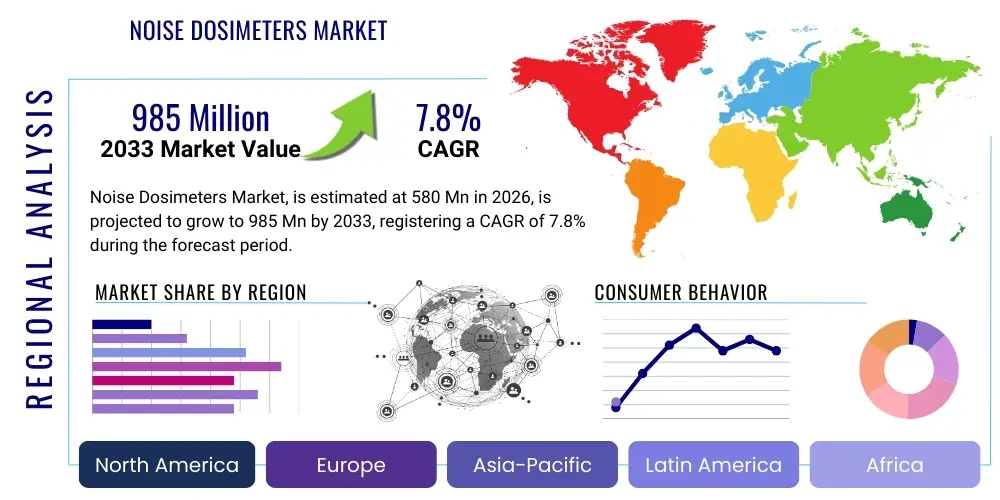

Noise Dosimeters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442316 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Noise Dosimeters Market Size

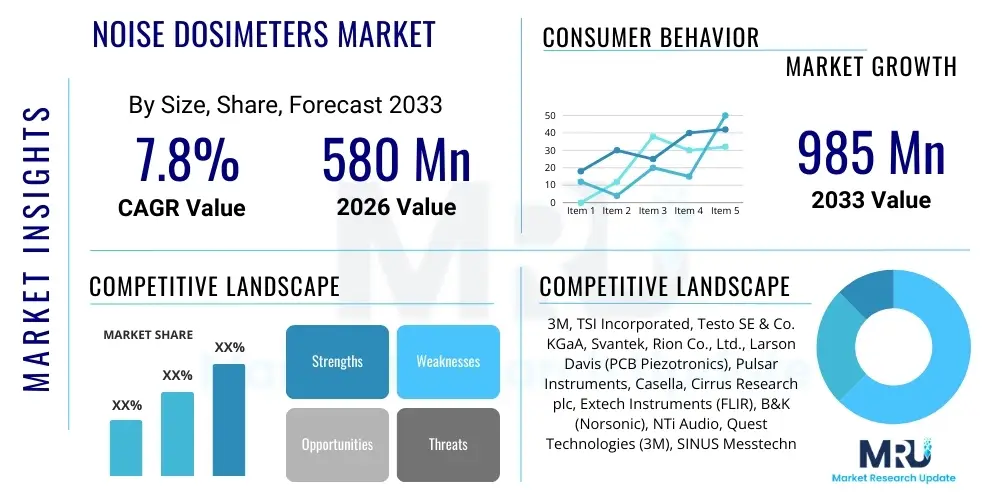

The Noise Dosimeters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $580 Million in 2026 and is projected to reach $985 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by increasingly stringent global occupational safety regulations and a heightened corporate focus on industrial hygiene. The market valuation reflects the growing adoption of personal protective equipment (PPE) integrating advanced noise monitoring capabilities, moving away from traditional sound level meters toward continuous, personal exposure tracking. Furthermore, the integration of IoT capabilities and sophisticated data analysis platforms is enhancing the utility and accuracy of modern dosimeters, solidifying their role as indispensable tools in preventing Noise-Induced Hearing Loss (NIHL) across high-decibel industrial sectors. The market trajectory indicates sustained demand fueled by replacement cycles and entry into emerging markets, particularly in Asia Pacific, where industrialization accelerates under developing regulatory frameworks.

Noise Dosimeters Market introduction

The Noise Dosimeters Market encompasses devices designed to measure and record an individual’s cumulative exposure to noise over an occupational shift or extended period. These sophisticated instruments are crucial for calculating the Personal Daily Noise Exposure (PDNE) and ensuring compliance with international standards set by bodies such as OSHA (Occupational Safety and Health Administration) and the EU Physical Agents Directive. Noise dosimeters typically comprise a sensitive microphone, a robust data logging unit, and specialized software for analysis, providing legally defensible data on noise exposure. The fundamental application lies in occupational health and safety programs across diverse high-noise environments.

Major applications of noise dosimeters span heavy industry, including manufacturing, construction, mining, aerospace, and oil and gas exploration, where sound levels routinely exceed safe exposure limits. Beyond industrial settings, these devices are increasingly employed in environmental noise monitoring, healthcare (to assess noise pollution in hospitals), and entertainment venues. The inherent benefit of noise dosimeters is their ability to provide time-weighted average (TWA) data, which is far more representative of real-world exposure risk compared to instantaneous sound level measurements. This accurate data enables organizations to implement targeted hearing conservation programs, select appropriate hearing protection devices, and engineer control measures effectively.

The market is primarily driven by rigorous enforcement of occupational safety regulations worldwide, particularly concerning the reduction of Noise-Induced Hearing Loss (NIHL), which remains a significant public health burden. Technological advancements, such as miniaturization, wireless connectivity, improved battery life, and integration with cloud-based reporting systems, are further catalyzing market growth. As industries continue to automate and expand operations globally, the need for reliable, continuous personal noise monitoring equipment becomes paramount for ensuring workforce well-being and mitigating potential liability risks.

Noise Dosimeters Market Executive Summary

The Noise Dosimeters Market is undergoing robust growth, propelled by the convergence of stringent global safety mandates and significant technological innovation. Business trends indicate a strong shift towards wearable, user-friendly, and IoT-enabled devices that facilitate real-time data monitoring and predictive safety analytics, moving beyond simple data logging. Key market players are focusing on strategic partnerships and mergers to integrate software solutions with hardware offerings, creating comprehensive noise management ecosystems. Furthermore, the competitive landscape is intensifying, characterized by continuous product development aimed at improving accuracy (Class 1 vs. Class 2), durability for harsh industrial environments, and ease of deployment for large workforce monitoring programs. The trend toward subscription-based service models for software and calibration services is also gaining traction, ensuring recurring revenue streams and enhancing customer retention.

Regionally, North America and Europe maintain dominance, driven by established, mature regulatory frameworks (OSHA, NIOSH, EU Directives) and high awareness regarding occupational health standards. However, the Asia Pacific (APAC) region is projected to register the fastest growth rate, fueled by rapid industrialization in countries like China, India, and Southeast Asia. Regulatory bodies in these emerging economies are progressively adopting Western standards, leading to increased mandatory deployment of noise dosimeters in newly established manufacturing and infrastructure projects. Latin America and the Middle East & Africa (MEA) present nascent but growing markets, primarily driven by expanding oil & gas, mining, and construction sectors seeking to standardize safety protocols.

Segment trends highlight the increasing demand for Class 1 dosimeters, especially in high-precision measurement applications and environments where regulatory compliance requires the highest accuracy. The application segment sees significant uptake from the construction and manufacturing industries, which account for the highest incidences of noise exposure. Technologically, there is a strong inclination toward wireless dosimeters equipped with cloud connectivity, enabling safety managers to monitor exposure levels remotely and intervene proactively. This transition towards smarter, interconnected devices underscores the market’s evolution from simple measuring instruments to integral components of sophisticated industrial safety management systems, driving demand for devices that offer seamless integration with existing safety infrastructure and human resources management platforms.

AI Impact Analysis on Noise Dosimeters Market

User inquiries regarding AI's influence on the Noise Dosimeters Market frequently center on the potential for autonomous data interpretation, predictive modeling of noise exposure risk, and automated reporting compliance. Users are keen to understand how AI can move beyond simple threshold alerts to offering actionable, context-aware insights, such as identifying specific processes or times of day that correlate with peak exposure, or automatically optimizing work schedules to minimize TWA exposure. Concerns often revolve around data privacy, the cost of implementing AI-driven software, and the reliability of machine learning algorithms in interpreting diverse, complex industrial soundscapes accurately. Expectations are high for AI to reduce the manual burden of compliance reporting and enhance the overall effectiveness of hearing conservation programs by providing deep, diagnostic insights into workplace noise hazards.

The primary impact of Artificial Intelligence (AI) on the noise dosimeters market lies in significantly enhancing the analytical capabilities derived from collected raw data. While the dosimeter hardware itself remains a measurement tool, AI algorithms applied to the vast datasets generated by fleets of connected devices can detect complex noise patterns, classify specific noise sources (e.g., impact noise vs. continuous hum), and predict future exposure risk based on historical operational data. This predictive analysis allows safety professionals to transition from reactive monitoring to proactive risk mitigation, identifying high-risk areas or workers before harmful exposure limits are exceeded. AI also facilitates the development of smart calibration schedules and anomaly detection within the device itself, ensuring data integrity and operational reliability in challenging industrial environments.

Furthermore, Machine Learning (ML) models are revolutionizing compliance reporting. Instead of manually reviewing thousands of data points, AI can automatically generate sophisticated compliance reports tailored to specific regulatory requirements (e.g., OSHA, ISO, MSHA) and highlight deviations or breaches, streamlining administrative processes. This not only saves significant time but also improves the consistency and defensibility of regulatory documentation. As AI systems mature, they are expected to power augmented reality (AR) or integrated safety platforms that provide real-time, context-specific recommendations to workers on the factory floor, dynamically adjusting hearing protection requirements based on instantaneous, localized sound analysis, thereby embedding intelligence directly into the safety workflow.

- AI enables predictive risk modeling based on historical noise profiles and operational metadata.

- Machine Learning algorithms automatically classify and identify specific noise sources (e.g., machinery, alarms, impact events).

- Automated generation of compliance reports tailored to regional regulatory standards (OSHA, NIOSH, etc.).

- Optimization of work schedules and personnel rotation to minimize cumulative noise exposure (TWA optimization).

- Enhanced data anomaly detection and automated system diagnostics for ensuring dosimeter data integrity.

- Integration with industrial safety platforms for holistic, real-time safety management and intervention.

DRO & Impact Forces Of Noise Dosimeters Market

The Noise Dosimeters Market is fundamentally shaped by a dynamic interplay of rigorous regulatory drivers and significant technological advancements, balanced against budgetary and operational restraints. The primary driver is the globally increasing pressure from governmental agencies to enforce occupational noise limits, forcing industries to adopt sophisticated monitoring solutions to avoid hefty fines and litigation related to Noise-Induced Hearing Loss (NIHL). Opportunities arise from the convergence of dosimeter technology with IoT and cloud computing, allowing for scalable, real-time remote monitoring solutions, particularly appealing to large, multi-site organizations. However, the market faces restraints such as the high initial cost of advanced Class 1 devices, the complexity associated with mandated calibration, and inherent employee resistance to wearing monitoring equipment, which necessitates continuous training and simplified user interfaces to overcome.

Key drivers include the established link between noise exposure and productivity losses, compelling corporations to invest in employee well-being beyond mere regulatory compliance, viewing noise management as a component of operational efficiency. The emergence of affordable, ruggedized, and smaller personal dosimeters is broadening the adoption base beyond heavy industries into logistics, education, and service sectors. On the restraint side, a major challenge is the relative lack of standardized regulations across developing countries, leading to fragmented market adoption, and the persistent issue of data security and management when utilizing cloud-connected devices, requiring manufacturers to invest heavily in cyber-resilient platforms. Additionally, the life cycle of dosimeters necessitates regular, professional calibration (typically yearly), creating a recurring operational cost that can deter small and medium-sized enterprises (SMEs).

Impact forces on the market are high, primarily stemming from the legal and societal push for improved worker protection. Regulatory impact acts as the strongest external force, directly mandating product usage and specification, thereby ensuring consistent demand. Technological innovation, specifically miniaturization and improved data processing capabilities, acts as a significant internal force, driving product differentiation and value proposition. The opportunity landscape is expanding through customized monitoring solutions for niche markets, such as military aviation and high-fidelity acoustic testing environments, requiring specialized dosimeters with extended frequency ranges and impulse noise measurement capabilities. Successfully navigating these forces—leveraging technological drivers while mitigating cost restraints and complexity—will define the strategic successes of market participants over the forecast period.

Segmentation Analysis

The Noise Dosimeters Market is comprehensively segmented based on Type, catering to varying degrees of measurement accuracy and regulatory requirements; Component, which defines the sophistication and functionality of the device; Application, reflecting the diverse industrial environments utilizing the technology; and End-Use, categorizing the primary purpose of the monitoring effort. Understanding these segments is crucial as market dynamics vary significantly—for instance, demand for Class 1 (Precision) dosimeters is rapidly rising in regulated manufacturing environments, while the need for simple data logging drives the volume of Class 2 (General Purpose) devices. The complexity of segmentation reflects the specialized demands of different industries, requiring manufacturers to offer modular and highly adaptable products to capture maximum market share across the diverse user base, from compliance officers to environmental consultants.

- By Type:

- Class 1 (Precision)

- Class 2 (General Purpose)

- By Application:

- Manufacturing and Processing

- Construction and Infrastructure

- Mining and Quarrying

- Oil & Gas and Energy

- Transportation (Aviation, Rail, Maritime)

- Environmental Noise Monitoring

- Healthcare and Education

- By Component:

- Microphones (MEMS, Electret Condenser)

- Data Loggers and Processing Units

- Display Units and Interfaces

- Software and Connectivity Solutions

- By End-Use:

- Industrial Safety and Occupational Health

- Environmental Compliance

- Product Testing and Quality Control

Value Chain Analysis For Noise Dosimeters Market

The value chain for the Noise Dosimeters Market begins with upstream activities focused on the procurement and fabrication of highly specialized components, primarily high-precision microphones (often MEMS or Electret Condenser types), durable casing materials, high-capacity batteries, and advanced microprocessors necessary for accurate data logging. Key upstream suppliers include electronic component manufacturers and specialized acoustic sensor developers. Manufacturers must establish stringent quality control protocols at this stage, as the accuracy and durability of the final product are highly dependent on the quality of the raw components. Strategic relationships with niche sensor producers who can provide miniaturized, low-power components are essential for creating the next generation of wearable dosimeters.

Midstream involves the core manufacturing, assembly, and integration of the hardware, followed by the development and packaging of proprietary software for data analysis and reporting. This stage adds significant value through calibration, certification (ensuring devices meet Class 1 or Class 2 international standards), and integrating sophisticated firmware for features like real-time data transmission and robust memory storage. Direct distribution channels involve manufacturers selling high-end, customized solutions and calibration services directly to large industrial end-users (e.g., major automotive manufacturers or mining companies) who require technical support and specialized training. Indirect channels, primarily utilized for general-purpose Class 2 devices and reaching SMEs, involve distribution through safety equipment wholesalers, specialized industrial tool retailers, and online e-commerce platforms, offering scale and market penetration.

The downstream segment focuses on market consumption, installation, maintenance, and essential post-sale support. After procurement, end-users require continuous software updates, certified re-calibration services (often mandated annually), and training for safety managers on data interpretation and compliance reporting. Potential customers in construction or manufacturing often purchase not just the hardware but a complete system, including calibration kits, docking stations, and cloud subscriptions. Service revenue generated from mandatory calibration, software licensing, and technical support represents a critical, high-margin aspect of the downstream value chain, ensuring long-term engagement and strengthening the relationship between manufacturers and industrial safety professionals. This lifecycle management is integral to maintaining the overall reliability and compliance utility of the noise dosimeter fleet deployed in the field.

Noise Dosimeters Market Potential Customers

The primary consumers and end-users of noise dosimeters are occupational health and safety departments across industries characterized by high noise levels. These buyers, driven largely by regulatory necessity and the imperative to prevent employee litigation and chronic health issues, include safety managers, industrial hygienists, and environmental health specialists. The largest consumer base is concentrated within heavy manufacturing, particularly automotive, heavy machinery fabrication, and metal processing sectors, which require continuous monitoring of fluctuating noise levels associated with stamping, cutting, and grinding operations. These customers prioritize robustness, multi-shift battery life, and seamless data integration with existing safety management software platforms.

Another significant segment of potential customers includes large-scale construction and infrastructure projects, such as civil engineering, road building, and commercial property development. Workers in these environments are frequently exposed to intermittent, high-peak noise from heavy equipment (drills, generators, earth movers). For these users, wearable, wireless dosimeters that are easy to deploy, resistant to dust and moisture, and capable of geo-location tagging of noise events are highly desirable. Additionally, the mining and oil & gas sectors represent high-value customers due to the extreme noise levels in confined spaces and the strict regulatory frameworks governing worker safety in these hazardous environments, demanding highly durable, intrinsically safe (IS) rated dosimeters for explosive atmospheres.

Beyond traditional heavy industries, the customer base is expanding to include institutions responsible for environmental noise assessment, such as municipal planning departments and consulting firms. These buyers use dosimeters, often mounted for fixed, long-term monitoring, to assess the impact of industrial or infrastructure noise on residential areas and ensure compliance with municipal ordinances. Furthermore, customers in healthcare, particularly hospital administrators, are increasingly utilizing dosimeters to monitor internal sound levels (e.g., in ICUs or operating rooms) to improve patient recovery and staff performance, representing a nascent but rapidly growing application area emphasizing highly accurate and non-intrusive monitoring solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $580 Million |

| Market Forecast in 2033 | $985 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M, TSI Incorporated, Testo SE & Co. KGaA, Svantek, Rion Co., Ltd., Larson Davis (PCB Piezotronics), Pulsar Instruments, Casella, Cirrus Research plc, Extech Instruments (FLIR), B&K (Norsonic), NTi Audio, Quest Technologies (3M), SINUS Messtechnik GmbH, CESVA Instruments, Reed Instruments, Kanomax USA, OHD L.P., Sound level measuring instrument manufacturers, ESI. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Noise Dosimeters Market Key Technology Landscape

The technological landscape of the Noise Dosimeters Market is rapidly evolving, driven primarily by the need for enhanced accuracy, improved usability, and seamless data management. A critical shift involves the integration of Internet of Things (IoT) connectivity, which allows dosimeters to transmit real-time noise exposure data wirelessly to centralized cloud platforms or safety management systems. This transition enables proactive safety alerts and remote monitoring of high-risk personnel, significantly improving response times compared to traditional models that require manual data download post-shift. Manufacturers are leveraging low-power wide-area network (LPWAN) technologies and Bluetooth Low Energy (BLE) to ensure reliable data transfer over long ranges while maximizing battery life, an essential feature for devices worn throughout lengthy work shifts. Furthermore, the incorporation of advanced Micro-Electro-Mechanical Systems (MEMS) microphones is driving miniaturization and increasing the durability and shock resistance of the devices without compromising the stringent accuracy requirements for Class 1 standards.

Another major technological trend is the development of advanced signal processing and acoustic fingerprinting capabilities within the dosimeter firmware. Modern devices are equipped with digital signal processors (DSPs) capable of filtering out non-occupational noise (such as speech or temporary environmental sounds) and focusing only on noises relevant to the worker’s exposure profile. This enhancement improves the reliability of compliance data and simplifies the interpretation process for industrial hygienists. Furthermore, the market is seeing an increased focus on enhanced battery technology, utilizing lithium-ion polymer cells to achieve multi-day operation without recharging, a critical factor for remote or continuous monitoring applications. The software aspect is equally vital, with manufacturers continuously updating graphical user interfaces (GUIs) to simplify setup, calibration, and report generation, ensuring greater accessibility for safety professionals who may not possess deep acoustic engineering expertise.

The adoption of standardized open communication protocols facilitates integration with third-party software, such as environmental health and safety (EHS) platforms and human resources management (HRM) systems, allowing noise exposure data to be correlated with other safety metrics, such as incident reports or training attendance. Calibration technology is also advancing, moving toward automated field calibration checks using integrated sound sources or highly precise, self-calibrating features, which reduces dependency on costly external calibration labs and downtime. The convergence of these technologies—wireless data transmission, sophisticated signal filtering, high-precision sensors, and intelligent software integration—is transforming noise dosimeters from passive measurement tools into active, intelligent components of a holistic industrial safety ecosystem, ready for integration with future augmented reality or wearable safety platforms.

Regional Highlights

- North America: North America, particularly the United States and Canada, holds a dominant share of the Noise Dosimeters Market, primarily due to the established and rigidly enforced regulatory environment mandated by OSHA, NIOSH, and specific state-level occupational safety agencies. The region boasts a high level of industrial safety awareness and a robust history of litigation related to workplace injuries, driving continuous corporate investment in premium monitoring equipment, predominantly Class 1 precision dosimeters. The strong presence of major multinational corporations in manufacturing, aerospace, and energy sectors ensures sustained demand for fleet deployment and advanced, integrated safety solutions. Technological adoption is high, with rapid uptake of IoT-enabled and cloud-connected devices, positioning North America as a leader in deploying predictive noise analytics. The U.S. market specifically benefits from mandatory hearing conservation programs, requiring regular noise surveys and personal exposure monitoring, fueling consistent sales and calibration service demands.

- Europe: Europe represents another significant market, driven by the implementation of the European Union’s Physical Agents Directive (Noise) and stringent national regulations (e.g., in Germany, the UK, and France). The European market is characterized by a strong focus on worker health and environmental protection, leading to high demand for both occupational and fixed environmental noise monitoring solutions. The presence of major automotive, chemical, and engineering industries contributes substantially to market size. European users often prioritize high-quality, reliable instrumentation and certified calibration services. The emphasis on minimizing long-term occupational illnesses also supports continuous market growth. Eastern Europe, while smaller, is catching up rapidly as it aligns its safety standards with EU directives, offering substantial expansion opportunities for market penetration.

- Asia Pacific (APAC): The APAC region is anticipated to be the fastest-growing market globally over the forecast period. This accelerated growth is primarily attributed to rapid industrialization, extensive infrastructural development (e.g., in China, India, and Southeast Asian nations), and the emerging standardization of occupational safety laws. While historically reliant on basic monitoring tools, increasing foreign direct investment and regulatory development are spurring demand for sophisticated dosimeters, particularly in organized manufacturing and construction sectors. Challenges related to workplace noise exposure are particularly acute in the APAC region due to high density of factory operations and poor historical enforcement, creating a vast untapped market for entry-level and mid-range noise dosimeters. Japan, South Korea, and Australia represent mature sub-markets within APAC, exhibiting demand patterns similar to North America and Europe, focusing on high-precision and integrated systems.

- Latin America, Middle East, and Africa (LAMEA): This region offers considerable long-term potential, though currently characterized by moderate adoption rates. Market growth is heavily concentrated in resource-rich nations (e.g., Saudi Arabia, Brazil, South Africa) where major industries like mining, oil & gas, and large-scale infrastructure projects necessitate compliance with international safety standards to secure funding and insurance. The MEA region’s expansion is tied to massive energy and construction projects. Market penetration in LAMEA is often driven by international contractors who import best practices and require certified monitoring equipment. Challenges include inconsistent regulatory enforcement and economic volatility, but the increasing presence of multinational corporations serves as a strong driver for adopting high-quality noise dosimeters for workforce protection.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Noise Dosimeters Market.- 3M

- TSI Incorporated

- Testo SE & Co. KGaA

- Svantek

- Rion Co., Ltd.

- Larson Davis (PCB Piezotronics)

- Pulsar Instruments

- Casella

- Cirrus Research plc

- Extech Instruments (FLIR)

- Brüel & Kjær (B&K)

- NTi Audio

- Quest Technologies (3M subsidiary)

- SINUS Messtechnik GmbH

- CESVA Instruments

- Reed Instruments

- Kanomax USA

- OHD L.P.

- Sensear

- Acoem Group

Frequently Asked Questions

Analyze common user questions about the Noise Dosimeters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental difference between Class 1 and Class 2 noise dosimeters?

Class 1 dosimeters, often referred to as precision instruments, offer the highest level of accuracy and meet stringent international standards (e.g., IEC 61672-1 Class 1), making them suitable for legal and highly critical compliance measurements. Class 2 dosimeters, or general purpose instruments, are less expensive and slightly less precise, primarily used for general workplace screening and non-critical surveys where absolute scientific accuracy is not legally mandated, adhering to IEC 61672-1 Class 2 standards.

How do noise dosimeters contribute to OSHA and NIOSH compliance?

Noise dosimeters are essential tools for compliance by measuring the time-weighted average (TWA) noise exposure over an entire work shift, which is the metric used by both OSHA and NIOSH to determine potential hearing hazard risk. Dosimeter data helps employers identify areas or individuals exceeding Permissible Exposure Limits (PELs) or Recommended Exposure Limits (RELs), enabling the mandatory implementation of hearing conservation programs, engineering controls, and required audiometric testing, thereby ensuring regulatory adherence and avoiding penalties.

Are wireless and IoT-enabled noise dosimeters standard in the industry today?

While not universally standard yet, the adoption of wireless and IoT-enabled dosimeters is rapidly increasing, establishing them as the preferred technology for large industrial deployments. These devices facilitate real-time data transmission and remote monitoring, significantly improving safety manager efficiency and enabling immediate intervention if hazardous noise levels are detected. Their growing prevalence is driven by the demand for centralized data management and predictive safety analytics, moving beyond traditional, manual data downloading processes.

What are the primary factors restraining the growth of the Noise Dosimeters Market?

The key restraints include the high initial acquisition cost of certified, high-precision Class 1 devices, making fleet purchases challenging for small and medium-sized enterprises (SMEs). Furthermore, the necessity for mandatory annual calibration by accredited labs imposes significant recurring operational expenditure and device downtime, which can deter investment. Lack of stringent regulatory enforcement in certain developing regions also limits market penetration and growth potential.

Which application segment currently generates the highest demand for noise dosimeters?

The Manufacturing and Processing segment consistently generates the highest demand for noise dosimeters globally. This is due to the inherent high noise levels associated with machinery operation, metal fabrication, assembly lines, and continuous production processes. Stringent occupational health regulations in these sectors, coupled with large employee populations, necessitate widespread personal noise exposure monitoring to prevent long-term Noise-Induced Hearing Loss (NIHL) and manage liability risks effectively.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager