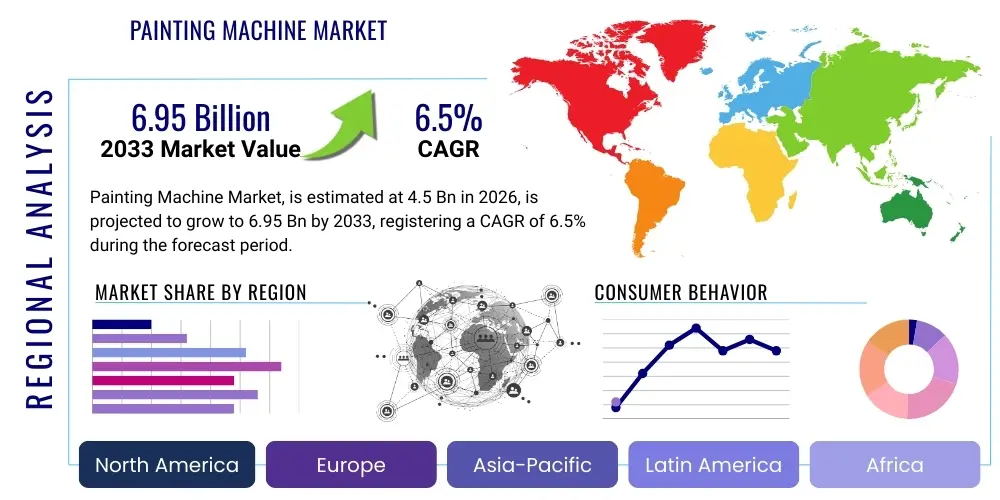

Painting Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441431 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Painting Machine Market Size

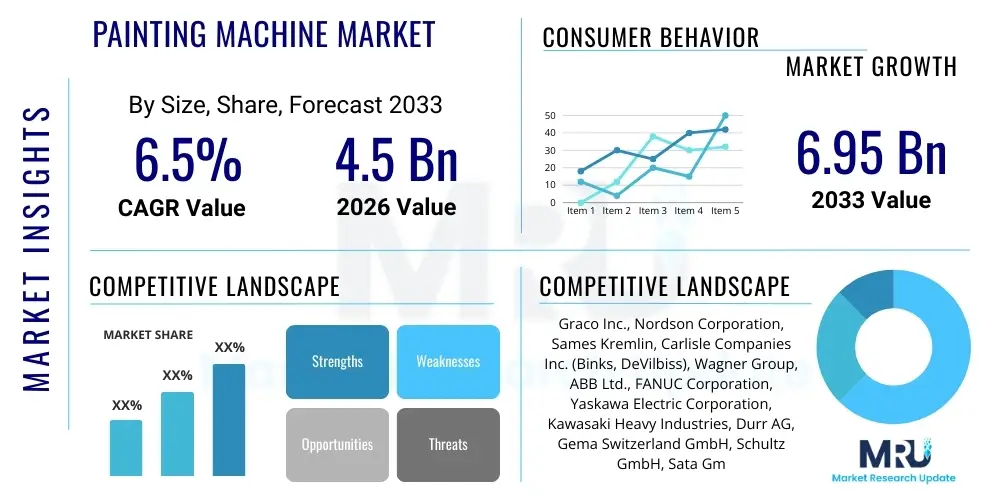

The Painting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.95 Billion by the end of the forecast period in 2033.

Painting Machine Market introduction

The Painting Machine Market encompasses a wide range of automated and semi-automated equipment designed for applying coatings, paints, and protective layers across various industrial and commercial surfaces. These machines are integral to manufacturing efficiency, offering consistency, speed, and quality superior to manual application methods. Products range from sophisticated robotic painting systems utilized in automotive assembly lines and aerospace manufacturing to electrostatic spray guns and large-scale powder coating systems used in general industry and construction. The fundamental function of these machines is to optimize material usage, reduce overspray, minimize volatile organic compound (VOC) emissions, and ensure uniform coating thickness, thereby enhancing product durability and aesthetic appeal. Key technological advancements, particularly in automation and precision control, are continuously shaping the market landscape, leading to higher adoption rates in sectors prioritizing finish quality and operational safety.

Major applications of painting machines span diverse industries, including automotive refinishing and original equipment manufacturing (OEM), heavy machinery and equipment production, construction (for infrastructure coatings and residential painting), wood finishing, and consumer electronics manufacturing. The automotive industry remains the largest consumer, driven by the need for flawless surface finishes and corrosion resistance for vehicles. Benefits derived from the adoption of modern painting machinery include significant labor cost reduction, improved throughput, enhanced workplace safety by limiting worker exposure to hazardous chemicals, and achieving repeatable, high-quality finishes that meet stringent industry standards. These advantages solidify the necessity of these machines in modern industrialized economies where manufacturing precision is paramount. Furthermore, the integration of advanced filtration and environmental control systems within these machines addresses growing regulatory pressures concerning environmental sustainability.

Driving factors for the expansion of the Painting Machine Market include the rapid global growth in the automotive and construction sectors, particularly in emerging economies, alongside the increasing focus on advanced manufacturing techniques (Industry 4.0). The continuous demand for high-quality, durable coatings that protect components from extreme environmental conditions (such as corrosion, abrasion, and UV exposure) further propels market expansion. Technological innovation, such as the development of smart painting robots equipped with vision systems and AI algorithms for path optimization, enables complex geometries to be painted efficiently. The shift toward sustainable coating materials, like water-based paints and powder coatings, requires specialized machinery designed to handle these specific formulations effectively, thereby stimulating replacement and upgrade cycles within the established industrial base. These synergistic factors underscore the robust growth trajectory projected for the forecast period.

Painting Machine Market Executive Summary

The global Painting Machine Market is characterized by robust growth, primarily fueled by rapid industrial automation adoption across sectors such as automotive, aerospace, and general manufacturing. Business trends indicate a strong move toward highly customized, flexible robotic painting systems that can handle diverse product lines and varying batch sizes, moving away from rigid, specialized setups. Manufacturers are increasingly integrating IoT capabilities and advanced sensors into painting machinery to enable real-time monitoring, predictive maintenance, and data-driven process optimization, significantly improving operational efficiency and reducing downtime. Furthermore, the push for environmental compliance and the adoption of high-solids, powder, and waterborne coatings necessitate substantial investment in new equipment capable of processing these eco-friendly materials efficiently, driving technological convergence among key market players who focus on developing multi-coating application capabilities.

Regional trends highlight Asia Pacific (APAC) as the dominant market, driven by rapid industrialization, massive infrastructure development, and the high concentration of automotive and electronics manufacturing bases, particularly in China, India, and Southeast Asian nations. North America and Europe maintain strong market shares, characterized by early adoption of advanced robotics and stringent quality control standards, leading to consistent demand for premium, high-precision equipment and refurbishment services. Growth in Latin America and the Middle East & Africa (MEA) is accelerating, spurred by growing construction activity and investments in localized manufacturing hubs, though these regions primarily focus on entry-level and mid-range automated spray painting systems initially. The competitive landscape is intensely focused on intellectual property, with companies striving to offer holistic solutions that include not just the machine hardware but also integrated software platforms for paint application management.

Segmentation trends reveal that robotic painting systems are expected to exhibit the fastest growth rate due to their flexibility, precision, and ability to operate continuously in hazardous environments, addressing critical labor shortage issues in highly industrialized countries. In terms of technology, electrostatic spray painting equipment dominates due to its superior transfer efficiency, minimizing material waste, a crucial factor given the rising cost of industrial coatings. End-use analysis confirms the enduring supremacy of the automotive sector, although the general industry segment, including machinery and consumer goods, shows substantial potential as smaller manufacturers begin to automate their coating processes. The trend is moving towards modular painting booths and systems that allow rapid reconfiguration and scaling, addressing the volatile demand fluctuations characteristic of modern global supply chains.

AI Impact Analysis on Painting Machine Market

Common user questions regarding AI's influence on the Painting Machine Market frequently revolve around how artificial intelligence can enhance coating quality consistency, optimize paint path programming for complex geometries, and improve predictive maintenance schedules to minimize unscheduled downtime. Users are concerned about the implementation costs, the integration of AI vision systems with existing robotic infrastructure, and the capability of AI algorithms to handle the variability inherent in different paint chemistries and environmental conditions. The central expectation is that AI will move painting from a skilled, manual programming task to an automated, self-learning process, dramatically cutting down setup time and material waste, while simultaneously improving overall finish uniformity. Analysis indicates a strong demand for AI-driven solutions that simplify complex task deployment and reduce the reliance on specialized robotic programmers, making high-end automation accessible to a broader range of manufacturers.

- AI-driven path planning and optimization algorithms reduce material overspray by up to 15%, improving transfer efficiency significantly.

- Integrated AI vision systems allow real-time defect detection and quality control, correcting application parameters instantaneously during the painting process.

- Machine learning models predict optimal maintenance cycles for critical components (e.g., pumps, nozzles), extending equipment lifespan and ensuring maximum uptime.

- AI facilitates automatic recipe generation and adjustment based on sensor input regarding ambient temperature, humidity, and substrate variability, ensuring consistent coating thickness.

- Cognitive robotic systems use reinforcement learning to efficiently paint geometrically complex parts without extensive manual programming, streamlining setup.

- Data analytics derived from AI processing enable manufacturers to trace quality issues back to specific process variables, leading to proactive process improvements.

- AI assists in optimizing booth climate control systems, minimizing energy consumption while maintaining ideal painting conditions.

DRO & Impact Forces Of Painting Machine Market

The Painting Machine Market is primarily driven by the escalating demand for automation across high-volume manufacturing sectors, particularly automotive and aerospace, where precision and repeatability are non-negotiable standards. The continuous pressure to improve manufacturing efficiency and reduce labor costs serves as a major impetus, compelling companies worldwide to replace manual painting operations with automated systems. Furthermore, global regulatory bodies are enforcing stricter environmental standards regarding VOC emissions and material waste, which intrinsically favors sophisticated painting machines designed for high transfer efficiency (like electrostatic sprayers and robotic systems), thereby fueling market adoption. These strong, persistent drivers interact to create a foundational demand for advanced coating equipment capable of meeting both economic and ecological objectives.

Restraints, however, pose significant challenges to widespread market penetration. The primary barrier is the high initial capital investment required for purchasing and installing advanced robotic painting systems, especially for Small and Medium Enterprises (SMEs). Integration complexity—connecting new automated equipment with existing factory infrastructure and IT systems—also serves as a restraint, requiring specialized training and expertise. Moreover, the performance of painting machines is highly dependent on auxiliary factors such as paint formulation, environmental controls (temperature, humidity), and preparatory processes; any inconsistency in these areas can undermine the efficiency and quality promised by the machinery, leading to operational bottlenecks and user dissatisfaction, thereby tempering adoption rates in less standardized environments. The ongoing scarcity of highly skilled technicians capable of programming and maintaining these complex robotic systems is another crucial constraint in several geographical markets.

Opportunities for market expansion are substantial, centered mainly around the proliferation of specialized coating applications such as anti-microbial coatings, thermal barrier coatings, and advanced corrosion protection layers required in harsh environments (e.g., offshore oil and gas, marine industries). The emergence of additive manufacturing (3D printing) requires specialized post-processing coating solutions, opening new niches for precision painting robots designed to handle unique surface textures and complex part geometries generated by 3D printing technologies. Developing affordable, modular, and easy-to-program automation solutions specifically tailored for SMEs represents a significant untapped market opportunity. These machines, often incorporating simplified teach-and-learn functions, would democratize high-quality coating automation, expanding the customer base beyond traditional large-scale industrial users. The collective weight of these drivers, restraints, and opportunities dictates the overall impact forces shaping the market's trajectory.

Segmentation Analysis

The Painting Machine Market is comprehensively segmented based on several critical parameters, including the type of product, the coating method employed, the level of automation, and the predominant end-use industry. This layered segmentation is crucial for understanding the varying needs of different industrial applications, ranging from high-precision finishing in aerospace to large-scale protective coatings in construction. Analyzing these segments helps market participants tailor product development and sales strategies to specific industry requirements, acknowledging the difference between the demand for highly flexible robotic systems in automotive manufacturing and the preference for cost-effective manual or semi-automatic airless sprayers in architectural applications. The market structure reflects a dynamic interplay between technological advancement and application-specific demands, leading to distinct growth rates across sub-segments.

- By Product Type:

- Air Spray Guns

- Airless Spray Painters

- Electrostatic Painting Equipment

- Robotic Painting Systems

- Powder Coating Equipment

- By Technology/Coating Method:

- Spray Painting (Liquid)

- Powder Coating

- Electrophoretic Deposition (E-Coat)

- Flow Coating/Dip Coating

- By Automation Level:

- Manual/Portable Equipment

- Semi-Automatic Systems

- Fully Automatic/Robotic Systems

- By End-Use Industry:

- Automotive & Transportation (OEM and Refinish)

- General Industrial Manufacturing

- Construction & Infrastructure

- Aerospace & Defense

- Wood and Furniture Finishing

- Consumer Goods & Appliances

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Painting Machine Market

The value chain of the Painting Machine Market begins with upstream activities, primarily involving raw material sourcing, which includes specialized metals (aluminum, stainless steel), plastics, electronics, high-precision nozzles, and fluid handling components like pumps and regulators. Key suppliers in this stage include specialized component manufacturers and electronics firms providing crucial sensors and control units for robotic systems. Upstream analysis highlights the necessity of secure and consistent sourcing of high-quality materials, as the durability and precision of painting equipment depend heavily on the quality of internal components, especially those exposed to abrasive or chemically aggressive coating materials. Strategic partnerships with sensor and automation component providers are critical for ensuring technological superiority and managing component obsolescence, particularly in high-tech robotic segments.

The core manufacturing and assembly stage involves design, component fabrication, system integration, and rigorous testing. This is where Original Equipment Manufacturers (OEMs) add significant value through proprietary nozzle design, fluid control engineering, and the development of sophisticated motion control software for robotic platforms. Distribution channels are varied, encompassing direct sales for large, customized robotic lines (where technical consultation and integration services are paramount) and indirect channels utilizing distributors and dealer networks for standard spray guns and portable equipment. Indirect channels are crucial for reaching smaller refinishing shops and construction contractors. Furthermore, specialized system integrators play a vital role in taking standard equipment components and designing a tailored painting solution for a specific customer’s factory layout and production needs, adding substantial value through expertise and localized support.

Downstream activities center on deployment, maintenance, and post-sales support. This includes providing application training, offering spare parts (like tips, seals, and filters), and delivering preventive maintenance contracts. The longevity and performance consistency of painting machines heavily rely on effective post-sales support. Direct engagement is common for high-value installations like automotive plants, ensuring rapid response to technical issues. The end-users, such as Tier 1 automotive suppliers or large furniture manufacturers, often rely on certified maintenance professionals to ensure compliance with quality standards. The effectiveness of the value chain is measured by the ability of the system to deliver optimal coating quality, high transfer efficiency, and long-term operational reliability to the end-user while minimizing material waste and energy consumption.

Painting Machine Market Potential Customers

Potential customers for the Painting Machine Market are widely distributed across the entire industrial spectrum, defined fundamentally by any manufacturing or maintenance operation requiring uniform surface coating, aesthetic finishing, or protection against environmental degradation. The automotive OEM sector represents the most significant customer segment, requiring multi-stage, fully automated robotic systems for applying basecoats, clearcoats, and anti-chip protection layers with zero defects. This segment is characterized by large volume purchases, a demand for high precision, and long-term maintenance contracts, focusing heavily on robotic and electrophoretic deposition (E-Coat) technologies to achieve exceptional finish quality and durability required for vehicle longevity.

Another major segment includes the general industrial sector, comprising manufacturers of heavy machinery (tractors, construction equipment), metal fabrication shops, and producers of consumer appliances (refrigerators, washers). These buyers seek robust, versatile equipment, often utilizing powder coating systems or large-scale airless sprayers for durable protective finishes. Their purchasing decisions are often based on balancing initial cost with operational efficiency and resistance to harsh industrial environments. Furthermore, the construction and infrastructure sector, including contractors responsible for bridges, pipelines, and large steel structures, represents a burgeoning customer base, predominantly requiring robust, portable, and high-output airless spray painting units capable of applying specialized protective coatings and marine-grade paints efficiently in demanding outdoor settings.

The aerospace and defense industries constitute a high-value niche segment, demanding ultra-precise, often highly customized robotic systems for applying complex specialized coatings, such as stealth materials or thermal barrier coatings, to aircraft and defense components where thickness variation tolerances are extremely narrow. Finally, smaller enterprises, including local automotive refinish shops and custom furniture makers, represent a large volume of customers for manual and semi-automatic equipment, focusing on ease of use, rapid setup, and cost-effectiveness. The purchasing strategy across all these segments is moving towards integrated solutions where the equipment provider also offers training, process consultation, and ongoing technological upgrades to maintain competitive advantages in manufacturing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.95 Billion |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Graco Inc., Nordson Corporation, Sames Kremlin, Carlisle Companies Inc. (Binks, DeVilbiss), Wagner Group, ABB Ltd., FANUC Corporation, Yaskawa Electric Corporation, Kawasaki Heavy Industries, Durr AG, Gema Switzerland GmbH, Schultz GmbH, Sata GmbH & Co. KG, Ingersoll Rand, Ransburg Corporation, Lesta S.r.l., Euroimpianti S.p.A., Cefla S.p.A., Eisenmann SE, Parker Hannifin Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Painting Machine Market Key Technology Landscape

The technological landscape of the Painting Machine Market is currently dominated by advancements focused on precision control, material efficiency, and seamless integration into smart factory environments (Industry 4.0). One of the most significant technologies is the proliferation of high-precision six-axis and seven-axis articulated robots, often equipped with advanced closed-loop control systems. These robots utilize highly sophisticated software for trajectory planning, allowing them to navigate complex product geometries with minimal waste and maintain precise distance and angle relative to the surface being coated. Furthermore, the shift towards smart nozzle technology, incorporating piezoelectric actuators and precise fluid metering devices, ensures consistent atomization and flow rate, essential for achieving ultra-smooth finishes and efficient consumption of expensive coatings. The incorporation of servo drives and advanced pneumatic systems also contributes to faster cycling times and increased production throughput across automated lines, minimizing bottlenecks in the coating process.

Electrostatic application technology remains a cornerstone, continually evolving to improve transfer efficiency. Modern electrostatic guns are designed to handle high-solids and waterborne coatings, addressing environmental compliance without sacrificing quality. This technology works by electrically charging the atomized paint particles, which are then naturally attracted to the grounded workpiece, minimizing overspray and reducing the amount of paint wasted during the process. The advancement in powder coating systems, including tribo-charging guns and cartridge-based color change systems, allows for faster color shifts and better penetration into complex internal corners (Faraday cage effect areas), making powder coating viable for a wider range of industrial applications beyond traditional metal components. These continuous improvements ensure that the market remains responsive to both productivity demands and sustainability mandates, driving innovation in material handling and curing stages.

The most transformative recent development is the integration of digital technologies, specifically AI, machine vision, and the Internet of Things (IoT). Machine vision systems use high-resolution cameras and 3D scanners to map the exact shape and orientation of the product prior to painting, feeding real-time data to AI algorithms which dynamically adjust the robot’s path and application parameters. IoT sensors embedded throughout the system monitor critical variables such as temperature, humidity, booth pressure, and paint viscosity, transmitting data to cloud platforms for predictive maintenance analysis and process optimization. This data-driven approach allows for condition monitoring, ensuring consistent uptime, and facilitates remote diagnostics and calibration, drastically reducing the reliance on on-site maintenance personnel. The convergence of robotics, fluid dynamics, and intelligent software defines the cutting edge of painting machine technology, enabling unprecedented levels of efficiency and quality control.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market globally, primarily driven by robust economic expansion, massive governmental investment in infrastructure, and the region's status as a global manufacturing hub for automotive, electronics, and consumer goods. China, India, Japan, and South Korea are key contributors. The demand here is dual-natured: high-end robotic systems are utilized in OEM automotive plants, while cost-effective, semi-automatic equipment is highly sought after by the rapidly expanding base of SMEs and construction companies. Stricter environmental regulations in countries like China are also forcing manufacturers to adopt modern, high-efficiency equipment to comply with reduced VOC emission targets, accelerating market uptake.

- North America: This region is characterized by early adoption of highly automated and intelligent painting systems, focusing heavily on integrating Industry 4.0 standards into existing manufacturing infrastructure. The market is mature, emphasizing high-precision applications in aerospace, defense, and high-quality automotive refinishing. Growth is driven primarily by replacement cycles for older equipment, the push toward AI and machine vision integration for defect detection, and specialized coating applications (e.g., lightweight materials coating). Regulatory compliance and worker safety standards significantly influence purchasing decisions, favoring robotic solutions that minimize human exposure to hazardous environments.

- Europe: Europe holds a strong position, driven by stringent quality requirements, particularly in Germany's automotive sector and high-end wood finishing industries in Italy. The market is highly focused on sustainability, leading to strong demand for equipment optimized for powder coatings and waterborne paints. Innovation centers on developing flexible production lines that can quickly switch between different colors and coating chemistries with minimal material waste. Eastern European countries show faster growth rates as manufacturing operations decentralize and new industrial parks adopt automated painting solutions from the outset, aiming for world-class efficiency.

- Latin America (LATAM): The LATAM market, while smaller, is exhibiting steady growth, fueled by infrastructure projects and expanding domestic automotive assembly capabilities, particularly in Mexico and Brazil. Market penetration for advanced robotics is lower compared to North America and Europe, focusing more on mid-range automated spray booth systems and robust, reliable airless spray equipment for construction. Price sensitivity is a key factor, with customers often prioritizing operational simplicity and durability over cutting-edge AI features, although the long-term trend favors gradual automation adoption.

- Middle East & Africa (MEA): Growth in MEA is highly localized and project-driven, tied to major construction initiatives, oil and gas infrastructure, and developing industrial diversification programs, such as Saudi Arabia's Vision 2030. There is strong demand for heavy-duty protective coating systems (often airless or thermal spray) to withstand harsh desert and coastal environments. The market for high-end robotic systems is emerging, concentrated in newly established manufacturing zones and aerospace maintenance facilities. The overall market size remains modest but presents significant future potential based on planned industrial capacity expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Painting Machine Market.- Graco Inc.

- Nordson Corporation

- Sames Kremlin

- Carlisle Companies Inc. (Binks, DeVilbiss)

- Wagner Group

- ABB Ltd.

- FANUC Corporation

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries

- Durr AG

- Gema Switzerland GmbH

- Schultz GmbH

- Sata GmbH & Co. KG

- Ingersoll Rand

- Ransburg Corporation

- Lesta S.r.l.

- Euroimpianti S.p.A.

- Cefla S.p.A.

- Eisenmann SE

- Parker Hannifin Corporation

Frequently Asked Questions

Analyze common user questions about the Painting Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Painting Machine Market?

The Painting Machine Market is projected to grow at a steady Compound Annual Growth Rate (CAGR) of approximately 6.5% during the forecast period from 2026 to 2033, driven primarily by increasing automation in manufacturing and rising demand for quality finishes in the automotive sector.

Which end-use industry is the primary driver of demand for painting machines?

The Automotive and Transportation industry remains the largest end-user segment globally, due to its stringent requirements for flawless, protective, and aesthetic coatings, heavily utilizing advanced robotic and electrophoretic deposition (E-Coat) systems for high-volume production.

How is Artificial Intelligence (AI) impacting the functionality of modern painting machines?

AI impacts functionality by enabling real-time optimization of paint application paths, improving transfer efficiency to reduce material waste, facilitating immediate defect detection via integrated vision systems, and enhancing predictive maintenance capabilities to maximize equipment uptime.

What are the key technological restraints limiting the widespread adoption of robotic painting systems?

The primary technological restraints include the high initial capital investment required for robotic installation, the complexity of integrating sophisticated control software with existing factory infrastructure, and the persistent shortage of highly specialized technicians capable of programming and maintaining these advanced systems.

Which geographical region exhibits the fastest market growth and why?

The Asia Pacific (APAC) region is expected to demonstrate the fastest market growth due to rapid industrialization, expansion of regional manufacturing hubs (especially automotive and electronics), and growing infrastructure investments, alongside increasing regulatory pressure favoring modern, efficient coating technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager