devices essential for New Energy Vehicles (NEVs). These inverters convert the DC power from the battery into AC power required to drive the electric motor, playing a critical role in the vehicle's powertrain efficiency and performance. As the core component for power conversion, traction motor inverters are vital for controlling motor speed, torque, and regenerative braking, directly influencing the NEV's range, acceleration, and overall energy management.

Product descriptions typically highlight features like high power density, efficiency, reliability, and advanced thermal management, crucial for meeting the demanding operational conditions of NEVs. Major applications span across various NEV categories including Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Fuel Cell Electric Vehicles (FCEVs). The fundamental benefits of sophisticated traction motor inverters include optimized energy consumption, extended battery life, enhanced driving dynamics, and reduced emissions, aligning with global sustainability goals.

Driving factors for this market's robust expansion include the escalating global adoption of electric vehicles driven by stringent environmental regulations, supportive government policies and incentives for NEV purchases, and significant advancements in battery technology that enhance range and reduce charging times. Furthermore, increasing consumer awareness regarding climate change and the long-term cost benefits of electric mobility are fueling demand for high-performance and efficient NEV components like traction motor inverters.

NEV Traction Motor Inverter Market Executive Summary

The NEV Traction Motor Inverter Market is experiencing dynamic growth, propelled by the global shift towards sustainable transportation and rapid technological advancements within the automotive sector. Business trends indicate a strong focus on research and development to integrate next-generation semiconductor materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) into inverter designs, aiming for higher efficiency, reduced size, and lower weight. Strategic collaborations and partnerships between automotive OEMs and power electronics suppliers are becoming increasingly prevalent to accelerate innovation and ensure a stable supply chain for critical components. The market is also witnessing a surge in vertical integration strategies, with some NEV manufacturers developing proprietary inverter technologies to gain a competitive edge in performance and cost.

Regional trends highlight Asia Pacific, particularly China, as the dominant market due to massive NEV production volumes, supportive government policies, and a burgeoning domestic supply chain. Europe is another significant growth region, driven by ambitious decarbonization targets and robust consumer adoption of EVs, leading to increased investment in manufacturing capabilities. North America is also showing accelerated growth, bolstered by recent policy initiatives aimed at promoting electric vehicle manufacturing and adoption. Emerging markets in Latin America, the Middle East, and Africa are gradually contributing to market expansion as NEV infrastructure develops and consumer awareness rises.

Segment trends underscore the increasing preference for high-power inverters suitable for advanced BEVs and performance-oriented PHEVs, reflecting the ongoing evolution of vehicle capabilities. The adoption of SiC-based inverters is rapidly gaining traction across all segments, largely due to their superior thermal performance and efficiency advantages over traditional silicon-based alternatives. Furthermore, the market is seeing a move towards modular and scalable inverter designs that can be adapted across various vehicle platforms, offering cost efficiencies and manufacturing flexibility for automakers. The growing demand for charging infrastructure and vehicle-to-grid (V2G) capabilities is also influencing inverter development, pushing for bidirectional power flow capabilities.

AI Impact Analysis on NEV Traction Motor Inverter Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the design, operation, and maintenance of NEV traction motor inverters, with common questions centering on performance optimization, predictive diagnostics, and manufacturing efficiency. Key themes emerge around AI's potential to enhance energy management, improve control algorithms for greater precision, and extend component lifespan through intelligent monitoring. Users are particularly interested in how AI can contribute to more resilient supply chains and accelerate the development of next-generation inverter technologies, balancing cost with cutting-edge performance.

- AI-driven algorithms optimize inverter efficiency and energy management by predicting driving conditions and adjusting power output in real-time.

- Predictive maintenance analytics, powered by AI, monitor inverter performance to forecast potential failures, reducing downtime and maintenance costs.

- AI enhances control precision for motor torque and speed, leading to smoother acceleration, improved regenerative braking, and extended vehicle range.

- Machine learning models are used in the design phase to simulate and optimize new inverter architectures, accelerating R&D cycles and reducing material usage.

- AI facilitates smarter manufacturing processes through automated quality control, defect detection, and optimization of production lines, increasing throughput and reliability.

- Intelligent thermal management systems, leveraging AI, adapt cooling strategies dynamically to prevent overheating and prolong inverter component life.

- AI contributes to cybersecurity by monitoring and detecting anomalies in inverter software, protecting against unauthorized access and malicious attacks.

- Supply chain optimization benefits from AI, which predicts demand fluctuations and identifies potential disruptions, ensuring timely delivery of critical components.

DRO & Impact Forces Of NEV Traction Motor Inverter Market

The NEV Traction Motor Inverter Market is profoundly shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively constitute the Impact Forces influencing its growth trajectory. Key drivers include accelerating global NEV adoption, propelled by increasing environmental consciousness, stringent emission regulations, and substantial government incentives promoting electric mobility. Technological advancements in power semiconductor materials, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), are significantly enhancing inverter efficiency and power density, further fueling market expansion by enabling superior vehicle performance and range. Additionally, the continuous expansion of charging infrastructure and improvements in battery technology directly bolster the demand for efficient and robust inverters.

However, several restraints pose challenges to the market. The high initial cost of NEVs, partially attributed to advanced inverter components, can deter price-sensitive consumers. Supply chain vulnerabilities, particularly concerning critical rare earth minerals and specialized semiconductor components, can lead to production delays and increased costs. Moreover, the complexity of integrating advanced inverter systems with diverse NEV architectures requires sophisticated engineering expertise, and the rapid pace of technological change necessitates continuous investment in R&D, which can be a barrier for smaller players. Concerns over charging time and range anxiety, though diminishing, still present psychological hurdles for some potential NEV buyers.

Opportunities for growth are abundant, particularly in the development of bidirectional inverters for Vehicle-to-Grid (V2G) and Vehicle-to-Home (V2H) applications, which could transform NEVs into mobile energy storage units. The ongoing trend towards ultra-fast charging capabilities demands more robust and efficient inverter designs capable of handling higher power levels. Miniaturization and integration of inverter components offer pathways to reduce overall vehicle weight and improve packaging efficiency, thereby enhancing performance and design flexibility. Emerging markets also present significant long-term opportunities as NEV infrastructure develops and consumer purchasing power increases, opening new avenues for market penetration.

Segmentation Analysis

The NEV Traction Motor Inverter Market is meticulously segmented to provide a granular understanding of its diverse components, applications, and technological underpinnings. This segmentation allows for precise market analysis, identifying key trends and growth pockets across different vehicle types, power outputs, and material technologies. Understanding these distinct segments is crucial for stakeholders to tailor product development, marketing strategies, and investment decisions, ensuring alignment with specific market demands and technological shifts.

- By Vehicle Type:

- Battery Electric Vehicle (BEV)

- Plug-in Hybrid Electric Vehicle (PHEV)

- Fuel Cell Electric Vehicle (FCEV)

- By Power Output:

- Less than 100 kW

- 100 kW to 200 kW

- More than 200 kW

- By Component:

- Inverter Module

- DC-DC Converter

- Auxiliary Power Unit

- By Material Type:

- Silicon (Si)

- Silicon Carbide (SiC)

- Gallium Nitride (GaN)

- By Sales Channel:

- OEM (Original Equipment Manufacturer)

- Aftermarket

- By Voltage Type:

- 400V System

- 800V System

- Other (e.g., 200V, 1000V)

Value Chain Analysis For NEV Traction Motor Inverter Market

The value chain for the NEV Traction Motor Inverter Market begins with upstream activities, primarily encompassing the sourcing and processing of raw materials such as silicon, silicon carbide, gallium nitride, copper, aluminum, and various rare earth elements crucial for semiconductor and packaging components. This stage also involves the manufacturing of discrete semiconductor devices, passive components like capacitors and resistors, and specialized substrates. Key upstream players include material suppliers, wafer manufacturers, and component manufacturers specializing in power semiconductors, which form the foundational building blocks of the inverter system. Strategic sourcing and long-term supply agreements are vital here due to the specialized nature and potential scarcity of certain materials.

Midstream activities involve the design, assembly, and testing of the traction motor inverter modules. This includes the development of complex control algorithms, thermal management solutions, and electromagnetic compatibility (EMC) integration. Manufacturers at this stage focus on optimizing power density, efficiency, and reliability, often collaborating closely with research institutions and technology partners. These companies typically integrate the semiconductor devices with other electronic components, cooling systems, and protective enclosures to create a complete, functional inverter unit. Rigorous testing and quality assurance procedures are paramount to ensure the inverters meet automotive-grade standards and regulatory compliance.

Downstream activities involve the integration of the finished traction motor inverters into NEV powertrains by automotive OEMs. This stage includes vehicle assembly, system-level testing, and final vehicle delivery to end-users. The distribution channel for these inverters is predominantly direct, with inverter manufacturers supplying components directly to automotive OEMs under long-term contracts and specifications. Indirect distribution, though less common for initial integration into new vehicles, can occur in the aftermarket for replacement parts or specialized vehicle modifications, often through authorized service networks or third-party distributors. The close collaboration between inverter manufacturers and OEMs throughout the product lifecycle is critical for successful market penetration and continuous innovation.

NEV Traction Motor Inverter Market Potential Customers

The primary potential customers and end-users of NEV Traction Motor Inverters are global automotive Original Equipment Manufacturers (OEMs) specializing in the production of Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Fuel Cell Electric Vehicles (FCEVs). These OEMs, ranging from established automotive giants to emerging electric vehicle startups, require high-performance, reliable, and cost-effective inverter solutions for integration into their diverse vehicle platforms. Their purchasing decisions are driven by factors such as inverter efficiency, power density, thermal management capabilities, safety standards, and overall cost-effectiveness. The demand from these manufacturers is directly linked to their production volumes and the pace of their NEV model development and launches, making them the most critical segment of the customer base.

Beyond direct OEM integration, the aftermarket segment also represents a growing pool of potential customers. This includes independent repair shops, specialized performance tuning companies, and individual vehicle owners who may require replacement inverters due to wear and tear, damage, or for performance upgrades. As the NEV fleet on roads expands, the demand for aftermarket service and replacement parts, including traction motor inverters, is expected to grow steadily. These customers prioritize availability, compatibility with existing vehicle systems, and often a balance between cost and performance.

Furthermore, commercial fleet operators, public transportation authorities, and logistics companies are increasingly electrifying their fleets, making them indirect but significant end-users. Their demand for robust and durable NEVs translates into a demand for highly reliable and efficient inverters within the vehicles they procure. The military and defense sectors are also exploring electric and hybrid vehicle applications, representing a niche but high-value customer segment for specialized, ruggedized inverter solutions. Research and development institutions and university programs focusing on advanced automotive technologies also constitute a smaller, yet influential, customer base for cutting-edge inverter components for prototyping and experimental purposes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 12.5 Billion |

| Market Forecast in 2033 | USD 70.0 Billion |

| Growth Rate | 28.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Infineon Technologies AG, ON Semiconductor Corporation, BorgWarner Inc., Denso Corporation, Hitachi Astemo, Inc., Mitsubishi Electric Corporation, Robert Bosch GmbH, Continental AG, ZF Friedrichshafen AG, Valeo S.A., Schaeffler AG, Magna International Inc., Nidec Corporation, Siemens AG, STMicroelectronics N.V., Renesas Electronics Corporation, Fuji Electric Co., Ltd., Vitesco Technologies Group AG, Delta Electronics, Inc., Toshiba Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

NEV Traction Motor Inverter Market Key Technology Landscape

The NEV Traction Motor Inverter Market is at the forefront of power electronics innovation, driven by a continuous push for higher efficiency, greater power density, and enhanced reliability. A pivotal technological shift is the widespread adoption of Wide Bandgap (WBG) semiconductors, primarily Silicon Carbide (SiC) and increasingly Gallium Nitride (GaN). These materials offer superior performance compared to traditional silicon-based devices, enabling inverters to operate at much higher switching frequencies, withstand higher temperatures and voltages, and significantly reduce energy losses, leading to improved NEV range and acceleration. The integration of SiC MOSFETs is a key differentiator, allowing for smaller, lighter, and more efficient inverter designs that contribute to overall vehicle weight reduction.

Another critical area of technological advancement is in advanced thermal management solutions. As power density increases, effective heat dissipation becomes paramount to ensure component longevity and optimal performance. Innovations include enhanced cooling plate designs, direct liquid cooling, and novel heatsink materials and architectures. Furthermore, the development of integrated inverter solutions, where the inverter is combined with the electric motor or other power electronics components, is gaining traction. This integration minimizes cabling, reduces electromagnetic interference (EMI), and allows for more compact packaging, which is crucial for modern NEV designs with limited space.

The intelligence embedded within inverters is also evolving rapidly, incorporating sophisticated digital control units that leverage advanced algorithms for precise motor control, fault detection, and predictive maintenance. Communication interfaces such as CAN (Controller Area Network) and Ethernet are becoming standard, enabling seamless interaction with the vehicle's central control unit and other systems. Furthermore, there is a strong focus on modular and scalable designs to cater to diverse vehicle platforms and power requirements, from compact city cars to heavy-duty trucks. Developments in passive components, such as high-temperature capacitors and low-inductance busbars, also play a vital role in supporting the overall performance and reliability of these advanced inverter systems.

Regional Highlights

- Asia Pacific: Dominates the NEV Traction Motor Inverter Market, primarily driven by China's leading position in NEV production and sales. Favorable government policies, extensive manufacturing capabilities, and a large consumer base contribute significantly to market growth. Countries like South Korea, Japan, and India are also witnessing increasing NEV adoption and local manufacturing initiatives.

- Europe: A rapidly expanding market fueled by stringent emission regulations, generous government subsidies for EV purchases, and a strong consumer preference for sustainable transportation. Germany, Norway, France, and the UK are key players, with substantial investments in both NEV manufacturing and charging infrastructure.

- North America: Experiencing accelerated growth, particularly in the United States, due to supportive federal and state policies promoting EV adoption and domestic manufacturing. Major automotive OEMs are investing heavily in EV production, boosting demand for advanced inverter technologies. Canada and Mexico also contribute to regional market expansion.

- Latin America: An emerging market with increasing interest in NEVs, driven by urbanization and efforts to reduce air pollution in major cities. Brazil and Mexico are leading the adoption curve, with gradual infrastructure development and local assembly initiatives setting the stage for future growth.

- Middle East and Africa (MEA): Currently a nascent market, but with significant potential, particularly in countries like the UAE and Saudi Arabia, which are investing in smart city initiatives and diversifying their economies away from fossil fuels. Government support and infrastructure development will be crucial for accelerating NEV and inverter market growth in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the NEV Traction Motor Inverter Market.- Infineon Technologies AG

- ON Semiconductor Corporation

- BorgWarner Inc.

- Denso Corporation

- Hitachi Astemo, Inc.

- Mitsubishi Electric Corporation

- Robert Bosch GmbH

- Continental AG

- ZF Friedrichshafen AG

- Valeo S.A.

- Schaeffler AG

- Magna International Inc.

- Nidec Corporation

- Siemens AG

- STMicroelectronics N.V.

- Renesas Electronics Corporation

- Fuji Electric Co., Ltd.

- Vitesco Technologies Group AG

- Delta Electronics, Inc.

- Toshiba Corporation

Frequently Asked Questions

Analyze common user questions about the NEV Traction Motor Inverter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a NEV Traction Motor Inverter?

A NEV traction motor inverter is a crucial power electronics component in New Energy Vehicles (NEVs) that converts the battery's DC power into variable frequency AC power to drive the electric motor, controlling its speed and torque for vehicle propulsion.

Why are Silicon Carbide (SiC) inverters gaining popularity?

SiC inverters are popular due to their superior efficiency, higher power density, better thermal performance, and ability to operate at higher switching frequencies and temperatures compared to traditional silicon-based inverters, leading to improved NEV range and performance.

What are the primary drivers for the NEV Traction Motor Inverter Market growth?

Key drivers include the accelerating global adoption of electric vehicles, stringent environmental regulations, government incentives for NEVs, and continuous advancements in power semiconductor technologies and battery capabilities.

How does AI impact the NEV Traction Motor Inverter Market?

AI impacts include optimizing inverter efficiency, enabling predictive maintenance, enhancing motor control precision, accelerating R&D through simulations, and improving manufacturing processes for greater reliability and cost-effectiveness.

Which region currently leads the NEV Traction Motor Inverter Market?

Asia Pacific, particularly China, currently leads the NEV Traction Motor Inverter Market due to its extensive NEV production volumes, supportive government policies, and established supply chain for electric vehicle components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager