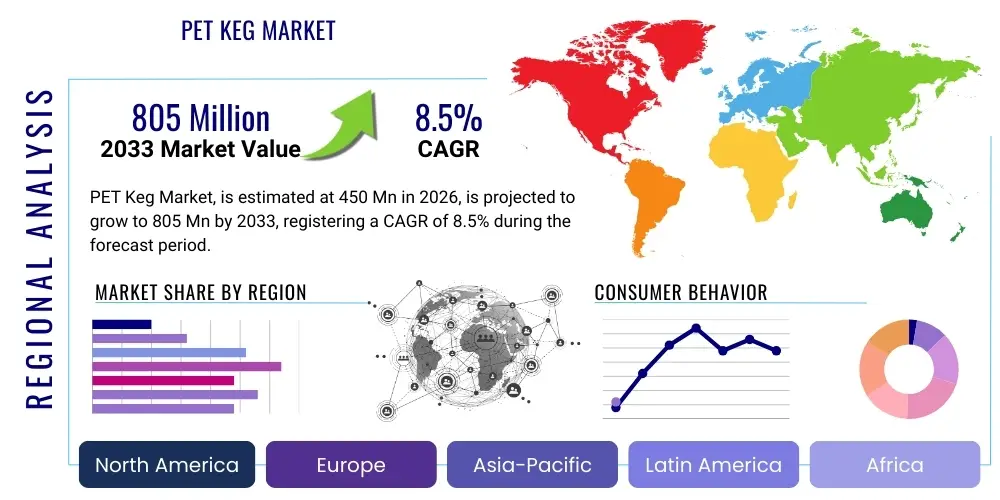

PET Keg Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441348 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

PET Keg Market Size

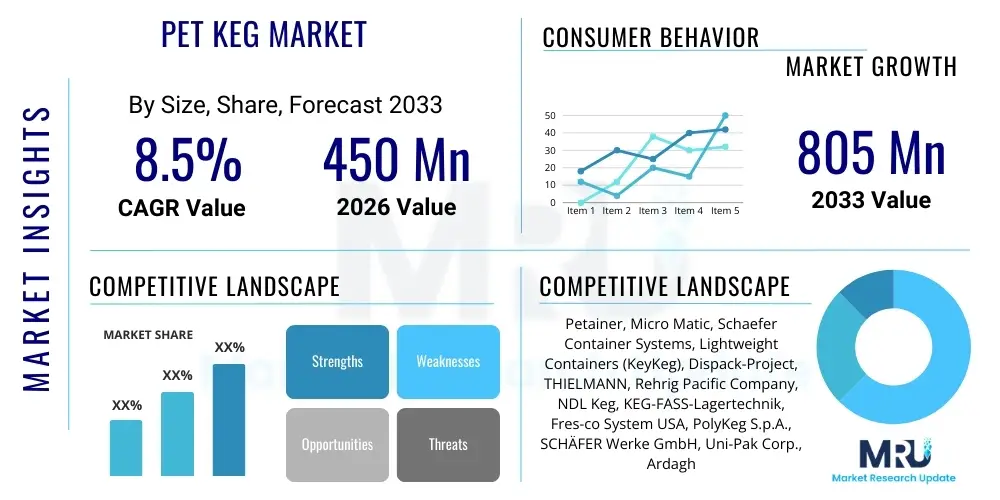

The PET Keg Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 805 Million by the end of the forecast period in 2033.

PET Keg Market introduction

The Polyethylene Terephthalate (PET) Keg Market encompasses the manufacturing and distribution of specialized, single-use, or refillable plastic containers designed primarily for the storage and dispensing of beverages, predominantly beer, wine, and cider. These innovative packaging solutions are rapidly gaining traction as a lightweight and cost-effective alternative to traditional stainless steel kegs. PET kegs offer superior handling, elimination of the need for reverse logistics associated with cleaning and returning metal kegs, and robust protection against oxygen ingress, ensuring extended shelf life for sensitive products.

The core product features of PET kegs include their lightweight nature, which significantly reduces transportation costs and carbon footprint, and their inherent recyclability, aligning with global sustainability mandates. Key applications span the entire beverage industry, from large-scale breweries and vineyards distributing internationally to microbreweries and local craft beverage producers seeking efficient and flexible packaging options. The market benefits substantially from continuous technological advancements in barrier materials, such as multi-layer PET structures incorporating Nylon or EVOH (Ethylene Vinyl Alcohol), which are critical for preserving the integrity and quality of carbonated beverages over extended periods.

Driving factors for market expansion include the burgeoning popularity of craft beer across North America and Europe, the increasing demand for eco-friendly and lightweight packaging solutions, and the cost-efficiency realized by eliminating the complex cleaning and maintenance processes required for steel keg fleets. Furthermore, the expansion of global beverage trade and the need for simplified export logistics are positioning PET kegs as the preferred choice for cross-border shipping, ensuring product consistency from production facility to the point of consumption.

PET Keg Market Executive Summary

The PET Keg Market is characterized by robust growth fueled by sustainability pressures and logistical efficiencies sought by the global beverage industry. Key business trends indicate a strong move toward multi-layer barrier technologies and an increased adoption rate among premium craft beverage segments. Manufacturers are focusing heavily on integrating radio-frequency identification (RFID) tags and unique tracking systems within PET kegs to enhance supply chain visibility, reduce losses, and optimize inventory management, thus adding significant value beyond mere containment. Strategic partnerships between PET keg producers and specialized filling/dispensing equipment providers are crucial for standardization and further market penetration.

Regionally, North America and Europe remain the dominant markets, driven by established craft beverage consumption cultures and stringent regulatory frameworks favoring recyclable packaging. However, the Asia Pacific (APAC) region is emerging as the fastest-growing market, propelled by rapid urbanization, increasing disposable incomes, and the modernization of alcoholic beverage distribution channels in countries like China and India. This regional shift mandates that global players localize their manufacturing and distribution networks to capitalize on burgeoning demand from local breweries and quick-service restaurants.

Segment trends reveal that the 20-liter capacity kegs currently hold the largest market share due to their optimal balance between handling ease and commercial volume requirements, particularly within the draft beer sector. The multi-layer segment is expected to witness accelerated growth, as advanced oxygen and light barrier properties are essential for high-quality, long-distance shipments of sensitive beverages like specific wine varietals and premium craft beers. The shift towards lightweight, disposable solutions fundamentally alters traditional beverage distribution paradigms, promoting efficiency and reducing capital expenditure requirements for end-users.

AI Impact Analysis on PET Keg Market

User queries regarding AI's influence on the PET Keg market commonly revolve around optimizing manufacturing efficiency, enhancing predictive maintenance for specialized filling machinery, and improving supply chain resilience through advanced data analytics. Users seek confirmation on whether AI can reduce material waste during the PET blowing process, how machine learning algorithms can predict peak regional demand to optimize inventory deployment, and the potential for smart packaging integration using AI-driven sensor data. The overarching expectation is that AI will primarily drive down operational costs, enhance quality control through automated inspection systems, and make the inherently linear PET keg supply chain more agile and responsive to volatile market demand.

The integration of Artificial Intelligence specifically impacts manufacturing precision, enabling predictive modeling for material stress and barrier integrity in complex multi-layer structures. Machine vision systems powered by deep learning are being deployed on production lines to detect microscopic flaws, ensuring every keg meets stringent quality standards regarding wall thickness, internal cleanliness, and valve assembly, which is critical for product safety and brand reputation. Furthermore, generative AI tools are assisting packaging engineers in designing lightweight structures that maintain maximum structural integrity under pressure, minimizing material usage while maximizing performance.

In logistics and distribution, AI algorithms optimize routing for delivery of filled kegs and model demand forecasting based on real-time sales data, seasonal variations, and specific event schedules. This allows brewers and distributors to minimize stockouts and reduce capital tied up in inventory, particularly important for single-use containers where efficient rotation is key. Ultimately, AI transforms the handling of PET kegs from a manual, estimation-driven process to a precise, data-backed operation, ensuring optimal use of these lightweight, high-performance packaging solutions.

- AI-driven predictive maintenance for PET molding and filling equipment, reducing downtime.

- Machine vision quality control ensuring barrier layer integrity and structural precision.

- Optimization of material usage (lightweighting) through Generative Design simulations.

- Enhanced supply chain visibility and demand forecasting using machine learning models.

- Automated inventory management and dynamic routing for filled keg distribution.

- Integration of smart sensor data (IoT) processed by AI for real-time monitoring of temperature and pressure during transit.

DRO & Impact Forces Of PET Keg Market

The PET Keg market is shaped by strong drivers, including sustainability mandates and logistical benefits, which are somewhat counterbalanced by restraints such as material permeability risks and the initial investment in specialized filling equipment. Opportunities arise from expanding into new beverage categories like cold brew coffee and functional beverages, alongside geographic expansion into rapidly developing economies. These factors collectively exert significant impact forces on market dynamics, compelling manufacturers to continuously innovate barrier technologies and expand production capacity to meet escalating demand while addressing environmental concerns regarding plastic usage.

Key drivers include the demonstrable cost savings associated with reduced freight weight and the elimination of complex reverse logistics loops typical of steel kegs, making them highly attractive for export-oriented businesses. The market is also propelled by strong consumer and regulatory pressure towards recyclable and disposable packaging options that minimize environmental impact. Conversely, the primary restraints center on consumer perception regarding plastic packaging versus traditional materials and the inherent limitations of PET in comparison to steel regarding long-term, high-pressure storage, necessitating advanced, multi-layer constructions to ensure adequate shelf life for highly sensitive products like certain types of champagne or sour beers.

Opportunities for growth are abundant in leveraging the kegs’ suitability for small-batch, seasonal, or limited-edition beverages, providing flexibility to craft producers. Furthermore, developing enhanced recycling infrastructures specifically tailored for multi-layer PET/EVOH compositions will mitigate disposal concerns and solidify PET kegs’ position as a truly circular packaging solution. The competitive forces within the market are intensified by patented valve systems and unique lightweighting designs, pushing companies to invest heavily in R&D to optimize performance and reduce per-unit cost.

Segmentation Analysis

The PET Keg market is segmented based on capacity, end-use application, closure type, and layer type, reflecting the diverse requirements of the beverage industry. This segmentation is crucial for understanding specific market dynamics, such as the preference for larger capacity kegs in established industrial brewing sectors versus smaller formats favored by craft beverage producers or home-use scenarios. Analyzing these segments helps in targeting specific vertical markets and tailoring product specifications, particularly concerning barrier protection and required shelf life for various beverage types like highly carbonated sodas versus low-alcohol wines.

The segmentation by layer type is arguably the most technologically significant, dividing the market between simpler single-layer PET, suitable for non-sensitive liquids, and advanced multi-layer structures that utilize barrier polymers (like EVOH or Nylon) to prevent oxygen permeation and CO2 loss. This technological differentiation directly influences the cost, performance, and suitability of the keg for high-value export beverages requiring extended shelf life protection. End-use segmentation highlights that the beer industry remains the largest consumer, but significant growth is being witnessed in the wine and cider segments seeking alternatives to traditional glass bottles and heavy metal containers.

- By Capacity:

- 10 Liters

- 20 Liters

- 30 Liters

- Others (e.g., 5 Liters, 15 Liters)

- By End-Use:

- Beer

- Wine

- Carbonated Soft Drinks (CSD)

- Cider and Perry

- Others (e.g., Cold Brew Coffee, Cocktails, Water)

- By Closure Type:

- Threaded

- Non-Threaded (Snap-on)

- By Layer Type:

- Single Layer

- Multi-Layer (High Barrier)

Value Chain Analysis For PET Keg Market

The value chain for the PET Keg market begins with upstream activities, focusing heavily on the procurement and processing of virgin and recycled PET resins, specialized barrier polymers (EVOH, Nylon), and high-grade valve system components (plastics and specialized seals). Efficiency in this phase relies on strong relationships with petrochemical suppliers and innovation in recycling technologies to incorporate higher percentages of recycled PET (rPET) into the manufacturing process, aligning with circular economy goals. Key upstream challenges involve managing the volatility of polymer prices and ensuring a consistent supply of specialized barrier materials essential for high-performance kegs.

Midstream activities involve the core manufacturing processes: injection molding of the preforms, blow molding the keg bodies, and complex co-extrusion or multi-layer injection processes for barrier enhancement. Assembly includes integrating the proprietary dispensing valve systems. Distribution channels are highly specialized; direct distribution often involves sales to major multinational breweries and large wineries, where bulk purchasing and tailored supply contracts are common. Indirect channels utilize specialized beverage packaging distributors and logistics firms that cater to smaller craft breweries, hospitality suppliers, and international export markets, managing crucial regulatory compliance and warehousing.

Downstream analysis focuses on the end-users—breweries, wineries, and beverage companies—who fill the kegs and the final point of sale, which includes bars, restaurants, event venues, and retail chains. The success of the PET keg downstream relies on easy integration with existing dispensing equipment and training staff on handling disposable or one-way systems. The reverse logistics aspect, inherent in traditional kegging, is minimized or eliminated here, streamlining the entire consumption-to-disposal cycle, making the value proposition highly attractive for long-distance shipping and temporary use scenarios.

PET Keg Market Potential Customers

The primary customers for PET Kegs are beverage producers requiring cost-effective, lightweight, and logistically efficient packaging solutions, especially those involved in export or those lacking the infrastructure for maintaining and cleaning traditional stainless steel fleets. This includes global brewing giants seeking consistency across diverse international markets, mid-sized regional breweries capitalizing on craft beer trends, and craft beverage producers who prioritize flexibility and low initial capital outlay over reusable systems. The wine industry represents a rapidly expanding customer base, utilizing PET kegs for preserving freshness and reducing the carbon footprint associated with shipping heavy glass bottles.

Furthermore, specialized end-users include producers of non-alcoholic beverages such as carbonated soft drinks, premium chilled juices, and cold-brew coffee manufacturers, who are increasingly looking for bulk dispensing solutions suitable for office environments, cafes, and specialized beverage fountains. Event organizers and catering companies are also significant potential customers, preferring disposable kegs to eliminate collection and sanitization headaches after large-scale temporary events. These diverse segments value the safety, ease of handling, and reduced weight provided by PET alternatives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 805 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Petainer, Micro Matic, Schaefer Container Systems, Lightweight Containers (KeyKeg), Dispack-Project, THIELMANN, Rehrig Pacific Company, NDL Keg, KEG-FASS-Lagertechnik, Fres-co System USA, PolyKeg S.p.A., SCHÄFER Werke GmbH, Uni-Pak Corp., Ardagh Group, Dolium, The Petainer Group, Eco-Keg, Refresher Keg, Disposable Keg Systems, Ropak Packaging. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PET Keg Market Key Technology Landscape

The technological landscape of the PET Keg market is primarily dominated by advancements in material science and barrier technology, crucial for extending the shelf life of oxygen-sensitive beverages. Multi-layer co-extrusion and barrier coating technologies, particularly those involving specialized polymers like EVOH (Ethylene Vinyl Alcohol) or proprietary Nylon blends, are paramount. EVOH layers are highly effective at restricting oxygen ingress and maintaining CO2 retention, which is indispensable for ensuring the quality of draft beer and sparkling wine. Manufacturers are continually refining the thickness and placement of these barrier layers to achieve maximum protection while minimizing the overall weight and cost of the container, balancing performance with sustainability targets.

Another significant area of technological innovation is in valve and coupler systems. These components must ensure secure filling, safe pressurization, and compatibility with standard dispensing equipment (e.g., Sankey, D-type, S-type). Companies hold critical patents on proprietary one-way valves and bag-in-keg systems—such as those popularized by KeyKeg—where the beverage is isolated from the pressurizing gas via an internal bag, eliminating the need for complex and costly external gas systems and preserving product quality even when the keg is partially dispensed. The development of quick-connect and tamper-evident closure mechanisms also remains a priority to ensure product safety and authenticity throughout the distribution chain.

Furthermore, technology is playing a major role in logistics integration. The adoption of IoT devices, specifically NFC (Near Field Communication) and RFID (Radio-Frequency Identification) tags embedded within the keg structure, allows for real-time tracking, temperature monitoring, and inventory optimization across complex global supply chains. This "smart packaging" trend provides unparalleled data on handling conditions, minimizes loss due to spoilage, and supports the implementation of advanced AI-driven demand forecasting, marking a significant step towards fully digitized beverage distribution systems.

Regional Highlights

- North America: This region holds a dominant share, primarily driven by the massive expansion of the craft beer segment, particularly in the United States. Craft breweries, requiring flexibility for smaller batches and seasonal releases, find the logistical ease of PET kegs highly appealing. The emphasis on minimizing supply chain complexity and high labor costs for washing steel kegs also accelerates adoption. Regulatory support for recyclable plastics further cements market position.

- Europe: Europe represents a mature market with high adoption rates, particularly in countries like Germany, the UK, and Spain. The stringent European Union sustainability goals and the strong export focus of European brewers and vintners necessitate lightweight, high-barrier packaging solutions. The market is also highly competitive, driven by regional players focusing on developing innovative recyclable multi-layer structures compliant with diverse national waste management schemes.

- Asia Pacific (APAC): The fastest-growing region, APAC is characterized by rapidly modernizing beverage distribution networks and increasing per capita consumption of alcoholic and non-alcoholic premium draft beverages. Key growth drivers include rising urbanization, expanding cold chain infrastructure, and the influx of Western brewing styles. Countries like China, Australia, and Japan are investing heavily in establishing local PET keg manufacturing facilities to cater to rising demand and reduce import dependence.

- Latin America (LATAM): Growth in LATAM is attributed to the developing brewing industry, particularly in Mexico and Brazil. PET kegs are favored for simplifying distribution across large geographic areas with often challenging road infrastructure, where the lightweight nature reduces transport damage and cost. Adoption is slower but steady, focusing mainly on the beer segment and moving into cost-sensitive wine markets.

- Middle East and Africa (MEA): This region is niche but expanding, driven primarily by tourism-related hospitality sectors and the increasing demand for high-quality, non-alcoholic draft beverages (e.g., specialty sodas, mocktails) in urban centers. PET kegs provide sanitary, disposable options suitable for temporary venues and areas lacking sophisticated reverse logistics infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PET Keg Market.- Petainer

- Micro Matic

- Schaefer Container Systems

- Lightweight Containers (KeyKeg)

- Dispack-Project

- THIELMANN

- Rehrig Pacific Company

- NDL Keg

- KEG-FASS-Lagertechnik

- Fres-co System USA

- PolyKeg S.p.A.

- SCHÄFER Werke GmbH

- Uni-Pak Corp.

- Ardagh Group

- Dolium

- The Petainer Group

- Eco-Keg

- Refresher Keg

- Disposable Keg Systems

- Ropak Packaging

Frequently Asked Questions

Analyze common user questions about the PET Keg market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary sustainability benefit of using PET kegs?

The main sustainability benefit is the significant reduction in transportation emissions due to their lightweight nature, alongside the elimination of complex water and chemical intensive cleaning processes required for traditional stainless steel kegs. Most PET kegs are fully recyclable.

Are PET kegs suitable for beverages requiring extended shelf life and high carbonation?

Yes, modern PET kegs utilize multi-layer barrier technologies, often incorporating polymers like EVOH, which provide excellent protection against oxygen ingress and CO2 loss, ensuring beverages retain their quality and carbonation for up to 12 months or more.

How do PET kegs compare in cost to traditional stainless steel kegs?

While the per-unit cost of a stainless steel keg is initially higher, PET kegs offer lower Total Cost of Ownership (TCO) because they eliminate associated operational expenses such as cleaning, maintenance, reverse logistics, and capital depreciation, making them economically advantageous for one-way shipping.

Which end-use segment accounts for the largest share of the PET Keg Market?

The Beer industry, driven specifically by the global craft beer and micro-brewing boom, currently accounts for the largest market share due to the high volume of draft products requiring efficient and flexible packaging solutions for regional and international distribution.

What are the key technical challenges facing the widespread adoption of PET kegs?

Key challenges include ensuring consistent barrier performance across all capacities, addressing concerns regarding recycling infrastructure for multi-layer composite plastics, and maintaining compatibility with the diverse range of dispensing couplers and pressure regulations globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager