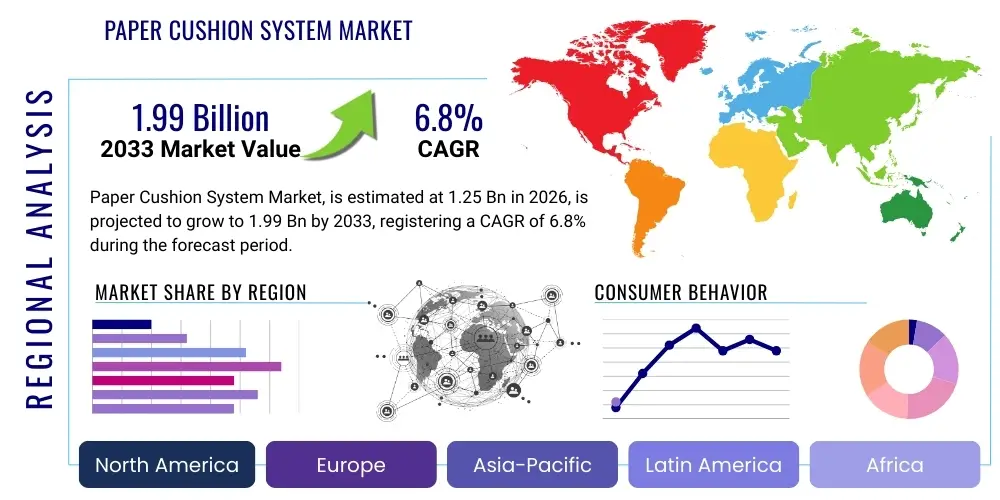

Paper Cushion System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442492 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Paper Cushion System Market Size

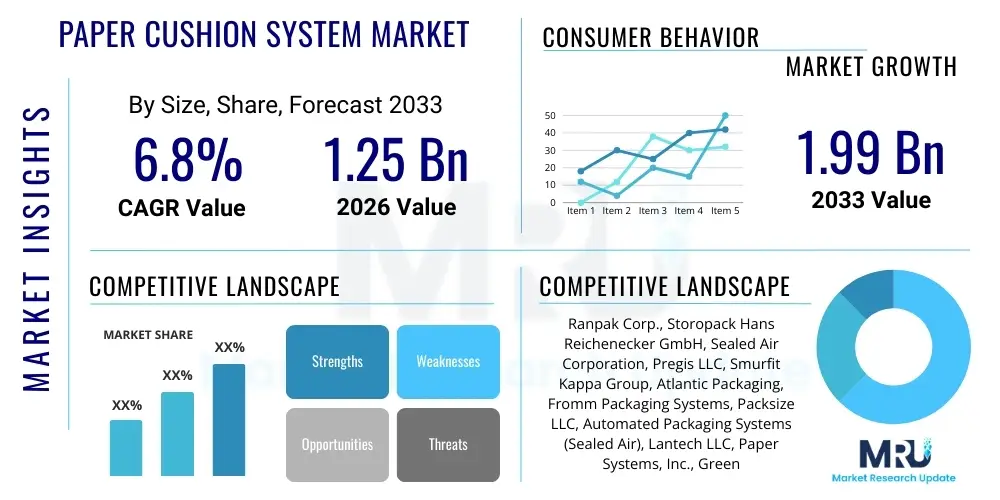

The Paper Cushion System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.99 billion by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by the escalating demand for sustainable, protective packaging solutions across rapidly expanding e-commerce and logistics sectors globally, coupled with stringent environmental regulations mandating reduced reliance on plastic packaging materials. The market expansion reflects significant investments by packaging companies in automated machinery that enhances throughput and minimizes material waste.

Paper Cushion System Market introduction

The Paper Cushion System Market encompasses specialized equipment and consumables designed to convert rolls or bundles of paper into resilient cushioning pads used for void fill, blocking and bracing, and wrapping delicate items within transit packaging. These systems range from compact tabletop units suitable for small-scale operations to fully integrated, high-speed automated machines used in large distribution centers. The core product, the paper cushion, offers superior protection against shock and vibration during shipping, serving as an eco-friendly alternative to traditional foam or plastic-based protective packaging solutions.

Major applications of paper cushion systems span diverse industries, including e-commerce fulfillment, electronics manufacturing, automotive components, medical devices, and industrial machinery parts. The transition towards paper-based protective packaging is accelerated by corporate sustainability mandates and increasing consumer preference for recyclable materials. Key benefits include enhanced product protection, ease of recyclability, reduction in packaging waste volume, and the ability to customize cushioning density and length on demand, leading to significant material optimization and reduction in storage footprint for packaging materials.

Driving factors propelling market growth include the exponential rise of the global e-commerce industry, which necessitates high-volume, reliable protective packaging; growing legislative pressure, particularly in Europe and North America, to transition away from non-recyclable plastics; and continuous technological advancements in paper cushion machinery, offering faster processing speeds, greater reliability, and seamless integration with existing warehouse management systems (WMS). These factors solidify the paper cushion system's position as a critical component in modern logistics and supply chain operations focused on efficiency and environmental responsibility.

Paper Cushion System Market Executive Summary

The Paper Cushion System Market is characterized by robust business trends centered on automation adoption and material innovation, specifically the development of lighter, stronger recycled paper grades optimized for cushioning performance. Market players are heavily investing in modular machine designs that offer scalability and flexibility to e-commerce fulfillment centers facing fluctuating seasonal demand. A key business trend involves strategic mergers and acquisitions aimed at consolidating machinery expertise with raw material supply chains, ensuring consistent quality and cost-effectiveness across the protective packaging ecosystem. The focus remains on Total Cost of Ownership (TCO) reduction for end-users, achieved through minimized material usage and labor efficiency gains provided by high-speed converting equipment.

Regionally, North America and Europe dominate the market due to early adoption of sustainable packaging policies and the mature presence of large e-commerce giants and stringent environmental legislation like the EU Packaging and Packaging Waste Regulation (PPWR). The Asia Pacific region, particularly China and India, represents the fastest-growing segment, driven by rapid urbanization, increasing middle-class consumption, and burgeoning domestic e-commerce markets, though sustainability mandates are evolving at a different pace. Key growth opportunities lie in emerging economies where centralized logistics operations are rapidly replacing traditional manual packing methods, leading to high demand for automated paper cushioning solutions.

Segment trends highlight the dominance of floor-standing, high-throughput systems, reflecting the move towards automation in large warehouses. The end-use segment is led overwhelmingly by e-commerce, which requires versatile void fill and heavy-duty protection for diverse product SKUs. Furthermore, there is a distinct trend towards systems capable of processing specialized paper types, such as multi-ply or honeycomb structures, designed for superior cushioning characteristics required in sectors like automotive or delicate electronics. This focus on specialized performance ensures that paper cushions can replace more robust, yet less sustainable, traditional protective materials in demanding industrial applications.

AI Impact Analysis on Paper Cushion System Market

Common user questions regarding AI's influence on the Paper Cushion System Market primarily revolve around operational efficiency, material optimization, and predictive maintenance. Users frequently ask if AI can reduce material waste by calculating the exact cushioning required per package, how intelligent automation can improve packaging line throughput without increasing labor, and whether AI-driven diagnostics can predict system failures before they impact crucial peak season operations. These inquiries highlight a collective expectation that AI will transition paper cushioning from a standard protective measure to a highly sophisticated, data-driven element of the supply chain, moving beyond simple machine operation to integrated resource management and dynamic packaging specification.

AI's primary impact involves integrating deep learning models with robotic packaging lines to dynamically determine the optimal amount and placement of paper cushioning based on product characteristics (weight, fragility, dimensions) and anticipated transit stresses. This advanced integration dramatically reduces material consumption (geo-optimized for "Paper Cushioning Material Reduction") and ensures compliance with over-packaging mitigation efforts. Predictive maintenance algorithms, powered by machine learning, analyze operational data—such as motor temperature, conversion speed variability, and paper density fluctuations—to alert operators to potential mechanical issues, drastically minimizing unplanned downtime, which is crucial during high-volume e-commerce periods.

Furthermore, AI facilitates the optimization of the entire fulfillment process by connecting the paper cushioning system to the Warehouse Management System (WMS) and ERP software. This connectivity allows for real-time inventory management of paper rolls and dynamic routing of packages to the most efficient cushioning station based on package complexity, thereby enhancing overall supply chain responsiveness and labor efficiency (AEO focus on "Automated Packaging Line Efficiency"). The ultimate outcome is a highly responsive, resource-efficient, and predictive packaging operation that significantly lowers operational expenditure and enhances the sustainability footprint of packaged goods.

- AI-driven optimization of paper consumption based on real-time dimensional scanning and fragility assessment.

- Implementation of predictive maintenance protocols utilizing machine learning to forecast equipment failures and schedule preemptive servicing.

- Integration with WMS for dynamic inventory tracking and automated paper replenishment orders.

- Enhanced quality control through vision systems identifying improper cushioning placement or density issues.

- Optimization of labor allocation by automating complex packaging instructions and minimizing manual adjustments to the cushioning system.

DRO & Impact Forces Of Paper Cushion System Market

The Paper Cushion System Market is primarily driven by the imperative shift towards environmental sustainability, fueled by both consumer demand and legislative mandates targeting single-use plastics. Restraints include the higher perceived initial capital expenditure required for automated machinery compared to manual packing methods, and the ongoing challenge of optimizing paper cushioning density and performance against cheaper, though less eco-friendly, alternatives like traditional bubble wrap or foam peanuts. Significant opportunities lie in developing highly modular, portable systems that cater specifically to the expanding small and medium-sized enterprise (SME) e-commerce sector and in advancing paper technology to achieve cushioning properties comparable to or exceeding plastic foam, suitable for heavy industrial protection.

Key drivers include the global expansion of e-commerce, which mandates scalable and efficient protective packaging; stringent government regulations imposing plastic taxes and recycling targets; and continuous innovation in paper grades offering enhanced strength and lighter weight. These factors create positive momentum, establishing paper cushioning as the preferred protective method. However, the market faces restraints such as fluctuations in raw material (pulp) prices, which affect the cost of consumables, and the potential complexity involved in integrating advanced cushioning machinery into legacy packaging lines without significant overhaul. Overcoming these technical and economic barriers is crucial for broader adoption, particularly in emerging markets where cost sensitivity is higher.

The core impact forces shaping the market are the rapidly evolving consumer preference for green packaging and the competitive pressure among major logistics providers (like Amazon and FedEx) to demonstrate robust sustainability credentials, pushing their suppliers towards paper-based solutions. Opportunities are amplified by the trend toward customized packaging on demand, facilitated by connected machinery capable of precise material dispensing. These forces collectively dictate that future market leadership will belong to companies that can simultaneously offer high performance protection, superior sustainability indexing, and seamless operational integration across diverse fulfillment environments, making efficiency and ecological responsibility mutually reinforcing goals.

Segmentation Analysis

The Paper Cushion System Market is comprehensively segmented based on several critical dimensions, including system type, end-use application, and the type of paper utilized. Analyzing these segments provides a nuanced view of market dynamics, revealing that the demand structure varies significantly across industrial and e-commerce applications. The segmentation by system type—specifically the distinction between desktop/portable units and floor-standing/automated machines—reflects the scale of operations, with large fulfillment centers driving the high-end floor-standing segment due to requirements for continuous, high-speed output. End-use segmentation clearly indicates the e-commerce sector’s overwhelming reliance on these systems for void fill and protection, while industrial segments, such as automotive and electronics, emphasize systems capable of producing heavy-duty, customized blocking and bracing solutions.

The segmentation by paper type, covering recycled paper, virgin paper, and specialized laminated or coated papers, demonstrates a clear industry preference for high-recycled content papers, aligning with overarching sustainability goals. However, virgin paper is still utilized where maximum strength and specific governmental certifications are required, particularly in pharmaceutical or sensitive component packaging. This detailed segmentation allows market participants to tailor their product offerings—whether machinery or consumables—to specific operational needs, maximizing operational efficiency and minimizing material waste for distinct user categories. Understanding these segment behaviors is essential for developing targeted marketing strategies and optimizing supply chain logistics within this increasingly competitive landscape.

- By System Type:

- Floor-Standing (High-Volume Automated)

- Desktop/Portable (Low to Medium Volume)

- Integrated Packaging Line Systems

- By Paper Type:

- Recycled Paper

- Virgin Kraft Paper

- Specialized Coated/Laminated Paper

- By Application:

- Void Fill

- Blocking & Bracing

- Wrapping & Isolation

- By End-Use Industry:

- E-commerce & Logistics

- Electronics & Technology

- Automotive & Heavy Machinery

- Healthcare & Pharmaceuticals

- Cosmetics & Personal Care

Value Chain Analysis For Paper Cushion System Market

The value chain for the Paper Cushion System Market commences with upstream activities centered on raw material procurement, primarily focusing on high-quality paper pulp (virgin or recycled fiber) used for manufacturing the paper rolls. Key players in this stage are large pulp and paper manufacturers who must ensure consistent density, tear resistance, and tensile strength tailored for conversion into cushioning material. Consistency in raw material input directly impacts the performance and reliability of the downstream converting equipment. Suppliers in this phase are increasingly scrutinized for their sustainability practices, favoring those with certified sustainable forestry or robust recycling programs.

Midstream operations involve the manufacturing of the paper cushion machinery (converters) and the conversion of large paper rolls into specific formats suitable for the machines. Machinery manufacturers focus on precision engineering, integrating features like automated cutting, adjustable speed controls, ergonomic design, and connectivity for IoT functionality. Distribution channels for both machinery and consumables are bifurcated: direct sales channels handle large, custom-integrated machine installations for major e-commerce clients, requiring extensive technical support and consultation; while indirect channels, utilizing specialized industrial packaging distributors, serve the vast SME market, offering readily available stock and localized support services.

Downstream activities include the integration of the systems into the end-user's packaging line, training, maintenance, and the final use of the paper cushions in product protection. End-users evaluate systems based on efficiency (packs per minute), ease of operation, minimal maintenance requirements, and the environmental certification of the consumed paper. The increasing importance of reverse logistics and end-of-life management for packaging further emphasizes the recyclability inherent in paper cushioning, reinforcing its value proposition against non-recyclable materials throughout the final stages of the supply chain.

Paper Cushion System Market Potential Customers

Potential customers for the Paper Cushion System Market span a broad spectrum of industries united by the critical need for effective product protection during transit and a growing commitment to sustainable packaging mandates. The primary and most rapidly expanding customer base consists of large-scale e-commerce fulfillment centers and 3PL (Third-Party Logistics) providers. These entities require high-throughput, reliable paper cushioning systems capable of handling massive volumes of diverse product sizes (AEO: "High-Volume E-commerce Protective Packaging Solutions"). Their purchasing decisions are driven by the Total Cost of Ownership, focusing on labor reduction, material optimization, and uptime reliability, making automated, floor-standing systems highly attractive.

Beyond e-commerce, significant demand originates from specialized industrial sectors. The electronics industry, including manufacturers of high-value servers, medical imaging equipment, and delicate consumer electronics, utilizes paper cushioning for blocking, bracing, and shock absorption where precision placement is paramount. Similarly, the automotive spare parts industry relies on heavy-duty paper pads for securing heavy, irregularly shaped components within transport containers. These industrial buyers prioritize robust paper formulations and machine versatility that can handle complex cushioning geometries, often opting for customized, integrated systems designed specifically for their assembly lines.

The market also includes a large segment of small to medium-sized enterprises (SMEs) entering the direct-to-consumer (DTC) market. These smaller entities typically purchase desktop or portable paper cushion systems, valuing ease of use, minimal footprint, and low initial investment. Their focus is often on brand presentation and ensuring product integrity upon arrival, seeking flexible systems that can easily adapt to fluctuating packaging needs without requiring a dedicated packaging engineering team. Targeting this vast SME sector through effective distributor networks and simplified machine interfaces represents a substantial growth opportunity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.99 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ranpak Corp., Storopack Hans Reichenecker GmbH, Sealed Air Corporation, Pregis LLC, Smurfit Kappa Group, Atlantic Packaging, Fromm Packaging Systems, Packsize LLC, Automated Packaging Systems (Sealed Air), Lantech LLC, Paper Systems, Inc., Greenleaf Packaging, Inc., Flexipack S.p.A., Geami Protective Packaging, Wenzhou Jiyou Packaging Equipment Co., Ltd., Cushion-Wrap Systems, Inc., FP International, Pro-Pac Packaging Group, Neenah, Inc., Eltete TPM Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Paper Cushion System Market Key Technology Landscape

The technological evolution of the Paper Cushion System Market is primarily focused on enhancing machine speed, improving material efficiency, and integrating connectivity features (IoT and Industry 4.0 standards). Modern converters employ sophisticated, high-speed mechanisms that can produce cushioning material at rates exceeding 150 feet per minute, minimizing bottlenecks in rapid fulfillment environments. Key advancements include patented folding and crimping technologies designed to maximize the shock-absorbing capacity of the paper while using minimal material, ensuring a superior cushioning-to-weight ratio compared to older systems. Furthermore, automated cutting mechanisms are now highly precise, allowing for variable-length cushions to be generated on demand, reducing waste and providing optimal protection for mixed-SKU shipments.

A crucial technological trend is the adoption of sensor-based automation and smart interfaces. New systems feature touch-screen controls with embedded diagnostics, providing real-time operational data and simplifying troubleshooting for non-technical users. IoT integration enables remote monitoring of machine performance, material consumption rates, and automated alerts for preventative maintenance, crucial for maintaining high uptime in high-volume settings. This connectivity allows large packaging operations to centrally manage a fleet of cushioning systems across multiple facilities, standardizing procedures and optimizing material procurement based on consolidated usage data.

Material science also plays a significant role, with advancements in multi-ply paper composites and specialized die-cut papers that offer enhanced structural integrity and lighter weight. Researchers are focused on developing recycled paper grades that maintain superior tensile strength and memory (the ability to spring back after compression), crucial for long-haul protection. These technological leaps—from hardware automation and software integration to specialized material development—are positioning paper cushioning systems as indispensable components of smart, sustainable, and highly efficient modern packaging lines, capable of handling the demands of next-generation logistics.

Regional Highlights

- North America: This region holds a dominant share, primarily driven by the massive scale of the U.S. e-commerce sector and strong corporate sustainability commitments among major retailers and logistics companies. Regulatory environments, while less centralized than in Europe, strongly favor recyclable solutions. The market is mature, characterized by high adoption rates of fully automated, integrated systems to manage high labor costs and optimize packaging throughput. Innovation often focuses on software integration and AI-driven dispensing optimization.

- Europe: Europe is a key market leader, particularly in regulatory impetus. Strict directives, such as those related to plastic reduction and extended producer responsibility (EPR) schemes, have accelerated the shift from plastic fillers to paper cushioning solutions. Countries like Germany and the Netherlands are at the forefront of adopting high-recycled content packaging. The market growth here is driven by both legislation and a strong consumer preference for ecological products, leading to a high demand for sustainable paper consumables.

- Asia Pacific (APAC): APAC is the fastest-growing region, fueled by the exponential growth of domestic e-commerce markets in China, India, and Southeast Asia. While sustainability concerns are rapidly increasing, initial market drivers are often cost-efficiency and logistics scale. The region exhibits high demand for both automated high-volume systems (for large urban fulfillment centers) and affordable, semi-automatic desktop units (for thousands of emerging small online sellers). Investment in logistics infrastructure and warehouse automation is propelling market expansion.

- Latin America (LATAM): Growth in LATAM is steady, driven by improving logistics infrastructure and the expansion of international e-commerce platforms into the region. Brazil and Mexico are leading markets, where paper cushioning systems address the need for reliable protection against challenging transit conditions. Market adoption is currently focused on mid-range, flexible systems that offer a balance between investment cost and operational efficiency.

- Middle East and Africa (MEA): This region is an emerging market, with adoption concentrated in key logistics hubs like the UAE and Saudi Arabia. Market growth is spurred by large-scale infrastructure projects and diversification away from oil economies, leading to investment in modern logistics and retail sectors. Sustainability is gaining importance, but the primary drivers remain product protection reliability and the professionalization of supply chain operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Paper Cushion System Market.- Ranpak Corp.

- Storopack Hans Reichenecker GmbH

- Sealed Air Corporation

- Pregis LLC

- Smurfit Kappa Group

- Atlantic Packaging

- Fromm Packaging Systems

- Packsize LLC

- Automated Packaging Systems (Sealed Air)

- Lantech LLC

- Paper Systems, Inc.

- Greenleaf Packaging, Inc.

- Flexipack S.p.A.

- Geami Protective Packaging

- Wenzhou Jiyou Packaging Equipment Co., Ltd.

- Cushion-Wrap Systems, Inc.

- FP International

- Pro-Pac Packaging Group

- Neenah, Inc.

- Eltete TPM Ltd.

Frequently Asked Questions

Analyze common user questions about the Paper Cushion System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Paper Cushion System Market?

The predominant driver is the global regulatory shift away from single-use plastics coupled with the exponential expansion of the e-commerce sector. Paper cushions offer a highly recyclable, effective void-fill and protective packaging solution that aligns with corporate and consumer sustainability goals, directly replacing plastic-based protective materials.

How do automated paper cushion systems compare to traditional protective packaging in terms of Total Cost of Ownership (TCO)?

While automated paper cushion systems have a higher initial capital cost than manual methods or plastic fillers, their TCO is often lower over time due to significant reductions in labor costs, optimization of material usage via automated dispensing, and lower storage space requirements for compressed paper rolls compared to bulky foam or loose-fill materials.

Which end-use industry represents the largest segment for paper cushioning technology?

The E-commerce and Logistics industry is the largest end-user segment. E-commerce platforms require scalable, efficient, and versatile cushioning solutions to protect a vast array of product shapes and weights during high-volume shipping, making paper cushion systems indispensable for reliable fulfillment operations.

What technological advancements are enhancing the performance and efficiency of paper cushion converters?

Key technological advancements include the integration of IoT for remote diagnostics and monitoring, AI-driven material dispensing algorithms to minimize waste, and high-speed folding mechanisms capable of producing cushions at over 150 feet per minute, significantly improving packaging line throughput and operational efficiency.

Is paper cushioning effective for protecting heavy or highly fragile industrial components?

Yes, modern paper cushion systems utilize specialized multi-ply and high-density kraft papers combined with advanced crimping techniques to create robust, shock-absorbing pads suitable for blocking and bracing heavy industrial components, automotive parts, and sensitive electronics, offering performance comparable to dense foam while maintaining recyclability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager