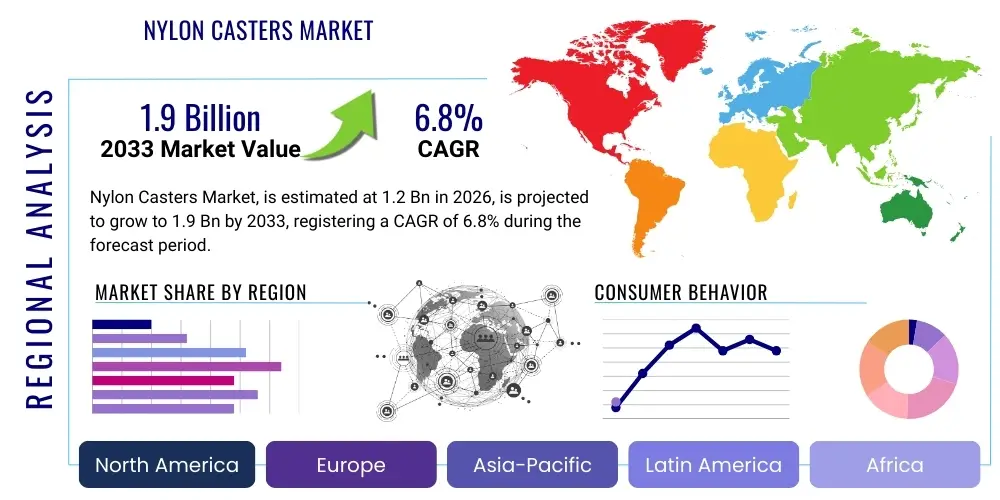

Nylon Casters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440895 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Nylon Casters Market Size

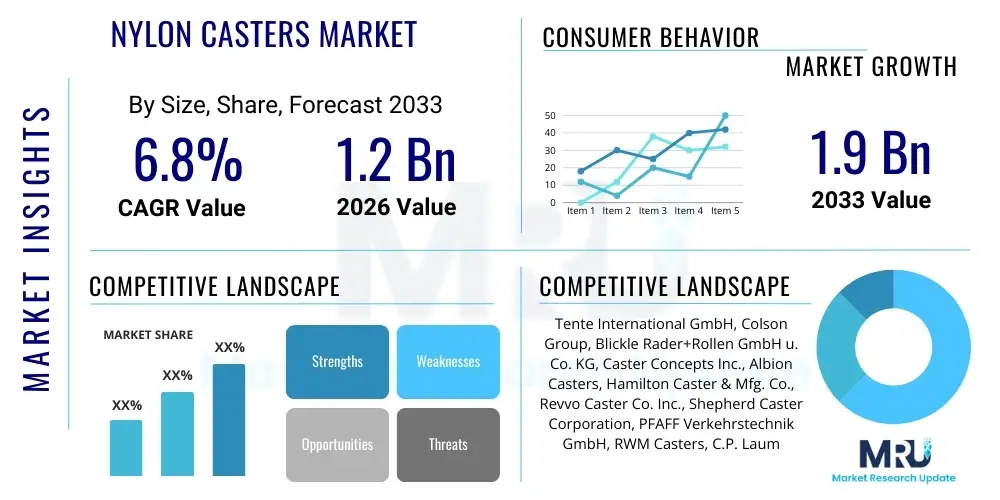

The Nylon Casters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2033.

Nylon Casters Market introduction

The Nylon Casters Market encompasses the manufacturing, distribution, and sale of caster wheels utilizing nylon or related polyamide compounds as the primary wheel material. These components are essential in enabling smooth, low-friction movement for a vast array of equipment across industrial, commercial, and institutional sectors. Nylon casters are highly favored due to their unique balance of strength, lightweight properties, non-marking characteristics, resistance to chemicals, and superior load-bearing capabilities relative to their cost. The market growth is intricately linked to the expansion of automated material handling systems, the proliferation of specialized medical equipment requiring sterilization compatibility, and the sustained demand from the furniture and institutional sectors where durability and floor protection are paramount considerations. These casters often excel in environments requiring hygienic standards or where exposure to moisture and certain solvents is frequent, differentiating them from traditional rubber or metal wheels.

Nylon casters primarily function as mobility solutions for carts, dollies, industrial trolleys, scaffoldings, hospital beds, and office chairs. Product differentiation within the market often hinges on factors such as bearing quality, housing material (e.g., stainless steel for corrosive environments), wheel diameter, and specific nylon formulation, such as glass-filled or conductive variants designed for specialized applications. Major applications span heavy-duty manufacturing floors, commercial food processing facilities, cleanrooms, and sophisticated retail environments. The inherent benefits of nylon, including high impact resistance, quiet operation when paired with appropriate bearings, and minimal rolling resistance, continue to drive their adoption over alternative materials in specific load ranges and operational settings, particularly where sanitation and non-abrasiveness are critical performance metrics.

Driving factors propelling this market include the global expansion of e-commerce necessitating robust logistics infrastructure, leading to increased demand for material handling equipment. Furthermore, stringent regulatory requirements in healthcare and food processing industries favor materials like nylon that are easy to clean and resist bacterial growth. The continuous technological advancements in manufacturing techniques, particularly injection molding processes, allow for the production of increasingly precise and durable nylon wheels at competitive costs, enhancing market penetration across developing economies. These factors collectively establish a resilient growth trajectory for the Nylon Casters Market, positioned to capitalize on sustained industrial modernization and infrastructural development worldwide.

Nylon Casters Market Executive Summary

The global Nylon Casters Market is characterized by steady expansion driven primarily by escalating industrial automation and modernization across key manufacturing hubs in Asia Pacific and North America. Business trends indicate a strong move toward specialized, high-performance nylon formulations, such as those enhanced with glass fiber or utilized for electrostatic discharge (ESD) control, catering specifically to electronics and automotive assembly lines. Key market players are concentrating on developing complete caster systems—including advanced braking mechanisms and swivel locks—rather than standalone wheels, aiming to provide integrated mobility solutions that meet increasingly rigorous safety and ergonomic standards. Consolidation among medium-sized manufacturers and strategic acquisitions by major multinational corporations are shaping the competitive landscape, focused on achieving economies of scale and expanding geographical reach, particularly into rapidly industrializing regions where infrastructural development is accelerating.

Regionally, Asia Pacific (APAC) stands as the dominant and fastest-growing segment, fueled by massive investment in manufacturing infrastructure, rapid urbanization, and the exponential growth of logistics and warehousing activities driven by e-commerce giants. China, India, and Southeast Asian nations are central to this growth trajectory due to high demand across furniture production, automotive sectors, and rapidly developing healthcare facilities. North America and Europe, while mature markets, maintain significant demand, focusing heavily on premium, high-load capacity nylon casters engineered for advanced manufacturing environments and strict ergonomic compliance. Trends in these regions include prioritizing sustainability and lightweight designs, often utilizing recycled or bio-based nylon variants to align with corporate environmental objectives.

Segment trends reveal that the heavy-duty category, defined by substantial load capacities suitable for machinery and heavy industrial transport, is experiencing robust growth due to infrastructural projects and industrial expansion. Concurrently, the medical devices application segment shows high profitability potential, driven by the global aging population and increasing expenditure on hospital infrastructure, demanding hygienic, non-corrosive nylon casters compatible with frequent chemical sterilization. The distribution landscape is also shifting, with a growing reliance on e-commerce platforms and specialized industrial distributors to ensure rapid procurement and delivery of standardized caster components, especially for maintenance, repair, and operations (MRO) purposes, streamlining the supply chain efficiency across all segments.

AI Impact Analysis on Nylon Casters Market

User queries regarding AI's impact on the Nylon Casters Market commonly revolve around themes such as optimization of manufacturing processes, predictive maintenance for large caster fleets, and the integration of casters into autonomous mobile robots (AMRs). Users frequently ask how AI can enhance the durability and operational lifespan of nylon casters, particularly in high-stress environments like automated warehouses. Key concerns include the potential for AI-driven manufacturing to reduce production costs, leading to price compression, and how predictive analytics can forecast caster failure based on operational telemetry, minimizing downtime in critical logistics applications. Users expect AI to fundamentally transform both the production side—through smart factory implementation—and the application side, by enabling more intelligent, wear-aware mobility systems that are prerequisites for next-generation material handling.

- AI optimizes injection molding parameters for superior nylon consistency and reduced defect rates.

- Predictive maintenance algorithms analyze vibration and load data from caster-equipped machinery to forecast wear patterns.

- AI-driven demand forecasting improves inventory management for standard and specialized nylon caster components.

- Integration of machine learning facilitates quality control, rapidly identifying structural imperfections in finished caster wheels.

- AI enhances logistics efficiency by optimizing routing for carts and AMRs relying on precise caster performance.

- Robotics and AI are critical enablers for fully automated material handling systems that demand stringent caster reliability.

DRO & Impact Forces Of Nylon Casters Market

The Nylon Casters Market is significantly shaped by a compelling combination of market drivers, specific industry restraints, and untapped opportunities, all interacting to create dynamic impact forces. Primary drivers include the global push towards automation and mechanization across manufacturing and warehousing sectors, where the inherent low-friction and high-load capacity of nylon casters make them indispensable components. Restraints often center on the material limitations of standard nylon, which can suffer from reduced performance in extremely high-temperature environments or where sharp impact loads exceed specified limits. Opportunities are abundant in the development of specialized, advanced polymer blends, such as glass-filled nylon or composites, tailored for niche applications like cleanrooms and high-tech automotive facilities, along with leveraging e-commerce channels for efficient global distribution.

Impact forces currently influencing the market structure involve the rapid technological substitution threat posed by alternative wheel materials, such as polyurethane and high-grade rubber, which offer superior cushioning or anti-vibration properties in specific applications. However, nylon maintains a cost-performance advantage in many general-purpose and high-load, low-profile scenarios. Regulatory forces, particularly those relating to occupational safety and health standards (OSHA), mandate reliable locking mechanisms and specified load ratings, driving product innovation towards safer, certified caster assemblies. Additionally, fluctuating raw material costs, specifically petrochemical derivatives used in nylon production, introduce supply chain volatility, directly influencing manufacturer profitability and end-user pricing strategies across all geographical regions.

The combination of these factors results in a market environment focused on maximizing product lifespan and reliability while managing cost pressures. The long-term impact force remains industrial infrastructural spending, which consistently generates baseline demand. The market’s resilience is demonstrated by its continuous ability to innovate, offering specialized solutions like conductive nylon for electronics manufacturing and non-marking, corrosion-resistant casters for food and pharmaceutical applications, ensuring nylon remains a cornerstone material in industrial mobility solutions despite competing material technologies emerging in specific niche areas.

Segmentation Analysis

The Nylon Casters Market is primarily segmented based on material composition, load capacity, primary application sector, and distribution channel, reflecting the diverse requirements of end-user industries ranging from delicate laboratory environments to harsh, heavy-duty manufacturing floors. This segmentation is crucial for understanding specific consumer demands and tailoring product development efforts to meet varied performance criteria, such as resistance to chemicals, temperature tolerance, and required rolling noise levels. The dominance of the medium-duty and standard nylon segments highlights the substantial general-purpose industrial and commercial usage, while the growing penetration of reinforced nylon indicates increasing specialization and the need for higher load-bearing capabilities and enhanced durability across demanding applications.

- By Material Type:

- Standard Nylon (Polyamide 6/6)

- Reinforced Nylon (e.g., Glass-Filled Nylon)

- Conductive/ESD Nylon

- By Load Capacity:

- Light Duty (e.g., Office Furniture, Small Carts)

- Medium Duty (e.g., Institutional Carts, Retail Displays)

- Heavy Duty (e.g., Industrial Machinery, Scaffolding)

- By Application:

- Industrial Equipment & Manufacturing

- Medical Devices & Healthcare

- Furniture & Office Equipment

- Logistics & Material Handling (Warehousing)

- Retail & Commercial Use

- By Distribution Channel:

- Direct Sales (OEMs)

- Industrial Distributors & Wholesalers

- E-commerce & Online Retail

Value Chain Analysis For Nylon Casters Market

The value chain for the Nylon Casters Market begins with the upstream procurement of raw materials, primarily nylon resins (polyamides) sourced from major chemical and petrochemical suppliers globally. This stage involves managing volatile polymer pricing and ensuring quality consistency, as the grade and purity of the nylon directly influence the caster’s final performance metrics, such as load capacity and chemical resistance. Key activities include polymerization, compounding (mixing with additives like glass fibers or anti-static agents), and the subsequent transport of these bulk materials to specialized caster manufacturers. Efficiency in this upstream segment is vital for controlling overall production costs and ensuring a reliable supply of specialized nylon variants required for high-performance applications like conductive wheels.

The core manufacturing process involves highly specialized tooling, injection molding, and assembly of the wheel into its housing, bearing, and mounting structure. Manufacturers focus on precision engineering to reduce rolling resistance and maximize swivel articulation. Downstream activities are dominated by distribution channels, which are bifurcated into direct sales to large Original Equipment Manufacturers (OEMs)—such as hospital bed producers or heavy machinery makers—and indirect sales through a network of specialized industrial distributors, wholesalers, and increasingly, powerful e-commerce platforms. The complexity of the product range, defined by hundreds of variations in diameter, bearing type, and mounting method, necessitates robust inventory management systems throughout the distribution network to meet varied customer needs efficiently.

The final stage involves reaching the end-user, often segmented into MRO procurement for existing facilities and new equipment integration (OEM). Direct channels offer tailored technical support and large-volume purchasing agreements, essential for automotive or aerospace manufacturers. Conversely, the indirect distribution route, particularly through e-commerce, caters effectively to smaller businesses, MRO requirements, and customers needing immediate replacement parts. Optimization of this value chain hinges on streamlining the logistics between manufacturers and industrial distributors, leveraging digital platforms to enhance product visibility, technical specifications access, and rapid order fulfillment, thereby maintaining competitive positioning against lower-cost global alternatives.

Nylon Casters Market Potential Customers

Potential customers for nylon casters span a broad industrial spectrum, fundamentally comprising any entity requiring mobility solutions for non-powered equipment ranging from light-duty office furniture to heavy-duty industrial machinery. The largest customer bases reside within the Logistics and Material Handling sectors, including large e-commerce fulfillment centers, third-party logistics (3PL) providers, and traditional warehousing operations that rely extensively on carts, dollies, and mobile storage racks. These customers prioritize durability, floor protection, and the non-marking properties characteristic of nylon, often seeking specialized features like quiet operation and high chemical resistance for wash-down environments in food processing facilities.

The Healthcare and Institutional sectors represent another high-value customer segment, encompassing hospitals, laboratories, nursing homes, and educational institutions. Customers here demand casters that are easily sterilizable, non-corrosive (often requiring stainless steel fittings), and capable of smooth operation under moderate loads, such as those found on medical carts, hospital beds, and laboratory equipment. The requirement for anti-static or conductive casters is particularly relevant in hospital environments near sensitive electronic monitoring equipment and in specialized electronics manufacturing assembly lines where electrostatic discharge must be rigorously controlled to prevent component damage, driving demand for specialized nylon variants tailored to these regulatory needs.

Furthermore, Original Equipment Manufacturers (OEMs) across various industries—including furniture manufacturing (office chairs, shelving), automotive assembly (component transport racks), and construction (scaffolding systems)—constitute perennial and high-volume customers. These OEMs integrate nylon casters directly into their final products, often requiring custom specifications regarding mounting plates, load ratings, and specific color requirements to match the aesthetic or functional design of their equipment. The sustained activity in global infrastructure development and the cyclical nature of furniture replacement and industrial equipment upgrades ensure a continuous and diversified customer base across the global market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tente International GmbH, Colson Group, Blickle Rader+Rollen GmbH u. Co. KG, Caster Concepts Inc., Albion Casters, Hamilton Caster & Mfg. Co., Revvo Caster Co. Inc., Shepherd Caster Corporation, PFAFF Verkehrstechnik GmbH, RWM Casters, C.P. Lauman Co., Darcor Casters, Kee Safety Inc., Jarvis Caster, Eichenlaub GmbH, Footmaster Caster, Stellana AB, Pemko Manufacturing, G-D Industrial Casters, Algood Casters. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nylon Casters Market Key Technology Landscape

The technology landscape in the Nylon Casters Market is primarily dominated by advancements in materials science and sophisticated manufacturing processes, rather than purely electronic or digital integration, focusing instead on optimizing mechanical performance. Key technological developments include the refinement of nylon polymer blends, specifically the integration of glass fibers, carbon fibers, or other reinforcing agents into the PA 6 or PA 6/6 matrix. This reinforcement significantly enhances the tensile strength, increases the load-bearing capacity without substantially increasing the physical size, and improves resistance to impact and abrasion, crucial for heavy-duty industrial applications where operational failure must be minimized. These material innovations are pivotal in extending the functional life cycle of the casters under rigorous usage conditions, thereby offering superior value proposition to end-users in manufacturing and logistics.

In manufacturing technology, precision injection molding remains the core process. Modern machinery utilizes advanced controls to manage temperature, pressure, and cooling cycles with extreme accuracy, ensuring minimal internal stresses in the finished nylon wheel. This precision manufacturing is essential for achieving tight tolerances required for smooth operation and compatibility with high-quality bearings, such as sealed precision ball bearings, which reduce rolling resistance and noise—a key requirement in institutional and office environments. Furthermore, technology related to anti-static and conductive formulations involves carefully controlled compounding processes to uniformly disperse carbon black or specialized conductive polymers within the nylon matrix, ensuring reliable electrostatic discharge (ESD) protection critical for electronics manufacturing and volatile environments.

Beyond the wheel material itself, significant technological focus is placed on the entire caster assembly system, particularly swivel and braking mechanisms. Advanced swivel technologies incorporate precision machined raceways or sealed kingpinless designs to handle side impacts and heavy dynamic loads more effectively, enhancing maneuverability and durability. Braking system innovations include total lock brakes, which simultaneously secure both the wheel rotation and the swivel action, and directional lock mechanisms, which allow movement only in a straight line, critical for maintaining control of heavy or sensitive equipment during transit. The increasing standardization of computer-aided design (CAD) and simulation tools allows manufacturers to rapidly prototype and test new designs for specific application stresses, accelerating the time-to-market for optimized, specialized caster solutions.

Regional Highlights

- Asia Pacific (APAC): This region dominates the market due to robust growth in manufacturing, particularly in China, India, and Southeast Asia. The massive expansion of warehousing and logistics infrastructure, fueled by explosive e-commerce growth, drives high volume demand for medium to heavy-duty nylon casters. Government initiatives supporting industrial corridors and infrastructure modernization further solidify APAC's position as the fastest-growing market globally.

- North America: Characterized by high adoption rates of automated material handling systems and strong regulatory focus on ergonomic workplace solutions. The demand here leans towards specialized, high-performance nylon casters, including anti-static and precision-bearing types, predominantly utilized in the automotive, aerospace, and high-tech manufacturing sectors, maintaining a focus on product reliability and compliance.

- Europe: A mature market defined by strict quality standards, especially in the healthcare and food processing industries. European demand is often directed toward premium, corrosion-resistant nylon casters with stainless steel fittings, emphasizing durability and hygiene. Germany, France, and the UK are key contributors, driven by stringent environmental policies that encourage manufacturers to innovate using sustainable materials and energy-efficient production methods.

- Latin America (LATAM): Exhibits strong potential growth tied to industrial recovery and infrastructure investment, particularly in Brazil and Mexico. The market is highly price-sensitive, with demand concentrated in general-purpose and medium-duty casters for retail and regional manufacturing operations. Expansion in logistics infrastructure is a critical long-term driver in this region.

- Middle East and Africa (MEA): This region is witnessing rapid urbanization and heavy investment in commercial infrastructure, including large retail complexes and advanced healthcare facilities, particularly in the Gulf Cooperation Council (GCC) states. Demand focuses on robust casters capable of withstanding harsh, dusty environments and supporting the growing construction and warehousing sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nylon Casters Market.- Tente International GmbH

- Colson Group

- Blickle Rader+Rollen GmbH u. Co. KG

- Caster Concepts Inc.

- Albion Casters

- Hamilton Caster & Mfg. Co.

- Revvo Caster Co. Inc.

- Shepherd Caster Corporation

- PFAFF Verkehrstechnik GmbH

- RWM Casters

- C.P. Lauman Co.

- Darcor Casters

- Kee Safety Inc.

- Jarvis Caster

- Eichenlaub GmbH

- Footmaster Caster

- Stellana AB

- Pemko Manufacturing

- G-D Industrial Casters

- Algood Casters

Frequently Asked Questions

Analyze common user questions about the Nylon Casters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of nylon casters over rubber or polyurethane?

Nylon casters offer superior load capacity per wheel size, excellent resistance to chemicals, non-marking properties, and minimal rolling resistance, making them ideal for high-load, non-cushioned applications and environments requiring frequent wash-downs.

In which industries are conductive (ESD) nylon casters essential?

Conductive or ESD nylon casters are essential in the electronics manufacturing industry, cleanrooms, munitions handling, and hospital operating theaters where static electricity accumulation must be safely dissipated to protect sensitive components or prevent sparks.

How does the global growth of e-commerce impact the demand for nylon casters?

E-commerce expansion drives massive investment in automated warehouses and logistics centers, directly increasing the demand for durable, low-maintenance nylon casters used on transport trolleys, conveyor supports, and autonomous mobile robot (AMR) components.

Are reinforced nylon casters suitable for heavy-duty outdoor applications?

Reinforced nylon casters, often using glass fiber, provide high static and dynamic load capacities suitable for heavy industrial use. While chemically resistant, they are generally best suited for smooth indoor surfaces; outdoor use requires careful consideration of bearing seals and potential exposure to sharp debris or uneven terrain.

What is the projected Compound Annual Growth Rate (CAGR) for the Nylon Casters Market?

The Nylon Casters Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period from 2026 to 2033, driven by industrial automation and infrastructural development globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager