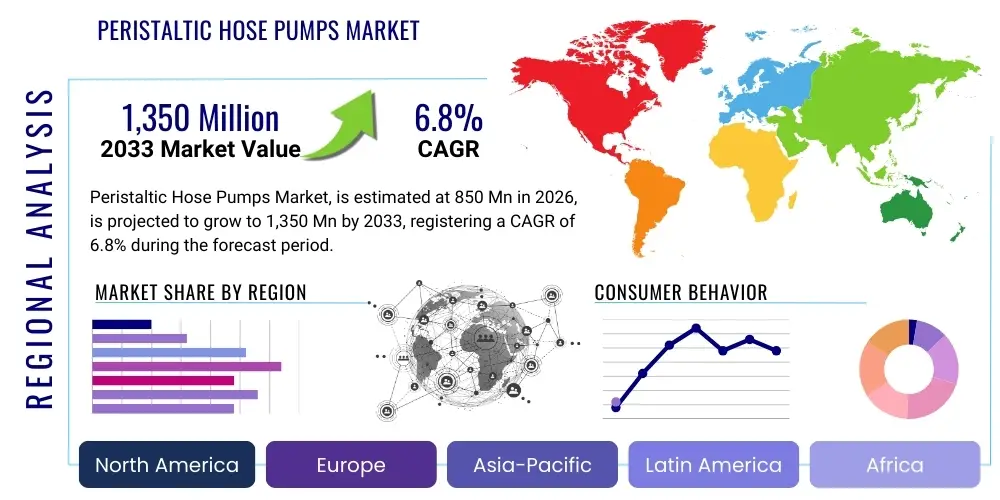

Peristaltic Hose Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443517 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Peristaltic Hose Pumps Market Size

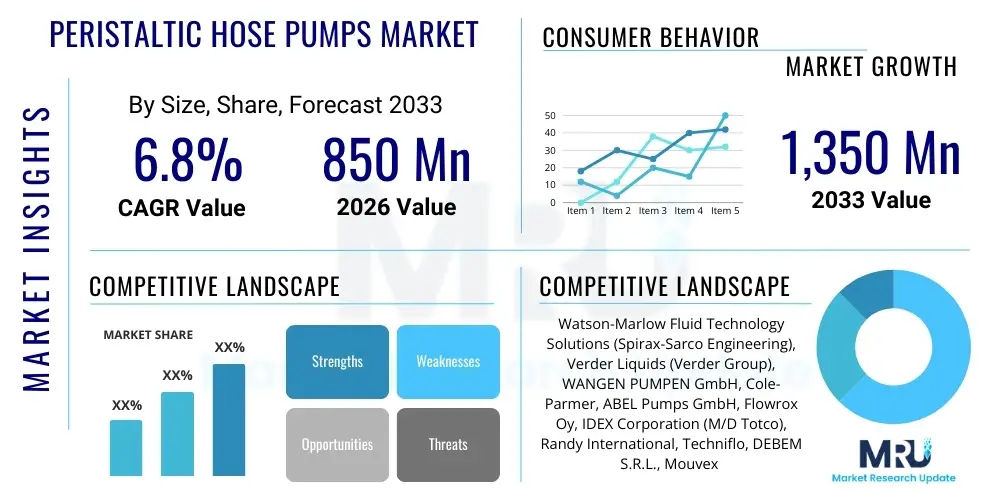

The Peristaltic Hose Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,350 Million by the end of the forecast period in 2033.

Peristaltic Hose Pumps Market introduction

The Peristaltic Hose Pumps Market encompasses specialized positive displacement pumps designed for handling highly abrasive, corrosive, or viscous fluids. These pumps operate on the principle of peristalsis, where a rotating roller or shoe compresses a flexible hose, creating a sealed cavity that propels the fluid forward. This unique design ensures that the pumped fluid only contacts the internal wall of the hose, eliminating the risk of contamination and protecting sensitive mechanical parts from wear and tear. The technology is critical across heavy industries where fluid integrity and material handling efficiency are paramount, differentiating it from traditional centrifugal or diaphragm pumps which often struggle with high solid content slurries or shear-sensitive substances.

Peristaltic hose pumps, often referred to simply as hose pumps or tube pumps, are highly valued for their exceptional dosing accuracy, inherent self-priming capabilities, and robust dry-running protection. Their application spectrum is broad, ranging from precise chemical metering in pharmaceutical manufacturing to the transfer of heavy sludge in municipal wastewater treatment facilities and highly abrasive ore slurries in the mining sector. The modular nature and relatively simple maintenance—primarily involving the replacement of the hose—contribute to lower total cost of ownership (TCO) compared to complex pump systems. Furthermore, regulatory pressures emphasizing environmentally safe chemical handling and minimized leakage drive the adoption of these sealed systems globally.

Major applications driving market expansion include industrial sectors such as mining and mineral processing, where high-solid content slurries necessitate rugged, reliable pumping solutions. In the water and wastewater industry, these pumps are indispensable for metering flocculants, polymers, and lime slurry due to their precise volumetric control, essential for efficient treatment processes. The expanding global infrastructure development, particularly in emerging economies, coupled with increased focus on advanced manufacturing processes requiring high-purity fluid transfer, firmly positions peristaltic hose pumps as a vital component of modern industrial fluid dynamics infrastructure.

Peristaltic Hose Pumps Market Executive Summary

The global Peristaltic Hose Pumps market is experiencing robust growth driven by accelerating industrialization in Asia Pacific, coupled with stringent environmental regulations concerning wastewater treatment in established economies like North America and Europe. Business trends indicate a strong move toward high-pressure, heavy-duty hose pump variants capable of handling higher flow rates and pressures, particularly demanded by large-scale mining operations and chemical processing plants. Furthermore, manufacturers are increasingly integrating smart sensor technology and IoT capabilities into pump systems to enable predictive maintenance and optimize operational efficiency, shifting the market paradigm from reactive repairs to proactive asset management. Supply chain resilience, following recent global disruptions, is also prompting diversification of manufacturing hubs and increased localization efforts.

Regional trends highlight the dominance of the Asia Pacific (APAC) region, fueled by massive infrastructure projects, burgeoning pharmaceutical production, and significant investment in water management systems in countries like China and India. North America and Europe, while mature, exhibit demand driven primarily by replacement cycles, regulatory compliance requiring higher efficiency equipment, and the adoption of advanced automation in chemical dosing applications. The Middle East and Africa (MEA) are emerging rapidly, particularly due to heavy investment in mining activities and oil and gas processing, requiring durable pumps for abrasive muds and chemical injections. The competitive landscape remains fragmented but is consolidating toward providers offering comprehensive fluid handling solutions rather than just standalone pump units.

Segmentation trends reveal that the High-Pressure Peristaltic Pump segment is outpacing the low-pressure variants in terms of revenue growth, reflecting the demand for transferring viscous and high-density materials over longer distances or against significant head. Application-wise, the Water & Wastewater Treatment sector remains the largest consumer, but the Mining and Mineral Processing segment is poised for the fastest expansion, driven by global commodity demand and the need to process low-grade ores efficiently. Material innovation is also critical, with enhanced hose materials (such as reinforced NBR and EPDM compounds) extending service life and broadening chemical compatibility, thereby minimizing downtime and operational costs for end-users across all segments.

AI Impact Analysis on Peristaltic Hose Pumps Market

Common user questions regarding AI's impact on the Peristaltic Hose Pumps Market revolve primarily around predictive maintenance capabilities, optimization of dosing accuracy, and the automation of operational parameters. Users frequently ask if AI can reduce hose rupture events, how machine learning algorithms analyze fluid viscosity and adjust pump speed in real-time, and whether AI integration justifies the initial investment cost. The core concern centers on translating complex operational data (pressure spikes, temperature variations, motor load) into actionable insights that minimize unexpected downtime and maximize throughput efficiency. Users anticipate that AI-driven diagnostics will lead to a significant reduction in maintenance expenses and extend the mean time between failures (MTBF) for critical components, transforming the maintenance schedule from time-based to condition-based across highly regulated industries.

- AI-driven Predictive Maintenance: Analyzing motor vibration, pressure fluctuations, and temperature data to forecast potential hose failure, shoe wear, or gearbox issues, significantly reducing unplanned downtime.

- Optimized Dosing Control: Machine learning algorithms dynamically adjust pump speed and flow rate based on real-time process inputs (e.g., pH, concentration), enhancing chemical dosing accuracy and minimizing material wastage.

- Energy Efficiency Management: AI systems monitor energy consumption patterns against operational load, identifying and executing optimal duty cycles to reduce overall power consumption.

- Remote Diagnostics and Monitoring: Implementing IoT sensors integrated with AI platforms for remote performance tracking, allowing immediate intervention and calibration adjustment without requiring on-site personnel.

- Automated Process Calibration: Utilizing machine vision and AI to confirm correct hose loading and shoe alignment during maintenance, ensuring optimal pump performance immediately after servicing.

- Enhanced Safety Protocols: AI algorithms detect abnormal operating conditions that could indicate leakage or pressure buildup, triggering automated shutdowns or alerts to prevent catastrophic failure and ensure operator safety.

DRO & Impact Forces Of Peristaltic Hose Pumps Market

The market trajectory for peristaltic hose pumps is fundamentally shaped by several powerful drivers, significant restraints, and clear opportunities that collectively define the impact forces. Key drivers include the inherent suitability of these pumps for handling highly abrasive and corrosive slurries, which is critical in expanding sectors such as mining (especially non-ferrous metals and rare earths) and specialized chemical manufacturing. The demand for accurate and consistent metering in water purification and pharmaceutical industries further accelerates adoption, as these pumps offer superior volumetric accuracy compared to many competing technologies. Additionally, the low shear action of peristaltic pumps makes them ideal for sensitive fluids and polymer dosing, which is essential for advanced manufacturing processes.

However, market growth is moderated by notable restraints, primarily the cost associated with the consumable component—the hose element. Frequent replacement, particularly in high-duty cycles or extremely abrasive applications, contributes significantly to operational expenditure, deterring some price-sensitive end-users. Furthermore, the inherent flow pulsation and the maximum achievable pressure ratings are generally lower than those of plunger or piston pumps, limiting their use in ultra-high-pressure applications. Noise generation, particularly in high-speed operations, and heat buildup within the hose element can also restrict deployment in certain noise-sensitive or temperature-controlled environments, requiring specialized cooling mechanisms.

Opportunities for expansion are abundant, centered around technological innovation and geographic penetration. Developing composite, high-durability hose materials that extend operational life and chemical resistance presents a major growth pathway. Furthermore, integrating smart technologies, such as advanced pressure sensors and IoT capabilities, allows manufacturers to offer value-added predictive maintenance solutions. The untapped potential in emerging markets, specifically in municipal water infrastructure upgrades and localized food processing plants, offers fertile ground for sustained market penetration. The global push towards sustainability and reduced chemical consumption also favors peristaltic pumps due to their precise dosing capabilities, minimizing resource waste.

Segmentation Analysis

The Peristaltic Hose Pumps Market is rigorously segmented based on crucial technical and application parameters to provide a detailed view of market dynamics and opportunity mapping. Key segmentation focuses on the pump type (low pressure versus high pressure), defining their suitability for varying operational demands; the flow rate, which dictates their utility in batch processing versus continuous high-volume transfer; the drive technology (electric versus hydraulic), influencing power requirements and installation flexibility; and the end-user application, highlighting demand concentration across diverse industrial verticals. Analyzing these segments provides stakeholders with actionable insights into product development needs and strategic market entry points, reflecting the specialized requirements of each industrial sector.

The segmentation by pressure type is particularly indicative of market sophistication. Low-pressure peristaltic pumps (typically operating below 15 bar) dominate micro-dosing and laboratory applications, valued for their simplicity and cost-effectiveness. Conversely, high-pressure models (often exceeding 20 bar, sometimes up to 30 bar) are essential for transferring dense slurries over long distances or against high static head, typical requirements in mining tailing management and certain heavy chemical transfers. The shift towards higher processing efficiency globally is bolstering the high-pressure segment, as industries seek robust solutions for increasingly difficult-to-handle mediums while maintaining operational consistency and minimizing the risk of pipeline blockage.

Geographic segmentation remains crucial, with localized demands significantly impacting product features. For instance, North America and Europe prioritize pumps with high levels of automation and compliance with strict environmental standards, driving demand for pumps with integrated leakage detection and advanced diagnostic capabilities. In contrast, APAC and MEA markets show higher demand for rugged, high-flow rate, and relatively low-cost pumps suitable for initial infrastructure build-out and large-scale bulk material handling, demonstrating varying maturity levels and investment priorities across regions.

- By Type:

- Low-Pressure Peristaltic Pumps (< 15 Bar)

- High-Pressure Peristaltic Pumps (> 15 Bar)

- By Flow Rate:

- Below 10 m³/hr

- 10 to 50 m³/hr

- Above 50 m³/hr (High Volume Pumps)

- By Drive Technology:

- Electric Drive

- Hydraulic Drive

- By Hose Material:

- Natural Rubber (NR)

- Nitrile Rubber (NBR)

- EPDM (Ethylene Propylene Diene Monomer)

- Hypalon (CSM)

- Other Polymers (e.g., Neoprene, Fluoropolymers)

- By Application/End-User:

- Water and Wastewater Treatment

- Mining and Mineral Processing

- Chemical Processing and Petrochemicals

- Food and Beverage

- Pharmaceutical and Biotechnology

- Pulp and Paper

- Ceramics and Construction

Value Chain Analysis For Peristaltic Hose Pumps Market

The value chain for the Peristaltic Hose Pumps Market is characterized by a high degree of specialization, beginning with upstream material providers. Upstream analysis focuses heavily on suppliers of high-grade elastomers and polymers (such as Natural Rubber, EPDM, and NBR) that form the critical hose element, alongside suppliers of precision-machined metals for the pump casing, rotors, and shoes. The quality and longevity of the core pump component—the hose—are entirely dependent on the innovation and consistency of these raw material suppliers. Intense R&D efforts at this stage aim to create composite materials capable of resisting extreme abrasive wear and chemical degradation, directly impacting the final product’s performance metrics and operational lifespan, thereby setting the foundational cost structure.

Midstream activities involve core manufacturing, including precision casting and assembly of the pump units, followed by rigorous testing and quality assurance checks. Key manufacturers often maintain tight control over the hose vulcanization process to ensure uniform wall thickness and tensile strength, crucial for high-pressure applications. Distribution channels form the link between manufacturers and diverse industrial end-users. Direct channels are commonly used for large-scale, customized projects (e.g., massive mining facilities) where manufacturers provide specialized engineering support, installation, and long-term maintenance contracts. These direct relationships facilitate comprehensive training and quick response times for critical system failures.

Indirect channels, encompassing regional distributors, specialized fluid control equipment suppliers, and independent agents, dominate sales to small to medium enterprises (SMEs) and for standard, off-the-shelf models. These indirect partners provide local inventory, basic technical support, and logistical advantages, particularly in geographically dispersed markets. Downstream analysis focuses on after-sales service, which is a significant revenue driver due to the continuous demand for replacement hoses (a consumable part) and maintenance services. The effectiveness of the service network—ensuring rapid supply of spare parts and qualified technicians—is a crucial competitive differentiator that impacts customer loyalty and minimizes process downtime across various end-user industries.

Peristaltic Hose Pumps Market Potential Customers

Potential customers for peristaltic hose pumps span a wide spectrum of heavy and precision industries where the transfer of difficult, abrasive, or shear-sensitive fluids is routine. The primary end-users are those requiring high dosing accuracy and the ability to handle high-solid content slurries without clogging or internal contamination. This includes, fundamentally, municipal and industrial wastewater treatment plants, which utilize these pumps for precise metering of lime, carbon slurry, and various corrosive chemicals vital for flocculation and pH neutralization processes. Their self-priming nature and consistent flow rate make them highly desirable in these continuous operation environments, ensuring regulatory compliance regarding effluent quality.

The mining and mineral processing sector represents another critical customer base, particularly in operations involving gold, copper, iron ore, and specialized lithium processing. These processes inherently generate highly abrasive tailings and slurries that rapidly degrade conventional pump impellers. Peristaltic pumps, where the fluid only contacts the hose, offer superior longevity and reliability in these punishing applications, transferring thick muds, grout, and concentrated ores. The shift toward processing lower-grade ores necessitates more intensive grinding and slurrying processes, further elevating the demand for robust peristaltic technology capable of handling extremely high solid concentrations efficiently.

Beyond heavy industry, the pharmaceutical and biotechnology sectors constitute high-value potential customers. These industries require non-contaminating, highly sterile, and precise fluid handling for media transfer, fermentation processes, and accurate filling operations. The peristaltic action provides the required gentle handling for shear-sensitive biological materials, and the absence of mechanical seals ensures sterility. Additionally, the food and beverage industry utilizes these pumps for metering viscous sauces, batters, and fruit pulps, where preserving the product structure (low shear) and maintaining hygiene (easy cleanability and sterile paths) are non-negotiable operational requirements, highlighting the diverse yet specific needs of the product's buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,350 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Watson-Marlow Fluid Technology Solutions (Spirax-Sarco Engineering), Verder Liquids (Verder Group), WANGEN PUMPEN GmbH, Cole-Parmer, ABEL Pumps GmbH, Flowrox Oy, IDEX Corporation (M/D Totco), Randy International, Techniflo, DEBEM S.R.L., Mouvex (Pumps), ProMinent GmbH, SEEPEX GmbH, PCM Pumps, Netzer Pumps. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Peristaltic Hose Pumps Market Key Technology Landscape

The technological landscape of the Peristaltic Hose Pumps Market is predominantly focused on enhancing the two core performance factors: hose durability and control precision. Advances in materials science are central, driving the development of multi-layered and reinforced elastomers that significantly extend the hose life cycle, particularly crucial in high-abrasion applications like mineral slurry transfer. Contemporary hoses often incorporate specialized synthetic polymers and fabric reinforcement techniques to withstand higher operating pressures and temperatures while maintaining flexibility and chemical inertia, effectively broadening the scope of fluids that can be handled reliably. Furthermore, research is focused on minimizing internal friction heat buildup, a common challenge in high-speed peristaltic action, through optimized shoe lubrication and casing cooling systems, moving beyond basic glycerin bath systems to more advanced thermal management solutions.

In terms of pump design and operation, the adoption of advanced drive technologies and control systems is a major trend. Manufacturers are increasingly integrating Variable Frequency Drives (VFDs) and sophisticated servo motor controllers to allow for extremely precise flow rate adjustments and speed control. This precision is vital for proportional dosing applications in water treatment and chemical blending, where flow deviations can compromise process quality or lead to regulatory non-compliance. These modern electronic control systems also facilitate seamless integration with plant-wide Distributed Control Systems (DCS) and SCADA systems, enabling remote monitoring, historical data logging, and automated parameter adjustment, which aligns with the Industry 4.0 paradigm.

A burgeoning technological area involves optimizing the roller or shoe configuration to minimize flow pulsation and reduce stress on the hose. While peristaltic pumps are inherently prone to pulsation due to the cyclical compression and relaxation of the hose, advanced designs—including dual-head pumps or optimized track geometry—are employed to smooth the flow profile, essential for applications requiring laminar flow or highly consistent output pressure. Finally, condition monitoring technology is becoming standard, utilizing external sensors (pressure, vibration, temperature) and internal diagnostics to predict hose degradation and mechanical wear. This integration of sensing capability moves the technology toward condition-based maintenance (CBM), maximizing operational uptime and significantly lowering the risk of catastrophic failure through preemptive replacement strategies.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market segment, primarily driven by massive governmental investment in municipal water and wastewater infrastructure across China, India, and Southeast Asian nations. The region’s burgeoning mining and mineral processing industry, especially in Australia and Indonesia, demands heavy-duty, high-flow peristaltic pumps for managing tailing dams and concentrated slurries. Rapid industrialization, coupled with increasing environmental scrutiny, necessitates reliable dosing solutions for pollution control and chemical management, fueling robust demand for all pump types, particularly robust and cost-effective models.

- North America: This region is characterized by high technological maturity and strict regulatory environments. Demand is steady, driven mainly by the modernization of existing infrastructure and the adoption of high-efficiency pumps in the pharmaceutical and food processing sectors. The oil and gas industry utilizes these pumps for precise chemical injection and transfer of viscous drilling muds. Emphasis here is placed on pumps with IoT integration, advanced diagnostics, and compliance certifications, leading to a focus on high-margin, technically superior products over sheer volume.

- Europe: Similar to North America, Europe is a mature market focusing on technological excellence, energy efficiency (in line with EU directives), and compliance with stringent environmental standards (e.g., REACH). Germany, the UK, and France are key consumers, particularly in the chemical, pharmaceutical, and specialized industrial sectors. Innovation here is centered around enhancing hose materials for specific chemical resistance and developing low-pulsation pump designs suitable for precision laboratory and biotech applications, reflecting the region’s strong manufacturing base.

- Latin America: Market growth in Latin America is strongly tied to the extractive industries (copper in Chile, iron ore in Brazil) and expanding local infrastructure projects. The need for pumps capable of handling large volumes of abrasive mining slurries and processing wastewater is substantial. Price sensitivity and the need for durable equipment capable of operating in remote, sometimes challenging environments characterize the demand profile, making the total cost of ownership (TCO) a crucial purchasing factor.

- Middle East and Africa (MEA): This region is witnessing significant growth, largely propelled by investments in large-scale desalination plants, petrochemical facilities, and mining activities across South Africa and key Gulf Cooperation Council (GCC) countries. Peristaltic pumps are crucial for transferring corrosive brines, handling sludges in water treatment, and injecting specialized chemicals in oil production. Market expansion is currently centered on large capital projects, requiring high-pressure, durable pumps that can withstand high temperatures and salinity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Peristaltic Hose Pumps Market.- Watson-Marlow Fluid Technology Solutions (Spirax-Sarco Engineering)

- Verder Liquids (Verder Group)

- WANGEN PUMPEN GmbH

- Cole-Parmer

- ABEL Pumps GmbH

- Flowrox Oy

- IDEX Corporation (M/D Totco)

- Randy International

- Techniflo

- DEBEM S.R.L.

- Mouvex (Pumps)

- ProMinent GmbH

- SEEPEX GmbH

- PCM Pumps

- Netzer Pumps

- Depa GmbH

- Albin Pump SAS

- Dover Corporation (OPW)

- Lewa GmbH

- Seko S.p.A.

Frequently Asked Questions

Analyze common user questions about the Peristaltic Hose Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a peristaltic hose pump over traditional positive displacement pumps?

The primary advantage is that the fluid only contacts the internal surface of the hose, eliminating contamination risks and making it ideal for abrasive or corrosive fluids. This design minimizes maintenance, as there are no seals, valves, or gland packings in the fluid path, ensuring superior reliability when handling slurries and viscous liquids.

In which industrial application is the demand for high-pressure peristaltic pumps currently the strongest?

The demand is strongest in the Mining and Mineral Processing sector. These applications frequently require transferring high-density, abrasive slurries (like tailings or thickened sludge) over long distances or against high pressure heads, necessitating the robust capabilities of high-pressure hose pump models.

What factors determine the lifespan of the hose element in peristaltic pumps?

The lifespan is primarily determined by the abrasiveness and chemical compatibility of the pumped fluid, the operating pressure, the rotational speed (duty cycle), and the temperature. Regular maintenance and selecting the correct hose material (e.g., NBR, EPDM) for the specific chemical application are crucial for maximizing longevity.

How are Peristaltic Hose Pumps contributing to Industry 4.0 adoption?

Peristaltic pumps are integrating with Industry 4.0 through IoT connectivity and sensor integration. This enables real-time monitoring of operational parameters (vibration, temperature, pressure) and facilitates AI-driven predictive maintenance, optimizing flow rates, and allowing for seamless remote diagnostics via SCADA and DCS platforms.

What are the key materials used for manufacturing peristaltic pump hoses?

The key materials include Natural Rubber (NR) for high abrasion resistance, Nitrile Rubber (NBR) for oil and grease applications, EPDM (Ethylene Propylene Diene Monomer) for chemical resistance (especially acids and bases), and Hypalon (CSM) for broad chemical compatibility and weathering resistance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager