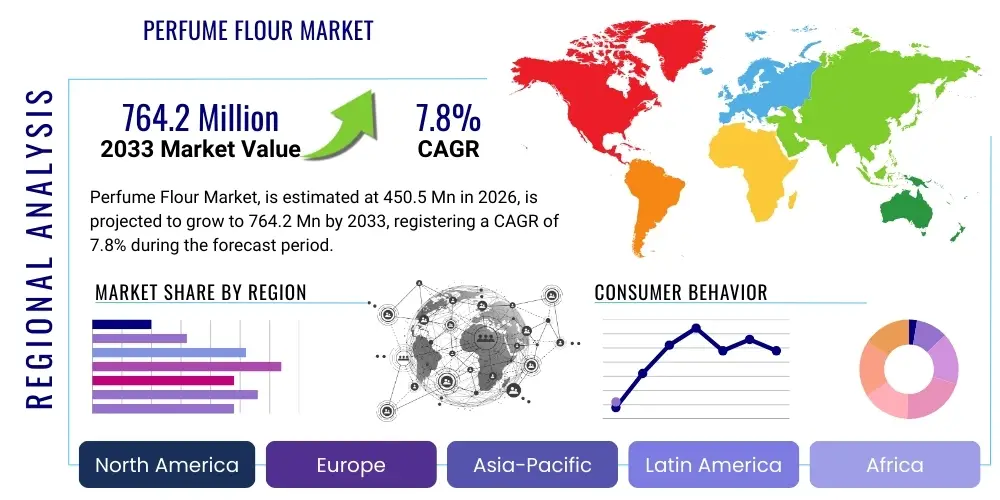

Perfume Flour Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442323 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Perfume Flour Market Size

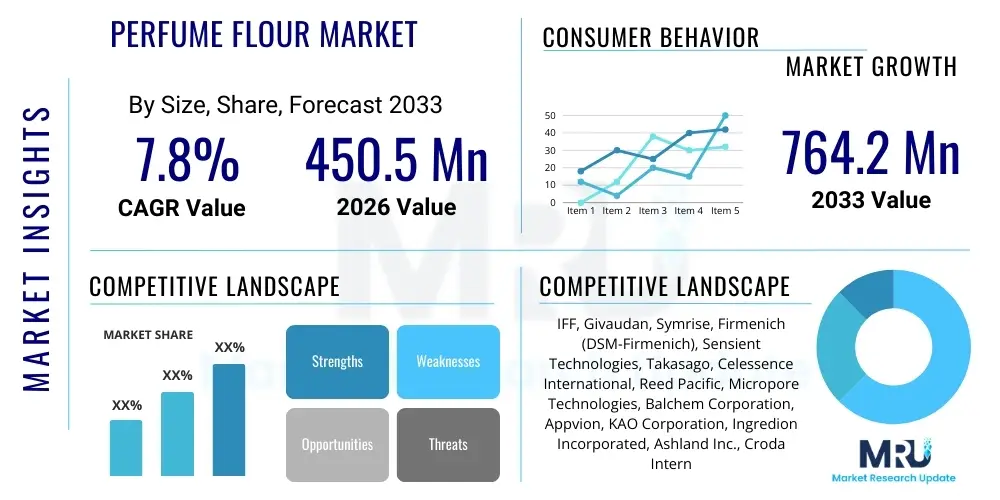

The Perfume Flour Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 764.2 Million by the end of the forecast period in 2033. This substantial growth is primarily driven by the increasing consumer demand for differentiated fragrance experiences, particularly in household and personal care products, where prolonged scent longevity and consistent release profiles are highly valued. Perfume flour, utilizing advanced microencapsulation and porous carrier technologies, offers superior performance compared to traditional liquid or granular fragrance systems, positioning it as a key disruptive ingredient in the specialty chemicals sector.

Perfume Flour Market introduction

The Perfume Flour Market encompasses the production, distribution, and application of fine, pulverized, and often encapsulated fragrance carrier particles designed for sustained scent delivery across various consumer and industrial products. These specialized powders, frequently based on starch, silica, or advanced polymer matrices, offer superior thermal stability and controlled release mechanisms, addressing the historical challenge of fragrance volatility and degradation in end-use matrices. Product descriptions typically highlight attributes such as micron size uniformity, high fragrance load capacity, and compatibility with complex formulations, making them indispensable for premium product lines seeking a competitive edge through sensory enhancement.

Major applications for Perfume Flour span personal care (deodorants, talcum powders, cosmetics), household products (detergents, fabric softeners, air care systems), and specialty applications such as polymer masterbatches for scented plastics and luxury packaging inserts. The primary benefit derived from using Perfume Flour is the significantly extended duration of scent perception, known as 'sillage' or 'bloom,' which enhances consumer satisfaction and product differentiation. Furthermore, the inherent stability allows manufacturers greater flexibility in processing and storage, reducing losses associated with volatile organic compounds (VOCs).

Driving factors stimulating the market include rising disposable incomes globally, leading to increased consumer spending on premium and aesthetically pleasing products, particularly in emerging economies of the Asia Pacific region. Regulatory pressures demanding lower VOC content in consumer goods also favor encapsulated powdered delivery systems over traditional solvents. Continuous innovation in materials science, particularly in developing bio-based and sustainable encapsulation materials, is further propelling adoption across environmentally conscious industries, establishing Perfume Flour as a critical component in future fragrance technology.

Perfume Flour Market Executive Summary

The Perfume Flour Market is characterized by robust commercial trends, dominated by a shift toward sustainable and high-performance fragrance carriers, notably driven by demand from the laundry and personal hygiene sectors. Business trends indicate aggressive merger and acquisition activity among specialty chemical suppliers aiming to consolidate technological expertise in microencapsulation and expand geographical reach, particularly into high-growth markets like India and China. Manufacturers are also focusing on forward integration strategies, partnering directly with major Fast-Moving Consumer Goods (FMCG) corporations to secure long-term supply agreements and tailor formulations to specific product lines, thereby minimizing generic competition and maximizing intellectual property value.

Regionally, Asia Pacific maintains the highest growth momentum due to its rapidly expanding population, increasing urbanization, and subsequent surge in demand for sophisticated consumer goods, alongside the localized establishment of advanced manufacturing capabilities. North America and Europe, while representing mature markets, exhibit strong demand for premium and hypoallergenic perfume flour formulations, driven by stringent consumer safety standards and a preference for natural, traceable ingredients. Latin America and the Middle East & Africa are emerging as pivotal markets, fueled by infrastructure development in manufacturing and rising adoption rates of modern household care practices.

Segmentation trends highlight the dominance of polymer-based encapsulation technologies due to their superior release kinetics and durability under harsh conditions, though silica and starch-based carriers are gaining traction in cost-sensitive and natural/organic product categories. Application-wise, the Household Care segment, particularly laundry detergents and fabric conditioners, consumes the largest volume of Perfume Flour, capitalizing on the need for long-lasting freshness signals. However, the Cosmetics and Personal Care segment is projected to record the fastest growth, primarily due to innovation in sensory marketing and functional cosmetic ingredients that require stable fragrance components.

AI Impact Analysis on Perfume Flour Market

Common user questions regarding AI's impact on the Perfume Flour Market center around personalized scent creation, predictive supply chain management, and optimizing the physical characteristics of the flour itself. Users frequently inquire about how AI can analyze complex sensory data (e.g., consumer preference by demographic and region) to design novel fragrance profiles specifically suited for encapsulation, minimizing waste during R&D. Furthermore, there is significant interest in using machine learning algorithms to fine-tune production processes, such as particle size distribution and fragrance load efficiency, thereby enhancing product consistency and reducing batch variation. Users also seek clarity on AI's role in detecting and responding to real-time shifts in raw material costs and availability, particularly for specialized carrier polymers or rare natural fragrance components, ensuring robust supply chains. The collective analysis suggests a high expectation for AI to drive efficiency, personalization, and material innovation within the production and application of Perfume Flour.

- AI-driven optimization of microencapsulation parameters (e.g., wall thickness, core material ratio) to ensure predictable release profiles and maximize fragrance lifespan.

- Predictive modeling of consumer scent preferences and regional fragrance trends, accelerating R&D cycles for new Perfume Flour formulations.

- Automated quality control systems utilizing computer vision and machine learning for real-time monitoring of particle uniformity and defect detection during manufacturing.

- Supply chain risk assessment and optimization, enabling dynamic sourcing strategies for specialized raw materials (carrier components and essential oils).

- Development of AI-powered formulation tools that recommend optimal Perfume Flour types for specific end-product matrices (e.g., high pH detergents vs. anhydrous cosmetics).

DRO & Impact Forces Of Perfume Flour Market

The dynamics of the Perfume Flour Market are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and potent Impact Forces. Key drivers include the escalating consumer demand for premium, long-lasting functional fragrances, particularly in fabric care and air care, coupled with technological advancements in advanced encapsulation techniques that offer superior performance and stability. Restraints primarily involve the high initial capital investment required for specialized milling and microencapsulation equipment, alongside increasing scrutiny over the environmental impact and biodegradability of synthetic polymer carriers, necessitating shifts toward sustainable alternatives. Significant opportunities emerge from the unexplored application potential in industrial sectors, such as scent-based marketing materials and advanced odor neutralization systems, especially in developing eco-friendly and natural fragrance delivery systems.

Impact forces currently exerting pressure on the market involve intense competition from established chemical giants and specialized fragrance houses, driving continuous price pressure and requiring perpetual innovation to maintain market share. Regulatory changes, such as stricter chemical registration requirements (e.g., REACH in Europe) and evolving definitions of 'natural' ingredients, mandate expensive compliance updates and formulation adjustments. Furthermore, fluctuations in the global supply chain for key petrochemical raw materials, exacerbated by geopolitical instability, introduce volatility in production costs, requiring robust hedging strategies and diversified sourcing protocols across the industry.

The balance between meeting consumer desires for intense, persistent fragrance experiences and addressing ecological mandates for safe, biodegradable ingredients forms the core operational challenge. Companies that successfully navigate these constraints by investing in green chemistry and optimizing production scale will capture significant market share, leveraging the global trend toward sensory value addition in everyday consumer staples.

Segmentation Analysis

The Perfume Flour Market is comprehensively segmented based on the type of encapsulation technology utilized, the nature of the carrier material, the specific application of the final product, and the geographical region. This detailed segmentation allows stakeholders to accurately identify core revenue streams, target specific industrial niches, and tailor product development strategies to meet differentiated end-user requirements. Understanding the interaction between these segments is crucial, particularly the interplay between carrier material selection (which affects cost and sustainability) and the target application (which dictates performance metrics like thermal stability and release kinetics).

- By Encapsulation Technology:

- Coacervation (Complex and Simple)

- Spray Drying/Chilling

- In-situ Polymerization

- Fluidized Bed Coating

- By Carrier Material:

- Polymer-based (e.g., Melamine-Formaldehyde, Polyurea)

- Starch and Cellulose Derivatives

- Silica and Zeolites

- Protein-based (Gelatin, Soy)

- By Application:

- Household Care (Laundry Care, Surface Cleaners, Air Care)

- Personal Care and Cosmetics (Deodorants, Talcum Powder, Makeup)

- Textiles and Apparel (Functional Finishes, Specialty Coatings)

- Industrial and Specialty (Plastic Masterbatches, Printing Inks)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Perfume Flour Market

The value chain for the Perfume Flour Market begins with upstream activities involving the sourcing of two primary components: fragrance raw materials (natural essential oils or synthetic aroma chemicals) and carrier raw materials (polymers, starches, or silica precursors). Upstream suppliers are characterized by specialized chemical synthesis capabilities and often face volatility in commodity pricing, necessitating long-term procurement contracts. Key considerations at this stage include the purity of aroma chemicals and the consistency of polymer matrices, which directly influence the final product's stability and fragrance load capacity. The intermediate stage involves the core manufacturing process, which is highly capital-intensive, focusing on precision milling, blending, and the final encapsulation process (e.g., spray drying or coacervation) to create the finalized Perfume Flour product with defined particle size and fragrance release characteristics.

The downstream analysis focuses on the distribution and integration of Perfume Flour into consumer end-products. Distribution channels are typically specialized, involving direct sales to large-scale FMCG manufacturers and specialty distributors for smaller, localized producers. Direct distribution is common for high-volume, proprietary formulations, allowing close technical collaboration between the Perfume Flour producer and the end-product formulator (e.g., a major detergent company). Indirect channels rely on regional chemical distributors who manage inventory and provide technical support to a diverse clientele across various application sectors, particularly in emerging markets where direct sales presence is limited.

The value addition occurs significantly at the manufacturing level through intellectual property surrounding the encapsulation technology and at the application level through successful integration into consumer products. Achieving optimal compatibility with detergents, plastic resins, or cosmetic bases requires extensive testing and technical expertise, making technical service a crucial competitive differentiator. Efficiency gains throughout the chain are targeted by vertical integration, where fragrance houses acquire encapsulation technology providers to offer a complete, bundled solution, simplifying procurement for FMCG customers and maximizing control over quality and innovation cycles.

Perfume Flour Market Potential Customers

Potential customers and end-users of Perfume Flour are primarily concentrated within the Fast-Moving Consumer Goods (FMCG) industry, seeking to enhance product efficacy, longevity, and sensory appeal. The largest segment of buyers includes global and regional manufacturers of laundry and fabric care products, such as powdered and liquid detergents, fabric softeners, and in-wash scent boosters, where the long-lasting fragrance delivery offered by Perfume Flour is a core marketing claim and consumer expectation. These large corporations require high-volume, cost-effective, and highly stable formulations that can withstand the rigorous conditions of washing cycles and extended shelf life.

Another critical customer base resides in the Personal Care and Cosmetics industry, including manufacturers of body powders, foot sprays, anhydrous cosmetic bases, and specialized deodorants. In this sector, the finely milled, non-clumping characteristics of Perfume Flour are highly valued, offering smooth application and consistent scent release without compromising skin feel or product texture. Furthermore, manufacturers of specialty materials, such as automotive interior components or packaging materials that require integrated, permanent scent branding, represent a niche but rapidly growing end-user segment demanding specialized polymer-compatible Perfume Flour grades.

The purchasing decisions of these end-users are driven by factors beyond just cost, heavily weighing technical performance metrics such as encapsulation efficiency, fragrance retention rates over time, release triggers (e.g., friction, moisture), and compliance with regional regulatory standards regarding ingredient safety and environmental impact. Therefore, specialized B2B marketers must focus on technical validation and partnership development rather than purely transactional sales to secure long-term client relationships within this market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 764.2 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IFF, Givaudan, Symrise, Firmenich (DSM-Firmenich), Sensient Technologies, Takasago, Celessence International, Reed Pacific, Micropore Technologies, Balchem Corporation, Appvion, KAO Corporation, Ingredion Incorporated, Ashland Inc., Croda International, Laleham Health and Beauty, Microtek Laboratories, Encapsys, Solvay SA, Evonik Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Perfume Flour Market Key Technology Landscape

The technological landscape of the Perfume Flour Market is defined by sophisticated particle engineering and microencapsulation techniques aimed at achieving controlled, predictable fragrance release. The predominant technologies currently employed include coacervation (both complex and simple), which is highly effective for forming durable, multi-layered polymer walls around liquid fragrance cores, offering superior protection against high temperatures and aggressive chemical environments found in detergents. Another major process is spray drying, which, while more cost-effective and scalable, often results in less durable capsules suitable for less demanding applications like dry mix products or cosmetics. Continuous innovation focuses on improving encapsulation efficiency (the percentage of fragrance successfully encapsulated) and reducing the size variability of the resulting powder particles to ensure smooth texture and uniform performance.

Emerging technologies are increasingly focused on sustainability and novel release mechanisms. This includes the development of environmentally friendly carrier materials, specifically bio-based polymers, starches, and naturally occurring porous materials like zeolites and specialized silica grades, which offer biodegradability and natural sourcing appeal. Furthermore, smart release technologies are gaining traction, allowing fragrance release to be triggered only by specific external stimuli such as friction (for fabric softeners), moisture (for dehumidifiers), or changes in pH or temperature. This advanced functionality maximizes the perceived persistence of the scent and minimizes fragrance loss during storage, greatly enhancing the value proposition of the Perfume Flour product.

Patents and intellectual property surrounding wall materials, particle structure, and trigger mechanisms are highly contested among major players, driving significant investment into materials science research. Nanoencapsulation, though still nascent due to safety and regulatory concerns, represents the next frontier, promising even finer powders suitable for highly technical applications where particle invisibility is crucial. The integration of advanced computational fluid dynamics (CFD) modeling is also being adopted to simulate and optimize the manufacturing process, ensuring precise control over particle morphology and maximizing the operational yield, thereby cementing technology as the primary competitive battleground in this specialized market.

Regional Highlights

- Asia Pacific (APAC): APAC is the fastest-growing region in the Perfume Flour Market, propelled by rapid urbanization, increasing per capita spending on hygiene and cosmetic products, and the localization of major FMCG manufacturing facilities. Countries like China and India represent massive consumer bases transitioning from basic necessities to premium, value-added products, driving demand for advanced sensory ingredients like Perfume Flour in laundry care and personal hygiene products. Local manufacturers are rapidly adopting sophisticated encapsulation technologies to compete with global brands, positioning APAC not only as a consumer hub but also as a significant manufacturing and export center for fragrance ingredients.

- North America: North America holds a substantial market share characterized by high demand for high-performance and hypoallergenic formulations. The regional market is mature but highly innovative, with consumers willing to pay a premium for certified 'clean label' products and unique, highly differentiated scents. Key growth drivers include the extensive use of Perfume Flour in advanced air care systems (diffusers, smart home fragrance delivery) and specialized pet care products. Strict regulatory environment necessitates robust testing and transparency regarding carrier materials, favoring established players with extensive compliance track records and R&D capability in bio-based solutions.

- Europe: The European market is highly influenced by stringent environmental regulations, particularly regarding microplastics and VOC emissions, which strongly favors the adoption of biodegradable and sustainable carrier materials. Demand is robust across Germany, the UK, and France, driven by strong consumer preference for ecological certifications (e.g., ECOCERT, EU Ecolabel) in laundry and household cleaning products. The key market activity involves developing natural polymer-based Perfume Flour that ensures high performance while meeting complex regulatory mandates, pushing R&D toward advanced starch and cellulose derivatives for encapsulation.

- Latin America (LATAM): LATAM is an emerging market characterized by significant growth potential, particularly in Brazil and Mexico, due to increasing stability in consumer markets and growing adoption of global FMCG standards. The demand here is highly price-sensitive but rapidly increasing for mass-market applications like powdered detergents and basic personal care items. Market penetration strategies often focus on providing scalable, cost-effective Perfume Flour solutions, typically relying on established spray-drying technology rather than highly complex coacervation, to meet the burgeoning middle-class demand for persistent freshness in their daily routines.

- Middle East & Africa (MEA): The MEA market, while smaller in size, presents unique opportunities driven by specific cultural preferences for strong, long-lasting oriental and heavy fragrances, particularly in the Arabian Peninsula. The region is seeing increased investment in local manufacturing, reducing reliance on imports. High temperatures in the region necessitate Perfume Flour formulations with exceptional thermal stability to prevent premature degradation, making advanced polymer encapsulation technologies highly desirable for applications in high-end cosmetics and traditional regional household products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Perfume Flour Market.- International Flavors & Fragrances (IFF)

- Givaudan SA

- Symrise AG

- DSM-Firmenich (resulting from Firmenich merger with DSM)

- Sensient Technologies Corporation

- Takasago International Corporation

- Celessence International Ltd.

- Reed Pacific Pty Ltd.

- Micropore Technologies Ltd.

- Balchem Corporation

- Appvion LLC

- KAO Corporation

- Ingredion Incorporated

- Ashland Inc.

- Croda International Plc

- Laleham Health and Beauty

- Microtek Laboratories, Inc.

- Encapsys, LLC

- Solvay SA

- Evonik Industries AG

Frequently Asked Questions

Analyze common user questions about the Perfume Flour market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Perfume Flour and how does it extend fragrance life?

Perfume Flour is a specialized, micronized powder containing encapsulated fragrance oils within a solid carrier matrix (e.g., polymer, starch, or silica). It extends fragrance life by protecting the volatile oils from evaporation, heat, and chemical degradation until a specific trigger (like friction, moisture, or heat in laundry) releases the scent gradually over time.

Which encapsulation technologies are most prevalent in the Perfume Flour market?

The most prevalent technologies are Coacervation (used for highly durable, multi-layered capsules preferred in detergents) and Spray Drying/Chilling (a scalable, cost-effective method primarily used for lighter-duty applications like dry mixes and cosmetics). In-situ polymerization is also utilized for high-performance specialty applications.

How is the market addressing the demand for sustainable Perfume Flour alternatives?

The market is addressing sustainability by heavily investing in biodegradable carrier materials, moving away from conventional melamine-formaldehyde polymers toward bio-based polymers, modified starches, cellulose derivatives, and naturally sourced porous materials like zeolites, ensuring performance aligns with environmental compliance goals.

What are the primary applications driving growth in the Perfume Flour market?

The primary growth drivers are applications in Household Care, particularly premium laundry products (detergents and fabric softeners) that demand 24/7 scent freshness. Rapid growth is also observed in the Personal Care and Cosmetics segment due to increasing consumer expectations for high-performance sensory attributes.

What is the regulatory outlook regarding polymer-based Perfume Flour carriers?

The regulatory outlook is tightening, especially in Europe (EU) and North America, focusing on the categorization and potential restrictions of non-biodegradable microplastics used as carriers. This necessitates that manufacturers prioritize the development of easily degradable or non-plastic-based carrier systems to maintain market access and consumer trust.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager