Optical Fibre Cleaverame Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441444 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Optical Fibre Cleaverame Market Size

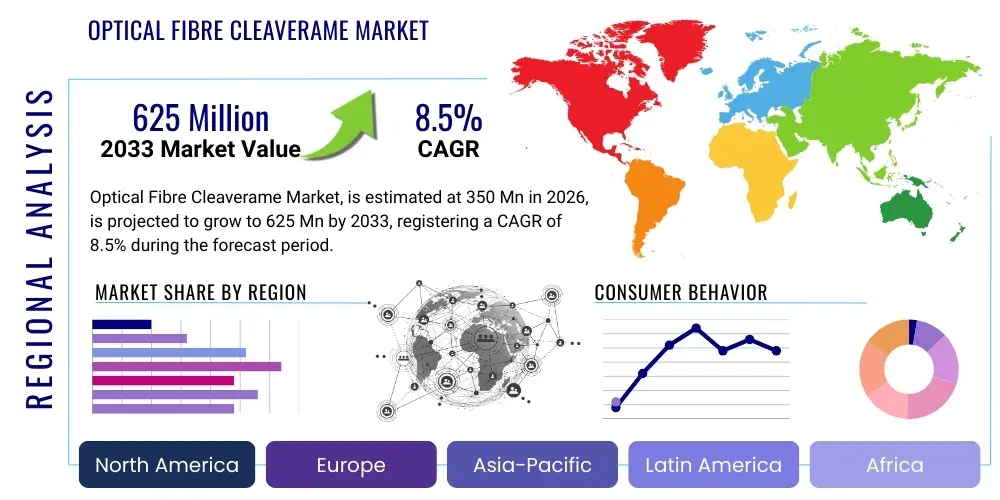

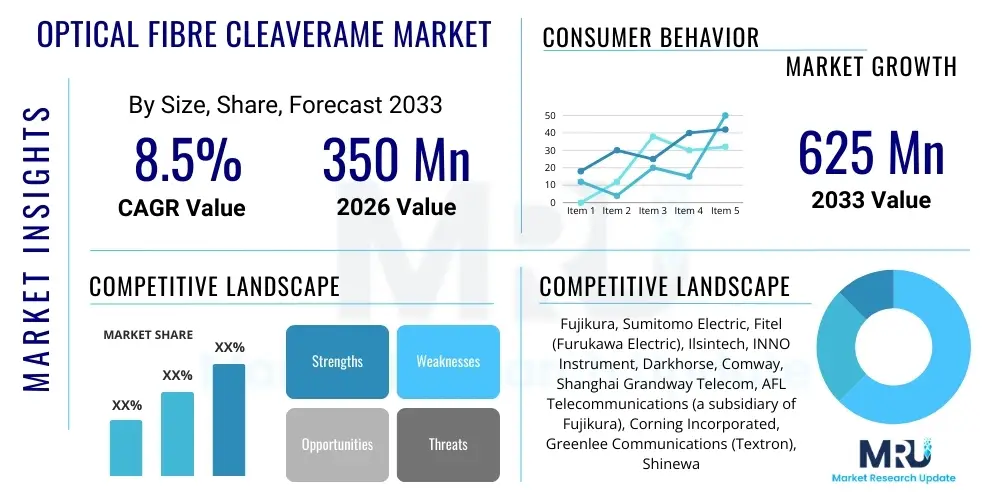

The Optical Fibre Cleaverame Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 625 Million by the end of the forecast period in 2033.

Optical Fibre Cleaverame Market introduction

The Optical Fibre Cleaverame Market encompasses specialized precision tools designed for preparing optical fibers by creating a clean, flat, and perpendicular end face prior to fusion splicing or mechanical termination. The quality of the cleave is paramount, directly influencing splice loss and overall network performance. A high-precision cleaverame (the mechanism and frame of the cleaver) ensures minimal angle deviation and mirror-surface integrity, which is indispensable for high-speed, low-attenuation data transmission requirements mandated by modern fiber optic networks. The increasing deployment of Fiber-to-the-x (FTTx) architectures, coupled with massive investments in 5G infrastructure globally, forms the foundational demand base for this market.

Optical fibre cleaverames are essential components in telecommunication, data centers, CATV, and defense applications. They utilize mechanisms, often involving diamond blades or high-precision carbide blades, to score the fiber and apply controlled tension, resulting in a perfect fracture. The market includes a range of products from basic single-fiber manual cleavers used for field termination to sophisticated automatic ribbon fiber cleavers integrated with splicing machines, optimizing workflow efficiency in high-volume installations. Product innovation focuses heavily on improving blade lifetime, portability, cleave angle consistency, and automation features, thereby reducing technician variability and installation time.

Key driving factors accelerating market expansion include the exponential growth in global data traffic, necessitating continuous upgrades and expansion of fiber optic backbones. Government initiatives supporting universal broadband access, particularly in emerging economies, are fueling FTTx deployments, which rely heavily on efficient cleaving equipment. Furthermore, the rising adoption of hyperscale data centers requiring high-density fiber connectivity mandates the use of highly reliable and repeatable cleaving solutions, solidifying the market's trajectory towards automation and superior precision tools.

Optical Fibre Cleaverame Market Executive Summary

The Optical Fibre Cleaverame Market is poised for robust expansion, driven primarily by pervasive global digitalization and the critical need for low-loss connectivity in telecommunication infrastructure. Business trends indicate a strong shift towards automated and semi-automatic cleaver solutions that minimize human error and accelerate deployment cycles, particularly in major FTTx projects and high-count fiber installations. This shift is leading manufacturers to invest heavily in smart cleaver technology featuring connectivity and predictive maintenance capabilities. Competition is characterized by the strategic consolidation among global leaders and niche players focusing on rugged, field-ready equipment. Sustainability and durability of the cleaving mechanisms, especially the replaceable blades, are becoming significant competitive differentiators, influencing procurement decisions among large network operators.

Regionally, Asia Pacific (APAC) dominates the market, largely due to unprecedented fiber infrastructure buildout in China, India, and Southeast Asian nations driven by 5G rollout and national broadband plans. North America and Europe demonstrate mature market characteristics, focusing on upgrading existing fiber networks and maintaining hyperscale data center infrastructure, driving demand for high-end, high-precision cleavers. Segments trends highlight the dominance of single-fiber automatic cleavers due to their versatility and ease of use in field applications. However, the ribbon fiber cleaver segment is experiencing the fastest growth rate, propelled by the increasing deployment of high-fiber-count cables in backbone and enterprise networks where mass splicing is essential for efficient installation.

The primary challenges facing the market include the high initial investment required for sophisticated automated systems and the ongoing global shortage of skilled technicians capable of maintaining and operating advanced fiber preparation tools effectively. Opportunities are abundant in specialized applications such as harsh environment deployments (e.g., military, aerospace) requiring specialized ruggedized cleaverames, and through the integration of Internet of Things (IoT) technologies into cleavers for real-time performance monitoring and asset management, optimizing fleet utilization for large contracting firms. The market outlook remains exceptionally positive, underpinned by the indispensable role of optical fiber in the modern digital economy.

AI Impact Analysis on Optical Fibre Cleaverame Market

Analysis of common user questions related to AI's impact on the Optical Fibre Cleaverame Market reveals key user themes centered on predictive maintenance, quality control automation, and integration with splicing robotics. Users frequently ask if AI can analyze cleave performance data to predict blade failure before it impacts splice loss, thereby minimizing costly rework and downtime. Concerns are also raised about the feasibility of integrating machine learning algorithms to automatically adjust cleaving parameters (e.g., tension, blade height) based on ambient conditions or fiber type in real-time. The prevailing expectation is that AI will transform cleaving from a manual, variable process into a highly optimized, self-correcting system, reducing the reliance on highly experienced technicians for quality assurance in the field and enhancing overall installation consistency across massive network deployments.

- AI-Enhanced Quality Control: Machine vision systems coupled with AI analyze the cleaved end face (image capture) in real-time, instantly identifying defects (hackle, lip, mist) and providing objective pass/fail decisions, significantly exceeding human visual inspection reliability.

- Predictive Maintenance: AI algorithms process vibration, usage cycles, and performance metrics (e.g., increasing cleave angle deviation) to predict the optimal replacement time for cleaver blades and mechanisms, maximizing blade lifespan and minimizing unexpected failures.

- Automated Calibration: Machine learning models optimize cleaving parameters based on environmental variables (temperature, humidity) and specific fiber characteristics (coating type, diameter), ensuring consistent high-quality cleaves regardless of field conditions.

- Integration with Robotics: AI facilitates seamless communication and automation between the cleaverame and the fusion splicer, ensuring precise robotic handling of the prepared fiber and reducing physical manipulation, which can introduce contamination or damage.

- Training and Diagnostics: AI-powered diagnostic tools simplify troubleshooting for field technicians, offering guided instructions based on performance anomalies detected in the cleaving process.

DRO & Impact Forces Of Optical Fibre Cleaverame Market

The dynamics of the Optical Fibre Cleaverame Market are governed by powerful structural forces, summarized by Drivers (D), Restraints (R), and Opportunities (O). Primary drivers include the massive global rollout of 5G networks, the accelerating need for FTTx infrastructure, and the continuous demand for increased bandwidth in data centers. Restraints center on the requirement for high capital expenditure for advanced automated equipment and the challenge of counterfeit or low-quality cleaving tools entering the market, which compromise network integrity. Opportunities lie in developing ultra-precision tools for specialty fibers (e.g., polarization-maintaining fibers), offering subscription-based maintenance services for cleaver fleet management, and penetrating underserved rural and remote infrastructure projects. The combined impact of these forces strongly favors market growth, contingent upon manufacturers' ability to maintain technological superiority and competitive pricing while addressing the need for durable, user-friendly field equipment.

Segmentation Analysis

The Optical Fibre Cleaverame Market is comprehensively segmented based on the mechanism type, degree of automation, and diverse application landscapes, allowing for targeted product development and market penetration strategies. Segmentation by Type includes single-fiber cleavers, which are ubiquitous in standard field installations, and ribbon fiber cleavers, crucial for high-capacity backbone networks. Automation levels separate manual (scribe-and-break), semi-automatic (controlled mechanism), and fully automatic cleavers (motorized feed and waste disposal). Application-wise, the market is dissected across major infrastructure sectors, where performance and reliability requirements vary significantly, driving specialization in product offerings tailored for robustness (e.g., military) versus speed (e.g., FTTx deployment).

- By Product Type:

- Single Fiber Cleavers

- Ribbon Fiber Cleavers (4-fiber, 8-fiber, 12-fiber, 16-fiber)

- Specialty Fiber Cleavers (Large Diameter Fiber, Polarization Maintaining Fiber)

- By Mechanism/Operation:

- Manual Cleavers (Scribe-and-Break Tools)

- Semi-Automatic Precision Cleavers (Lever-Actuated)

- Automatic (Motorized) Cleavers

- By Application:

- Telecommunications and Data Communication (Backbone Networks, Metropolitan Area Networks)

- FTTx Deployment (FTTH, FTTB, FTTC)

- Cable TV (CATV) Networks

- Military and Aerospace

- Industrial and Sensor Applications

- Data Centers and Enterprise Networks

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Optical Fibre Cleaverame Market

The value chain for the Optical Fibre Cleaverame Market begins with the highly specialized Upstream activities focused on sourcing ultra-hard materials, primarily for the cleaving blades (diamond, tungsten carbide, ceramic), and high-precision mechanical components for the cleaverame mechanism. This stage demands strict quality control to ensure blade geometry, hardness, and durability, which directly correlate with the tool's performance and lifetime. Key suppliers include specialized material science firms and precision engineering workshops. The Midstream involves the assembly, calibration, and quality testing of the final cleaver unit, where core manufacturers focus on integration of automatic features, motorization, and ergonomic design. Precision calibration of blade height and force is critical here, ensuring repeatable, low-angle cleaves across various fiber types and environmental conditions.

Downstream activities involve global Distribution Channels, including highly specialized optical equipment distributors, direct sales to large telecommunication operators (telcos), and relationships with system integrators and contracting firms handling large-scale FTTx projects. Given the technical nature of the product, distributor expertise in fiber optic deployment is essential for pre-sales consultation and post-sales support. Direct channels are often preferred by top-tier manufacturers for engagement with key accounts. Marketing efforts emphasize precision metrics (cleave angle reliability) and Total Cost of Ownership (TCO), factoring in blade life and replacement costs.

The end of the value chain is defined by the End-Users—field technicians, installation crews, and maintenance teams—whose requirement for rugged, reliable, and easy-to-use equipment drives product innovation. The market highly values comprehensive training and technical support provided either directly by the manufacturer or through qualified distribution partners. Indirect channels, such as large online industrial equipment suppliers, also play a role, particularly for basic or manual cleavers, although automatic precision tools typically require dedicated, authorized sales channels to ensure proper use and warranty adherence.

Optical Fibre Cleaverame Market Potential Customers

The potential customer base for the Optical Fibre Cleaverame Market is defined by any entity responsible for the installation, maintenance, or repair of fiber optic infrastructure. Primary customers are large Tier-1 and Tier-2 telecommunication service providers (telcos) who require thousands of precision cleavers for their massive infrastructure rollouts (5G, national broadband initiatives). These customers prioritize bulk purchasing efficiency, standardized performance metrics, and excellent post-sales service and warranty support. Network contracting firms and engineering, procurement, and construction (EPC) companies involved in civil works and network deployment are equally vital customers, often purchasing large fleets of ruggedized cleavers optimized for field use.

Secondary customer groups include hyperscale and enterprise data center operators who demand the highest precision tools for splicing high-fiber-count trunk cables within their tightly managed environments, where low insertion loss is non-negotiable for system performance. Furthermore, utility companies (power grids, pipelines) increasingly integrating smart grids relying on fiber optic sensing and communication require specialized, environmentally resistant cleavers. Specialized industries such as aerospace, defense, and medical device manufacturing, which use fiber for sensing or specialized data links, represent high-margin customers requiring cleavers capable of handling specialty and polarization-maintaining (PM) fibers with extreme accuracy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 625 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fujikura, Sumitomo Electric, Fitel (Furukawa Electric), Ilsintech, INNO Instrument, Darkhorse, Comway, Shanghai Grandway Telecom, AFL Telecommunications (a subsidiary of Fujikura), Corning Incorporated, Greenlee Communications (Textron), ShinewayTech, Seikoh Giken, Ripley Tools (Miller Brand), Diamond SA, Fiberfox, JDSU (Viavi Solutions), Jonard Tools, US Conec, Santec Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Optical Fibre Cleaverame Market Key Technology Landscape

The technological landscape of the Optical Fibre Cleaverame Market is characterized by continuous refinement aimed at achieving sub-0.5-degree cleave angles consistently, a non-negotiable requirement for modern low-loss splicing. Key innovations center around the cleaving mechanism, specifically the control over the scoring depth and the application of controlled tension. Modern cleavers utilize motorized precision drives to ensure constant, repeatable speed during the cleaving process, drastically reducing the variance associated with manual operation. Advanced features include automatic rotation of the cleaver blade after each use (typically 12-24 positions) to maximize the overall lifetime of the blade (often exceeding 48,000 cleaves per blade) and automatic fiber scrap collection and disposal systems, enhancing safety and cleanliness in the field.

A significant technological advancement is the integration of digital features. Many high-end cleavers now incorporate Bluetooth or Wi-Fi connectivity, allowing them to communicate directly with fusion splicers. This integration ensures that the cleaver and splicer can share operational data, such as real-time environmental conditions and cleave counts, optimizing the splicing parameters automatically and logging performance for quality assurance reporting. Furthermore, battery technology has improved significantly, enabling automatic cleavers to perform hundreds of cleaves on a single charge, crucial for large-scale field deployments in remote areas.

The development of specialized cleaving technologies for multi-fiber ribbon cables is another critical area. Ribbon cleavers must ensure all 4, 8, or 12 fibers are cleaved simultaneously and accurately. This requires highly sophisticated alignment and clamping systems to maintain perfect fiber geometry before the score is made. The adoption of AI-powered machine vision systems to perform in-situ inspection of the cleave face immediately after the operation represents the next frontier, providing instant feedback and verifying compliance with stringent network quality standards before the fiber proceeds to splicing, thereby streamlining the entire fiber termination workflow.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global market, fueled by aggressive government investments in digital infrastructure, particularly in China and India, supporting vast FTTx and 5G network expansion projects. The region is the largest consumer of both high-volume manual/semi-automatic cleavers for widespread deployment and advanced ribbon cleavers for backbone capacity upgrades. The intense competition in regional telecom markets drives continuous demand for cost-effective, high-reliability cleaving solutions.

- North America: Characterized by a mature yet high-value market, North America focuses on technological sophistication. Demand is driven by upgrades of existing infrastructure, extensive data center construction (hyperscale and edge), and the need for precision cleavers for demanding applications like submarine cables and specialized industrial sensing fibers. Automated, IoT-enabled cleavers for efficient fleet management are highly sought after by major US and Canadian telcos.

- Europe: The European market is spurred by the EU's Digital Agenda goals, pushing fiber deployment in central and eastern Europe, alongside high utilization rates in countries like Germany and the UK. Emphasis is placed on ruggedized, environmentally compliant tools suitable for diverse field conditions. Growth is steady, focusing on maintaining quality standards through precision tooling and investing in cleavers compatible with various European fiber standards.

- Latin America (LATAM): Emerging market status with significant growth potential, driven by rapidly increasing internet penetration and modernization of legacy copper networks. Brazil and Mexico are key markets, showing high demand for cost-effective, durable semi-automatic cleavers suitable for new FTTx installations in dense urban and challenging rural terrains.

- Middle East and Africa (MEA): Growth in MEA is concentrated in the Gulf Cooperation Council (GCC) states due to substantial infrastructure spending on smart city projects and high-speed fiber backbones. Africa presents a long-term growth opportunity as major submarine cable landings catalyze national fiber builds, driving demand for basic yet robust cleaving tools for initial deployment phases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Optical Fibre Cleaverame Market.- Fujikura

- Sumitomo Electric

- Fitel (Furukawa Electric)

- Ilsintech

- INNO Instrument

- Darkhorse

- Comway

- Shanghai Grandway Telecom

- AFL Telecommunications (a subsidiary of Fujikura)

- Corning Incorporated

- Greenlee Communications (Textron)

- ShinewayTech

- Seikoh Giken

- Ripley Tools (Miller Brand)

- Diamond SA

- Fiberfox

- JDSU (Viavi Solutions)

- Jonard Tools

- US Conec

- Santec Corporation

Frequently Asked Questions

Analyze common user questions about the Optical Fibre Cleaverame market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for high-precision automatic optical cleavers?

The increasing complexity and density of modern fiber optic networks, especially the global rollout of 5G infrastructure and FTTx deployments, necessitate automated, ultra-low-loss splicing. Automatic cleavers reduce human error and ensure the consistent sub-0.5-degree cleave angles required for reliable, high-speed data transmission, minimizing overall network attenuation.

How long does a typical cleaver blade last, and what factors influence its longevity?

The lifespan of a high-quality optical cleaver blade can range significantly, typically between 16,000 and over 60,000 cleaves. Longevity is primarily influenced by the material quality, the blade rotation mechanism (automatic rotation maximizes the available scoring points), and environmental factors such as dust and humidity that can degrade the blade edge prematurely.

Which geographical region exhibits the fastest growth potential in the Optical Fibre Cleaverame Market?

The Asia Pacific (APAC) region is projected to show the fastest market growth, driven by unprecedented infrastructure investment in developing economies like India and Southeast Asia, coupled with China's continuous massive buildout of 5G and fiber-to-the-home networks, creating immense volume demand for cleaving equipment.

What is the significance of the cleave angle in fiber optic splicing?

The cleave angle is critically important as it determines the quality of the end-face preparation. A deviation from the ideal 90-degree angle (less than 0.5 degrees is ideal) results in increased splice loss, back reflection, and poor overall connection performance, making a precise cleave indispensable for achieving high-performance network links.

What role does Artificial Intelligence (AI) play in modern optical cleaving technology?

AI is increasingly used for predictive maintenance, analyzing usage data and cleave performance trends to forecast blade replacement needs. Additionally, AI-driven machine vision systems automate quality control by analyzing the cleaved fiber end-face for defects, ensuring optimal preparation consistency before the splicing process.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager