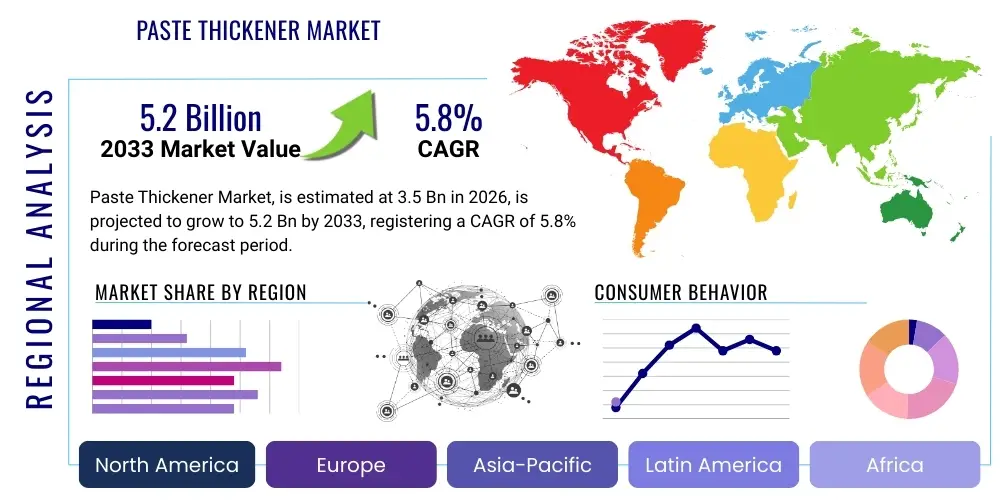

Paste Thickener Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442691 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Paste Thickener Market Size

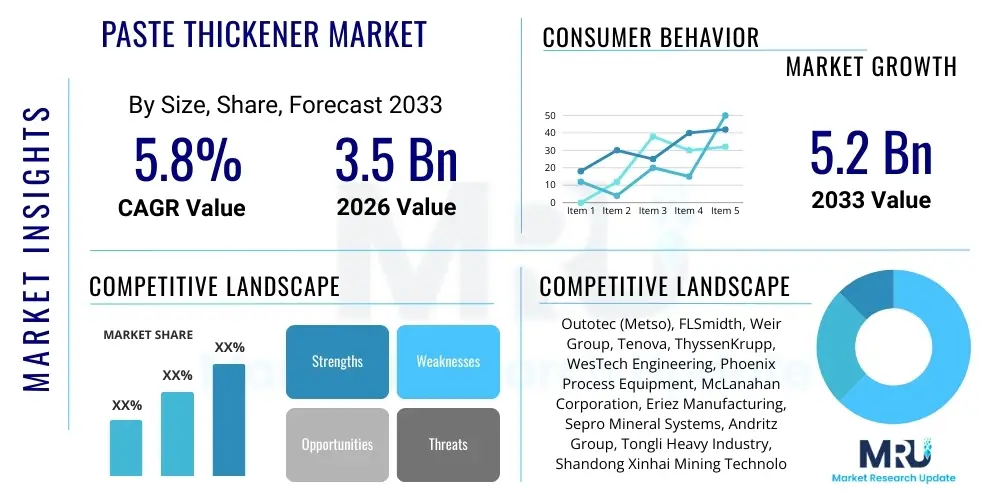

The Paste Thickener Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by the escalating demand for sustainable tailings management solutions across the global mining industry, coupled with increasingly stringent environmental regulations regarding water usage and waste disposal. Paste thickeners offer a critical solution by maximizing water recovery and producing a non-segregating, high-density underflow material suitable for safe and cost-effective surface disposal or backfilling operations.

The valuation reflects robust investment in infrastructure and mineral processing capacity, particularly in regions rich in base metals and precious minerals, where older conventional thickening methods are being phased out due to inefficiency and high environmental risk. Technological advancements leading to ultra-high-rate thickeners and deep cone designs are also contributing significantly to market expansion, allowing operators to achieve higher solid concentrations with smaller physical footprints. Furthermore, the imperative for operational efficiency, especially in remote or water-scarce mining environments, solidifies the market position of paste thickening technologies as essential capital equipment.

Paste Thickener Market introduction

Paste thickeners are sophisticated solid-liquid separation units designed to produce a non-settling, high-density suspension—or 'paste'—from a slurry, typically found in mineral processing and industrial wastewater treatment. These machines differentiate themselves from conventional clarifiers and high-rate thickeners by operating at higher solid concentrations, often achieving a yield stress in the underflow, which prevents segregation and significantly reduces the volume of tailings requiring disposal. The core application of paste thickeners lies predominantly within the mining sector, where they are vital for effective tailings dewatering, maximizing process water recovery, and creating environmentally stable tailings stacks that minimize geotechnical risk and water pollution.

The primary benefit of deploying paste thickening technology includes substantial reduction in overall water consumption, which is increasingly critical in global operations. By recovering up to 90% of process water, thickeners enable closed-loop water systems, lowering operational expenditure and improving environmental compliance. Major applications span across processing various ores, including copper, gold, iron ore, and bauxite, as well as industrial processes like alumina refining and chemical production where high-density solids separation is paramount. Driving factors for market growth include the global shift towards dry stacking of tailings, the exploration of lower-grade ores requiring increased processing efficiency, and stringent governmental mandates focused on sustainable resource management and dam safety.

Paste Thickener Market Executive Summary

The Paste Thickener Market is characterized by strong business trends focusing on innovation in automation, digitalization, and integration into overall plant control systems. Key players are heavily investing in deep cone thickener designs and flocculant optimization technologies to enhance performance and throughput efficiency, directly addressing the mining industry's need for higher capacity processing of finer materials. Regional trends show robust demand growth centered in Asia Pacific (APAC) due to massive mining operations in countries like Australia and China, coupled with significant modernization of existing facilities in Latin America, particularly in Chile and Peru, driven by copper and lithium extraction activities. Europe and North America demonstrate steady, mature growth, focusing primarily on replacement cycles, efficiency upgrades, and advanced environmental compliance solutions, particularly regarding legacy mine site remediation.

Segmentation trends indicate that the Deep Cone Thickener segment is experiencing the fastest expansion due to its superior performance in achieving high-density underflow and better water recovery compared to conventional models. Application-wise, the mining and mineral processing sector remains the dominant revenue generator, but the industrial wastewater treatment segment is emerging as a critical growth area, propelled by global urbanization and increased industrial discharges requiring advanced solid separation before release. Furthermore, the market exhibits a clear preference for specialized, heavy-duty thickeners capable of handling high tonnages and challenging slurry characteristics, pushing manufacturers toward offering comprehensive service contracts and performance guarantees.

AI Impact Analysis on Paste Thickener Market

User inquiries regarding AI's influence on the Paste Thickener Market primarily revolve around operational efficiency, predictive maintenance, and optimization of chemical dosing. Users seek to understand how machine learning algorithms can analyze real-time slurry characteristics (such as density, viscosity, and particle size distribution) and automatically adjust flocculant dosage and underflow pump rates, thereby maximizing water recovery and paste stability while minimizing chemical consumption. Key concerns include the complexity of integrating AI systems with existing legacy infrastructure and ensuring the reliability of predictive models in highly variable operational environments. Expectations are high for AI to deliver significant cost reductions through proactive failure prediction and substantial improvements in final paste quality and consistency, directly impacting tailings dam stability and overall safety.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast equipment failure (e.g., rake mechanism wear, pump issues), reducing unplanned downtime.

- Flocculant Dosage Optimization: Machine learning models analyzing slurry feed quality in real-time to precisely adjust polymer dosage, resulting in chemical cost savings and superior settling rates.

- Process Control and Automation: AI integration for adaptive control loops that optimize underflow density and rake torque, maintaining consistent paste characteristics despite feed fluctuations.

- Operational Efficiency Enhancement: Data analytics identifying bottlenecks and inefficiencies in the thickening circuit, leading to throughput maximization.

- Digital Twin Simulation: Creation of virtual models for paste thickeners to simulate different operational scenarios and training environments, improving operator decision-making.

DRO & Impact Forces Of Paste Thickener Market

The Paste Thickener Market is significantly influenced by a confluence of accelerating drivers and persistent restraints, creating a dynamic operational landscape, underpinned by substantial opportunities for growth. Key drivers include the global mining industry’s urgent need for water conservation technologies, driven by regulatory pressures and water scarcity in major mining jurisdictions. The increasing adoption of paste fill and dry stack tailings methods, recognized globally as safer alternatives to conventional wet tailings ponds, mandates the use of highly efficient paste thickeners. Conversely, restraints predominantly involve the high initial capital expenditure associated with purchasing and installing large-scale thickener equipment, along with the ongoing operational cost of flocculants, which can be substantial and highly sensitive to polymer market fluctuations. The necessity for highly skilled personnel to operate and maintain these complex systems also poses a challenge in remote locations.

Opportunities for expansion lie in the burgeoning demand from the lithium and critical mineral processing sectors, where efficient dewatering is vital for downstream processing and battery material production. Furthermore, the deployment of modular and mobile paste thickening units presents an opportunity to serve smaller mines or those with short operational lifespans, offering flexibility and reduced upfront costs. The market is also heavily shaped by impact forces such as stringent environmental, social, and governance (ESG) standards, which compel mining companies to prioritize low-risk, low-water-usage technologies. Regulatory shifts, particularly tightening global tailings standards following major dam failures, are forcing immediate adoption and retrofitting of existing facilities with advanced paste thickening solutions to ensure compliance and social license to operate.

Segmentation Analysis

The Paste Thickener Market segmentation provides a granular view of the industry, differentiating it based on technology, application, and geographical regions. Understanding these segments is crucial for strategic planning, as different end-user industries require distinct thickener designs and operational characteristics. Technological segmentation is driven by the performance characteristics, such as the ability to achieve ultra-high density underflow and high throughput rates, which directly impact project viability. Application segmentation highlights the diverse utilization across heavy industries, with mineral processing dominating the market share due to the sheer volume of material processed, while niche segments like food processing and specialized chemical manufacturing offer steady, specialized demand. The growing focus on environmental sustainability heavily influences the development and uptake within each segment.

Market segmentation allows suppliers to tailor their product offerings, focusing on specific performance metrics critical to the target sector. For instance, thickeners designed for iron ore tailings prioritize robustness and high capacity, whereas those for municipal sludge treatment focus more on compactness and automation. This targeted approach ensures that advancements in flocculant mixing systems and rake lifting mechanisms are optimized for the intended use. The analysis of these segments also highlights areas of rapid innovation, such as the increasing integration of sensor technology and data analytics into the thickener control systems across all major end-user industries.

- By Type:

- Deep Cone Thickener (DCT)

- High-Rate Paste Thickener (HRPT)

- Ultra-High Density Thickener (UHDT)

- Inclined Plate/Lamella Thickener

- Conventional Thickener (used in high-solids applications)

- By Mechanism:

- Hydraulic Rake Lift

- Mechanical Rake Lift

- By Application:

- Mining and Mineral Processing (Copper, Gold, Iron Ore, Bauxite, Coal, Base Metals)

- Chemical Processing and Manufacturing (Alumina, Pigments)

- Industrial Wastewater Treatment

- Aggregate and Construction Materials

- Food & Beverage Processing

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Paste Thickener Market

The value chain for the Paste Thickener Market begins with upstream activities involving the sourcing of high-grade raw materials, primarily structural steel, advanced ceramics, high-performance polymers, and precision mechanical components such as gearbox assemblies and hydraulic systems. Key players in this stage are specialized metal suppliers and engineering firms that provide proprietary designs for critical components like rake arms and feed wells. Efficiency in the upstream stage is paramount, as the integrity and longevity of thickener units, which operate in highly abrasive and corrosive environments, depend heavily on the quality and metallurgy of these sourced materials. Strategic partnerships with reliable component suppliers are crucial for manufacturers to maintain competitive pricing and ensure robust product quality, minimizing warranty claims and maximizing system uptime for the end-user.

The midstream involves the design, manufacturing, assembly, and rigorous testing of the thickener units. This stage is dominated by specialized OEMs (Original Equipment Manufacturers) who possess the intellectual property related to proprietary thickener designs, flocculant mixing technology, and automated control systems. Differentiation here is achieved through innovative designs that reduce footprint (Deep Cone Technology), enhance settling rates (High-Rate designs), and improve automation capability (Smart Thickeners). The distribution channel encompasses a combination of direct sales from the OEM to large-scale mining houses or EPC (Engineering, Procurement, and Construction) firms, and indirect sales through specialized regional distributors or service agents who handle installation, commissioning, and aftermarket support. The complexity and high value of the equipment typically necessitate a strong direct relationship between the manufacturer and the major client.

Downstream activities center on installation, commissioning, operations, and critically, comprehensive aftermarket services. End-users rely heavily on ongoing technical support, spare parts availability, and performance optimization services, especially regarding flocculant management and process control calibration. The lifecycle service segment, including retrofitting and modernization of older thickener installations, represents a significant revenue stream for OEMs. Direct distribution channels are generally favored for major capital projects to ensure seamless integration and technical expertise transfer, while indirect channels are effective for routine maintenance supplies and smaller installations in geographically diverse markets.

Paste Thickener Market Potential Customers

The primary end-users and potential customers of paste thickening technology are large-scale mining corporations and mineral processors operating high-tonnage facilities across various commodity sectors. These entities are driven by the imperative to manage vast volumes of tailings safely and recover maximum process water. Mining companies involved in extracting base metals (copper, nickel), precious metals (gold, silver), bulk commodities (iron ore, bauxite), and critical minerals (lithium, rare earth elements) represent the largest consumer base, as efficient dewatering directly impacts their operational license and environmental compliance status. These companies frequently invest in multi-million dollar thickening circuits as part of new mine development or major plant expansions.

Secondary, yet rapidly growing, customer segments include chemical manufacturing plants, particularly those involved in alumina production, titanium dioxide (pigment) manufacturing, and fertilizer production, where solid-liquid separation of high-concentration slurries is integral to the product yield and purity. Furthermore, municipal and industrial wastewater treatment facilities are increasingly adopting paste thickening principles, especially for sludge dewatering, before disposal or incineration. These customers seek solutions that minimize waste volume and meet increasingly stringent discharge regulations. Procurement decisions among these diverse groups are heavily influenced by performance guarantees, total cost of ownership (TCO), and the supplier’s proven track record in demanding industrial environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Outotec (Metso), FLSmidth, Weir Group, Tenova, ThyssenKrupp, WesTech Engineering, Phoenix Process Equipment, McLanahan Corporation, Eriez Manufacturing, Sepro Mineral Systems, Andritz Group, Tongli Heavy Industry, Shandong Xinhai Mining Technology, Tega Industries, Multotec Group, Metso Outotec, TechnipFMC, Komatsu Ltd., Hitachi Construction Machinery, CITIC Heavy Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Paste Thickener Market Key Technology Landscape

The technology landscape of the Paste Thickener Market is characterized by continuous innovation aimed at increasing solid concentration, reducing flocculant consumption, and enhancing automation for operational stability. Key advancements are concentrated in Deep Cone Thickener (DCT) designs, which utilize steep-sided tanks and high-efficiency feed wells to maximize residence time and gravitational settling, reliably producing underflow concentrations exceeding 60% solids by weight, often exhibiting yield stress properties essential for paste applications. Furthermore, the integration of advanced feed well technology, employing specialized mixing and dilution zones, is crucial for optimizing the interaction between the slurry particles and flocculants, ensuring rapid settling and reduced polymer dosage, directly addressing one of the major operational cost factors.

A significant technological focus is placed on monitoring and control systems. Modern paste thickeners incorporate sophisticated sensor arrays—including densitometers, turbidity meters, and torque sensors—to provide real-time data on process variables. This data feeds into advanced PLC (Programmable Logic Controller) systems and specialized control algorithms that automate rake adjustments and underflow pump speeds. The development of Ultra-High Density Thickener (UHDT) systems represents the cutting edge, designed for extremely fine tailings where water recovery requirements are maximized, often exceeding 70% solids concentration. These systems rely on precise control over shear rates within the thickening zone to prevent floc breakage and achieve maximal compaction, moving the technology closer to fully integrated dry stacking preparation.

The emerging trend involves the deployment of modular and mobile thickener units, particularly beneficial for small-scale operations, pilot projects, or mines transitioning through different ore bodies. These modular units offer accelerated deployment timelines and relocation flexibility, significantly lowering the initial capital outlay compared to traditionally constructed thickener installations. Overall, the technological trajectory points toward smarter, more efficient units that minimize environmental footprint, maximize water recycling capabilities, and offer seamless integration with digital plant management systems, aligning with Industry 4.0 principles.

Regional Highlights

Geographical dynamics play a critical role in shaping the Paste Thickener Market, reflecting regional variations in mining activity, water scarcity levels, and regulatory environments. The Asia Pacific (APAC) region is projected to dominate the market share and exhibit the highest growth rate during the forecast period. This dominance is attributed to massive mining sectors in Australia, China, and Indonesia, which are undertaking significant expansions and modernizations, particularly in iron ore, copper, and coal processing. Strict environmental mandates in China regarding tailings safety and water usage are accelerating the adoption of paste thickening technology across existing and new mine sites. Furthermore, Australia’s dry climate makes water recovery a paramount operational objective, driving demand for high-efficiency deep cone thickeners.

Latin America represents another powerhouse region, primarily driven by copper, gold, and increasingly, lithium extraction in Chile, Peru, and Argentina. These countries possess some of the world's largest metal reserves and face acute water stress, necessitating the immediate implementation of advanced dewatering solutions. Governments in this region are actively enforcing tighter environmental standards, making paste thickening not just an efficiency choice, but a regulatory necessity, especially for new mega-projects. North America and Europe, while representing mature markets, show steady demand focused on technological upgrades, replacing aging conventional thickeners with high-rate and deep cone variants to improve energy efficiency and meet evolving disposal requirements, especially related to mine closure and remediation projects.

- Asia Pacific (APAC): Highest growth market driven by large-scale mining operations in Australia and China; strong focus on water management and environmental compliance in resource-intensive sectors.

- Latin America: Major hub for copper, gold, and lithium; rapid adoption forced by severe regional water scarcity and stringent governmental tailings regulations in countries like Chile and Peru.

- North America: Mature market focused on technology replacement cycles, enhancing existing infrastructure efficiency, and implementing paste fill for safer underground mining operations.

- Europe: Demand largely stable, focused on industrial mineral processing (e.g., bauxite/alumina) and sophisticated municipal sludge treatment; emphasis on automation and minimizing energy consumption.

- Middle East & Africa (MEA): Emerging market driven by phosphate, gold, and bauxite mining; growth tied to investment in new processing capacity and the need for water solutions in arid environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Paste Thickener Market.- Outotec (Metso)

- FLSmidth

- Weir Group

- Tenova

- ThyssenKrupp

- WesTech Engineering

- Phoenix Process Equipment

- McLanahan Corporation

- Eriez Manufacturing

- Sepro Mineral Systems

- Andritz Group

- Tongli Heavy Industry

- Shandong Xinhai Mining Technology

- Tega Industries

- Multotec Group

- Metso Outotec

- TechnipFMC

- Komatsu Ltd.

- Hitachi Construction Machinery

- CITIC Heavy Industries

Frequently Asked Questions

Analyze common user questions about the Paste Thickener market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a Deep Cone Thickener (DCT) over a conventional thickener?

The primary advantage of a Deep Cone Thickener (DCT) is its ability to generate high-density, non-segregating underflow (paste) with a measurable yield stress, which is essential for dry stacking or paste backfilling. This is achieved through its deep sidewalls and steep cone design, maximizing solids retention time and compaction, thereby significantly increasing water recovery and reducing tailings volume compared to conventional models.

Which application segment drives the highest demand in the Paste Thickener Market globally?

The Mining and Mineral Processing segment dominates the Paste Thickener Market. Specifically, large-scale operations involving copper, iron ore, and gold require high-volume, continuous solid-liquid separation to manage tailings safely and maximize the recycling of precious process water, which is critical for operational sustainability and regulatory compliance.

How do stringent ESG standards impact the future growth of the Paste Thickener Market?

Stringent Environmental, Social, and Governance (ESG) standards, especially post-disaster regulations concerning tailings dam safety, are the strongest growth catalysts. These standards mandate the shift from traditional wet tailings disposal to safer methods like paste filling and dry stacking, directly increasing the mandatory adoption and investment in high-efficiency paste thickening technology globally.

What is the biggest operational challenge associated with running paste thickeners?

The biggest operational challenge is the optimization and management of flocculant dosage. Flocculants are a significant operating expense, and achieving optimal paste quality requires continuous, precise adjustment based on variable feed slurry conditions. Incorrect dosing leads to poor settling, reduced water clarity, or insufficient underflow density, compromising safety and efficiency.

In which region is the highest CAGR expected for paste thickeners and why?

The Asia Pacific (APAC) region is expected to demonstrate the highest Compound Annual Growth Rate (CAGR). This is due to massive ongoing investments in mining expansion projects, mandatory environmental upgrades across key resource sectors in countries like China and Australia, and the escalating demand for sustainable water management practices in water-scarce mining areas.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager